Charles Machine Works Ditch Witch SK5BB User manual

Issue 2.0

Operator’s

Manual

SK5BB

Backfill Blade Attachment

SK5BB Operator’s Manual Overview - 1

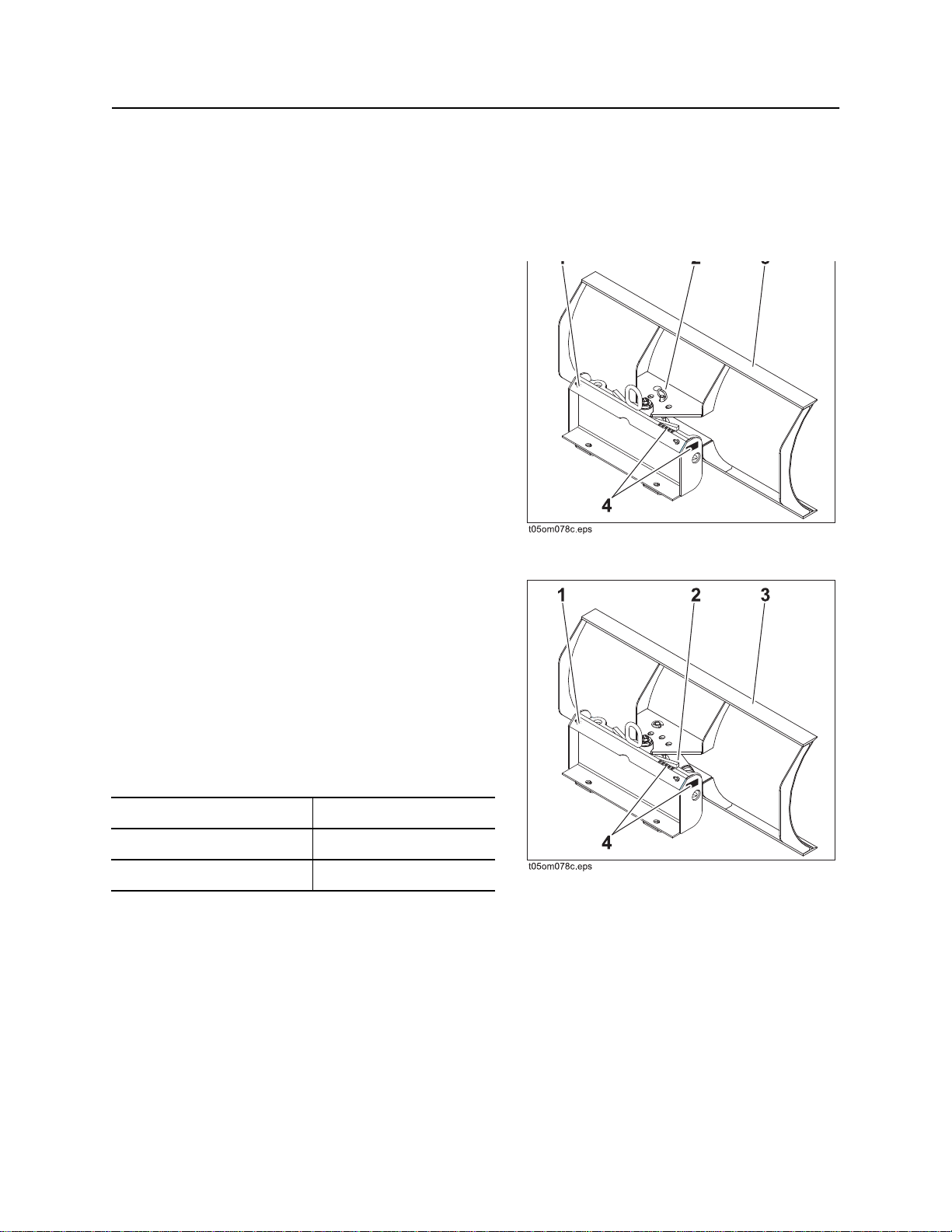

Serial Number/Unit Components Overview

Serial Number/Unit Components

Attachment serial number location and unit components

are called out below. Record serial number and date of

purchase in spaces provided.

