Chatoyer KRO - 3000 User manual

KRO - 3000

AUGUST 2006

Prepared for:

WashTec Australia

1, 33 Maddox Street

Alexandria NSW 2015

Sydney, Australia

Prepared by:

Chatoyer Holdings Pty. Ltd.

ABN: 99 080 301 515

www.chatoyer.com.au

BRISBANE OFFICE

14 Parkview Street

Milton QLD 4064

PO Box 2156 Milton QLD 4064

Tel: (07) 3367.3866

Fax: (07) 3367 2886

brisbane@chatoyer.com.au

Operation Manual

KRO3000 Rev2

2

Table of Contents

1.0 Principles of Reverse Osmosis 3

2.0 Pre Treatment 3

3.0 System Configuration 4

3.1 KRO3000 4

3.2 Pre Treatment 4

4.0 Process Description and System Components 5

4.1 General Process 5

4.2 System Components 5

4.2.1 Water Softener 5

4.2.2 Carbon Filter and Cartridge Filters 6

4.2.3 High Pressure Pump 6

4.2.4 RO Membrane Housing 6

4.2.5 RO Membrane 6

4.2.6 Conductivity Monitor 6

4.2.7 Reject Control Valve 6

4.2.8 Recycle Control valve 7

4.2.9 Flush Solenoid Valve 7

4.2.10 Rotameters 7

4.2.11 Pressure Gauges 7

4.2.12 Low Pressure Switch 7

4.2.13 Float Switch 7

4.2.14 Pressure Reducing Valve 7

5.0 Installation Guide 7

6.0 Description of Operation 8

6.1 Starting Up the Unit 8

6.2 Shutting Down the Unit 9

7.0 Maintenance 9

8.0 Trouble Shooting 10

9.0 Servicing 11

10.0 Expected Values 11

Appendices 12

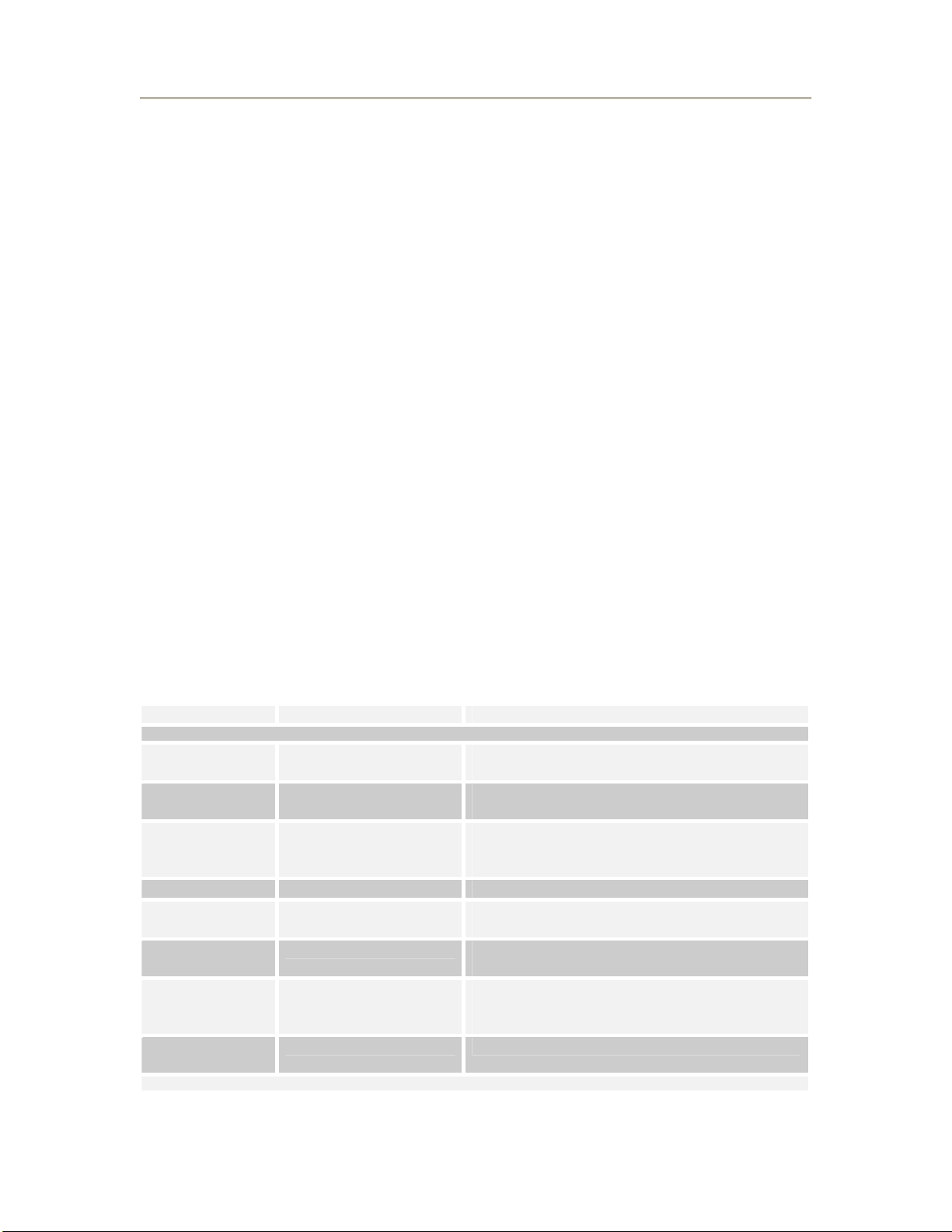

Appendix I - General Arrangement 13

Appendix II - Electrical Diagram 14

Appendix III – Performa Softener Manual 15

Operation Manual

KRO3000 Rev2

3

Please read this operating manual prior to use and store in a safe place for referral at a

later date.

1.0 Principles of Reverse Osmosis

The heart of the system is a semi-permeable membrane that will allow small molecules to

pass through, such as water (H2O) and reject larger molecules such as sodium Chloride

