Image Industries CD 110 User manual

ILM004D

June, 2007

Capacitor Discharge Stud Welding Power Source CD110

Price $5.50 USD

Operation Manual

These INsTRUCTIONs aRe fOR expeRIeNCed OpeRaTORs. If you are not fully

familiar with the principles of operation and safe practices for arc welding equipment, we urge

you to read AWS SP - “Safe Practices” available from the American Welding Society.

DO NOT permit untrained persons to install, operate, or maintain this equipment. DO NOT

attempt to install or operate this equipment until you have read and fully understand these

instructions. If you do not fully understand these instructions, contact your supplier for further

information. Be sure to read the Safety Precautions before installing or operating this equipment.

BE SURE THIS INFORMATION REACHES THE OPERATOR. EXTRA COPIES ARE AVAILABLE THROUGH YOUR SUPPLIER.

CAUTION

2

Table of Contents

SECTION 1: Safety Precautions 3

SECTION 2: Set Up 8

SECTION 3: Normal Operation 11

SECTION 4: Trouble Shooting 15

SECTION 5: System Maintenance 18

SECTION 6: Schematic Diagram 19

SECTION 7: Parts List 20

W A R R A N T Y

Image warrants that the goods sold will be free from defects in workmanship and material. This warranty is

expressly in lieu of other warranties, expressed or implied or for fitness for a particular purpose. The liability shall

arise only upon return of the defective goods at Buyer’s expense after notice to Image. The warranty shall be

limited to replacement with like goods or, at Image’s option, to refunding the purchase price. Image will not accept

receipt of equipment returned unless buyer has previously afforded Image’s personnel a reasonable opportunity

to inspect and repair said equipment. Image will warrant components for 1 year and labor for 180 days from date

of shipment. Image shall not be liable for any consequential damages including improper set up by customer.

3

Safety Precautions

Section 1

USERS RESPONSIBILITY

This equipment will perform in conformity with the description contained in this manual and accompanying labels and/or

inserts when installed, maintained and repaired in accordance with the instructions provided. This equipment must be checked

periodically. Defective equipment should not be used. Parts that are broken, missing, worn, distorted or contaminated

should be replaced immediately. Should such repair or replacement become necessary, the manufacturer recommends

that a telephone or written request for service advice be made to the Authorized Distributor from whom purchased.

This equipment or any of it’s parts should not be altered without the prior written approval of the manufacturer. The user

of this equipment shall have the sole responsibility for any malfunction which results from improper use, faulty maintenance,

damage, improper repair or alteration by anyone other than the manufacturer or a service facility designated by the

manufacturer.

WARNING: These Safety Precautions are for your protection.

They summarize precautionary information from the references

listed in the Additional Safety Information section. Before

performing any installation or operating procedures, be sure to

read and follow the safety precautions listed below as well as all

other manuals, material safety data sheets, labels, etc. Failure to

observe Safety Precautions can result in injury or death.

This symbol appearing throughout this manual means

ATTENTION! BE ALERT!

Your safety is involved.

The following definitions apply to DANGER, WARNING, CAUTION

found throughout this manual.

Used to call attention to immediate haz-

ards which, if not avoided, will result in

immediate, serious personal injury or loss

of life.

Used to call attention to potential hazards

which could result in personal injury or lost

of life.

Used to call attention to hazards which

could result in minor personal injury.

CAUTION

WARNING

DANGER

4

Safety Precautions

Section 1

ARC RAYS CAN BURN EYES AND SKIN -

The arc, like the sun, emits ultraviolet and infrared (visible and

in-visible) and other radiation and can injure skin and eyes.

Sparks and hot metal can fly off the weld. Training in the proper

use of the processes and equipment is essential to prevent ac-

cidents. Therefore:

1) Always wear safety glasses with side shields in any work area, even if wearing a

welding helmet, face shields and goggles are also required.

2) Always use a face shield fitted with the correct shade of filter to protect your

face and eyes when welding or watching (See ANSI Z49.1 and Z87.1 listed

in Safety Standards). Cover sparks and rays of the arc when operating or

observing operations.

3) Use protective non-flammable screens or barriers to protect others from

flash and glare. Warn bystanders not to watch the arc and not to expose

themselves to the rays of the electric-arc or hot metal.

3) Wear flameproof gauntlet type gloves, heavy long-sleeve shirt, cuffless trou-

sers, high topped shoes, and a welding helmet or cap for hair protection, to

protect against arc rays and hot sparks or hot metal. A flameproof apron may

also be desirable as protection against radiated heat and sparks.

4) Hot sparks or metal can lodge in rolled up sleeves, trousers cuffs or pockets.

Sleeves and collars should be kept buttoned, and open pockets eliminated

from the front of clothing.

6) Use goggles over safety glasses when chipping slag or grinding. Chipped slag

may be hot and can fly far. Bystanders should also wear goggles over safety

glasses.

ELECTRICAL SHOCK -

Contact with live electrical parts and ground can cause severe

injury or death. The electrode (the weld stud and chuck) and

work circuit (ground) are electrically live whenever the output

is on. The input power circuit and the machine internal circuits

are also live whenever power is on. Improperly installed or

improperly grounded equipment is a hazard.

1) Disconnect input power before installing or servicing this equipment. Lock-

out/tagout input power according to OSHA 29 CFR 1910.147 (see Safety

Standards).

2) Do not touch live electrical parts. Do not touch the electrode (stud) if you

are in contact with the work, ground, or another electrode from a different

machine.

3) Be sure the power source frame (chassis) is connected to the ground system

of the input power.

4) When making input connections, attach proper grounding conductors first and

then double-check connections.

5) Always verify the supply ground - check and be sure that input power cord

ground wire is properly connected to ground terminal in disconnect box or

that cord plug is connected to a properly grounded receptacle outlet.

6) Refer to ANSI/ASC Standard Z49.1 (listed on page 6) for specific grounding

recommendations. Do not mistake the work lead for a ground cable.

7) Clamp work cable with good metal-to-metal contact (spring and/or magnetic

clamps are not recommended) to work piece as near the weld as practical.

8) DO NOT use welding current in damp areas, if movement is confined, or if

there is danger of falling.

