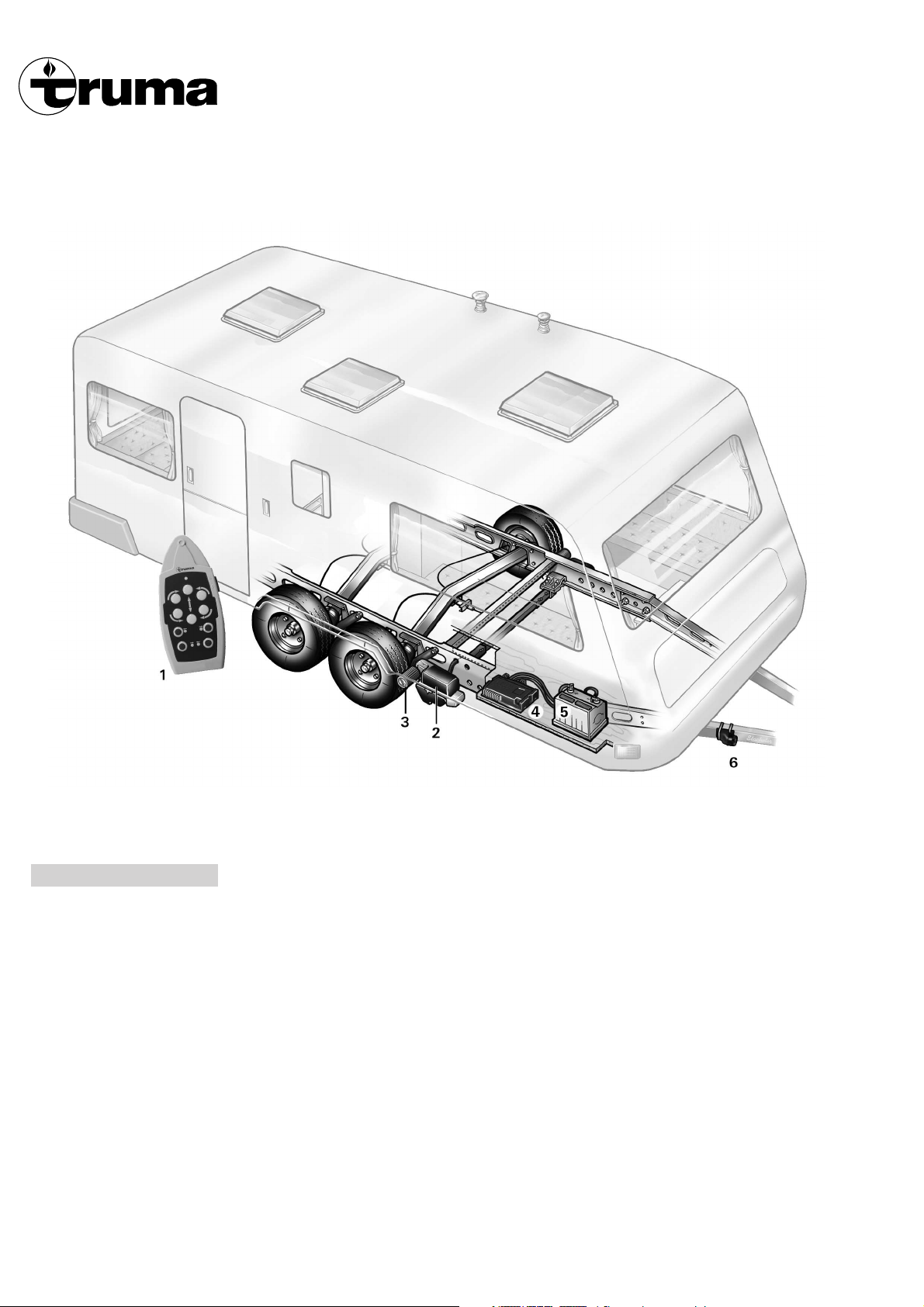

Manoeuvring the caravan

Please read the „Safety-related instructions” before

using the Mover!

