Charmhigh BRTRO-420 User manual

Simple | Fast | High-quality

BRTRO-420

Drawer Type Reflow Oven Operating Manual

V1.07

I

Contents

Contents .............................................................................................................................................I

1. Preface ..............................................................................................................................- 1 -

2. Precaution .........................................................................................................................- 1 -

3. Features.............................................................................................................................- 2 -

4. Performance......................................................................................................................- 2 -

5. Profile Introduction ...........................................................................................................- 2 -

6. Operation ..........................................................................................................................- 3 -

6.1. Power On...............................................................................................................- 3 -

6.2. Screen Element .....................................................................................................- 4 -

6.3. Use of Buttons.......................................................................................................- 4 -

6.4. Menu Page ............................................................................................................- 5 -

6.5. Edit Page................................................................................................................- 5 -

6.6. Reflow Curve .........................................................................................................- 7 -

6.7. Run Page................................................................................................................- 9 -

7. Preset Curve ................................................................................................................... - 10 -

8. Customer Service ........................................................................................................... - 11 -

BRTRO-420 Drawer Type Reflow Oven Operating Manual

- 1 -

1. Preface

Dear customer, welcome to use our machine.

This manual details the use of the machine, including safety precautions,

performance parameters, and parameter setting method. Spend a little time reading

this manual before formal production, will help you to produce high quality circuit

board safely and efficiently according to your needs.

If there is any problem in using, welcome to contact us. Your satisfaction is our

satisfaction; your success is our success.

2. Precaution

Too high or too low voltage may cause machine work properly, or damage

machine’s electrical control system;

Please do not disassemble, because it can lead to electric shock or poor heat

insulation;

Must use the power cord attached to the machine, the power cord that is

not up to the rated power requirements may cause overheat, even cause

fire;

Keep the machine away from flammable and explosive goods;

Keep the machine clean and ventilated, especially in the back of the

machine, keep at least 20cm of space, to ensure good heat dissipation and

welding effect;

The waste gas from the chimney needs to be collected and processed when

machine running, direct discharge may cause damage to the body, and

cause pollution to the environment;

The waste gas discharged from the chimney and the chimney itself has a

high temperature, rush contact has a risk of being scalded;

Pay attention to prevent waste heat of the drawer when operating.

BRTRO-420 Drawer Type Reflow Oven Operating Manual

- 2 -

3. Features

Hot air and infrared heating, heat evenly, short period;

8 Curves are optional, production is flexibility;

Curve adjustment simple, just need adjust a few parameters, the machine

can generate curves automatically and show it directly;

Built in PID controller, high control accuracy;

Drawer window design(optional), adjust convenient;

High life heating tube;

Double sensor temperature measurement;

Use iron double ball fan, high temperature resistance, high life;

Full stainless steel chamber;

Close thermal insulation;

Industrial grade display and control circuit;

Simple, intuitive and efficient human-machine interface design.