9) Properly install and ground this equipment according to this Owner’s Manual

and national, state and local codes.

10) Connect the work cable to the work piece. A poor or missing connection can

expose you or others to a fatal shock.

11) Keep everything dry, including clothing, work area, cables, torch/electrode

holder and power source.

12) Wear dry, hole-free insulated gloves & body protection before turning on

power.

13) Insulate yourself from work and ground using dry insulating mats or covers big

enough to prevent any physical contact with the work or ground.

14) Don’t stand directly on metal or the earth while working in tight quarters or a

damp area; stand on dry boards or an insulating platform and wear rubber-

soled shoes.

15) Turn off all equipment when not in use.

16) Use well-maintained equipment. Frequently inspect input power cord and out-

put weld cables for damage or bare wiring. Replace worn or damaged cables

immediately; bare wiring can kill. Repair or replace damaged parts at once.

Maintain this unit according to the manual.

17) Do not use worn, damage, undersized or poorly spliced cables.

18) Do not drape cables over your body.

19) If earth grounding of the work piece is required, use a separate cable.

20) Wear a safety harness if working above floor level.

21) Keep all panels and covers securely in place.

22) Insulate work clamp when not connected to work piece to prevent contact

with any metal object.

23) Don’t connect multiple electrodes or work cables to a single weld output

terminal.

SIGNIFICANT DC VOLTAGE exists after removal of the input power on

inverters. Turn off inverter, disconnect input power, and discharge input

capacitors according to instructions in Maintenance Section before touching

any parts.

ELECTRIC AND MAGNETIC FIELDS -

Electric and Magnetic Fields may be dangerous. Electric current

flowing through any conductor causes localized Electric and

Magnetic Fields (EMF). Welding and cutting current creates EMF

around welding cables and welding machines.

Therefore:

1) Welders having pacemakers should consult their physician before welding.

EMF may interfere with some pacemakers.

2) Exposure to EMF may have other health effects which are unknown.

3) Welders should use the following procedures to minimize exposure to EMF:

A) Route the electrode and work cables together. Secure them with tape

when possible.

B) Never coil the torch or work cable around your body.

C) Do not place your body between the torch and work cables. Route

cables on the same side of your body.

D) Connect the work cable to the work piece as close as possible to the

area being welded.

E) Keep welding power source and cables as far away from your body as

possible.

FLYING METAL CAN INJURE EYES -

1) Welding, chipping, wire brushing and grinding can cause

sparks and flying metal. As welds cool, they can throw

off slag.

2) Wear approved safety glasses with side shields even under

your welding helmet.

BUILD UP OF GAS CAN INJURE OR KILL -

1) Shut off shielding gas supply when not in use.

2) Always ventilate confined spaces or use approved air-

supplied respirator.

5

Safety Precautions

Section 1

CYLINDER HANDLING -

Shielding gas cylinders contain gas under high pressure. If dam-

aged or mishandled a cylinder can explode and violently release

gas. Sudden rupture of cylinder, valve, or relief device can injure

or kill. Since gas cylinders are normally part of the welding

process, be sure to treat them carefully. Therefore:

1) Protect compressed gas cylinders from excessive heat, mechanical shocks,

slag, open flames, sparks and arcs.

2) Keep cylinders away from any welding or other electrical circuits

3) Never drape a welding tool over a gas cylinder

4) Never allow a welding electrode (weld stud) to touch any cylinder

1) Use the proper gas for the process and use the proper pressure reducing

regulator, hoses and fittings designed to operate from the specific

compressed gas cylinder. Do not use adaptors. Maintain hoses and fittings

and other associated parts in good condition.

2) Always secure cylinders in an upright position by chain or strap to suitable

hand trucks, undercarriages, benches, walls, post, or racks. Never secure

cylinders to work tables or fixtures where they may become part of an

electrical circuit.

3) When not in use, keep cylinder valves closed. Have valve protection cap

in place if regulator is not connected. Secure and move cylinders by using

suitable hand trucks. Avoid rough handling of cylinders.

4) Locate cylinders away from heat, sparks, and flames. Never strike an arc or

weld on a cylinder; it will explode.

6) Turn face away from valve outlet when opening cylinder valve.

5) For additional information, refer to CGA Standard P-1, “Precautions for

Safe Handling of Compressed Gases in Cylinders”, which is available from

Compressed Gas Association, 1235 Jefferson Davis Highway, Arlington, VA

22202

WELDING CAN CAUSE FIRES AND EXPLOSIONS -

Welding on closed containers, such as tanks, drums or pipes, can

cause them to blow up. Sparks can fly off from the welding arc.

The flying sparks, hot work piece, and hot equipment can cause

fires and burns. Accidental contact of electrode to metal objects

can cause sparks, explosion, overheating or fire. Check and be

sure the area is safe before doing any welding. Therefore:

1) Protect yourself and others from flying sparks and hot metal.

2) Do not weld where flying sparks can strike flammable material.

3) Remove all combustible materials a minimum of 35ft away from the welding

arc or cover the materials with a protective nonflammable covering. Com-

bustible materials include wood, cloth, sawdust, liquid and gas fuels, solvents,

paints and coatings, paper, etc.

4) Hot sparks or hot metal can fall through cracks or crevices in floors or wall

openings and cause a hidden smoldering fire or fires on the floor below. Make

certain that such openings are protected from hot sparks and metal.

5) Do not weld, cut, or perform other hot work until the work piece has been

completely cleaned so that there are no substances on the work piece which

might produce flammable or toxic vapors.

6) Be aware that welding on a ceiling, floor, bulkhead or partition can cause fire

on the hidden side.

7) Do not weld on closed containers such as tanks, drums or pipes unless they

are properly prepared according to AWS F4.1.

8) Connect work cable to the work as close to the welding area as practical to

prevent welding current from traveling long, possibly unknown paths and caus-

ing electric shock and fire hazards.

9) Do not use welder to thaw frozen pipes.

10) Remove electrode (weld stud) from the stud weld tool when not in use.

11) Remove any combustibles, such as a butane lighter or matches from your

person before doing any welding.

12) Have appropriate fire extinguishing equipment handy for instant use, such as

a garden hose, water pail, sand bucket or portable fire extinguisher. Be sure

you are trained for proper use.