Apply handbrake with caravan uncoupled.

Unplug 7-pin plug from vehicle and plug into safety socket of

caravan.

For safety reasons the Mover can only be operated if the

7-pin plug of the caravan has been plugged into the safety

socket.

If there is a fault in both caravan brake lights, the safety

socket power circuit is not closed. In this case the Mover

cannot be operated.

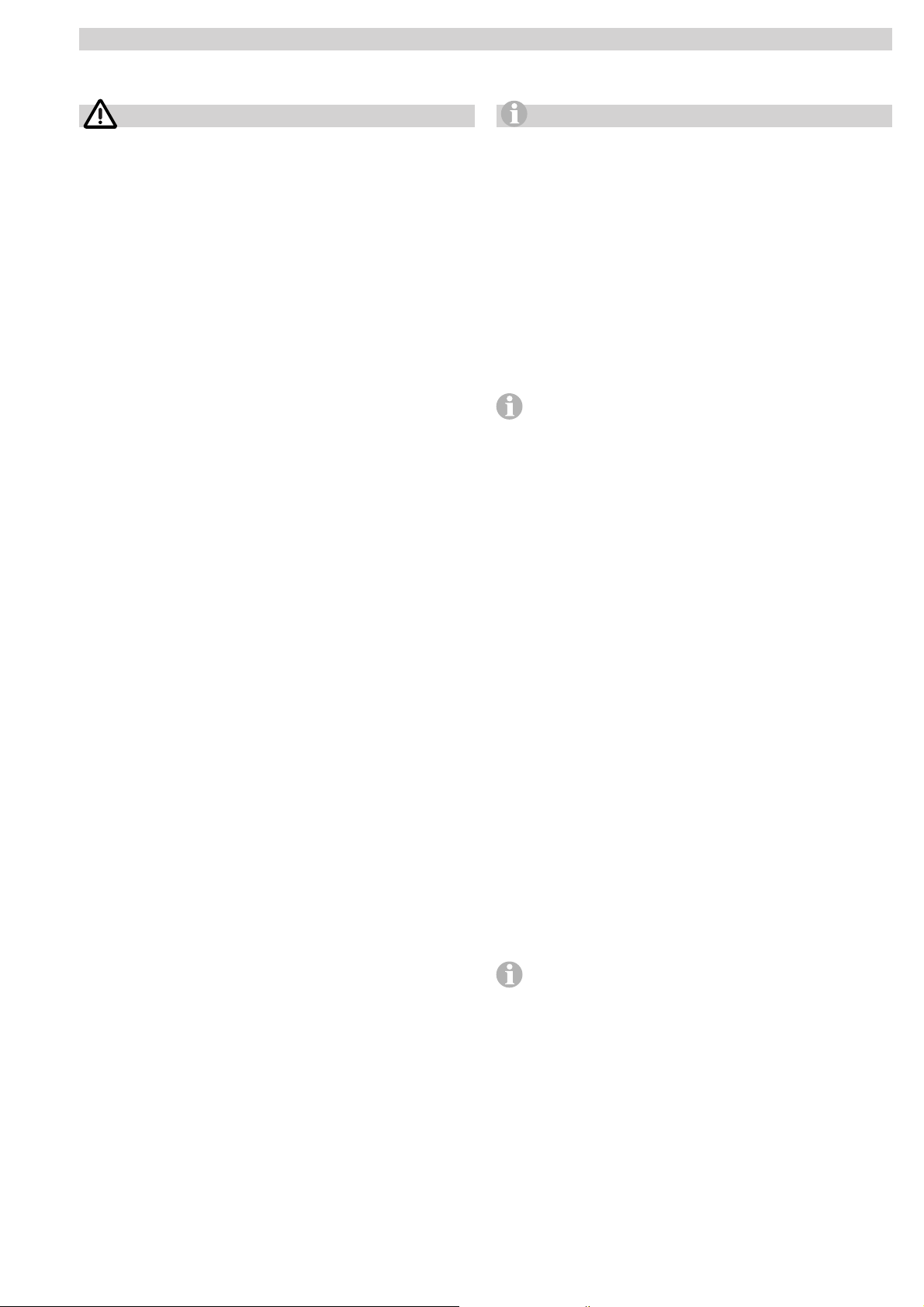

Switch remote hand set on – green LED flashes for 5 seconds

in combination with the acoustic alarm until the control unit is

ready for operation.