Manual Swing

Hydraulic Swing

Serial Number Record

Intended Use

The SK5BB backfill blade attachment is used for backfilling trenches and basic grading and scraping. A kit

is available for converting a manual swing blade to hydraulic swing.

1. Receiver plate

2. Swing pin

3. Blade

4. S/N location

1. Receiver plate

2. Swing cylinder

3. Blade

4. S/N location

Date of manufacture

Date of purchase

Attachment serial number

Foreword - 2 SK5BB Operator’s Manual

Foreword

This manual is an important part of your equipment. It provides safety information and operation

instructions to help you use and maintain your Ditch Witch equipment.

Read this manual before using your equipment. Keep it with the equipment at all times for future reference.

If you sell your equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer. If you need assistance in locating a

dealer, visit our website at www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject to change without notice. The Charles

Machine Works, Inc. reserves the right to improve equipment. Some product improvements may have

taken place after this manual was published. For the latest information on Ditch Witch equipment, see your

Ditch Witch dealer.

Thank you for buying and using Ditch Witch equipment.

SK5BB Attachment

Operator’s Manual

Issue number 2.0/OM-7/2010

Part number 054-100

Copyright 2003, 2010

by The Charles Machine Works, Inc.

, Ditch Witch, CMW, AutoCrowd, Jet Trac, Roto Witch, Subsite, Fluid Miser,

Power Pipe, Super Witch, Pierce Airrow, The Underground, The Underground Authority Worldwide, and

Zahn are registered trademarks of The Charles Machine Works, Inc.

SK5BB Operator’s Manual Contents - 3

Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

• Serial Number and Component Locations . . . . . . . . . . . . . . . . . . . . . . . 1

• Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

• Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

• Safety Alert Classifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

• Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

• Emergency Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Prepare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

• Inspect Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

• Check Supplies and Prepare Equipment . . . . . . . . . . . . . . . . . . . . . . . 11

• Connect Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

• Attachment Function Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

• Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

• Operating Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

• Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

• Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Contents - 4 SK5BB Operator’s Manual

Service and Specifications . . . . . . . . . . . . . . . . . . 19

• Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

• Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

• Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

• Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

SK5BB Operator’s Manual Safety - 5

Guidelines Safety

Guidelines

Follow these guidelines before operating any jobsite equipment:

• Complete proper training and read operator’s manual before using equipment.

• Contact One-Call (888-258-0808) and any utility companies which do not subscribe to One-Call. Have

all underground pipes and cables located and marked before operating equipment. If you damage a

utility, contact utility company.

• Classify jobsite based on its hazards and use correct tools and machinery, safety equipment, and work

methods for jobsite.

• Mark jobsite clearly and keep spectators away.

• Wear personal protective equipment.

• Review jobsite hazards, safety and emergency procedures, and individual responsibilities with all

personnel before work begins. Safety videos are available from your Ditch Witch dealer.

• Replace missing or damaged safety shields and safety signs.

• Use equipment carefully. Stop operation and investigate anything that does not look or feel right.

• Do not operate unit where flammable gas is present.

• Contact your Ditch Witch dealer if you have any question about operation, maintenance, or equipment

use.

Safety - 6 SK5BB Operator’s Manual

Safety Alert Classifications

Safety Alert Classifications

These classifications and the icons defined on the following pages work together to alert you to situations

which could be harmful to you, jobsite bystanders or your equipment. When you see these words and

icons in the book or on the machine, carefully read and follow all instructions. YOUR SAFETY IS AT

STAKE.

Watch for the three safety alert levels: DANGER, WARNING and CAUTION. Learn what each level

means.

indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Watch for two other words: NOTICE and IMPORTANT.

NOTICE can keep you from doing something that might damage the machine or someone's property. It

can also alert you against unsafe practices.

IMPORTANT can help you do a better job or make your job easier in some way.

SK5BB Operator’s Manual Safety - 7

Safety Alerts

Safety Alerts

Electric shock. Contacting electric lines will cause death or serious injury.

Know location of lines and stay away.

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

Moving parts could cut off hand or foot. Stay away.

Incorrect procedures could result in death, injury, or property damage.

Learn to use equipment correctly.

Fluid or air pressure could pierce skin and cause injury or

death. Stay away.