13) Do not use equipment beyond its ratings. For example, overloaded welding

cable can overheat and create a fire hazard.

14) After completing operations, inspect the work area to make certain there are

no hot sparks or hot metal which could cause a later fire. Use fire watchers

when necessary.

15) For additional information, refer to NFPA Standard 51B, “Fire Prevention

in Use of Cutting and Welding Processes,” available from the National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269

FUMES AND GASES -

Welding produces fumes and gases. Breathing these fumes and

gases can be hazardous to your health, particularly in confined

spaces. Do not breathe fumes and gases. Shielding gases can

cause asphyxiation. Therefore:

1) Keep your head out of the fumes. Do not breathe the fumes.

2) If inside, ventilate the area and/or use exhaust at the arc to remove welding

fumes and gases.

3) If ventilation is poor, use an approved air-supplied respirator.

4) Read the Material Safety Data Sheets (MSDS) and the manufacturer’s

instructions for metals, consumables, coatings, cleaners and degreasers.

5) Work in a confined space only if it is well ventilated, or while wearing an

air-supplied respirator. Always have a trained watch-person nearby. Welding

fumes and gases can displace air and lower the oxygen level causing injury or

death. Be sure the breathing air is safe.

6) Don’t weld in locations near degreasing, cleaning or spraying operations. The

heat & rays of an arc can react with vapors to form highly toxic & irritating

gases.

7) Don’t weld on coated metals, such as galvanized, lead or cadmium plated

steel, unless the coating is removed from the weld area, the area is well

ventilated, and if necessary, while wearing an air-supplied respirator. The

coatings and any metals containing these elements can give off toxic fumes if

welded.

8) Do not weld, cut, or gouge on materials such as galvanized steel, stainless

steel, copper, zinc, lead, beryllium or cadmium unless positive mechanical

ventilation is provided. Do not breathe fumes from these materials.

9) If your develop momentary eye, nose, or throat irritation while operating, this

is an indication that ventilation is not adequate. Stop work and take necessary

steps to improve ventilation in the work areas. Do not continue to operate if

physical discomfort persists.

10) Refer to ANSI/ASC Standard Z49.1 for specific ventilation recommendations.

NOISE CAN DAMAGE HEARING -

Noise from some processes or equipment can damage hearing.

1) Wear approved ear protection if noise level is high

FIRE OR EXPLOSION HAZARD -

1) Do not install or place unit on, over, or near combustible

surfaces.

2) Do not install unit near flammables.

3) Do not overload electrical wiring - be sure power supply

system is properly sized, rated and protected to handle the

unit.

6

Safety Precautions

Section 1

EQUIPMENT MAINTENANCE -

Faulty or improperly maintained equipment can cause injury or

death. Therefore:

1) Always have qualified personnel perform the installation,

troubleshooting, and maintenance work. Do not perform

any electrical work unless you are qualified to do the work.

2) Before performing any work inside a power source, disconnect the power

source from the incoming electrical power using the disconnect switch at the

fuse box before working on the equipment.

3) Maintain cables, grounding wire, connections, power cord, and power supply

in safe working order. Do not operate any equipment in faulty condition.

4) Do not abuse any equipment or accessories. Keep equipment away from:

- heat sources such as furnaces

- wet conditions such as water puddles and inclement weather

- oil or grease

- corrosive atmospheres.

5) Keep all safety devices and cabinet covers in position and in good repair.

6) Use equipment only for its intended purpose. Do not modify it in any

manner.

FALLING UNITS CAN CAUSE INJURY -

1) Use lifting eye to lift unit only, NOT running gear, gas

cylinders or any other accessories.

2) Use equipment of adequate capacity to lift and support unit.

3) If using lift forks to move unit, be sure forks are long enough

to extend beyond opposite side of the unit.

OVERUSE CAN CAUSE OVERHEATING -

1) Allow cooling period; follow rated duty cycle.

2) Reduce current or reduce duty cycle before starting to weld

again.

3) Do not block or filter airflow to unit

STATIC (ESD) CAN DAMAGE PC BOARDS -

1) Put on grounded wrist strap BEFORE handling boards or

parts.

2) Use proper static-proof bags and boxes to store, move or

ship PC boards.

MOVING PARTS CAN CAUSE INJURY -

1) Keep hands, hair, loose clothing and tools away from moving

parts.

2) Keep away from pinch points such as drive rolls.

WELDING WIRE CAN CAUSE INJURY -

1) Do not press weld tool trigger until instructed to do so.

2) Do not point weld tool toward any part of the body, other

people or any metal when threading welding wire.

MOVING PARTS CAN CAUSE INJURY -

1) Keep hands, hair loose clothing and tools away from moving

parts such as fans.

2) Keep all doors, panels, covers and guards closed and

securely in place.

3) Always disconnect electrical power prior to service to

prevent the fan from starting unexpectedly.

H.F. RADIATION CAN CAUSE INTERFERENCE -

1) High-Frequency (H.F.) can interfere with radio navigation,

safety services, computers and communications equipment.

2) Have only qualified persons familiar with electronic

equipment perform this installation.

3) The user is responsible for having a qualified electrician

promptly correct any interference problem resulting from the

installation.

4) If notified by the FCC about interference, stop using the equipment at once.

5) Have the installation regularly checked and maintained.

6) Keep high-frequency source doors and panels tightly shut, keep spark gaps at

correct setting, and use grounding and shielding to minimize the possibility of

interference.

ARC WELDING CAN CAUSE INTERFERENCE -

1) Electromagnetic energy can interfere with sensitive electronic

equipment such as computers and computer-driven

equipment such as robots.

2) Be sure all equipment in the welding area is electro-

magnetically compatible.

3) To reduce possible interference, keep weld cables as short as

possible, close together, and down low, such as on the floor.

4) Locate welding operation 100 meters from any sensitive electronic equipment.

5) Be sure this welding machine is installed and grounded according to this

manual.

6) If interference still occurs, the user must take extra measures such as moving

the welding machine, using shielded cables, using line filters, or shielding the

work area.