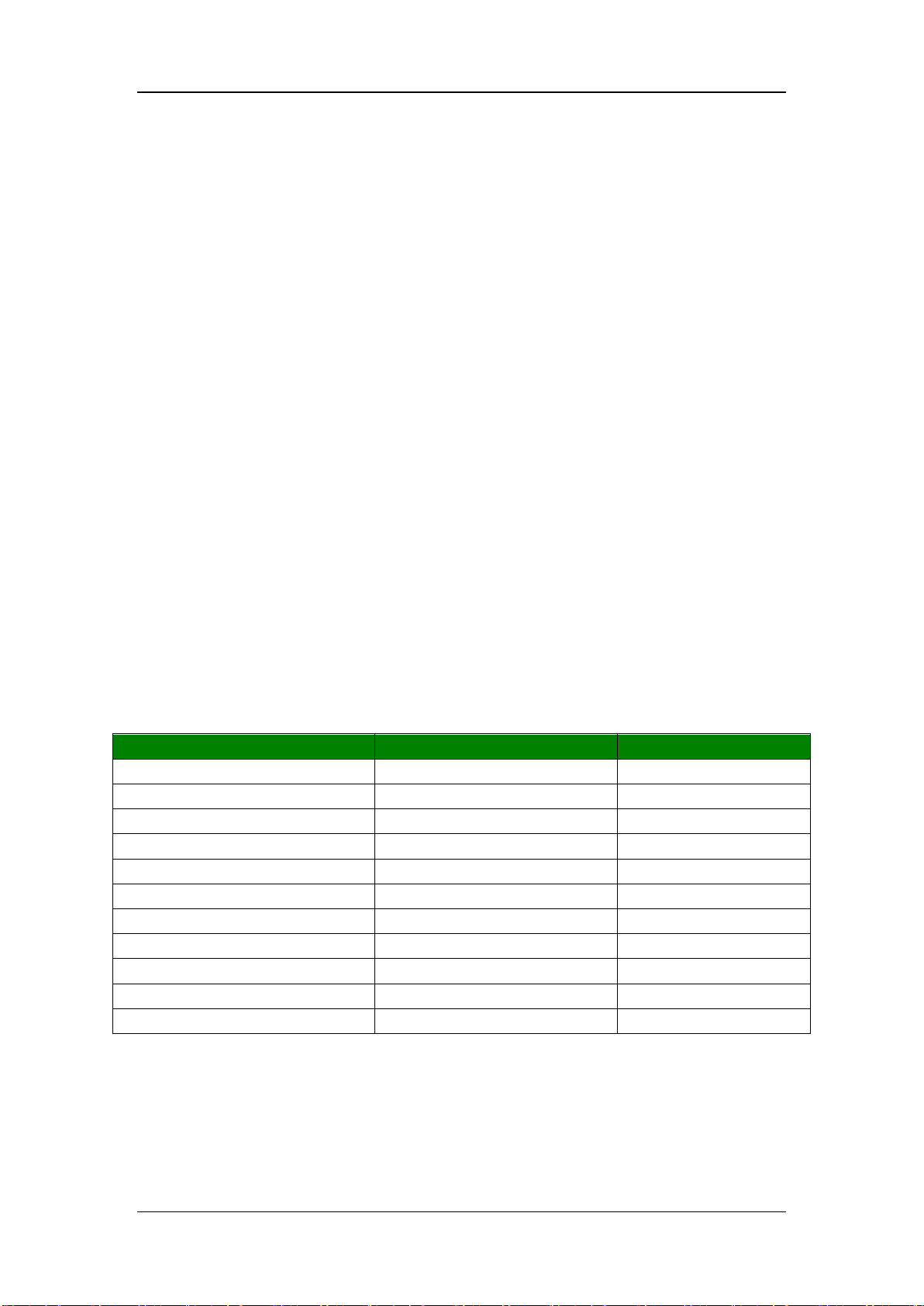

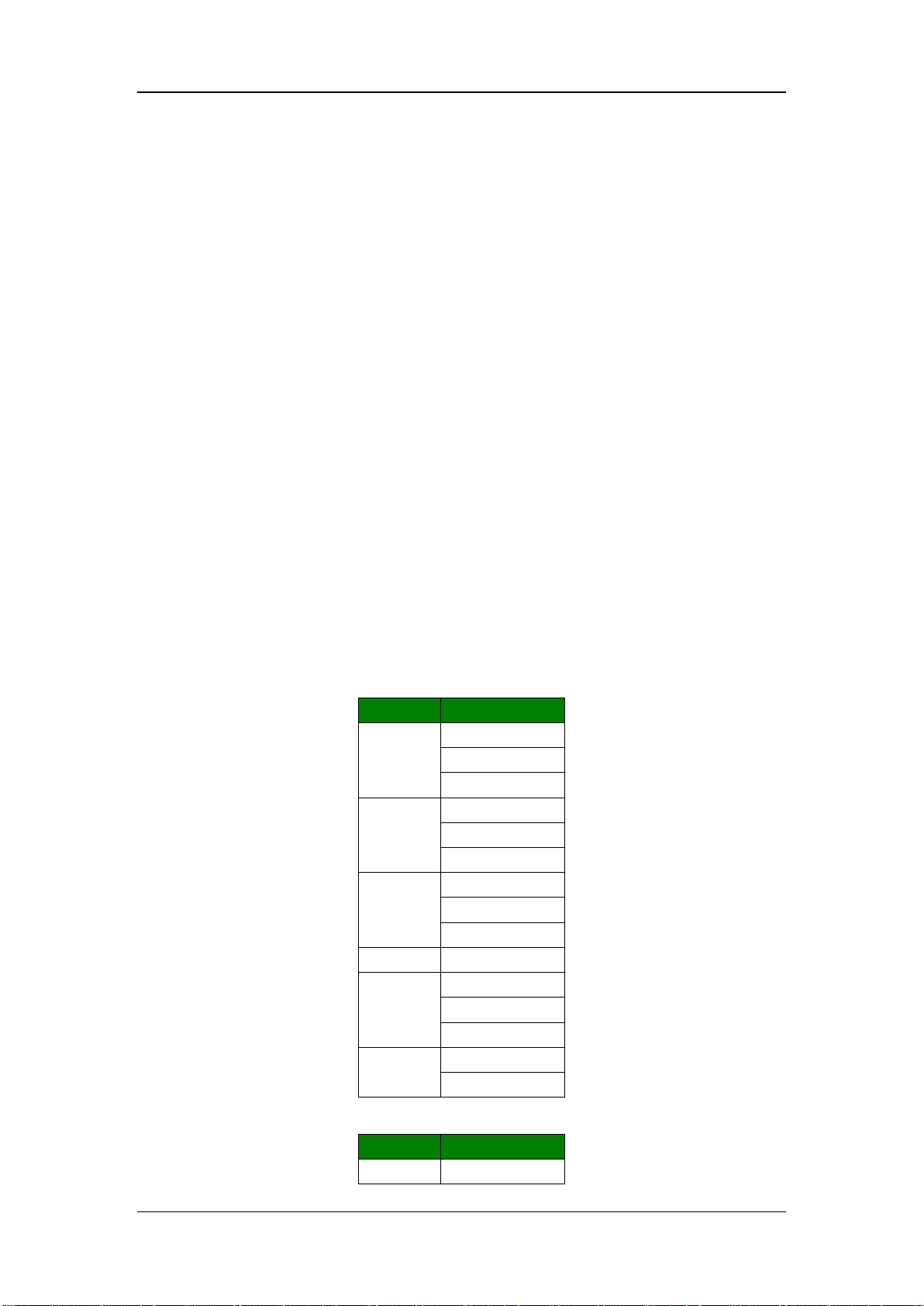

4. Performance

Item

Parameter

Remark

Outline Dimension

L 405mm W 420mm H 255mm

Net Weight

20kg

Rated Power

2500W

Peak Power

Rated Voltage

220V/60Hz

Drawer Area

300mm×300mm

Solder Type

Lead/Lead-free

Max. Temperature

300°C

Heating Mode

Hot Air and Infrared

Temperature Control Precision

±1°C

Constant Temperature

Production cycle

5~10min

Curve Number

8

5. Profile Introduction

Machine profile is shown as below.

BRTRO-420 Drawer Type Reflow Oven Operating Manual

- 3 -

Chimney

Observation

Window

Button

Screen

Pilot

Lamp

Air

Intake(Back) Power

Switch(Side)

Air Intake: At the back of the machine, used for inhaling cold air to cooling

chamber, need to keep ventilation;

Chimney: Used to discharge waste gas, must pay attention to high

temperature;

Pilot Lamp: There 3 lights altogether, ‘Heat’ light said chamber is heating,

‘Cool’ light said machine is cooling, and ‘Run’ light said machine is running;

Observation Window(optional): Used to observe circuit board in the

machine when welding;

Power Switch: Machine power switch;

Button 、Screen: Used to operate machine, see below for detailed

description.

6. Operation

6.1. Power On

Turn on the power switch, then the buzzer in the machine will give out a long

BRTRO-420 Drawer Type Reflow Oven Operating Manual

- 4 -

ringing, and the screen display as shown below, means that the machine starts OK,

then machine will enter the ‘Menu’ page automatically.

BRTRO-420

Welcom 欢迎使用

百瑞通|Brighten V1.06

Current firmware version was displayed on the bottom right corner of the

screen.