Safety - 8 SK5BB Operator’s Manual

Emergency Procedures

Emergency Procedures

Before operating any equipment, review emergency procedures and check that all safety precautions have

been taken.

Electric Strike Description

When working near electric cables, remember the following:

• Electricity follows all paths to ground, not just path of least resistance.

• Pipes, hoses, and cables will conduct electricity back to all equipment.

• Low voltage current can injure or kill. Almost one-third of work-related electrocutions result from

contact with less than 440 volts.

Most electric strikes are not noticeable, but indications of a strike include:

• power outage

• smoke

• explosion

• popping noises

• arcing electricity

If any of these occur, assume an electric strike has occurred.

EMERGENCY SHUTDOWN - Turn ignition switch to STOP.

SK5BB Operator’s Manual Safety - 9

Emergency Procedures

If an Electric Line is Damaged

If you suspect an electric line has been damaged and you are near pedestrian unit, DO NOT MOVE and

do not touch unit. Take the following actions. The order and degree of action will depend upon the

situation.

• Warn people nearby that an electric strike has occurred. Instruct them to leave the area and contact

utility.

• Do not allow anyone into area until given permission by utility company.

If a Gas Line is Damaged

If you suspect a gas line has been damaged, take the following actions. The order and degree of action will

depend on the situation.

• Immediately shut off engine(s), if this can be done safely and quickly.

• Remove any ignition source(s), if this can be done safely and quickly.

• Warn others that a gas line has been cut and that they should leave the area.

• Leave jobsite as quickly as possible.

• Immediately call your local emergency phone number and utility company.

• If jobsite is along street, stop traffic from driving near jobsite.

• Do not return to jobsite until given permission by emergency personnel and utility company.

If a Fiber Optic Cable is Damaged

Do not look into cut ends of fiber optic or unidentified cable. Vision damage can occur.

If Machine Catches on Fire

Perform emergency shutdown procedure and then take the following actions. The order and degree of

action will depend on the situation.

• Immediately move battery disconnect switch (if equipped) to disconnect position.

• If fire is small and fire extinguisher is available, attempt to extinguish fire.

• If fire cannot be extinguished, leave area as quickly as possible and contact emergency personnel.

Safety - 10 SK5BB Operator’s Manual

Emergency Procedures

SK5BB Operator’s Manual Prepare - 11

Inspect Site Prepare

Inspect Site

Inspect jobsite before transporting equipment. Check for the following:

• changes in elevation such as hills or other open trenches

• obstacles such as buildings, railroad crossings, or streams

• traffic

• access

• soil type and condition

Check Supplies and Prepare Equipment

Supplies

• personal protective equipment, such as hard hat and safety glasses

Condition and Function

• blade

• hoses and valves

• signs

Prepare - 12 SK5BB Operator’s Manual

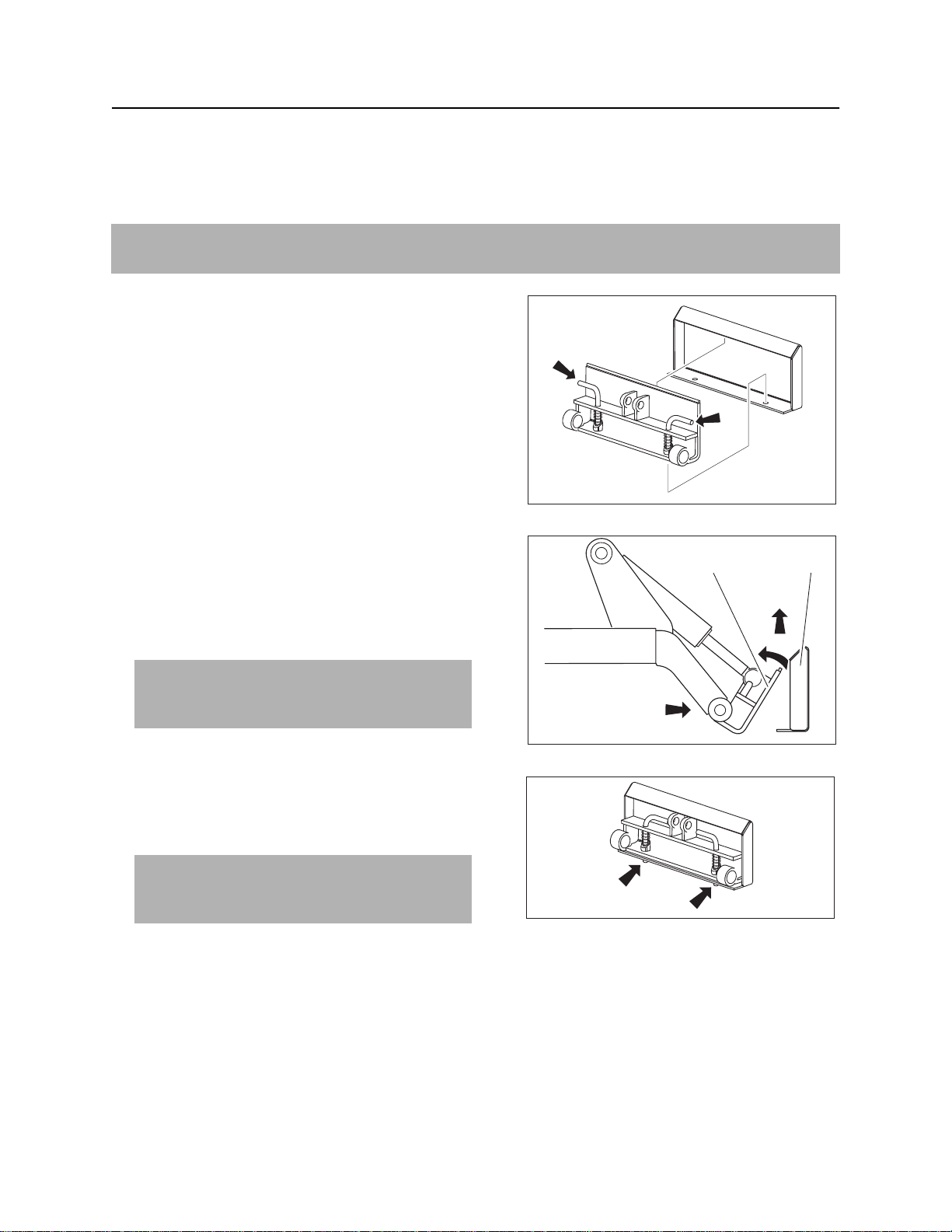

Connect Attachment

Connect Attachment

Attachment

1. Position attachment on level surface with enough

space behind it to accommodate loader.

2. Ensure that lock pin handles (shown) on mount

plate are turned away from center of attachment.

3. Start engine.

4. Tilt mount plate (2) forward.

5. Position mount plate in the upper lip of the receiver

plate (1) on attachment.

6. Raise lift (loader) arms while tilting back mount

plate.

7. Turn ignition switch off and remove key.

8. Rotate lock pin handles toward center of mount

plate to secure attachment to lift plate.

IMPORTANT: Before connecting attachment to loader, ensure that mount and receiver plates are free of

dirt and debris.

IMPORTANT: Attachment should be raised

enough to clear the ground. Mount plate

should be tilted back fully.

NOTICE: To ensure proper connection, verify

that bottoms of lock pins are visible under

attachment receiver plate (shown).