EMF Information

Considerations about welding and the effects of low frequency Electric and Magnetic

Fields (EMF):

Welding current, as it flows through welding cables, will cause electromagnetic

fields. There has been and still is some concern about such fields. However, after

examining more than 500 studies spanning 17 years of research, a special blue

ribbon committee of the National Research Council concluded that: “The body of

evidence, in the committee’s judgement, has not demonstrated that exposure to

power-frequency electric and magnetic fields is a human-health hazard.” However,

studies are still going forth and evidence continues to be examined. Until the final

conclusions of the research are reached, you may wish to minimize your exposure

to electromagnetic fields when welding or cutting. See section on EMF on page 2.

HOT PARTS CAN CAUSE SEVERE BURNS -

1) Do not touch hot parts with bare hands.

2) Allow cooling period before working on welding tool (gun

or torch).

7

Safety Precautions

Section 1

ADDITIONAL SAFETY INFORMATION -

For more information on safe practices for electric arc welding refer to the following publications:

American Welding Society

550 N.W. LeJuene Road, Miami, FL 33126, (phone 305-443-9353, website: www. aws.org)

1) ANSI/ASC Z49.1 - Safety in Welding, Cutting and Allied Processes

2) AWS CH5 - Recommended Practices for Stud Welding

3) AWS D1.1 - Structural Welding

2) AWS C5.1 - Recommended Practices for Plasma Arc Welding

3) AWS C5.6 - Recommended Practices for Gas Metal Arc Welding

4) AWS SP - Safe Practices - Reprint, Welding Handbook.

5) ANSI/AWS F4.1, Recommended Safe Practices for Welding and Cutting of Containers and Piping.

National Fire Protection Association

P.O. Box 9101, 1 Battery March Park, Quincy, MA 02269-9101 (phone 617-770-3000, website: www.nfpa.org and sparky.org)

1) NFPA Standard 70 - National Electrical Code

2) NFPA Standard 51B - Standard for Fire Prevention During Welding, Cutting and Other Hot Work

Compressed Gas Association

1735 Jefferson Davis Highway, Suite 1004; Arlington, VA 22202-4102 (phone 703-412-0900, website: www.cganet.com)

1) CGA Pamphlet P-1 - Safe Handling of Compressed Gas Cylinders

Canadian Standards Association

Standards Sales, 178 Rexdale Blvd, Rexdale, Ontario, Canada M9W 1R3 (phone 800-463-6727 in Toronto 416-747-4044, website: www.csa-international.org)

1) CSA Standard W117.2 - Code for Safety in Welding and Cutting

American National Standards Institute

11 West 42nd Street, New York, NY 10036-8002 (phone 212-642-4900, website: www.ansi.org)

1) ANSI Standard Z87.1 - Practice for Occupational and Educational Eye and Face Protection

U.S. Government Printing Office

Superintendent of Documents, P.O. Box 371954, Pittsburgh, PA 15250 (phone 312-353-2220, website: www.osha.gov)

1) Title 29, Code of Federal Regulations (CFR), Part 1910, Subpart Q, & Part 1926, Subpart J - Occupational Safety and Health Standards for General Industry

With any power source, it may or may not contain a battery which may contain hazardous materials. Please follow

local battery disposal procedures when changing batteries or disposing of the power supply.

California Proposition 65 Warnings

Welding or cutting equipment produces fumes or gases which contain chemicals known to the State of Cali-

fornia to cause birth defects and, in some cases, cancer. (California Health & Safety Code Section 25249.5 et

seq.)

Battery posts, terminals and related accessories contain lead and lead compounds, chemicals known to the

State of California to cause cancer and birth defects or other reproductive harm. Wash hands after handling.

For Gasoline Engines:

Engine exhaust contains chemicals known to the State of California to cause cancer, birth defects, or other

reproductive harm.

For Diesel Engines:

Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth

defects, and other reproductive harm.

8

Installation & Set Up

Section 2

LOCATION

The power supply should be located:

• On a flat, level surfaces with adequate air circulation

• Near the work area to limit welding cable length (shorter lengths are preferred). Avoid looping the weld cables

• In a dry area away from moisture.

• To protect it from grinding dust and other contaminates.

• To provide min. 6” clearance on all sides for cooling.

POWER REQUIREMENTS

Fusing / Cable Recommendations

Input Voltage Frequency Fusing

110 V 50/60Hz 15A

220 V 50/60Hz 10A

Extension Cord specifications for incoming power:

If an extension cable is required (one is not recommended) use the following guidelines

Up to 25 ft. (8 meters) use a minimum of 16-3 wire extension cable

30 ft. (10 meters) use a minimum of 14-3 wire extension cable

50 ft. (15 meters) use a minimum of 12-3 wire extension cable

SETTING JUMPER LINKS

The power supply ships pre-wired as 110V. If you plan on using 110V no changes are required. The unit can be configured

to operate on 220V AC . If you would like to wire your unit to operate on 220V the jumper link arrangement (and the

power cord plug) must be changed. NOTE: Charge time will not vary between 110 and 220V.

Incorrect connection of the voltage select jumpers can damage the welding power supply. If you are not comfortable

changing the jumper links seek help from your distributor or a trained electrician.

Remove the power supply lid by unscrewing eight (8) #10 hex head screws (5/16 wrench or nut runner).

The main transformer has configurable jumper links. These are located directly on the main transformer on the top side of

the transformer nearest the rear of the unit. There are two jumper wires connected to the transformer.

DANGER

Always be careful when working inside a capacitor storage unit.

Always disconnect the incoming power line when working inside of electrical

equipment. Even though the power switch is off and the power cable is

disconnected, there can still be voltages inside the unit.

WARNING DO NOT operate the power supply without the cover securely in place.

WARNING DO NOT defeat the ground on the incoming power cable.

9

Installation & Set Up

Section 2

For a 110V configuration the jumpers connect terminals H1 and H3 and H2 and H4.

For a 220V configuration only one jumper is used between terminals H2 and H3.

If connecting as a 220V unit, be sure and place the extra jumper in a safe place. You will need it to reconnect the

unit to 110V.Replace the cover and reinstall the 8 #10 hex head screws.