(NaCl). At atmospheric pressure, if a membrane separates two of different solution strengths,

ions from the stronger solution tend to flow into the weaker solution until equilibrium is

attained.

As the name suggests, “Reverse Osmosis,” reverses this natural tendency by exerting an

“Osmotic pressure” on the membrane.

Now the concentrated side of the membrane forces the smaller water molecules through the

membrane to the permeate collection manifold. The concentrated water becomes more

concentrated and the diluted water becomes more pure.

The most important aspect of reverse osmosis operation is to ensure the raw feed is correctly

treated to prevent fouling and possible irreversible damage to the reverse osmosis

membrane.

2.0 Pre Treatment

Rarely, in fact, almost never is water suitable for direct entry to the membrane housing.

Table 1 shows a number of contaminants present in raw water capable of causing a

permanent damage to the membranes. Please note these are the main contaminants.

However, other salts or metals may be encountered and would require a specific treatment.

Table 1.- Main Contaminants

Contaminant Membrane Effect Treatment Options

Chlorine (Cl) Oxidation

Membrane Destruction

Sodium Metabisulphite (SMBS) dosing/

Activated Carbon Filter

Chloramines Oxidation

Membrane Destruction

Sodium Metabisulphite (SMBS) dosing/

Activated Carbon Filter

Iron (Fe) Fouling Aerating/chlorination (followed by

dechlorination)

Ozone(followed by de-ozonation)

Manganese Fouling Manganese Greensand Filtration

Calcium

Bicarbonate

Scaling Base Exchange Water Softening

Proprietary Antiscalants

Magnesium

Sulphate

Scaling Base Exchange Water Softening

Proprietary Antiscalants

Biological

Activity

Biological Fouling Aerating/chlorination (followed by

dechlorination)

Ozone(followed by de-ozonation)