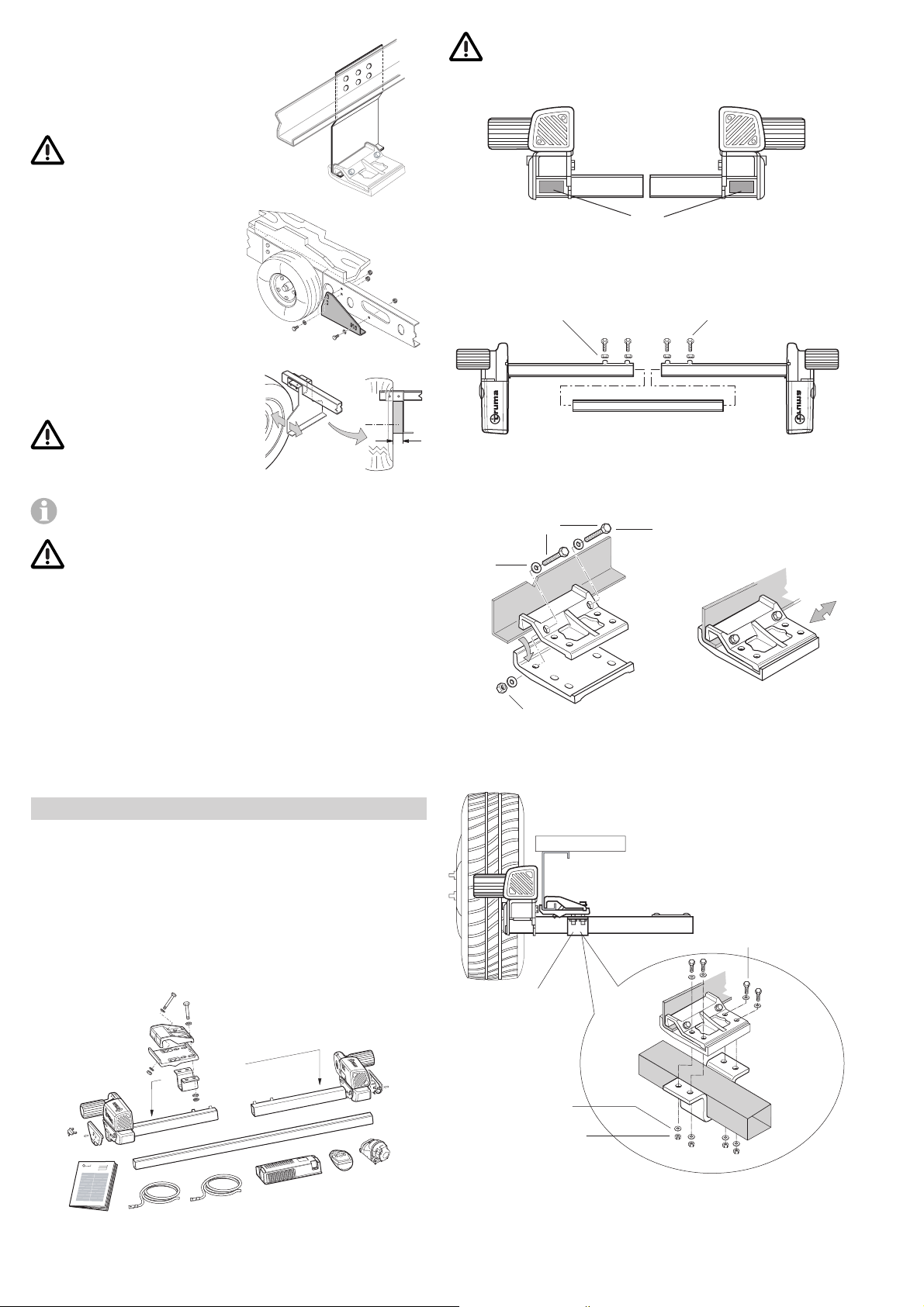

Simultaneously press the two buttons (h) for swivelling in,

which starts after approx. 3 seconds (safety delay).