H4 H3 H2 H1

110 V

110 V

H4 H3 H2 H1

220 V

Figure 1

Figure 2

10

Installation & Set Up

Section 2

1

2

Key

Key way

Flat

Dot

1

2

Guns

There are typically two cables on your welding tool: a weld cable and a control cable.

Weld Cable

The weld (gun) cable has a camlok style connector. Line up the flat

on the weld cable connector with the small dot on the top side of the

panel receptacle (typically the weld cable goes into the black or negative

receptacle). Push the weld cable connector straight in as far as it will go

[Step 1]. Hand turn clockwise to be tight [Step 2]. See Figure 3

Ground

The ground cable is connected in the same fashion as the welding

tool weld cable. The ground cable typically is inserted into the red

(or positive) receptacle.

Control Cable

There is a key in the end of the control cable connector. Align the key in the cable connector with the key way

in the front panel control cable receptacle. Push the cable connector into the

front panel receptacle [Step 1]. When the two are seated turn the screw ring

on the cable connector clockwise [Step 2]. This will lock the two together.

See Figure 4. The screw ring does not need to be overly tight.

Cable Connections

Straight Polarity: In straight polarity the weld tool (gun)

is connected to the black receptacle labeled gun (this is

electrode negative). The ground lead is connected to the

red receptacle. This cable arrangement is the preferred

arrangement for welding ferrous metals with either the gap

or contact processes.

Reverse Polarity: Reverse polarity reverses the weld tool and ground

connections. The weld tool connects to the red receptacle labeled ground

(this is electrode positive) and the ground cable connects to the black

receptacle labeled gun. This cable arrangement is preferred for welding materials such as aluminum, brass or

galvanized with either the gap or contact processes.

Layout: The cables must be laid out straight. If the cables are coiled the amount of energy available for weld will

be reduced. This will result in poor quality welds. This is true for both the gun weld cable and the ground cable

when using either the gap or contact processes.

Figure 4

Figure 3

11

Normal Operation

Section 3

DISPLAY FUNCTIONS

The main Weld Voltage Display shows the voltage that will be used for welding.

There are 3 indicator lights.

Trigger (Red) This indicator lights when the trigger is pulled. This shows there is a good connection through

the gun trigger switch and cables.

Contact (Amber) This indicator lights when the unit detects contact with the work. This means there is a good

welding path.

Ready (Green) This indicator lights when the unit is ready to weld. If the operator changes the weld voltage,

this light will go out for a moment as the proper voltage is reached. This light can also flash out

error codes if certain error conditions occur (see troubleshooting for specific error conditions).

ROTARY KNOBS

Voltage Control Knob

The upper rotary knob controls the weld voltage. Turning the knob clockwise increases the weld voltage up to about

190V, turning the knob counter clockwise will decrease the weld voltage down to about 40V. The power supply will take a

moment to achieve the desired setting. Small changes make it easier to hit a target voltage level.

Capacitance Select Knob

The lower rotary knob has 3 positions. The operator can select from 3 different capacitance levels.

Low: 66,000uF Medium: 88,000uF High: 110,000uF

These different capacitance levels allow the power supply to be fine tuned to match the exact welding application for the

highest quality, most repeatable results.

Voltage Display Voltage

Adjustment Knob

Capacitance

Adjustment Knob

(Green) Lights when welder

is ready to weld

(Red) Lights when gun

trigger is pulled

(Amber) Lights when

there is a good weld path

12

Normal Operation

Section 3

POWER UP

Before power up, make sure all cables are properly connected. It is also a good practice to turn the voltage control knob to

the minimum voltage (all the way counter clockwise). Press the power switch (to the right or towards the 1), located on the

lower left side of the control panel.

On power up the power supply initiates a self test. This test lasts approximately 2 seconds. The power supply will then

charge the level of capacitance set by the capacitance select knob to the voltage level set by the voltage select knob. When

charging is complete (3 seconds maximum) the ready light will turn on. Note: If the trigger is held or the weld gun is in

contact with the work, charging will be disabled until the trigger is released and/or the weld gun is not in contact with the

work.

WELDING

Stud Gun Settings

Refer to Stud Gun Manual

Welding Sequence

Position the gun against the work. Press down on the stud gun to make sure the spark shield or tripod legs sits firmly against

the work. While holding the gun in position, pull the trigger. The weld will initiate and complete. There is a loud bang

(hearing protection is recommended) associated with the weld process. This completes a weld sequence. Note: Contact

must be made BEFORE the trigger is pressed, otherwise welding will not occur.

Post Weld Sequence

After the weld is complete, but before the gun is pulled off the work, the unit will charge up to about 20V. When the gun

is pulled off the work (and the trigger is released) it will fully charge to the set point. If the operator pulls the gun off the

work immediately (and releases the trigger) the unit will charge to the set point. Pull the gun off of the stud.

SET UP

Base Metal Preparation

As with most welding, clean weld studs and clean base metal will provide the best results. Typical weld penetration is .002

to .004 inches (.05 to .1 mm). Mill scale may easily be this thick. When welding to steel with mill scale, the scale must be

removed first to achieve quality weld results.

A common CD welding mistake is to use a centerpunch mark for location. The ignition tip locates nicely in the centerpunch

mark, but it effectively shortens the tip length. Since the tip is sitting in a depression, the distance from the workpiece to the

face of the weld stud is shorter. Usually, this results in bad welds.

Aluminum can quickly form a layer of oxide. Oxide is non-conductive (not good for welding) and is tough. If welding onto

aluminum is causing problems, it is often best to remove the oxide layer. This can be accomplished via abrasives. A stainless

steel brush works well.