Suspended

Solids

Colloidal Fouling Coagulation and or Filtration

Operation Manual

KRO3000 Rev2

4

Table 2.- KRO Models

Item Model

800GPD 1500GPD 3000GPD(1) 6000GPD

Minimum Feed Flow Capacity 270 LPH 500 LPH 1000LPH 2000LPH

Minimum Feed Pressure 280 kPa

Water Temperature 5 45 °C

pH 6.5 – 9

Total Hardness Nominally 17ppm as CaCO3

Turbidity < 1 NTU’s

Silt Density Index SDI < 5

Total Dissolved Solids (TDS) < 1000ppm

Iron (Fe) < 0.1ppm

Manganese (Mn) < 0.05ppm

Dissolved Oxygen < 0.1ppm

Organics < 1ppm

(1) This manual is applicable for model KRO3000

3.0 System Configuration

3.1 The KRO3000 is completed with the following items:

RO membrane and Stainless Steel membrane Housing.

Stainless Steel frame.

Carbon / 5-Micron &1 Micron cartridge filters.

Horizontal Booster Pump.

Low-pressure protection switch.

Solenoid valve.

Permeate, Reject and Recycle Rotameters.

Digital controller.

CM-230 Conductivity meter.

Feed water pressure gauge.

Pre-membrane pressure gauge.

System (reject) pressure gauge.

3.2 Pre Treatment is completed with the following items:

Water Softener complete with automatic valve to control service, backwash and

regeneration cycles.

Operation Manual

KRO3000 Rev2

5

4.0 Process Description and System Components

4.1 General Process

This is to be read in conjunction with the General Arrangement drawing (Figure 1).

The raw water is pre treated before entering the KRO3000. The first stage of pre treatment is a

water softener which eliminates hardness to prevent scaling problems.

The softened water flows to a carbon filter to remove the chlorine which is detrimental to RO

membranes. Following the carbon filter the water passes through a 5 and 1 micron filters

arrangement to remove suspended material.

Filtered water is pumped via a high pressure (boost) pump through the RO housing, containing

the membrane. Permeate (treated water) is sent to a break tank and the Reject (brine) is sent to

the drain.

A Recycle line is also provided, this line goes from the reject line to the pump suction line. The

purpose of the recycle is to create a hydraulic equilibrium, correct recovery rate and system

pressure.

The system is completed with an inlet solenoid valve. This valve automatically turns off the water

supply between the feed water and the membrane. A level control inside the tank sends a signal

to the valve to close when the tank is full. Once the level in the tank is low, the level control sends

another signal to the solenoid valve to permit the flow of raw water into the system. Every time

the valve opens/closes the system will start/stop automatically.

A Flush solenoid valve is also provided with the unit. This valve is under the control of a timer.

Periodically the valve opens to flush the membrane at low pressure. This extends the periods

between membrane cleans.

4.2 System Components

4.2.1 Water Softener

The water is Hard when Calcium and Magnesium are dissolved in it. These salts precipitate out of

the water causing scaling problems. To prevent this situation the water is pre treated using a

water softener.

Raw water flows through a media (small plastic beads or chemical zeolite) covered in sodium

ions. The calcium and magnesium ions are replaced with sodium ions. As sodium does not

precipitate out of the water, the scaling problem is eliminated.

However, the media is exhausted after certain amount of water has been treated. This is because

no more sodium ions are available to swap places with calcium and magnesium. Consequently,

the media needs to be regenerated.

The regeneration process is very simple. The media is soaked with a Sodium Chloride (brine

tank) solution. The sodium ions change places with the calcium and magnesium trapped in the

media. In this way the media is being regenerated and is ready to exchange the sodium ions

again. The remaining brine plus all of the calcium and magnesium is flushed through a drain.

The regeneration cycles on the KRO3000 systems are programmed based on the hardness of

the inlet water.

Operation Manual

KRO3000 Rev2

6

Caution: THE SALT USED FOR REGENERATION OF THE WATER SOFTENER MUST BE

“CROWN HG WATER SOFTENER SALT”. NO OTHER SALT CAN BE USE FOR

REGENERATION.