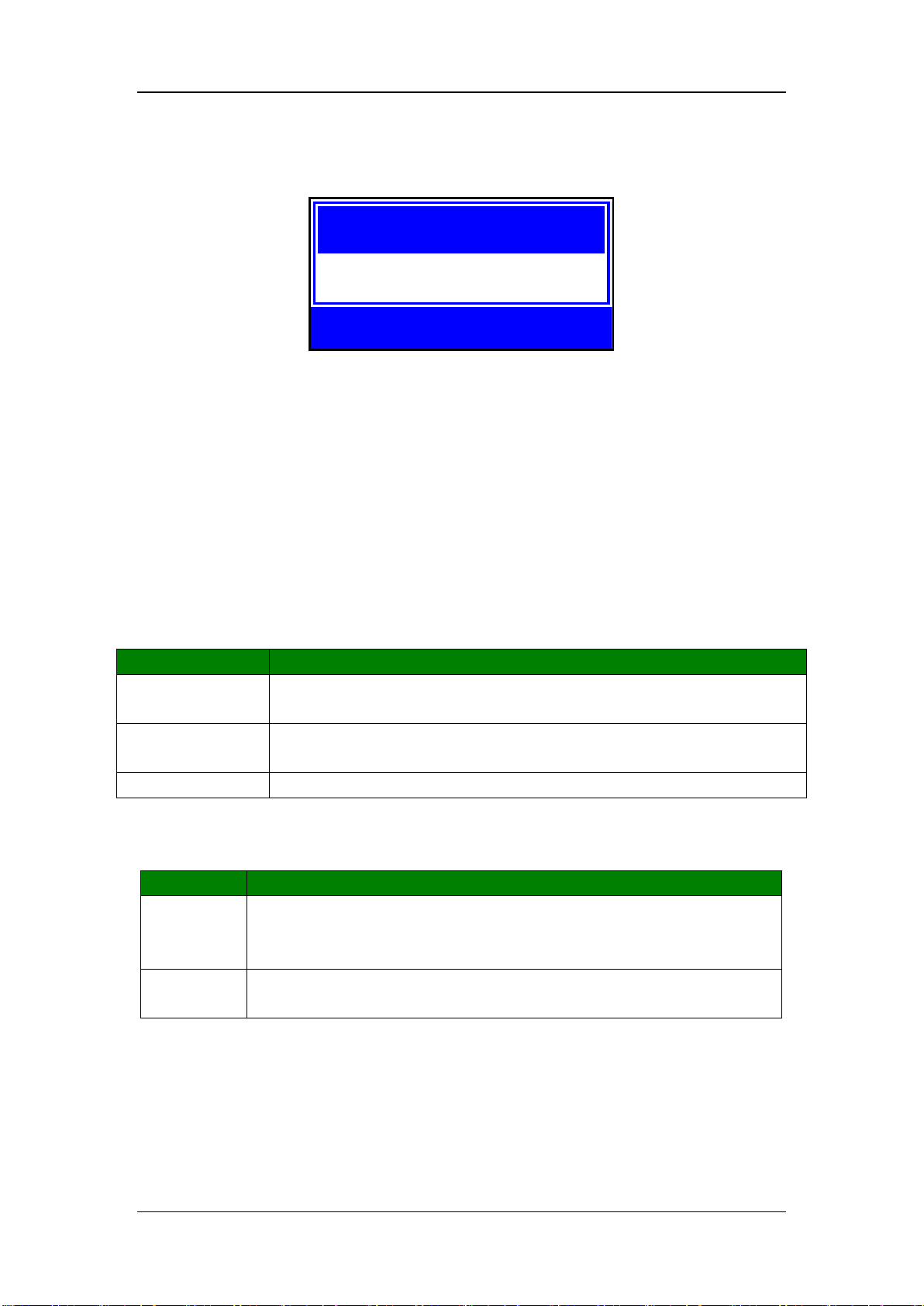

6.2. Screen Element

Before introducing specific screen page, first introduce the classification of

different elements on the screen, in fact, knowing the type of a screen element, then

know how to operate it, see following table, screen elements are simply divided into

three types.

Type

Description

Display Terms

Display fixed message or real-time data, however, it’s can not be framed and to

be operated

Function Terms

Display function name, can be framed and be selected to perform a specific

function

Parameter Terms

Display parameter values, can be framed and be selected to adjust values

Users are able to operate “function”and “parameter”types of screen elements,

two operating states are shown as below.

State

Description

Framed

The elements on the screen are occupied by a box, indicates that the current

element is selected, but can not be adjusted or perform the corresponding

functions

Selected

The screen elements are highlighted, indicates that the current element can

be modified at any time

6.3. Use of Buttons

All the operations are implemented through four buttons on the operation panel,

see the table below for details.

BRTRO-420 Drawer Type Reflow Oven Operating Manual

- 5 -

Button

Name

Description

Upward

When no element is selected on the screen, it is used to move the

selected box up; and when an element is selected on the screen, it is

used to adjust the value of the selected element

Downward

Just be opposite of the above

Confirm

Used to switch the framed parameter to selected state, or perform the

framed function

Return

Used to switch the parameter in selected state back to framed state, or

return to the upper page

The buzzer will short sound as confirmation when buttons that are able to

function currently action. Moreover, some parameters can be adjusted quickly by

long press.