13

Normal Operation

Section 3

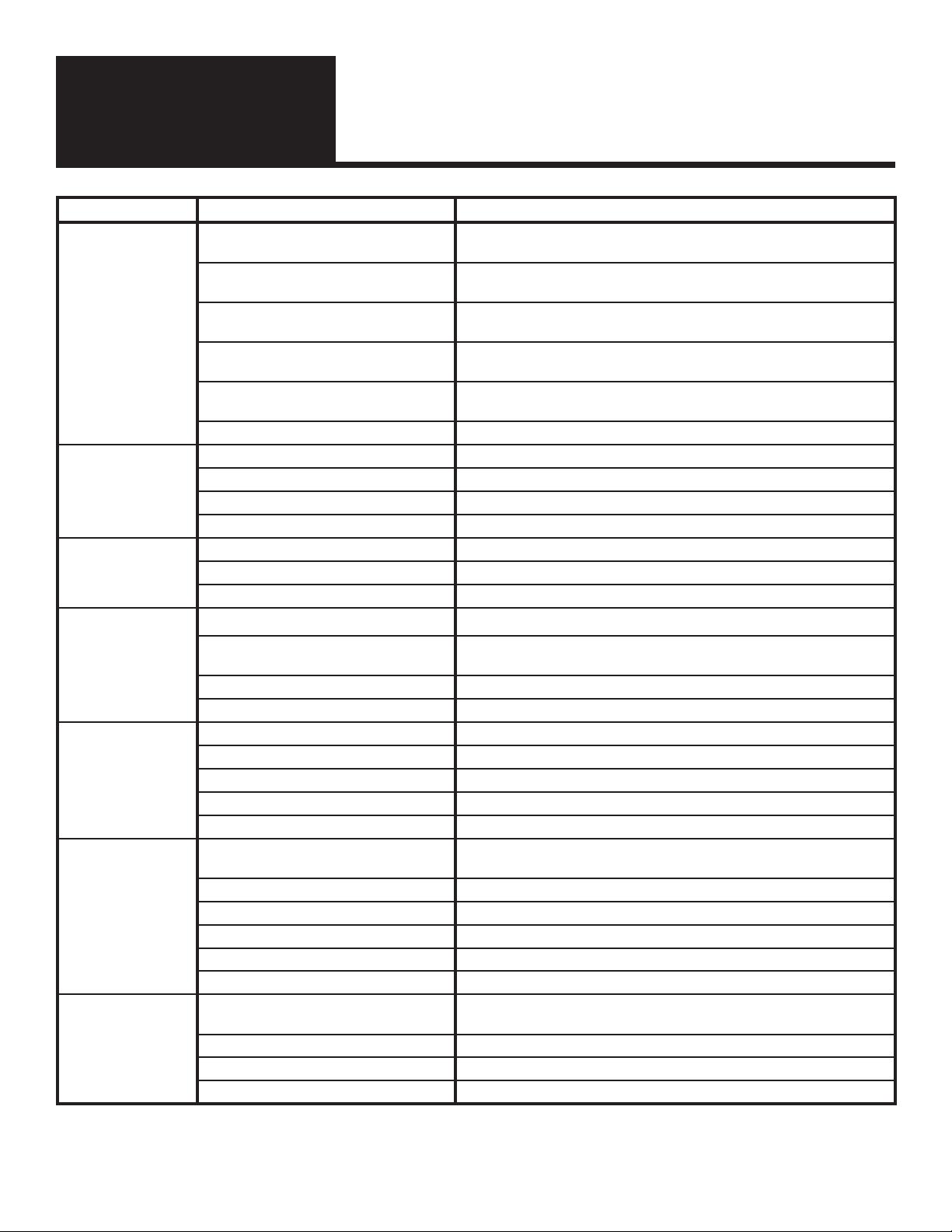

Recommended Power Supply Capacitance and Voltage Settings

Acceptable Material Combinations

Contact Weld Tool Recommended Voltage Settings

Mild Steel Stainless Steel Aluminum

Stud Size Capacitance Plunge Voltage Spring Capacitance Plunge Voltage Spring Capacitance Plunge Voltage Spring

12 ga Low 1/8 60 Low

10 ga Low 1/8 90 Low

#4 Low 1/8 65 Low Low 1/8 70 Med Low 1/8 75 Hi

#6 Low 1/8 75 Low Low 1/8 75 Med Med 1/8 80 Hi

#8 Med 1/8 85 Low Med 1/8 85 Med Med 1/8 90 Hi

#10 Med 1/8 95 Low Med 1/8 95 Med Med 1/8 105 Hi

1/4 Med 1/8 125 Low Med 1/8 130 Med 1/4 1/8 150 Hi

5/16 Hi 3/16 140 Med Hi 3/16 150 Med

3/8 Hi 1/4 170 Hi

6mm Med 1/8 125 Low Hi 1/8 130 Med Med 1/8 90 Hi

8mm Hi 3/16 140 Med Hi 3/16 150 Med

Base Weld Surface Material Acceptable Stud Material

LOW CARBON STEEL

AISI 1006 to 1022

LOW CARBON STEEL AISI 1006 to 1010,

STAINLESS STEEL 300 series except 303,

COPPER ALLOY (brass) 260 and 268

STAINLESS STEEL

300 and 400 series except 303

LOW CARBON STEEL AISI 1006 to 1010,

STAINLESS STEEL 300 series except 303

ALUMINUM ALLOYS

1100, 3000 series, 5000 series,

6061 and 6063

ALUMINUM ALLOYS 1100, 5086, 6063

ETP COPPER, LEAD FREE BRASS

and ROLLED COPPER

LOW CARBON STEEL AISI 1006 to 1010,

STAINLESS STEEL 300 series except 303,

COPPER ALLOY (brass) 260 and 268

ZINC ALLOYS (die cast) ALUMINUM ALLOYS 1100 and 5086

14

Normal Operation

Section 3

Too Hot

Excessive weld flash

and weld spatter.

This weld may break.

Correct

Normal weld flash.

No significant weld spatter.

This will be a good, strong weld.

Too Cold

No visible weld flash.

This weld will break.

Reduce Voltage,

Increase Spring Pressure,

or Reduce Capacitance

No Adjustments Required IncreaseVoltage,

Reduce Spring Pressure,

or Increase Capacitance.

Also could be caused by a

short tip or a center punch mark

Complete fusion

CD Stud is positioned against work

on the timing or ignition tip, the gun

mechanisms are compressed.

The Trigger is pulled, the ignition

tip vaporizes and an arc is formed.

This arc melts the bottom of the

stud and top of the base metal.

At the end of travel, the power source

is completely discharged and the stud

has formed a complete bond with the

base material.

The gun begins

to drive the stud

into the base metal.

