http://www.charmhigh.com

Charmhigh-V1.0-2016 | Hunan Charmhigh mechanical and electrical co., LTD

All Rights Reserved

Catalogue

1.SACURITY MATTERS....................................................................................................................... 1

2.MAIN PARAMETERS.........................................................................................................................2

2.1.CHM-T36VA................................................................................................................................... 2

2.2.CHM-T48VA................................................................................................................................... 3

2.3.CHM-T48VB...................................................................................................................................3

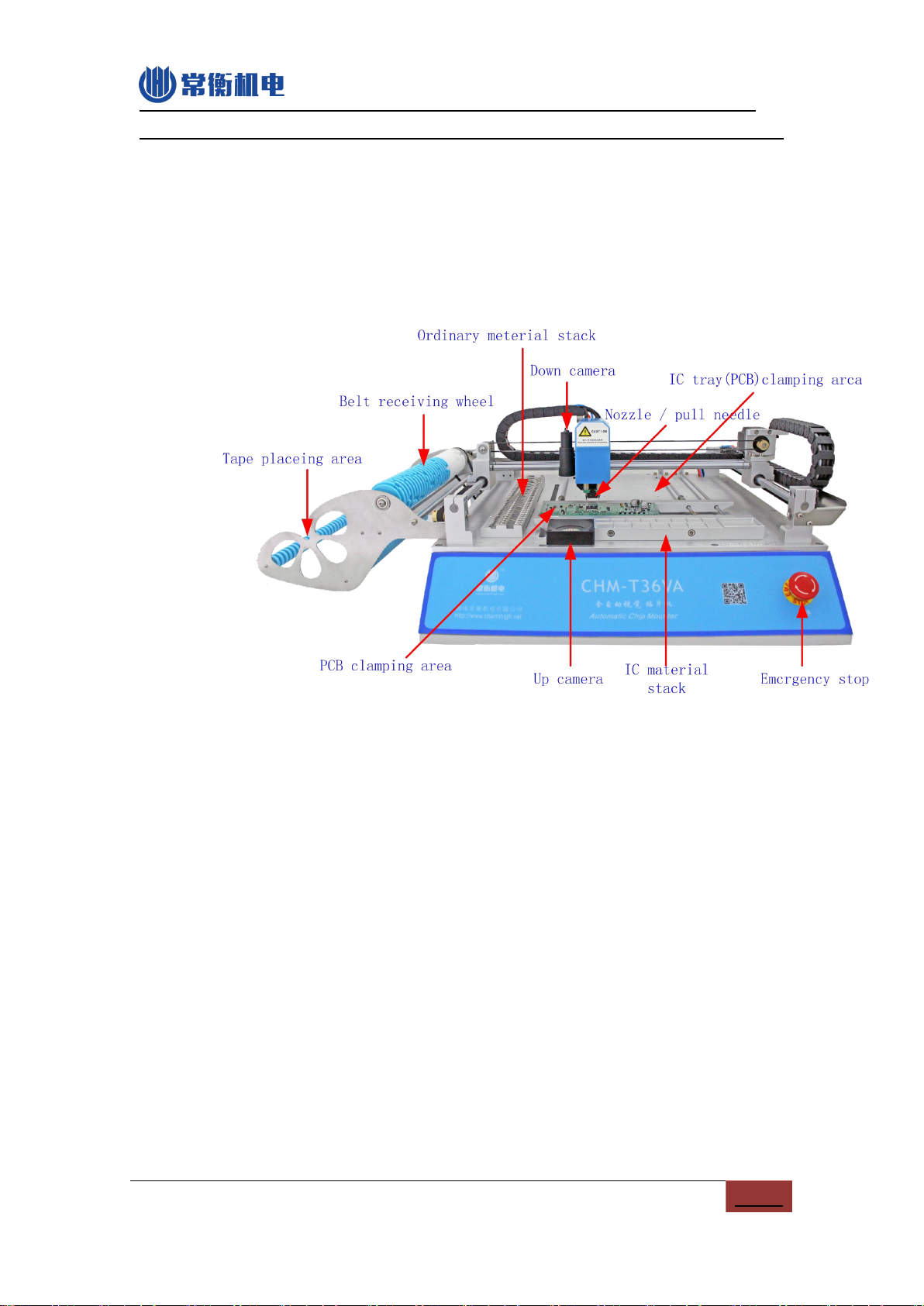

3.MACHINE PROFILE.......................................................................................................................... 5