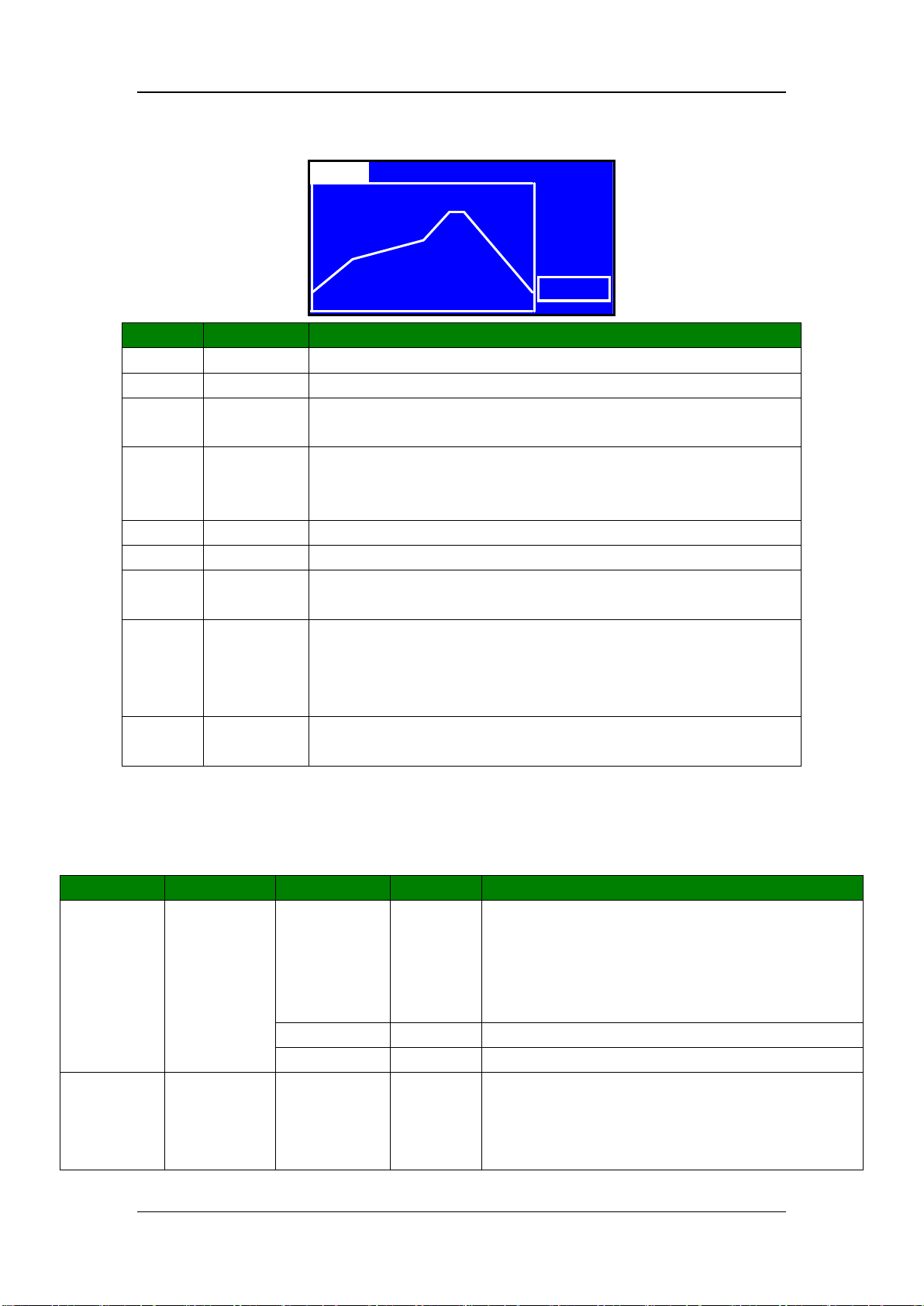

6.4. Menu Page

Screen is shown as below.

MENU Cur1

220°C

21.5°C

183°C

06:05

Run

Edit

Descriptions of the elements on the screen are shown in the following table.

Item

Type

Description

Remark

MENU

Display

Indicates that the current screen is

menu page

21.5°C

Display

Current temperature

Cur1

Display

Current selected curve

220°C

Display

Max. temperature of the curve

183°C

Display

The melting point of the solder

paste

Only for reference, no control

function is given

06:05

Display

Total running time

Curve

Display

Shape of curve

Edit

Function

Select to enter edit page

Run

Function

Select to enter run page and start

running

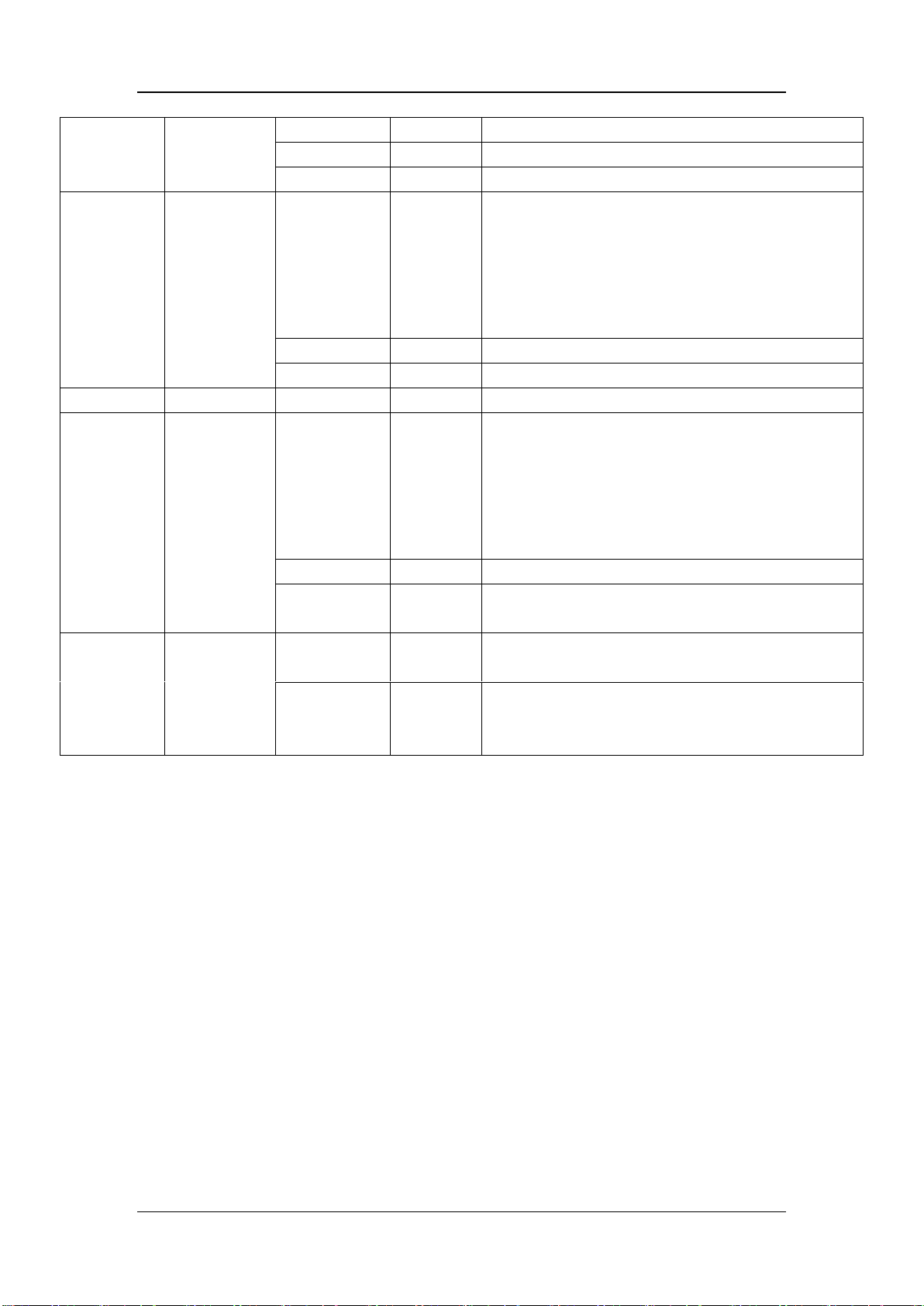

6.5. Edit Page

BRTRO-420 Drawer Type Reflow Oven Operating Manual

- 6 -

Edit page is used to select and edit curves.