4.2.2 Carbon Filter & Cartridge Filters

The carbon filter is designed to remove the chlorine from the water. Cartridge filters are designed

to remove suspended material greater than 5-Micron @ 1-Micron prior to the pre treated water

flows into the membrane. This protects the membrane from significant colloidal contamination.

The cartridges should be renewed every 4 months, as minimum. If the raw water is significantly

polluted then the cartridges should be changed in a shorter period of time.

Caution: It is EXTREMELY important to renew the cartridges. Mainly the carbon filter. If

any trace of chlorine goes into the housing, the membrane will be permanently damaged.

4.2.3 High-Pressure Pump

High-pressure pump is one of the key components, to boost the pressure for correct membrane

operating conditions.

4.2.4 RO Membrane Housing

RO membrane housing is to guarantee the RO membrane can work under the conditions of

normal pressure and seal arrangement.

Caution: The operator should apply silicon grease on the “Y’ type plastic ring in order to

ensure proper sealing of the membrane brine seal.

4.2.5 RO Membrane

RO membrane is the key component of the RO main unit and has a determinative effect on the

quantity and quality of water produced. The RO membrane utilizes pressure-energy to separate

larger contaminant molecules from the body of water.

For a given Temperature, Pressure and feed Total Dissolved Solids (TDS), if the quantity of water

produced decreases by 10%, please consult your supplier of the unit.

4.2.6 Conductivity Monitor

The function of conductivity monitor is to measure conductivity condition of the permeate water.

Caution: Please do not clean with strong acid and strong alkali to prevent the electrodes

from being damaged.

4.2.7 Reject Control Valve

The main function of the reject valve is to adjust the reject flow from the membrane. Adjust the

reject valve to attain the correct recovery rate and systems pressure in conjunction with the

recycle valve.

Caution: Please do not turn off the reject valve. The high pressure in the membrane

housing may cause irreversible damage to membrane and/or housing.

Operation Manual

KRO3000 Rev2

7

4.2.8 Recycle Control Valve

The main function of the recycle valve is to adjust the flow from the membrane brine port to the

booster pump suction. Adjust the recycle valve to attain the correct recovery rate and systems

pressure in conjunction with the reject valve.

Caution: Please do not turn off the recycle valve. The high pressure in the membrane

housing may cause irreversible damage to membrane and/or housing.

4.2.9 Flush Solenoid Valve

The flush solenoid valve is under the control of a timer. Periodically the valve opens to flush the

membrane at low pressure. This tends to extended the periods between membrane cleans.

4.2.10 Rotameters

Rotameters are provided to indicate the permeate and reject flow rates

4.2.11 Pressure Gauges

Pressure gauges are provided to monitor operating conditions and facilitate the adjustment of the

recycle and reject valves

4.2.12 Low-Pressure Switch

Low-pressure switch is a safety device that in conjunction with the controller shuts down the unit

in the event of low feed pressure.

4.2.13 Float Switch

.A facility is provided to connect an external float switch in the permeate storage tank. When the

circuit is broken between the, “HIGH-LEVEL,” contacts (no volt) the unit automatically stops. The

unit will remain on standby until the level in the tank drops, remaking the circuit.

4.2.14 Pressure Reducing Valve (PRV)

If no break tank and set pump is available for the raw water supply, then a PRV is provided to

guarantee the correct operating feed pressure going into the system. The PRV also protects the

unit from over pressure situations that may cause damage to the equipments.

The feed pressure must be between 250 to 500kPa.

5.0 Installation Guide

Installation Environment and Technical Requirements

5.1 The operator should install the unit in a covered dry place, shielded from the elements to

protect the electrical components and equipments generally from damage and

premature deterioration.

5.2 Sufficient room should be allowed to conveniently operate and service the unit.

5.3 Consideration should be given to any additional pre treatment that may be required prior

to operating the unit.

Operation Manual

KRO3000 Rev2

8

5.4 The influent water temperature must be between 5 and 45°C.

5.5 Permeate and reject lines must be no smaller than the unit outlet size. In the event of

long pipe runs, increasing the pipe size diameter may be necessary.