WELD QUALITY

Visual Inspection

CONTACT CAPACITOR DISCHARGE PROCESS

Note: The tip design/dimensions are very important. The ignition tip controls the arc length and weld duration. If the

ignition tip is too short there will not be enough weld time to ensure an adequate weld.

15

Trouble Shooting

Section 4

TROUBLE SHOOTING

This guide references components inside the welding power supply. Working inside

a capacitor discharge (CD) power supply is inherently dangerous. Do not attempt

to service components inside a CD power supply unless you have not been trained in

the proper safety and service procedures. If you have questions, please consult your

distributor or the factory directly.

DANGER

Problem Possible Cause Corrective Action

Poor Weld

Poor surface condition.

Properly prepare the weld surface. Make sure it is free of contaminants such as

dirt and oil. If there is heavy oxide (rust for steel or aluminum oxide for

aluminum) it must first be removed.

Poor ground connection. Make sure all cable connections are in good condition and tightly secured.

Broken or loose cables. Make sure all cable connections are in good condition and tightly secured.

Use of center punch or witness marks. Do not use center punch/witness marks to locate CD weld studs. They

effectively reduce the tip length degrading weld performance.

Loose collet or chuck.

The chuck should have a firm hold on the weld stud. If you are able to easily

(with no real resistance) pull the stud out of the collet then the collet is worn.

Replace collet/chuck.

If the inside of the collet looks like there are threads in it then the collet is worn

out and should be replaced.

Dirt in weld tool preventing smooth

operation.

Service weld tool per your weld tool’s Operation Manual.

Cables are coiled. Uncoil weld and ground cables.

Voltage incorrect for size stud to be welded. Check the weld parameter table on page 13 to ensure that you are using the cor-

rect voltage for the size stud you are trying to weld.

Studs or pins are not perpendicular to the

work surface.

If the operator can not suitably hold the welding tool perpendicular to the work

surface, then a template or fixture may be required.

Arc Blow (all weld material moves or

“blows” to one side).

Use double grounds, one on each side of the weld zone to balance current flow.

Move ground connections away from weld zone.

Space ground connections evenly around the weld zone.

Incorrect plunge setting. Adjust plunge per weld tool’s service manual.

Incorrect spring rate. Adjust spring pressure per weld tool’s service manual.

Weld is too hot.

Weld voltage too high. Decrease weld voltage.

Capacitance set too high. Turn the capacitance knob counter-clockwise to charge fewer banks.

Gap too small when using gap process. If using a gap weld tool, increase the weld gap per weld tool’s Operation Manual.

Plunge too small. Increase the plunge per weld tool’s Operation Manual.

Spring pressure too low. Increase the spring pressure per weld tool’s Operation Manual.

Weld is too cold. Weld voltage too low. Increase weld voltage.

Capacitance set too low. Turn the capacitance knob clockwise to charge more banks.

Gap too large when using gap process. If using a gap weld tool, decrease the weld gap per weld tool’s Operation Manual.

Plunge too large. Decrease the plunge per weld tool’s Operation Manual.

Spring pressure too high. Decrease the spring pressure per weld tool’s Operation Manual.

Arc blow (all weld

material moves or

“blows” to one side).

Ground(s) not positioned properly. Reposition ground clamp to “steer” weld material. Weld material will flow away

from the ground clamp.

Use double grounds, one on each side of the weld zone to balance current flow.

16

Trouble Shooting

Section 4

Problem Possible Cause Corrective Action

Welder turns on but

does not operate.

Broken ground cable or incomplete

connection.

Make sure all cable connections are in good condition and are tightly secured.

Broken weld tool, weld cable or incomplete

connection.

Make sure all cable connections are in good condition and are tightly secured.

Broken control cable. Verify continuity on all leads in the control cable (black and white only for

contact weld tools).

Shorted trigger switch (trigger LED always

on).

Verify continuity on the trigger switch. Replace if defective.

Faulty trigger switch (trigger LED doesn’t

light when trigger pulled).

Verify continuity on the trigger switch. Replace if defective.

Faulty control board. Replace control board.

Weld too hot

regardless of voltage

setting.

Shorted main charge SCR. Replace charge SCR.

Shorted bank charge SCR. Replace charge SCR.

Faulty voltage potentiometer Verify voltage pot wiper has a resistance of 0-500 ohms. Replace if defective.

Faulty control board. Replace control board.

Green ready LED

doesn’t light.

Faulty control board. Replace control board.

Disconnected LED Ensure LED is seated in holder and holder is pressed firmly onto bezel.

Faulty LED Replace LED

Green ready LED

blinks, welder doesn’t

operate.

Faulty control board. Replace control board.

Voltage Adjust knob turned up too high. Turn the Voltage Adjust knob counter-clockwise. Check voltage adjust

potentiometer for correct functionality.

Faulty voltage potentiometer. Verify voltage pot wiper has a resistance of 0-500 ohms. Replace if defective.

Faulty bank select switch. Verify switch selects one output per position. Replace if defective.

Yellow contact LED

doesn’t light when

weld tool is placed

against work.

Missing or faulty ground. Make sure all cable connections are in good condition and are tightly secured.

Broken sense wire (gap weld tool). Verify continuity on all leads in the control cable.

Disconnect LED. Ensure LED is seated in holder and holder is pressed firmly onto bezel.

Faulty LED Replace LED

Faulty control board. Replace control board.

Red trigger LED

doesn’t light.

Broken control cable. Verify continuity on all leads in the control cable (black and white only for

contact weld tools).

Control cable not fully connected. Make sure all cable connections are in good condition and are tightly secured.

Faulty trigger switch. Verify continuity on the trigger switch. Replace if defective.

Disconnect LED. Ensure LED is seated in holder and holder is pressed firmly onto bezel.

Faulty LED Replace LED

Faulty control board. Replace control board.

Circuit fuse or

CD110 breaker blows

each time unit is

powered on.

Shorted weld capacitor. Use a capacitance meter to test weld capacitor. Visually inspect weld capacitor

for obvious signs of damage. Replace defective weld capacitor.

Shortened bridge rectifier. Replace bridge rectifier.

Incorrect primary connections. Check the jumper links on the transformer.

Shortened transformer. Replace transformer.