EDIT Cur1

PreHt

50.3°C

100°C

48s

Save

S1.0

Item

Type

Description

EDIT

Display

Indicates that the current screen is edit page

50.3°C

Display

Current temperature

Cur1

Parameter

Select the curve, different curve contain a set of completely

independent parameters

PreHt

Parameter

Select section of the curve, for example, the current selection is the

preheating section of curve, the three parameters below will change

with different value of this parameter

100°C

Parameter

Target temperature of preheating section

48s

Parameter

Length of preheating section

S1.0

Display

Temperature change rate of preheating section, 1.0 said that the

temperature increased by 1°C per second

Save

Function

There has an ‘*’if there are parameters are modified but not saved,

select to save the modified parameters and the ‘*’ will disappear at

the same time; Note, even if the parameters are not saved, the

machine will run with new parameters until the power is off

Curve

Display

The shape of current curve, it changes with the change of the

parameters of curve

From above, it is obvious that the parameters in section will change along with the selection

of different sections. All of these changes are listed below. The values of the parameters in the

table are just examples.

Section

Name

Parameter

Type

Description

PreHt

Preheat

100°C

Parameter

Target temperature of preheating. The start

temperature of preheating is the target temperature of

cooling, taking the parameters in the table as example,

temperature will be changed from 50°C to 100°C in

preheating section

48s

Parameter

Time of preheating section

S1.0

Display

Temperature change rate of preheating section

Heat

Heat

150°C

Parameter

Target temperature of heating, The start temperature

of heating is the target temperature of preheating,

taking the parameters in the table as example,

temperature will be changed from 100°C to 150°C in

BRTRO-420 Drawer Type Reflow Oven Operating Manual

- 7 -

heating section

100s

Parameter

Time of heating section

S0.5

Display

Temperature change rate of heating section

Ref

Reflow

220°C

Parameter

Target temperature of reflowing, this parameter

determines the maximum temperature of curve. The

start temperature of reflowing is the target

temperature of heating, taking the parameters in the

table as example, temperature will be changed from

150°C to 220°C in reflowing section

60s

Parameter

Time of reflowing section

S1.2

Display

Temperature change rate of reflowing section

RefKp

Reflow Keep

15s

Parameter

Time of keeping max. temperature

Cool

Cool

50°C

Parameter

Target temperature of cooling, this parameter

determines the minimum temperature of curve. The

start temperature of cooling is the target temperature

of reflowing, taking the parameters in the table as

example, temperature will be changed from 220°C to

50°C in cooling section

140s

Parameter

Time of cooling section

S-1.2

Display

Temperature change rate of cooling section, note that

this value is negative

Melt

Melt

183°C

Parameter

Melting temperature of solder paste, only for

reference

77s

Display

The time that solder paste endured above melting

point, this parameter will change automatically when

the other parameters are changed

Note that the temperature in the table can not be lower than the target

temperature of previous or higher than the following.

6.6. Reflow Curve

The parameters editing of reflowing curve is introduced above, the figure below

shows a complete reflowing curve.

BRTRO-420 Drawer Type Reflow Oven Operating Manual

- 8 -

It is very important that a suitable reflowing curve is a guarantee of good

welding quality. However, Adjust reflowing curve will become very simple as long

as you have got the right method. The method is generally divided into the

following three steps.

Check the reference manual of solder paste, set the initial curve according to

the instructions in the manual;

Adjust the curve according to the maximum acceptable temperature of the

components, so as to prevent damage to the components in welding process

by high temperature;

Take actual welding test, and adjust curve according to the welding effect.

The function of each section and the points for attention of reflowing curve are

introduced below, in addition, a detailed description can be found in the manual of

solder paste.

PreHt: Preheating section, used for rapid heating, heat the circuit board to

the temperature of solder paste to start work, the target temperature of this

section should not be set too high, and heating time not too long.

Temperature too high or time too long is the main reason of solder paste

collapse, tiny balls around the pads, solder sticking together;

Heat: Heating section, this section mainly makes the temperature to the

same on circuit board, and the flux in solder paste begins to work at the

same time. The temperature rise rate of this section is smaller than the

previous, and the curve looks slower too, but if the temperature is too high

BRTRO-420 Drawer Type Reflow Oven Operating Manual

- 9 -

or time is too long, will cause flux volatile prematurely, and then lead to

oxidation and poor wetting;

Ref: Reflowing section, this section is mainly used to melt the solder paste,

it’s a key step in welding, temperature rise rate is greater than the previous,

too high temperature and too long time will lead to oxidation and impact of

components on circuit board;

RefKp: Reflowing keep section, used to set the time to maintain the

maximum temperature for full of flux volatile and solder flow;

Cool: Cooling section, mainly used to reduce the temperature of the circuit

board smoothly, solder will be re-solidified in this process, it is worth

mentioning that the cooling process also has a great impact on the welding

effect, too fast or too slow cooling process will produce pale and lightless

solder beads, what is worse, there may be potential defects;

Melt: Melting point, in fact, the solder paste has strict requirements on time

that the temperature above the melting point.