Ask for our suppliers engineer to consult on any item above that may be of concern.

Caution: Please check the power supply is the correct voltage and current rating. Refer to

the circuit diagram of RO main unit.

6.0 Description of Operation

6.1 Starting Up the Unit

6.1.1 Open the reject valve and recycle valves fully

6.1.2 Open feed water valve

6.1.3 Turn on the power supply.

6.1.4 Depress the RO Pump button

6.1.5 If the HIGH contacts are closed, after a short time delay the inlet valve will open

and allow water to enter the system. This first stage will expel air to prevent

damage to the membrane(s) [telescoping].

6.1.6 The flush valve will be open (the high reject flow rate will not be visible in the

reject rotameter).

6.1.7 After a few minutes the flush valve will close. The reject flow rate should be at the

maximum rate in the rotameter.

6.1.8 Slowly close in the reject valve and the recycle valve to attain the correct

operating pressures and reject flow rates*.

The correct operating conditions depend on:

Feed Temperature

Feed water analysis

Calculated recovery

Pre-treatment conditions

Caution: Do not start or operate the unit with either the recycle or reject valve closed.

Severe damage to the membrane and other component may result.

Caution: Do not operate the system at excessive pressures. If over a period:

The permeate conductivity increases by 15% or

The permeate production decrease by 10% or

The HP pump discharge pressure increases by 15%

The influent water quality has changed or membranes require periodic cleaning. Do not increase

the membrane pressure beyond 115% or permanent damage to the membranes may result.

When using the unit for the first time, discard the first hour of production to drain. This will rinse

out any preservative chemical used in membrane storage.

Operation Manual

KRO3000 Rev2

9

6.2 Shutting Down the Unit

6.2.1 Normally the unit will stop when the permeate tank if full. However, should the

unit be required to be stopped manually depress the RO PUMP button.

6.2.2 If the unit is not to be used for a period longer than 48 hours please consult your

supplier for advice regarding preservation of the membrane (membrane fouling

will occur if the unit is idle for long periods).

7.0 Maintenance

7.1 The membranes should be cleaned about every six months or whenever performance

diminishes as set out above.

7.2 Please consult your supplier to arrange cleaning of the membrane(s).

7.3 The filter cartridge should be replaced every four months as minimum.

7.4 Additional pre treatment should be serviced in accordance with the manufacturer’s

recommendations.

7.5 Should any component such as the HP pump not be performing according to

specifications, consult your supplier for servicing.

Operation Manual

KRO3000 Rev2

10

8.0 Trouble Shooting

Table 3.- Trouble Shooting

Symptoms Cause Remedies

Unit will not start •No power

•Insufficient Water

Pressure

•Permeate Tank Full

•Digital Controller

damaged

•Check power supply

•Check inlet valve is

open/ and Check

solenoid valve is

operational/Check

cartridge filter

•Reset float switch

•Service/Replace

HP Pump will not start •Circuit breaker Off

•Overload Tripped

•Pump Motor High

Temperature

•Switch on

•Reset check current

setting

•Allow to cool

HP Pump starts but water

Pressure low

•Flush Valve Open

•Recycle valve fully

open

•Reject valve fully open

•Pump fault

•Pump cavitation

•Wait until flush cycle

completes

•Close valve in

•Close valve in

•Inspect pump

•Bleed air from pump

HP Pump starts but Trips •Motor Overload •Check motor and

pump/Check overload

setting/Check controller

Excessive Membrane

Pressure

•Reject Valve Closed

•Recycle Valve Closed

•Membrane(s) fouled

•Excessive feed

Pressure

•Open

•Open

•Replace/clean

membrane(s)

•Check feed PRV setting

Permeate water quality

poor

•Membrane perforated

by chlorine attack

•Replace carbon

cartridge and

membrane

Operation Manual

KRO3000 Rev2

11

9.0 Servicing

Table 4 shows the basic steps maintenance personnel should follow when servicing a KRO3000

unit. This will allow them to identify if the unit is operating correctly.