3.1.CHM-T36VA................................................................................................................................... 5

3.2.CHM-T48VA................................................................................................................................... 6

3.3.CHM-T48VB...................................................................................................................................7

4.INSTALLTION MACHINE....................................................................................................................... 9

5.START..................................................................................................................................................... 9

6.RUN....................................................................................................................................................... 10

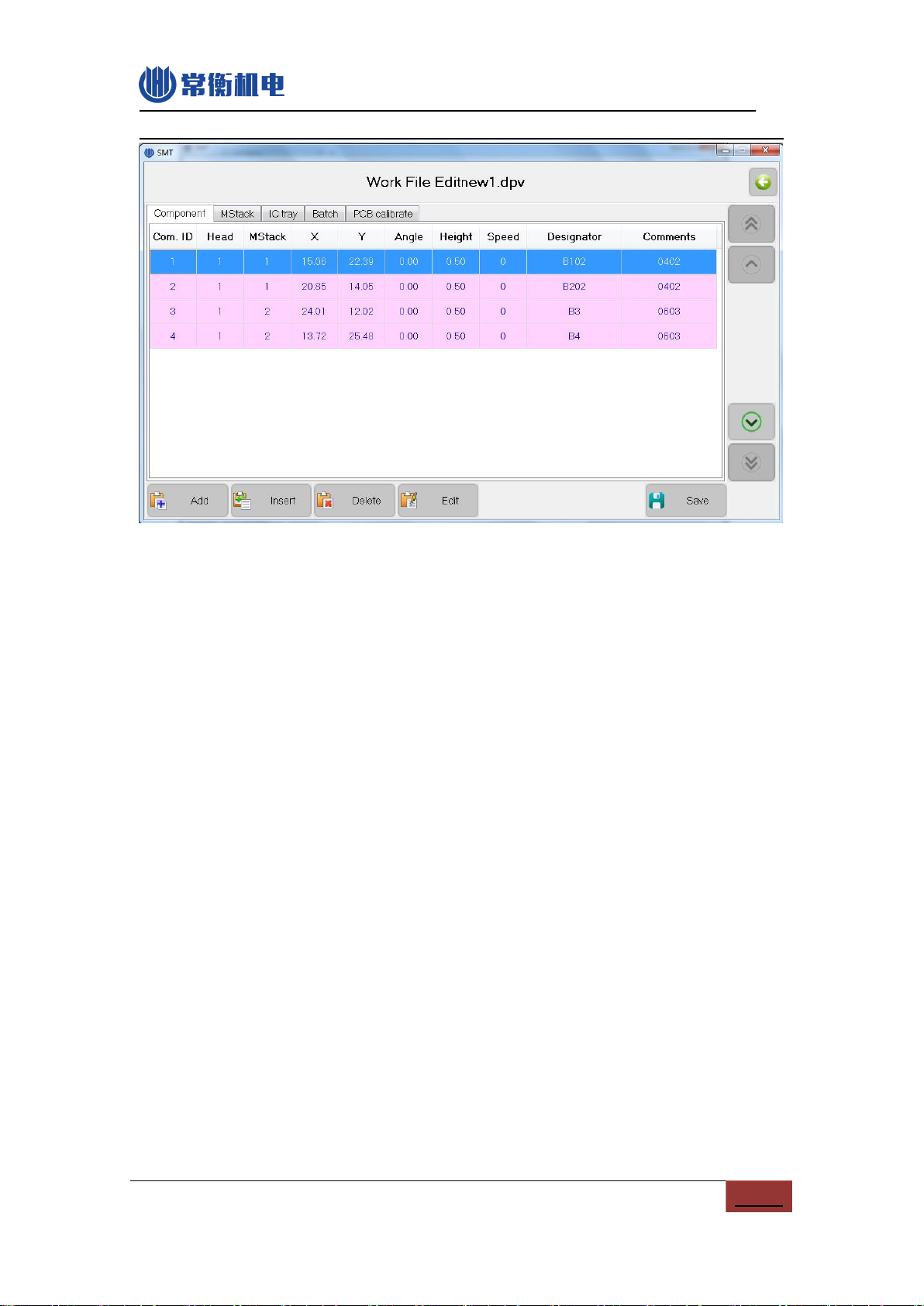

6.1. EDIT WORK FILE...........................................................................................................................10