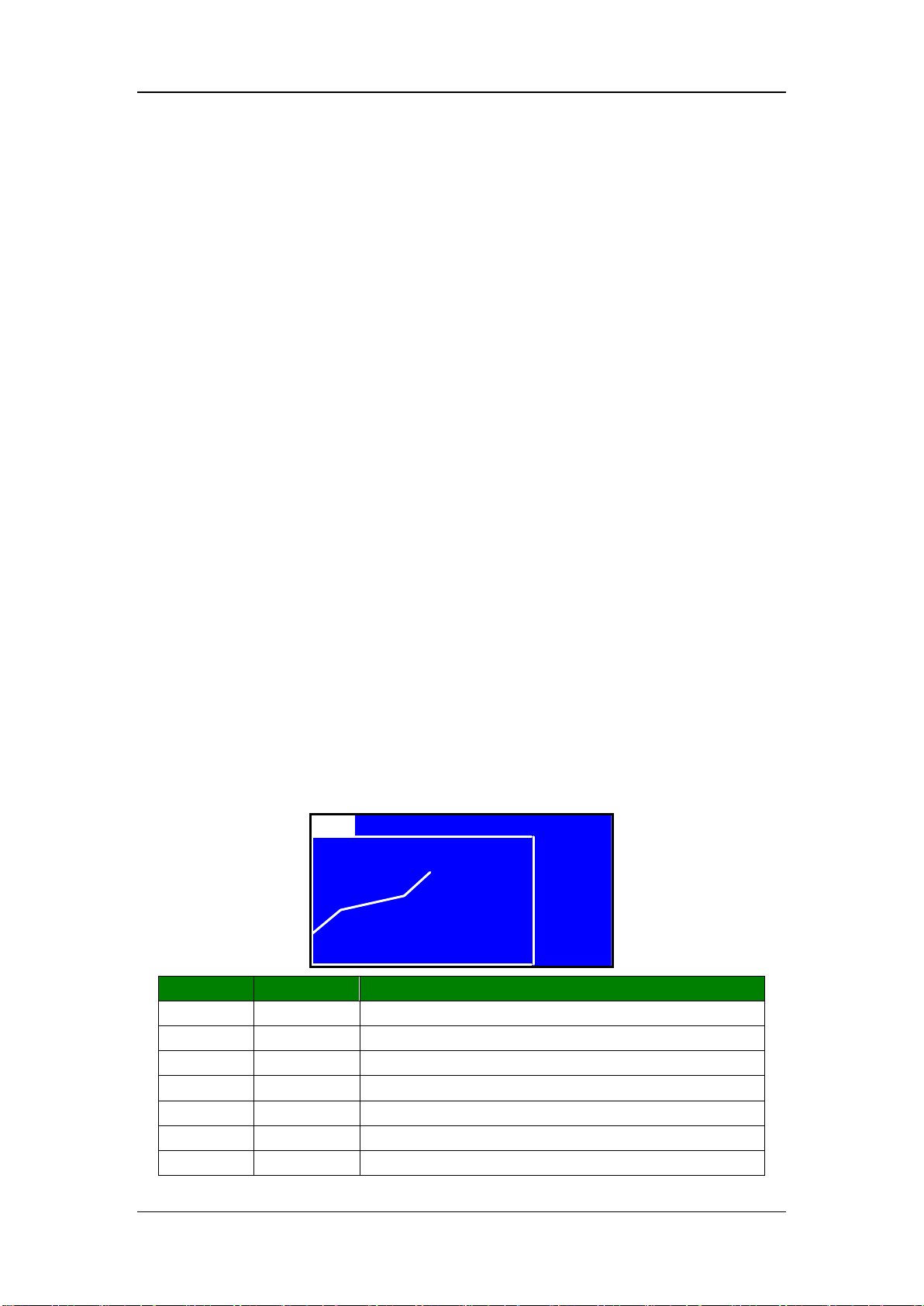

6.7. Run Page

Select ‘Run’ at the menu page to enter page as below, the buzzer will give out a

long ringing, once entering the run page, machine start run the reflowing curve.

Run Cur1

03:25

219.5°C

56%

220°C

Item

Type

Description

Run

Display

Indicates that the current screen is run page

219.5°C

Display

Current temperature

Cur1

Display

Current selected curve

03:25

Display

Run time

56%

Display

Percentage of completed

220°C

Display

Theoretical temperature

Curve

Display

Actually measured curve

BRTRO-420 Drawer Type Reflow Oven Operating Manual

- 10 -

Buzzer will long sound interval after completion, machine will stop running and

go back to menu page automatically until the temperature drops below the cooling

temperature. Of course, user can also end this running directly by press return

button.

Note, the stainless steel will absorb heat in cold start, and lead to temperature

rise slow, so it is suggested that running one time without load for preheating

before production. On the other hand, it appears that running has been completed

but the temperature has not been completely down. Even so, the two cases are

occurred below the temperature of solder paste working due to the careful design,

therefore, it will not affect the effect of welding.