t05om022c.eps

t05om026c.eps

12

t05om027c.eps

SK5BB Operator’s Manual Prepare - 13

Connect Attachment

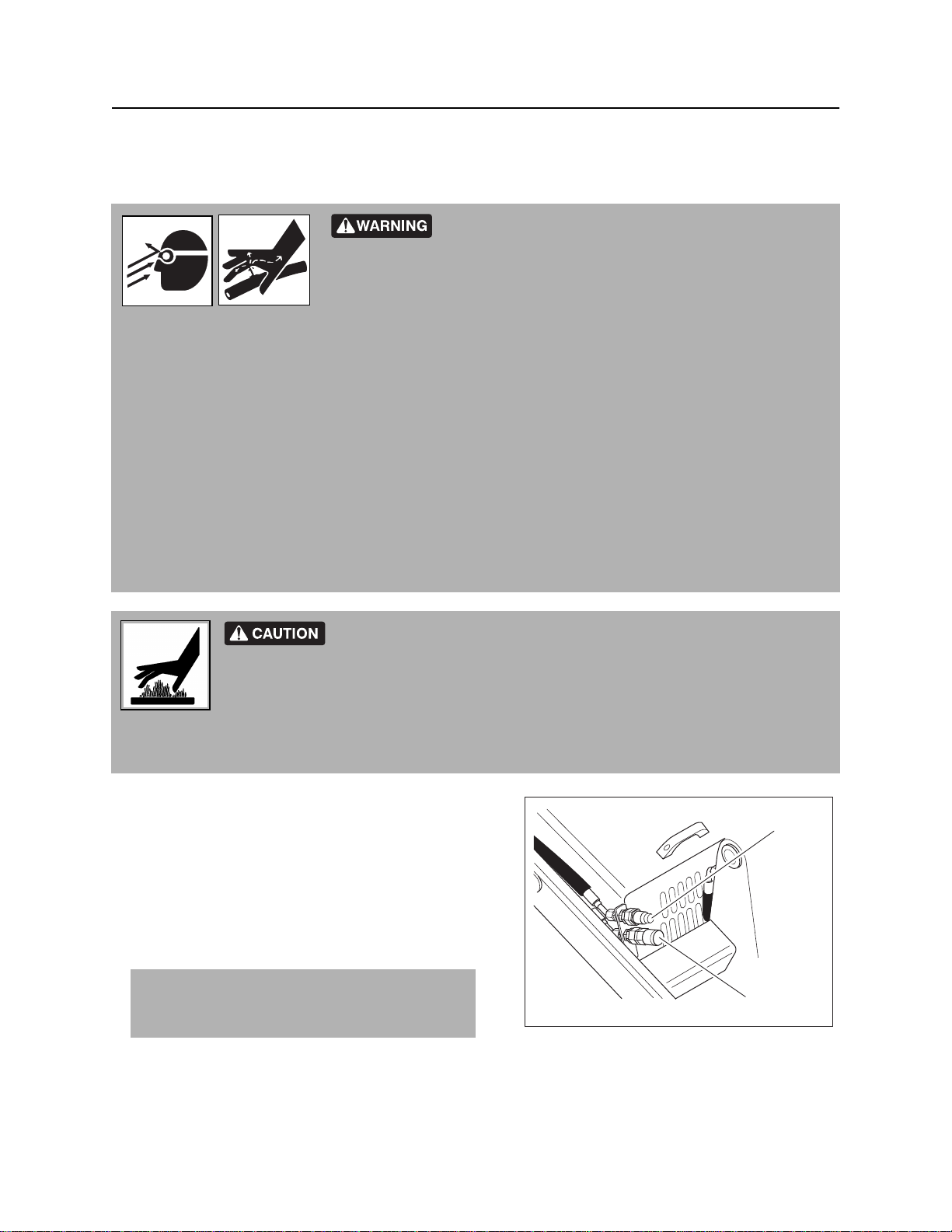

Hydraulic Hoses

If attachment requires hydraulic power for operation, connect hydraulic hoses.

1. Cycle attachment drive (auxiliary) control to relieve

residual pressure at hydraulic couplers.

2. Remove dirt and debris from hydraulic couplers.

3. Connect male coupler on attachment to female

coupler (2) on unit.

4. Connect female coupler on attachment to male

coupler (1) on unit.

5. Ensure that connections are secure by pulling on hoses.

Fluid or air pressure could pierce skin and cause injury or

death. Stay away.

NOTICE:

• Escaping pressurized fluid can cause injury or pierce skin and poison.

• Before disconnecting a hydraulic line, turn engine off and operate all controls to relieve pressure.

Lower, block, or support any raised component with a hoist. Cover connection with heavy cloth and

loosen connector nut slightly to relieve residual pressure. Catch all fluid in a container.

• Before using system, check that all connections are tight and all lines are undamaged.

• Fluid leaks can be hard to detect. Use a piece of cardboard or wood, rather than hands, to search

for leaks.

• Wear protective clothing, including gloves and eye protection.