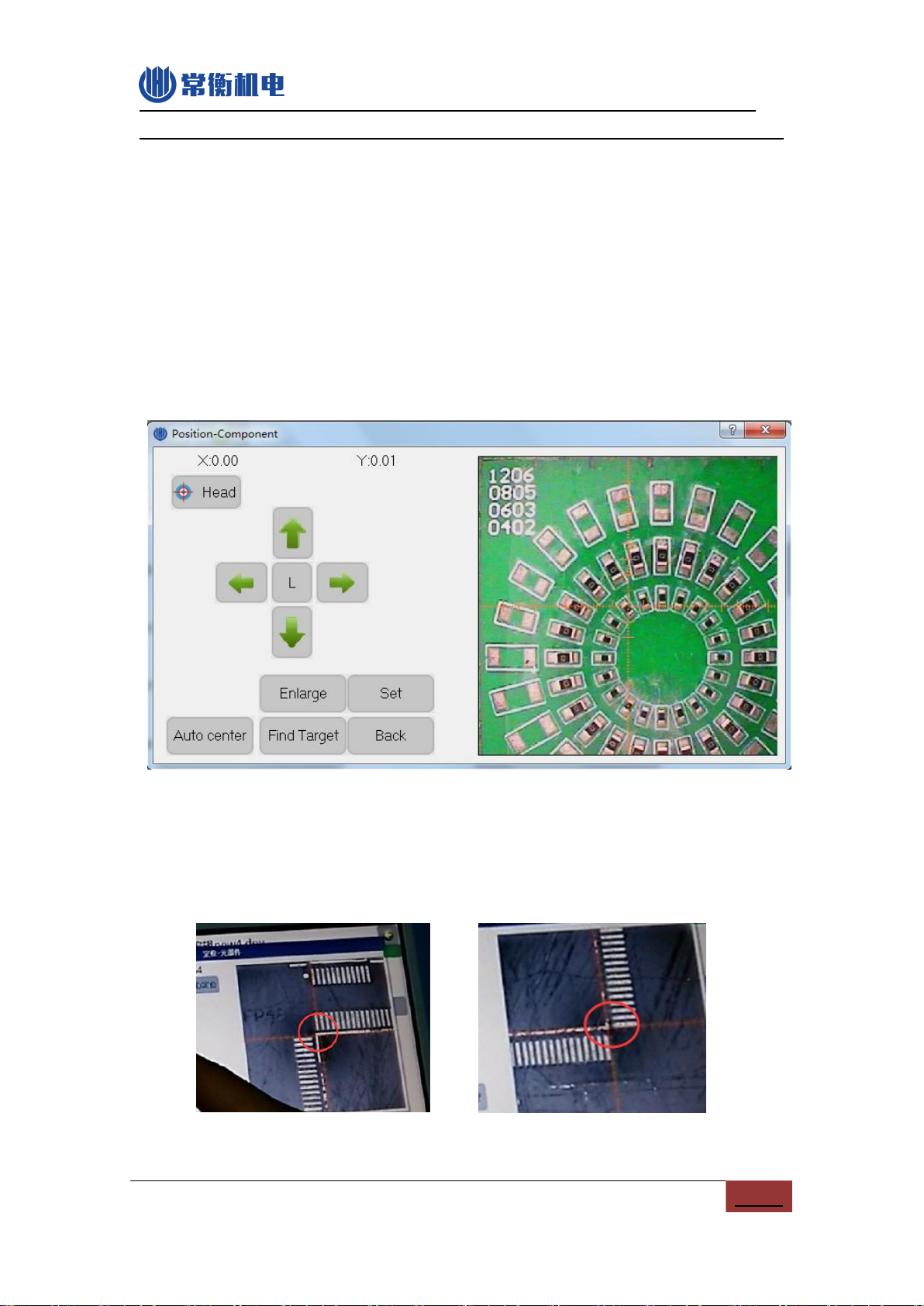

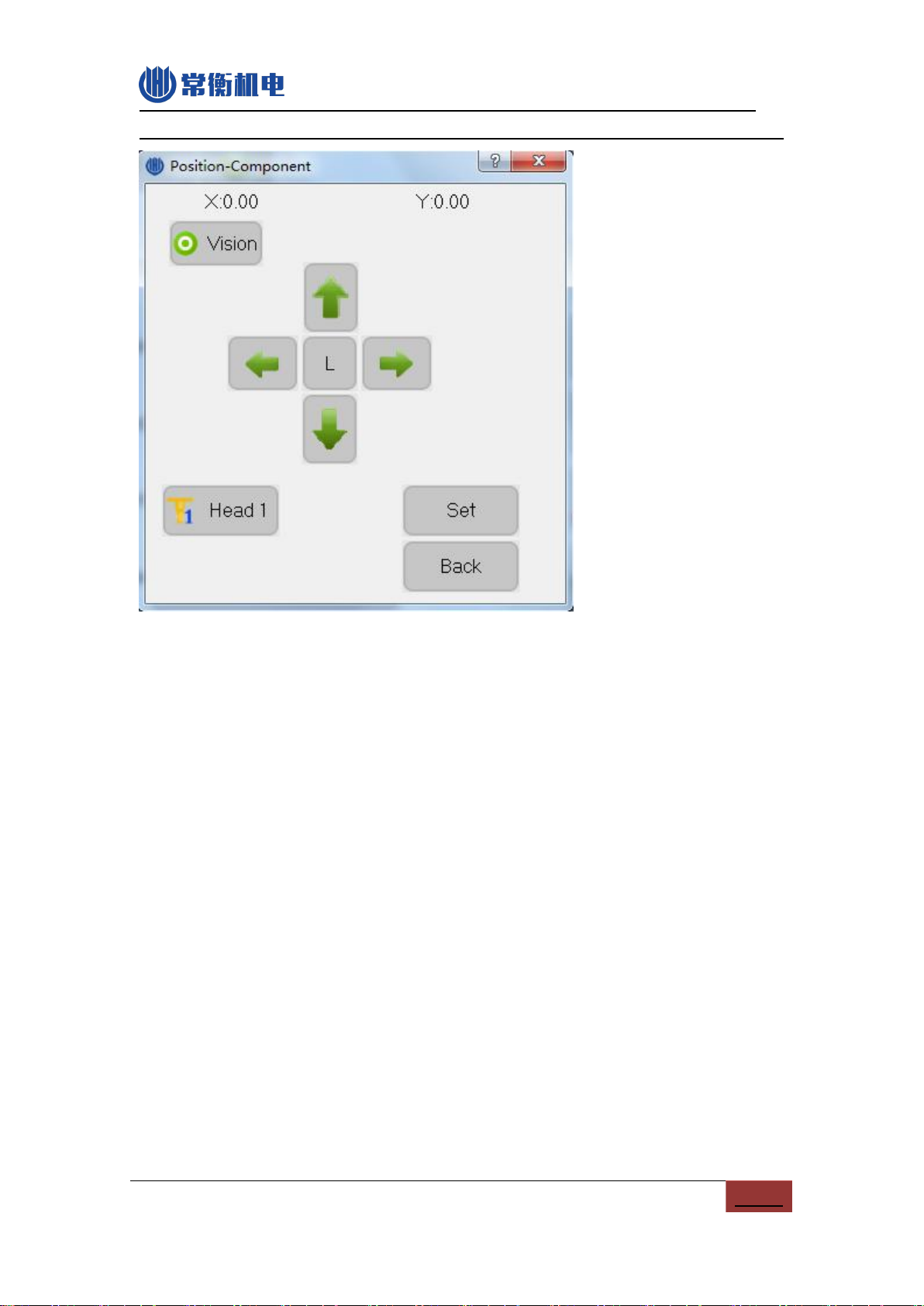

6.1.1.Component edit

................................................................................................................. 11

