Original Instruction

PR482/SK5PR

Attachment Operator’s Manual

Publication number: ID0443833; page 6 of 6

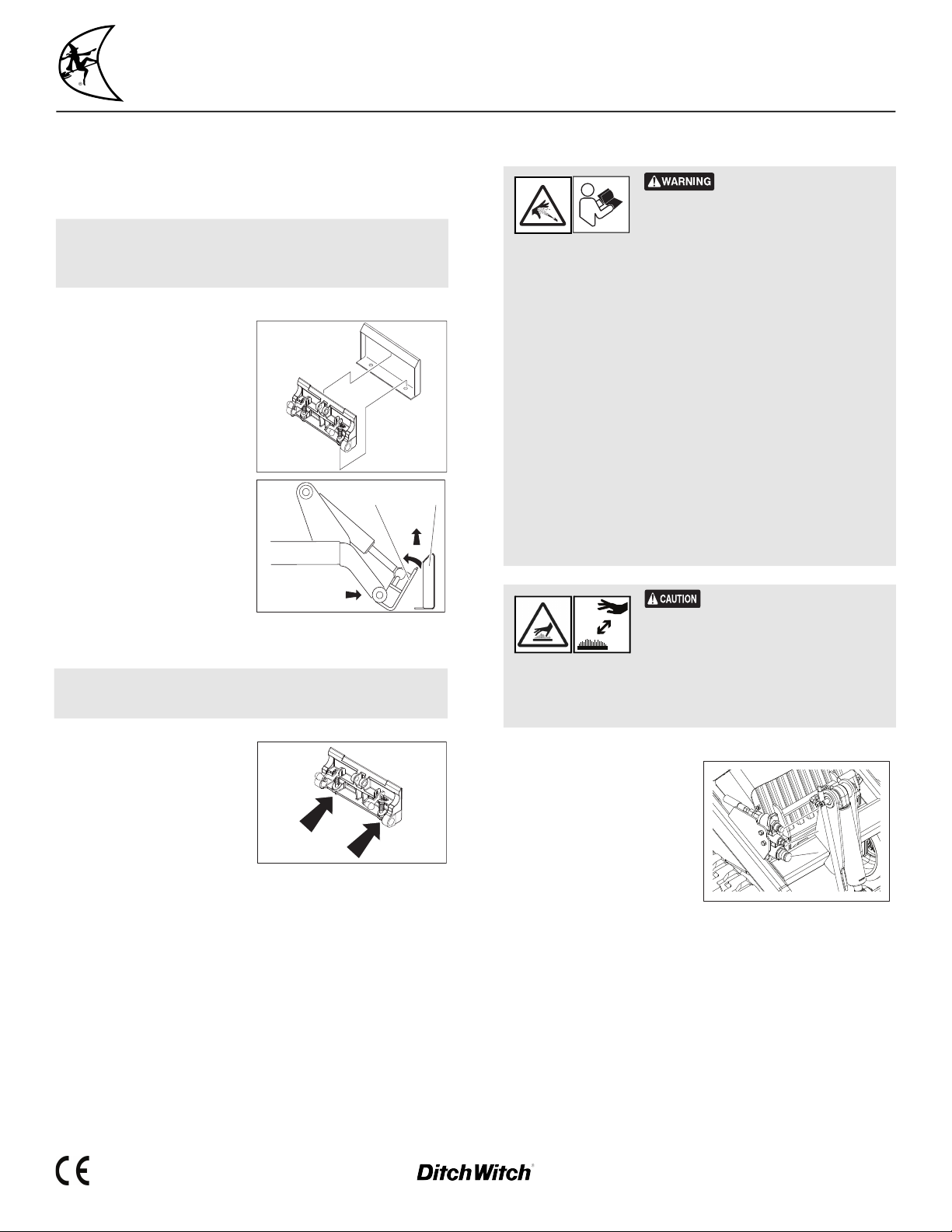

Support

Procedure

Notify your dealer immediately of any malfunction or failure of

Ditch Witch® equipment.

Always give model, serial number, and approximate date of your

equipment purchase. This information should be recorded and placed

on file by the owner at the time of purchase.

Return damaged parts to dealer for inspection and warranty

consideration if in warranty time frame.

Order genuine Ditch Witch replacement or repair parts from your

authorized Ditch Witch dealer. Use of another manufacturer's parts

may void warranty consideration.