17

Trouble Shooting

Section 4

Problem Possible Cause Corrective Action

Welder doesn’t

turn on.

Not plugged in. Plug in unit.

Panel breaker blown. Reset breaker.

Faulty power switch. Replace power switch.

Faulty control board. Replace control board.

Welder shuts down

immediately.

Weld SCR shorted. Check Error Code (E02 +and E03 -) take corrective action to replace weld

SCR.

Faulty power switch. Replace power switch.

Faulty control board. Replace control board.

Welder shuts down

after a few seconds.

Charge SCR shorted or open. Replace charge SCR.

Faulty power switch. Replace power switch.

Faulty control board. Replace control board.

Welder shuts down

after a few minutes.

Charge SCR shorted or open. Replace charge SCR.

Faulty control board. Replace control board.

Welder shuts down

after a weld.

Weld SCR shorted. Check Error Code (E02 +and E03 -) take corrective action to replace weld

SCR.

Breaker blown. Reset breaker.

Faulty power switch. Replace power switch.

Incorrect gap weld tool adjustment. Gap process welds must complete within 2 seconds of trigger pull. Make

adjustments per the weld tool’s Operation Manual.

Faulty control board. Replace control board.

18

System Maintenance

Section 5

SYSTEM MAINTENANCE

Power Supply

This system has been designed to be essentially maintenance free.

The only recommended maintenance is to blow out the power supply once a year. Dirt, grinding dust and other contami-

nates can accumulate over time and they deteriorate the power supply’s cooling performance.

If the unit is located in a dirty environment the unit should be blown out more frequently.

Welding Tool

Typically, most trouble stems from the stud gun. The stud gun should be serviced once every quarter. Monthly service may

be required if use is exceptionally heavy. Please refer to the stud gun service manual for maintenance guidelines and instruc-

tions.

Cables

Cables are also a frequent source trouble. Users often drag the power supply around by the cables. This can damage cables.

Whenever gun service is performed, the cables should be visually inspected for worn / damaged insulation or fraying wire.

If the cables are damaged they should be repaired to prevent any degradation of weld quality.

BUILT IN EQUIPMENT SAFETY

A fault in the welding power supply can create a potentially dangerous condtion. The microprocessor continually monitors

the system for faults and shuts the unit off when one is detected. This is done for operator and equipment safety purposes.

The unit can be restarted, but will shut down again as soon as the fault condition is detected. The unit must be repaired.

19

Schematic Diagram

Section 6

Bank #1

Primary

Bank

WIRE-9

WIRE-46 WIRE-48

WIRE-41

WIRE-44

WIRE-43

WIRE-13

WIRE-42

WIRE-12

WIRE-29

WIRE-13

WIRE-11

WIRE-5

WIRE-7

WIRE-42

WIRE-17

WIRE-21

WIRE-27

WIRE-29

WIRE-18

WIRE-22

WIRE-20

WIRE-24

WIRE-10

WIRE-15

WIRE-19

WIRE-26

BLACK

WHITE

BLUE

BROWN

1 2

3

1

4

3

2

WHITE

1

BLACK

2

AC1

AC2

WHITE

1

BLACK

2

13

2

3

6

4

58

9

1

10

11

12

7

WHITE

1

BLACK

2

J8

GUN CONNECTOR

J7

PLUG AC MALE

J9

WELD+

J10

WELD-

SW3

N.O. FAN

THEMALSWITCH

D3

BRIDGE

- +

R1

J12

SW2

N.O. SHUTDOWN

THEMALSWITCH

Q3

J3

GREEN - READY

Q4

J11

R5

C1

Q1

SW4

12(n)12

11

21 22(k)

12(k)

C2

C3

R2

FAN

C4

J13

J4

YELLOW - CONTACT

SW1

BANK SELECT

J14

R4

CONTROL BOARD

J1

J2

C6

C7

J5

RED - TRIGGER

Bank #2

WIRE-49WIRE-47

WIRE-23

R3

Q2

C5

D2D1

17V 1A

17V 1B

17V 3A

17V 3B

L1 Hot

VSET Low

L2 Hot

VSET High

120 VAC

Bank Switch Pin13

Breaker Trip

Neutral

Cap Minus

Discharge Resistor

Charge SCR Gate

Gun Common (Black)

Bridge Plus

Coil RTN (Blue)

Bank1 SCR Gate

Trigger RTN (White)

Bank2 SCR Gate

Gun Ground Ring (Brown)

Weld Minus

Weld SCR Gate (White)

Bank Switch Pin3

Cap Plus

Bank Switch Pin 2

VSET Sig

Ready LED White

Ready LED Black

Trigger LED White

Trigger LED Black

Contact LED White

Contact LED Black

17V 2A

17V 2B

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Wire 1

Wire 2

Wire 3

Wire 4

Wire 5

Wire 6

Wire 7

Wire 8

Wire 9

Wire 10

Wire 11

Wire 42

Wire 13

Wire 15

Wire 17

Wire 18

Wire 19

Wire 20

Wire 21

Wire 22

Wire 23

Wire 24

Wire 26

Wire 27

Wire 28

Wire 29

Wire 30

Wire 32

Wire 33

Wire 34

Wire 35

Wire 36

Wire 37

Wire 38

Wire 39

Wire 40

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

J6

1 2 1 2

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

1 2 3 4

5 6 7 8 910 11 12

T1

Revision D

20

Parts List

Section 7

1

2

3

4

6

7

11

12

15

16

20

6

9

10

8

5

19

13

14

22

18

17

23

24

30

32

28

35

36

37

39

42

34

33

41

31

27

26

25

40

29

7

38

to #24

to #34

Red

Yellow

Green

Table of contents

Other Image Industries Welding System manuals

Popular Welding System manuals by other brands

Miller

Miller Deltaweld Series owner's manual

Stel

Stel TIG mP 353H AC/DC instruction manual

Miller

Miller XMT 304 CC/CV owner's manual

Lincoln Electric

Lincoln Electric VANTAGE 580 Operator's manual

Master Appliance

Master Appliance ProHeat PH-1400WK quick start guide

SPT Plasmateknik AB

SPT Plasmateknik AB SPLITFIRE Instructions for use