• If you are injured, seek immediate medical attention from a doctor familiar with this type of injury.

Hot parts may cause burns. Do not touch until cool.

NOTICE: Hydraulic couplers, hoses and fluid may be hot. Wear gloves when connecting and

disconnecting hydraulic hoses and wait until unit has cooled before touching hydraulic components.

IMPORTANT: Loader shown is the Ditch Witch

SK500. Hydraulic couplers may be oriented

differently on other manufacturers’ loaders. t05om023c.eps

1

2

Prepare - 14 SK5BB Operator’s Manual

Connect Attachment

SK5BB Operator’s Manual Operate - 15

Attachment Function Overview Operate

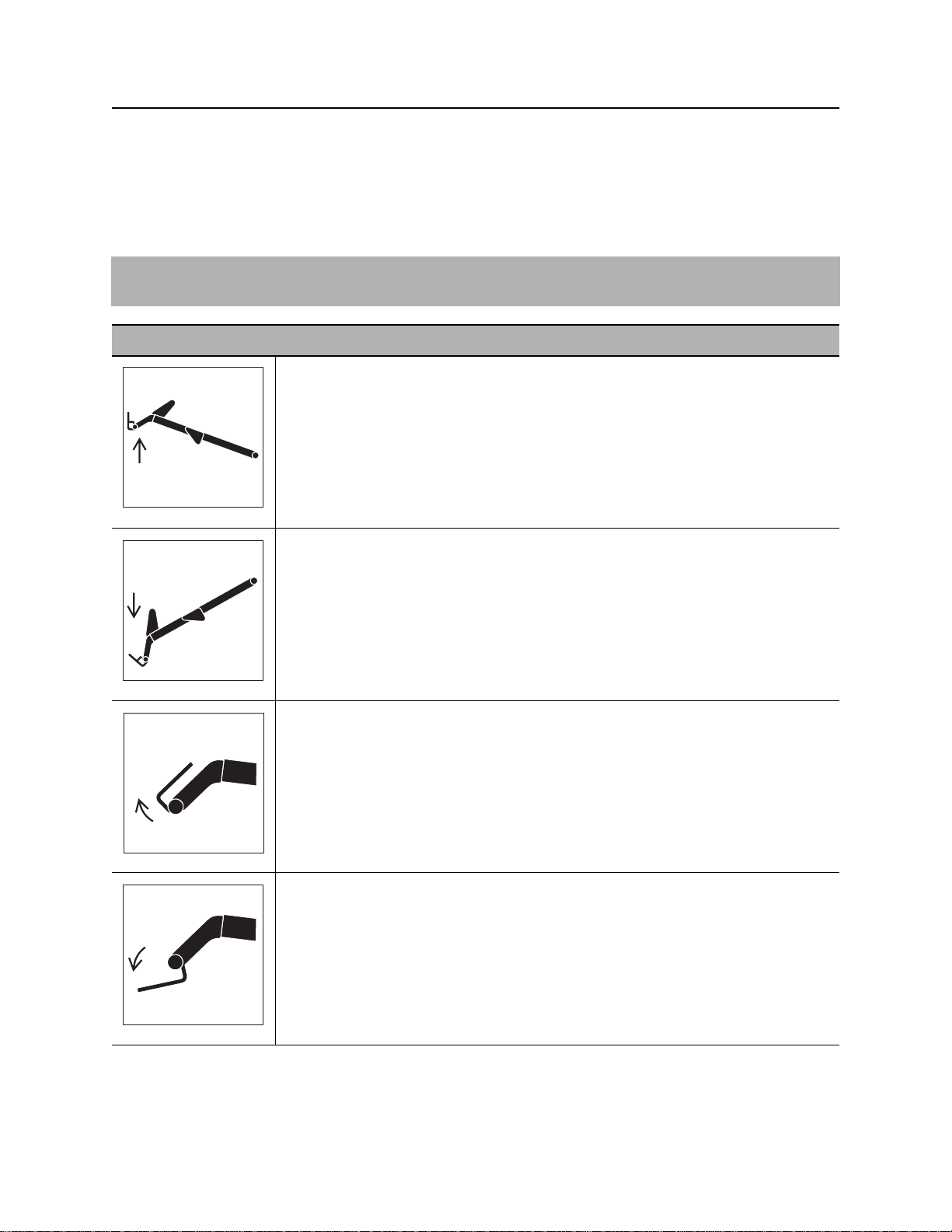

Attachment Function Overview

IMPORTANT: Refer to loader operator’s manual for proper control movement to achieve desired

attachment movement.