Table 4.- Servicing KRO3000

Steps Yes No

1. Check pressure and flow rates against values in table 5.

2. Check brine tank is full (Recommended level 50% of full

capacity).

3. Check that no hard layer of salt has been formed on the

surface of the brine tank.

4. Keep record of the last change of filters

5. If a problem is identified please refer to the Trouble Shooting

section (Section 8.0) or call your supplier of the unit.

Caution: THE SALT USED FOR REGENERATION OF THE WATER SOFTENER MUST BE

“CROWN HG WATER SOFTENER SALT”. NO OTHER SALT CAN BE USE FOR

REGENERATION.

10.0 Expected Values

Table 5 shows the expected flow rates and pressures for KRO3000 unit.

Table 5.- Expected values for KRO3000

Parameter Value

Feed Pressure 30 – 40 psi

RO Pressure 105 – 115 psi

Concentrate Pressure 110 – 120 psi

Permeate Flow 5 – 7 LPM

Recycle Flow 14 – 16 LPM

Concentrate Flow 8 – 10 LPM

Operation Manual

KRO3000 Rev2

12

Appendices

Operation Manual

KRO3000 Rev2

13

Appendix I

Operation Manual

KRO3000 Rev2

14

Appendix II

Operation Manual

KRO3000 Rev2

15

Appendix III

Softener/Filter

Water Control System

Installation, Operation and Maintenance Manual

Autotrol Performa Cv

®™

This system installed by:

1.0 Performa Cv System

1.1 Specifications

1.1.1 Performa Cv Softener

Flow Rates (Valve Only)

Service @ 15 psi (1.03 bar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25.0 gpm (5.7 m3/h)

Backwash (Softener) @ 25 psi (1.72 bar) drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.0 gpm (4.5 m3/h)

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cv = 6.5 (Kv = 5.58)

Backwash Softener. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cv = 4.0 (Kv = 3.46)

Control Configurations

962 Microprocessor Demand System and 962 Electronic Timeclock

Backwash. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 to 60 minutes

Brine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Electronically calculated

Slow rinse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 to 125 minutes

Fast rinse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 to 19 minutes

External Brine Valve Required - Timed Fill

Valve Connections/Dimensions

Tank Thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1/2 inches - 8, male

Inlet/Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3/4 inches - 12 UNC-2A, male

Drain Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3/4-inch NPT, male

Brine Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/8-inch NPT, male

Distributor Tube O.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.050 inches (27 mm)

Distributor Tube Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2 ± 1/2 inches (13 mm ± 13 mm) above top of tank

Operating

Valve Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Glass-Filled Noryl*

Rubber Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Compounded for cold water

Weight (Valve with Control). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.5 lbs (2.0 kg)

Transformer Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 VAC 400 mA (4.6 vA)

Transformer Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115V 50/60 Hz, 230V 50/60 Hz

100 V 50/60 Hz

Operating Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 120 psi (1.37 to 8.27 bar)

Canada: 20 to 100 psi (1.37 to 6.89 bar)

Water Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35°to 100°F (2°to 38°C)

Options

Bypass Valve, Model 1265 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3/4 inches - 12 UNC-2A male

Bypass Fitting Kits:

Copper, Sweat Tube Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1/4-inch, 1-inch, 3/4-inch, 28-mm, 22-mm

CPVC, Solvent Weld Tube Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-inch, 3/4-inch, 25-mm

Plastic NPT or BSPT Pipe Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-inch male, 3/4-inch male

Brass NPT or BSPT Pipe Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-inch male, 3/4-inch male

Flow Meter 962 Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-inch Autotrol Turbine

*Noryl is a trademark of the General Electric Company.