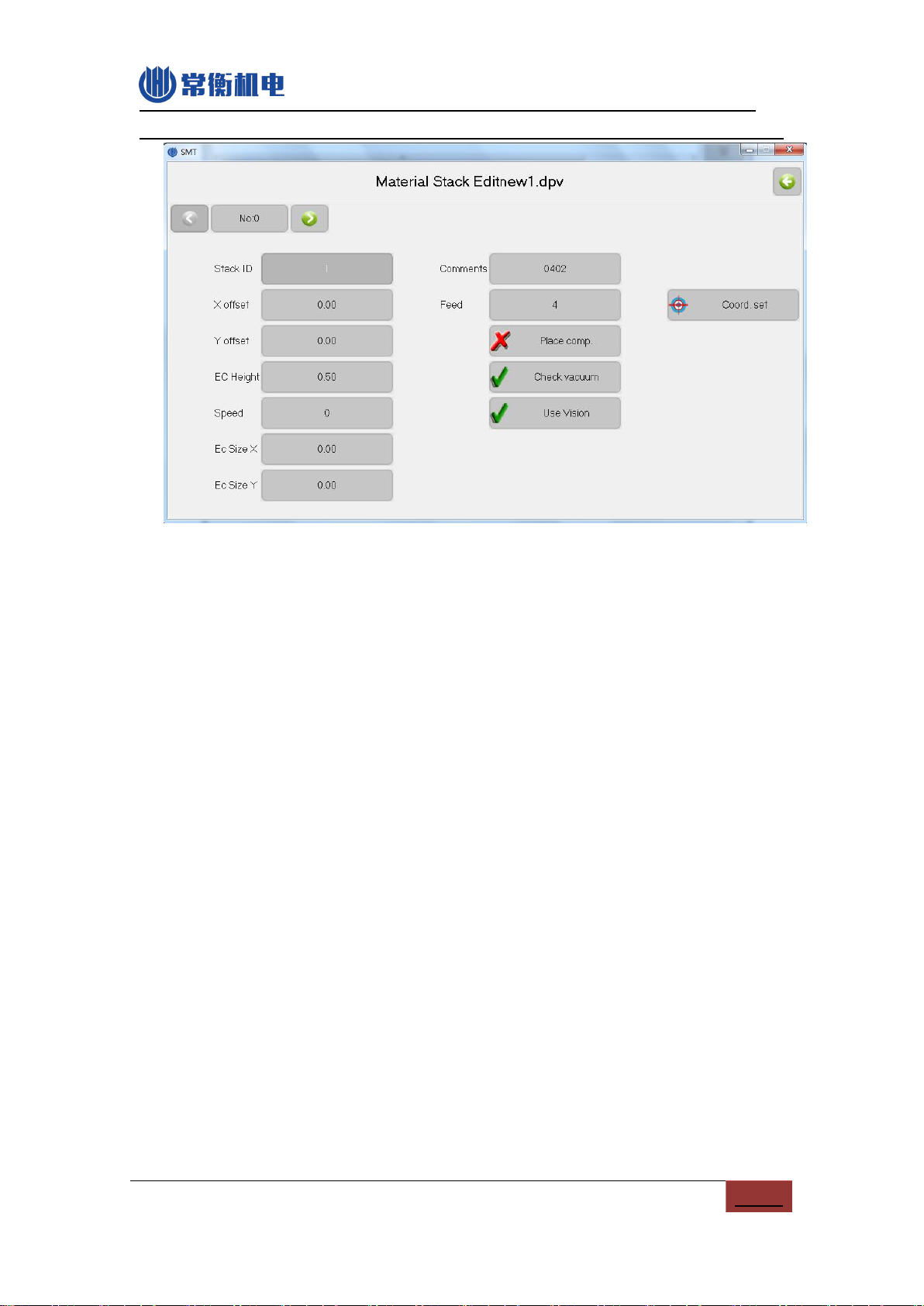

6.1.2.Material Stack edit

....................................................................................................... 15

6.1.3.Batch

................................................................................................................................... 18

6.1.4.IC Tray edit

..................................................................................................................... 20

6.1.5.PCB Calibration

............................................................................................................... 22