Use the position indicator to check whether both drive

rollers have been correctly applied (arrow of yellow position

indicator is above the line that is closest to the tyre).

Before operating the Mover, release the handbrake.

The six direction buttons provide movement in six directions –

forward, reverse, left forward, left reverse, right forward, right

reverse.

With the Mover SE, the „left forward” (e) and „right reverse” (f)

or „right forward” (d) and „left reverse” (g) buttons can also be

pressed simultaneously in order to turn the caravan in a circle

on the spot without moving it forwards.

The soft start/stop facility means that the caravan starts

without jerking and is gently braked when stopping.

If the buttons are released or the radio signal is interfered with

or becomes too weak, the caravan stops. Your Mover cannot

be activated by radio devices or other Mover remote hand sets.

After starting up, the Mover moves at one speed only. The

speed will increase a little when going downhill and decrease a

little when going uphill.

After manoeuvring, first apply the handbrake and then

swivel the drive rollers away from the tyres.

Move slide switch on remote control to the „Off” £position to

switch the remote control and the Mover off.

The slide switch also acts as an „Emergency stop”

switch.

When manoeuvring is complete or if the system is going to be

idle for long periods, unplug the plug from the safety socket.

Hitching to a tow car

1. It is totally possible to position the caravan’s hitch to a

stationary car tow ball using the Mover, but take some care.

2. Use the instructions above as your guide. Use the button

controls to bring the caravan to the car (car handbrake „ON“,

and car in gear). Use a button stabbing technique to exactly

position the hitch directly over the ball. Lower the hitch to the

ball and engage in the normal way using the jockey wheel.

3. Prepare the caravan for towing as usual. The caravan must

not be towed with the drive rollers swivelled in.

Maintenance

1. Please do not allow the drive units to become soiled with

coarse road material. When you are cleaning the caravan,

spray the Mover with a water hose to dissolve mud etc. Please

ensure that no stones, twigs or the like become trapped in the

equipment. The control unit does not require maintenance.