1.1.2 Performa Cv Filter Specifications

Flow Rates (Valve Only)

Service @ 15 psi (1.03 bar) drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25.0 gpm (5.7 m3/h)

Backwash (Filter) @ 25 psi (1.72 bar) drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25.0 gpm (4.5 m3/h)

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cv = 6.5 (Kv = 5.58)

Backwash Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cv = 5.0 (Kv = 5.78)

Control Operation

942F Mechanical Clock Timer - 7 Day or 12 Day

Backwash. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-30 minutes

Fixed Fast Rinse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 minutes

962F Microprocessor Demand

Backwash. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 to 60 minutes

Fast Rinse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 to 19 minutes

962 FTC Electronic Time Clock

Backwash. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 to 60 minutes

Fast Rinse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 to 19 minutes

Interval Regeneration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Day of the Week Regeneration

Valve Connections/Dimensions

Tank Thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1/2 inches - 8, male

Inlet/Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3/4 inches - 12 UNC-2A, male

Drain Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/4-inch NPT, male

Brine Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/8-inch NPT, male

Distributor Tube O.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.050 inches (27 mm)

Distributor Tube Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2 ± 1/2 inches (13 mm ± 13 mm) above top of tank

Operating

Valve Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Glass-filled Noryl

Rubber Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Compounded for cold water

Weight (Valve with Control). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.5 lbs (2.0 kg)

Transformer Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12VAC 400 mA (4.6 vA)

Transformer Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115V 50/60 Hz, 230V 50/60 Hz

100V 50/60 Hz

Operating Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 to 120 psi (1.37 to 8.27 bar)

Canada: 20 to 100 psi (1.37 to 6.89 bar)

Water Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34°to 100°F (1°to 38°C)

Options

Bypass Valve, Model 1265. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3/4 inches - 12 UNC - 2A male

Bypass Inlet/Outlet Fitting Kits:

Copper, Sweat Tube Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1/4-inch, 1-inch, 3/4-inch, 28-mm, 22-mm

CPVC, Solvent Weld Tube Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-inch, 3/4-inch, 25-mm

Plastic NPT or BSPT Pipe Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-inch male, 3/4-inch male

Brass NPT or BSPT Pipe Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-inch male, 3/4-inch male

Flow Meter 962 Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-inch Autotrol Turbine

1.2 Installation

All plumbing and electrical connections must conform

to local codes.

Inspect unit carefully for carrier shortage or shipping

damage.

Location Selection

1. Thedistancebetween theunitandadrainshouldbe

as short as possible.

2. If it is likely that supplementary water treatment

equipment will be required, make certain adequate

additional space is available.

3. Since salt must be added periodically to the brine

tank, the location should be easily accessible.

4. Do not install any unit closer to a water heater than

a total run of 10 feet (3 m) of piping between the

outlet of the conditioner and the inlet to the heater.

Water heaters can sometimes overheat to the

extent they will transmit heat back down the cold

pipe into the unit control valve.

Hot water can severely damage the conditioner. A

10-foot (3-m) total pipe run, including bends,

elbows, etc., is a reasonable distance to help

prevent this possibility. A positive way to prevent

hot water flowing from heat source to the

conditioner, in the event of a negative pressure

situation, is to install a check valve in the soft

water piping from the conditioner. If a check valve

is installed, make certain the water heating unit

is equipped with a properly rated temperature

and pressure safety relief valve. Also, be

certain that local codes are not violated.

5. Do not locate unit where it or its connections

(including the drain and overflow lines) will ever be

subjected to room temperatures under 34oF (1oC)

or over 120oF (49oC).

6. Do not install unit near acid or acid fumes.

7. The use of resin cleaners in an unvented enclosure

is not recommended.

Water Line Connection

The installation of a bypass valve system is

recommendedtoprovideforoccasionswhenthewater

conditioner must be bypassed for hard water or for

servicing.

The most common bypass systems are the Autotrol

Series 1265 bypass valve (Figure 1.1) and plumbed-in

globe valves (Figure 1.2). Though both are similar in

function, the Autotrol Series 1265 bypass offers

simplicity and ease of operation.

Figure 1.1 - Autotrol Series 1265 Bypass Valve

Figure 1.2 - Typical Globe Valve Bypass System

Drain Line Connection

Note: Standard commercial practices are expressed

here.Local codesmayrequire changesto thefollowing

suggestions.

1. Ideally located, the unit will be above and not more

than 20 feet (6.1 m) from the drain. For such

installations, using an appropriate adapter fitting,

connect 1/2-inch (1.3-cm) plastic tubing to the drain

line connection of the control valve.