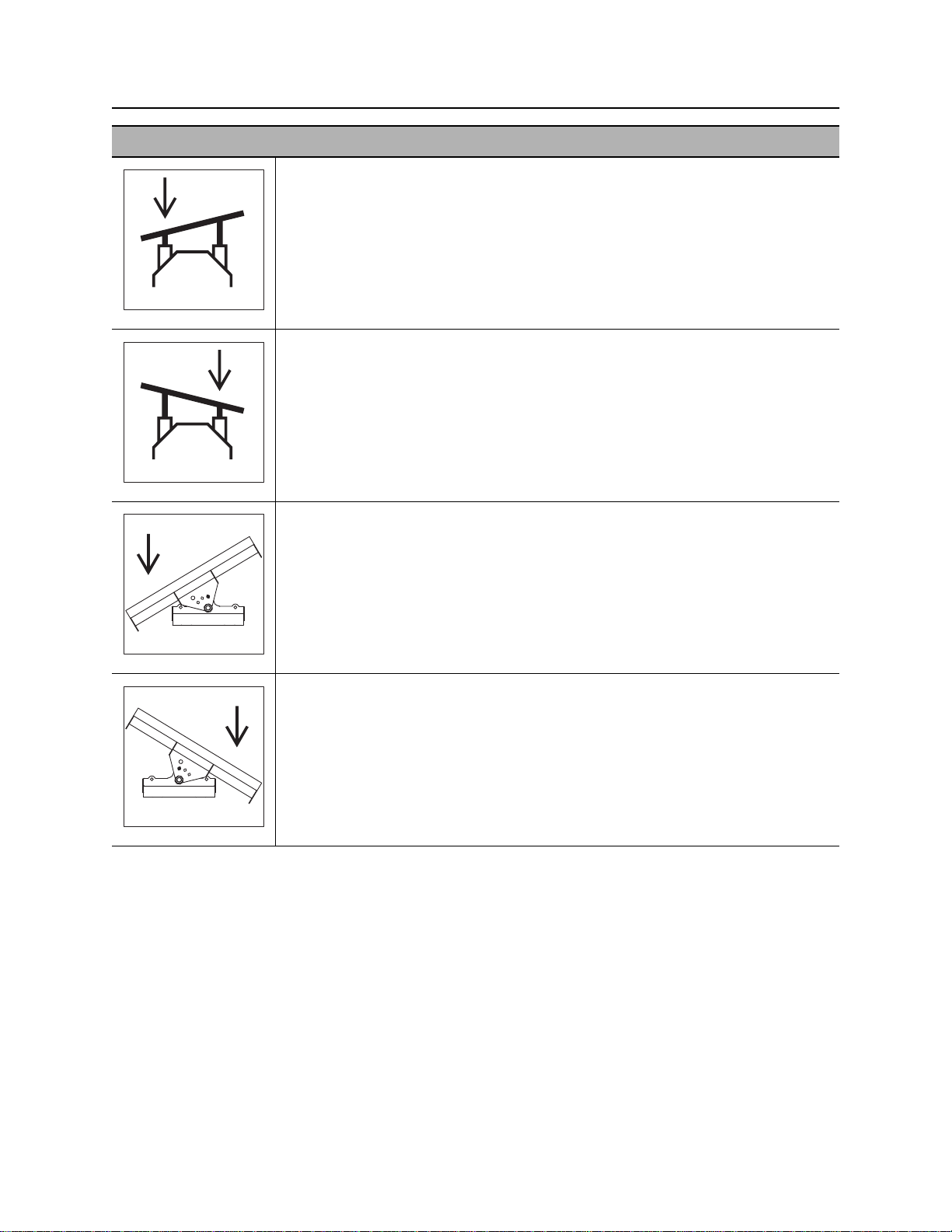

Attachment Function

To raise blade, raise lift (loader) arms.