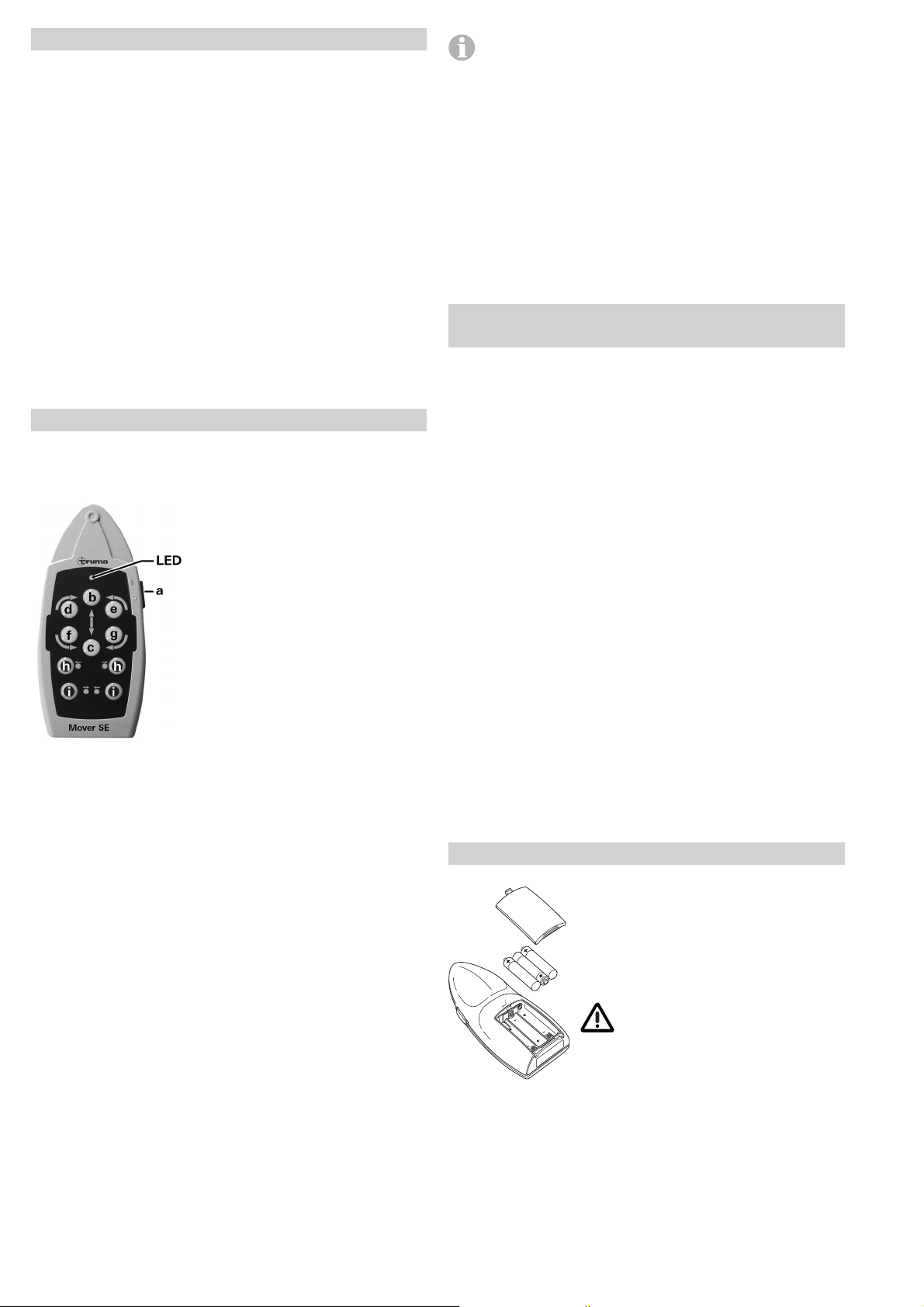

Please keep the remote hand set in a dry place.

2. Every year (and/or before putting away for the winter), clean

Mover as described, dry and lightly spray the drive unit guides

with oil spray or a similar water-repelling lubricant. Do not put

lubricant on the rollers or the tyres! Swivel the drive units

in and out several times to allow the lubricant to penetrate all

the guides. Do not park the caravan with the drive rollers

swivelled in.

3. To prevent the battery from becoming totally discharged du-

ring long periods of inactivity it must be disconnected or swit-

ched off using the isolating switch and occasionally recharged.

Charge the caravan battery before starting up.

It is extremely easy for you or your caravan dealer to perform

the checking and maintenance of your Mover during the an-

nual inspection of your caravan. If in doubt, please contact the

Truma Services.

Checks

lCheck the installation, wiring and connections for damage

at regular intervals. The drive units must be able to move

freely and be returned automatically to the safe idle position

when they are swivelled out. If this is not the case, examine

drive units for soiling or corrosion at the guides and clean if

necessary. Undo all moving parts as required and oil or spray

with a lubricant such as WD40 to ensure that the equipment

moves correctly and provides the full range of movement.

lAfter the annual inspection, check whether all motors react

properly to the buttons on the remote control.