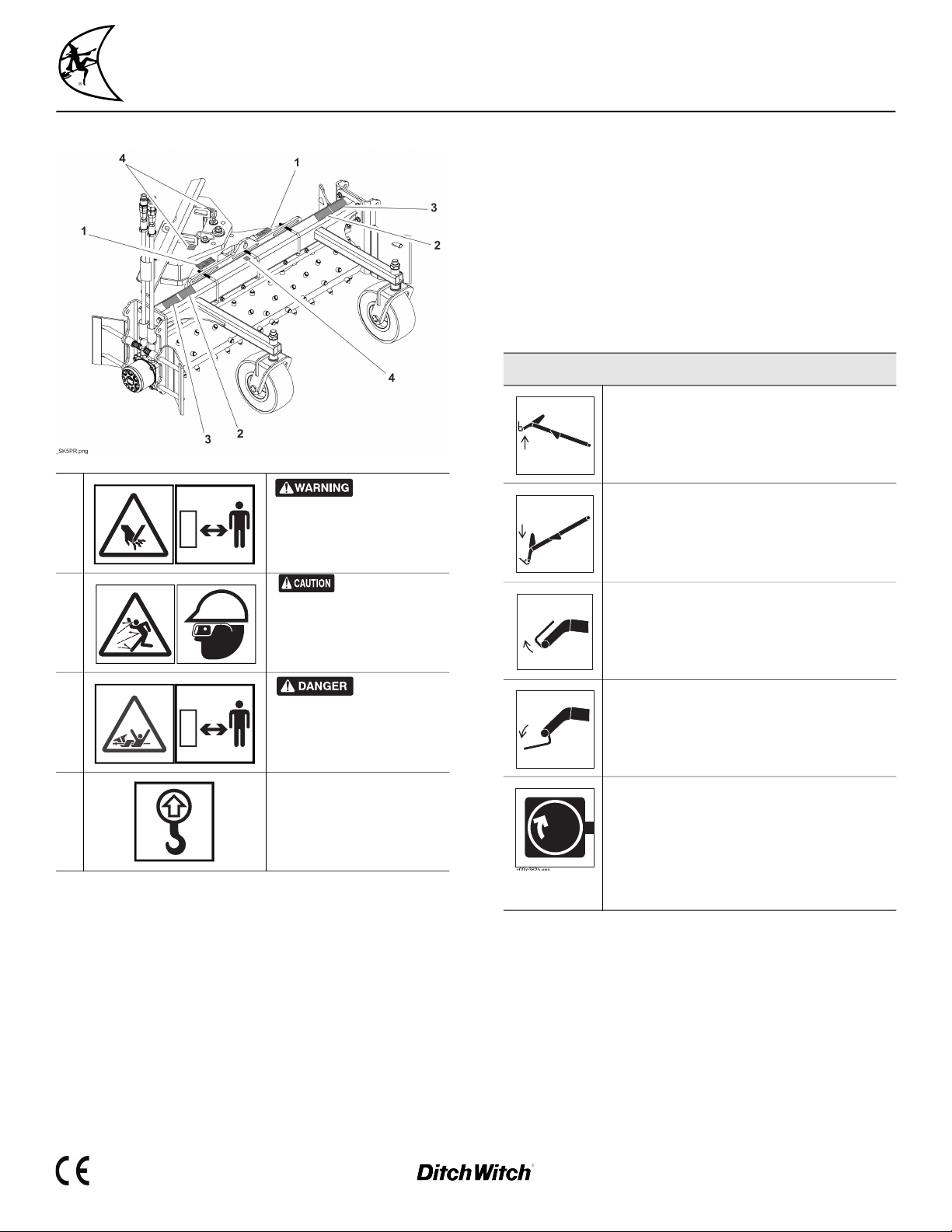

Serial Number Plate

1. Serial number

2. Attachment weight

3. Date of manufacture

Resources

Publications

Contact your Ditch Witch dealer for publications and videos covering

safety, operation, service, and repair of your equipment.

Ditch Witch Training

For information about on-site, individualized training, contact your

Ditch Witch dealer.

Warranty

Ditch Witch® Equipment and Replacement Parts

Limited Warranty Policy

Subject to the limitation and exclusions herein, free replacement parts will be

provided at any authorized Ditch Witch dealership for any Ditch Witch

equipment or parts manufactured by the Ditch Witch factory that fail due to a

defect in material or workmanship within one (1)year of first commercial use.

Free labor will be provided at any authorized Ditch Witch dealership for

installation of parts under this warranty during the first year following “initial

commercial” use of the serial-numbered Ditch Witch equipment on which it is

installed. The customer is responsible for transporting their equipment to an

authorized Ditch Witch dealership for all warranty work.

Exclusions from Product Warranty

• All incidental or consequential damages.

• All defects, damages, or injuries caused by misuse (including, but not

limited to, rollover), abuse, improper installation, alteration, neglect, or

uses other than those for which products were intended.

• All defects, damages, or injuries caused by improper training, operation, or

servicing of products in a manner inconsistent with manufacturer’s

recommendations.

• All engines and engine accessories (these are covered by original

manufacturer’s warranty).

• Tires, belts, and other parts which may be subject to another

manufacturer’s warranty (such warranty will be available to purchaser).

• ALL IMPLIED WARRANTIES NOT EXPRESSLY STATED HEREIN, INCLUDING

ANY WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE AND

MERCHANTABILITY.

IF THE PRODUCTS ARE PURCHASED FOR COMMERCIAL PURPOSES, AS DEFINED

BY THE UNIFORM COMMERCIAL CODE, THEN THERE ARE NO WARRANTIES

WHICH EXTEND BEYOND THE FACE HEREOF AND THERE ARE NO IMPLIED

WARRANTIES OF ANY KIND WHICH EXTEND TO A COMMERCIAL BUYER. ALL

OTHER PROVISIONS OF THIS LIMITED WARRANTY APPLY INCLUDING THE

DUTIES IMPOSED.

Ditch Witch products have been tested to deliver acceptable performance in

most conditions. This does not imply they will deliver acceptable performance

in all conditions. Therefore, to assure suitability, products should be operated

under anticipated working conditions prior to purchase.

Defects will be determined by an inspection within thirty (30) days of the date

of failure of the product or part by Ditch Witch Product Support (DWPS) or its

authorized dealer. DWPS will provide the location of its inspection facilities or

its nearest authorized dealer upon inquiry. DWPS reserves the right to supply

remanufactured replacements parts under this warranty as it deems

appropriate.

Extended warranties are available upon request from your local Ditch Witch

dealer or the Ditch Witch factory.

Some states do not allow exclusion or limitation of incidental or consequential

damages, so above limitation of exclusion may not apply. Further, some states

do not allow exclusion of or limitation of how long an implied warranty lasts,

so the above limitation may not apply. This limited warranty gives product

owner specific legal rights and the product owner may also have other rights

which vary from state to state.

For information regarding this limited warranty, contact the DWPS

department, P.O. Box 66, Perry, OK 73077-0066, or contact your local dealer.

First version: 1/91; Latest version: 7/19