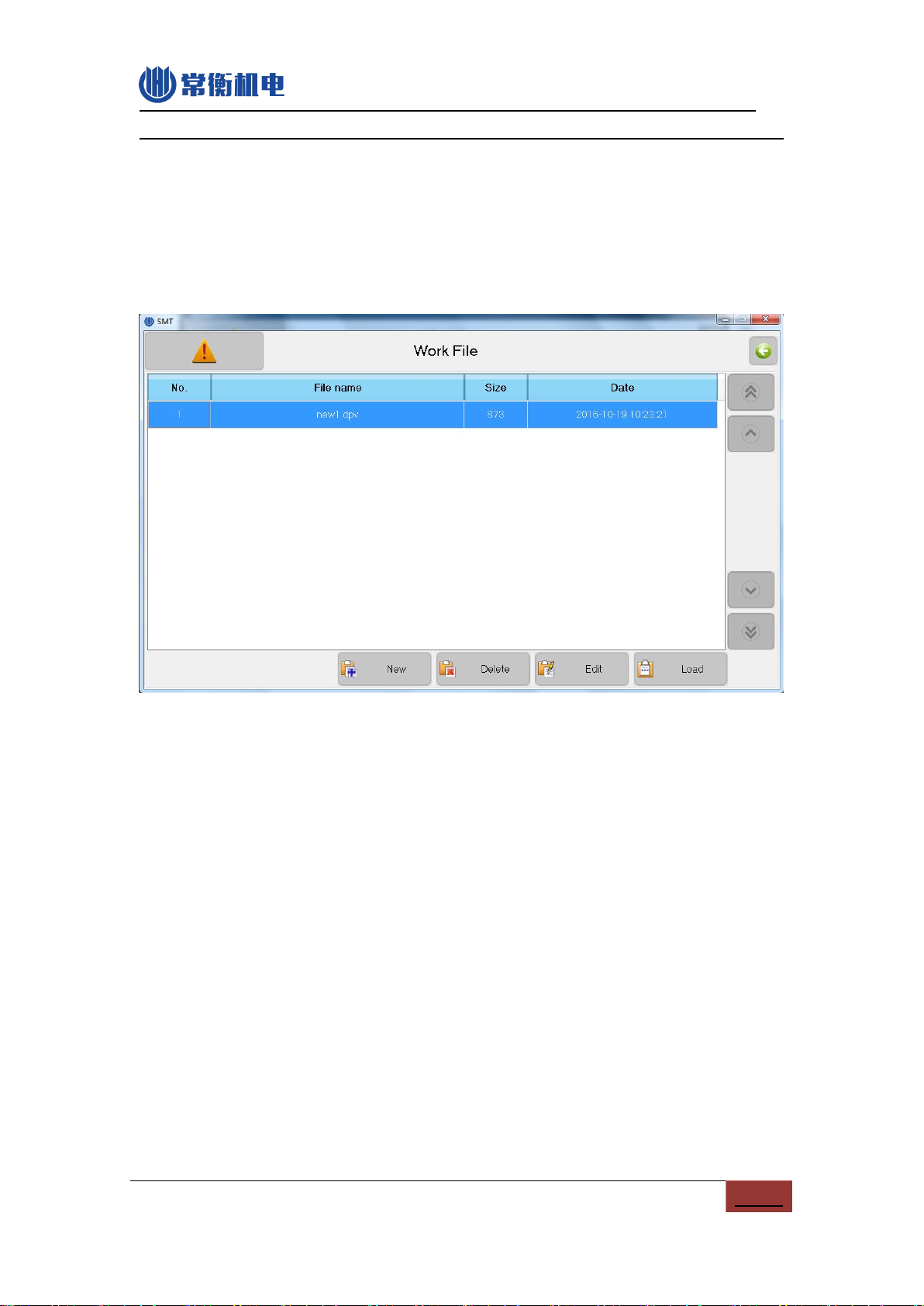

6.2.LOAD WORK FILE.............................................................................................................................24

7.TEST..................................................................................................................................................... 27

8.SET....................................................................................................................................................... 29

8.1.SYSTEM SET.................................................................................................................................... 30

8.2.VACUUM DETECTION SET................................................................................................................... 32

8.3.BACKUP/RESTORE..............................................................................................................................34

9.FILE..................................................................................................................................................... 36

9.1.GENERATE CSV FILE....................................................................................................................... 36

9.1.1.By Altium Designer

.........................................................................

错误!未定义书签。

9.1.2.By Protel

...........................................................................................

错误!未定义书签。

9.2.FILE CONVERT.................................................................................................................................38

9.2.1.Material Stack

................................................................................................................. 39

9.2.2.Components list

............................................................................................................... 40

9.2.3.Batch

................................................................................................................................... 41

10.LOG..................................................................................................................................................... 43

11.SYSTEM LOG....................................................................................................................................... 45