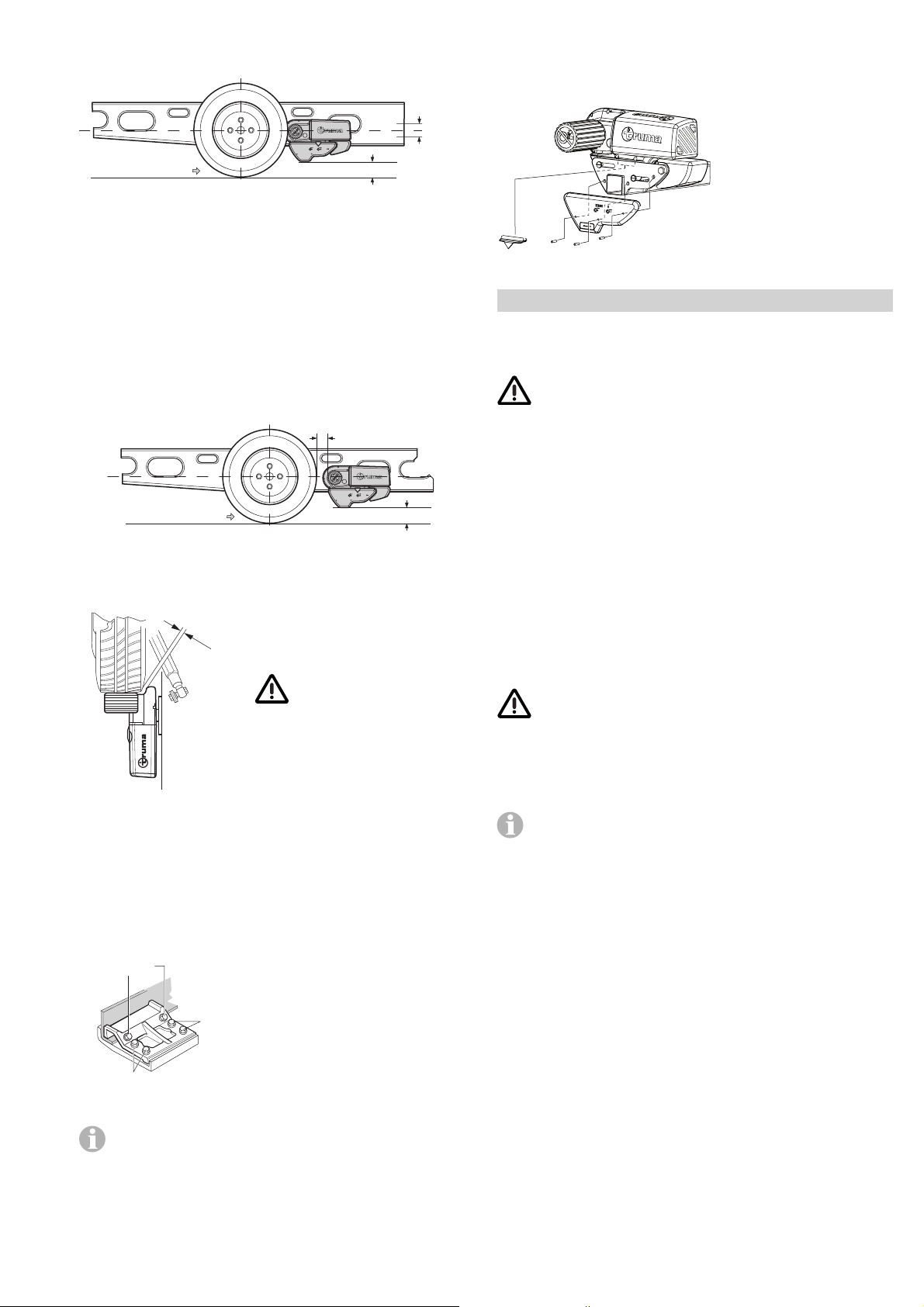

Emergency swivelling out function

If the caravan battery has become so discharged that swivel-

ling out cannot be performed using electrical means, or a fault

has occurred, the drive motors can be swivelled out manually.

m

Prise out the plastic cap (m) at the rear

end of the swivel-in motor using a screw-

driver. Place the socket wrench (size 7 –

included in scope of delivery) onto the

hexagon bolt and swivel the drive unit

out by turning anticlockwise. Repeat

procedure at the opposite side.

Once the battery has been recharged the rollers can be

swivelled in again electrically.

5