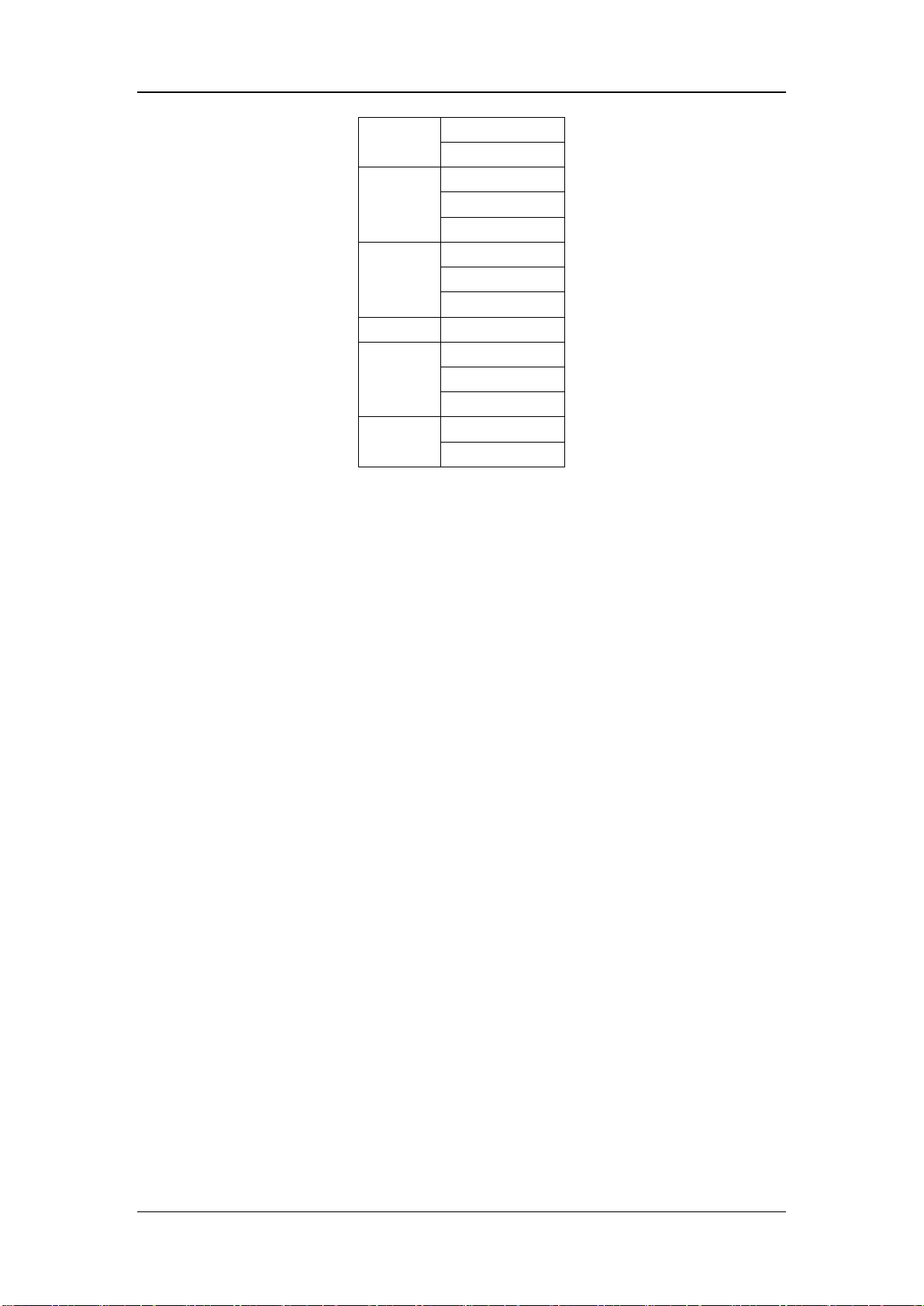

7. Preset Curve

Two sets of curves have been preset to facilitate users to setup, No. 1~4 are

lead curves, No. 5~8 are lead-free curves, users have to adjust them according to

the actual needs, parameters are listed as below for reference.

Lead, total run time 6 min. 5 sec.

Section

Parameter

PreHt

100°C

50s

S1.0

Heat

150°C

100s

S0.5

Ref

220°C

60s

S1.2

RefKp

15s

Cool

50°C

140s

S-1.2

Melt

183°C

77s

Lead-free, total run time 5 min. 10 sec.

Section

Parameter

PreHt

160°C

BRTRO-420 Drawer Type Reflow Oven Operating Manual

- 11 -

50s

S2.2

Heat

180°C

85s

S0.2

Ref

228°C

50s

S1.0

RefKp

25s

Cool

50°C

100s

S-1.8

Melt

220°C

37s

8. Customer Service

Thank you for using our products, please feel free to contact us if you have any

questions.

Table of contents

Other Charmhigh Welding System manuals

Popular Welding System manuals by other brands

Michigan Welding

Michigan Welding ARCTIG140 operating instructions

Miller Electric

Miller Electric XMS 4000 owner's manual

Lincoln Electric

Lincoln Electric INNERSHIELD PRO K126-10 Operator's manual

Amada

Amada PU-G Operation manual

Lampert

Lampert PUK S450 operating manual

Cebora

Cebora 359 instruction manual