To lower blade, lower lift (loader) arms.

To curl blade up, tilt mount plate up.

To curl blade down, tilt mount plate down.

c00ic015c.eps

c00ic016c.eps

c00ic018c.eps

c00ic017c.eps

Operate - 16 SK5BB Operator’s Manual

Attachment Function Overview

To swing blade left (hydraulic swing), engage attachment drive (auxiliary)

control in reverse.

To swing blade right (hydraulic swing), engage attachment drive (auxiliary)

control in forward.

To swing blade left (manual swing), place pin in hole on right.

IMPORTANT: To lock swing position, verify that pin goes through all four ears

and ball on bottom of pin engages below lower ear.

To swing blade right (manual swing), place pin in hole on left.

IMPORTANT: To lock swing position, verify that pin goes through all four ears

and ball on bottom of pin engages below lower ear.

Attachment Function

c00ic027c.eps

c00ic028c.eps

c00ic029c.eps

c00ic030c.eps

SK5BB Operator’s Manual Operate - 17

Operating Procedure

Operating Procedure

Backfilling

1. Use track drive controls to position loader at end of

trench, several feet from spoils. Aim loader at outer

edge of spoils.

2. Angle blade as needed.

With hydraulic swing, use attachment drive (auxiliary)

control to position blade.

With manual swing, stop loader engine and manually

position blade.

3. Use lift (loader) arm control to adjust backfill blade to

fit land contour.

4. Use track drive controls to drive forward and move

outer edge of spoils toward trench. Take two or more

passes at spoils rather than moving all spoils at once.

5. Repeat on other side of trench, if necessary.

6. Use lift (loader) arms control to engage float and make final pass over trench.

Grading/Scraping

1. Use track drive controls to move loader toward pile of material.

2. Position blade as needed.

With hydraulic swing, use attachment drive (auxiliary) control to position blade.

With manual swing, stop loader engine and manually position blade.

3. Use lift (loader) arm control to lower blade to ground level.

4. Use track drive controls to move loader slowly forward.

1

2

3

4

5

t05om080c.eps

Operate - 18 SK5BB Operator’s Manual

Operating Tips

Operating Tips

• Keep bystanders clear of work area.

• Do not walk or work under raised attachments unless lift (loader) arms are securely supported.

• Drive up or down, not across, slopes.

• Avoid sudden starts and stops.

Cleanup

Spray water onto attachment to remove dirt and mud.

Make sure all tools and accessories are loaded on trailer.

Storage

Store attachment in a clean, dry place. Cover attachment to keep it clean.

SK5BB Operator’s Manual Service and Specifications - 19

Service Service and Specifications

Service

10-Hour

Check Hydraulic Hoses and Fittings

Check hydraulic hoses for leaks every 10 hours.

Task Notes

Check hydraulic hoses and fittings (with hydraulic swing)

Check condition of backfill blade

Fluid or air pressure could pierce skin and cause injury or

death. Stay away.

NOTICE:

• Escaping pressurized fluid can cause injury or pierce skin and poison.

• Before disconnecting a hydraulic line, turn engine off and operate all controls to relieve pressure.

Lower, block, or support any raised component with a hoist. Cover connection with heavy cloth and

loosen connector nut slightly to relieve residual pressure. Catch all fluid in a container.

• Before using system, check that all connections are tight and all lines are undamaged.

• Fluid leaks can be hard to detect. Use a piece of cardboard or wood, rather than hands, to search

for leaks.

• Wear protective clothing, including gloves and eye protection.

• If you are injured, seek immediate medical attention from a doctor familiar with this type of injury.

Table of contents

Other Charles Machine Works Utility Vehicle manuals

Popular Utility Vehicle manuals by other brands

Coleman

Coleman CK100-S Assembly instructions

Superior

Superior spx 960 Instruction Manual for Operating and Maintenance

Cushman

Cushman HAULSTER 898487 Parts and maintenance manual

FamilyFun

FamilyFun GO-Cart instruction manual

Hammerhead

Hammerhead UM250IIR 2005 Owner's manual and parts manual

FLEMING

FLEMING TOP8SF Operator's manual & parts list