2. If the backwash flow rate exceeds 5 gpm

(22.7 Lpm)or if the unitis located more than 20 feet

(6.1 m) from drain, use 3/4-inch (1.9-cm) tubing for

runs up to 40 feet (12.2 m). Also, purchase

appropriatefittingtoconnectthe3/4-inchtubingto

the 3/4-inch NPT drain connection.

3. If the unit is located where the drain line must be

elevated, you may elevate the line up to 6 feet

(1.8 m) providing the run does not exceed

15 feet (4.6 m) and waterpressure at conditioner is

not less than 40 psi (2.76 bar). You may elevate an

additional 2 feet (61 cm) for each additional

10 psi (0.69 bar).

B

Y

P

A

S

S

B

Y

P

A

S

S

B

Y

P

A

S

S

B

Y

P

A

S

S

Not in Bypass In Bypass

Water

Conditioner

In Out

Water

Conditioner

In Out

Water Water

Not in Bypass In Bypass

Water

Conditioner Water

Conditioner

Table of contents

Popular Water Filtration System manuals by other brands

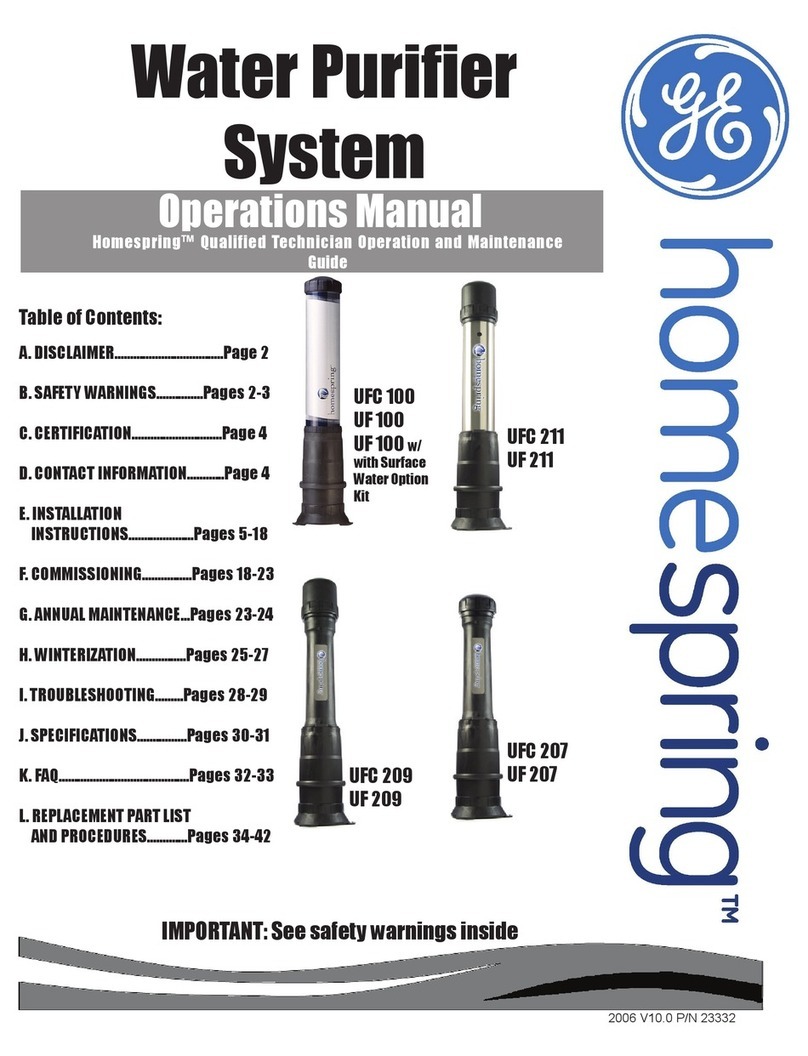

GE

GE Homespring UFC 100 Operation manual

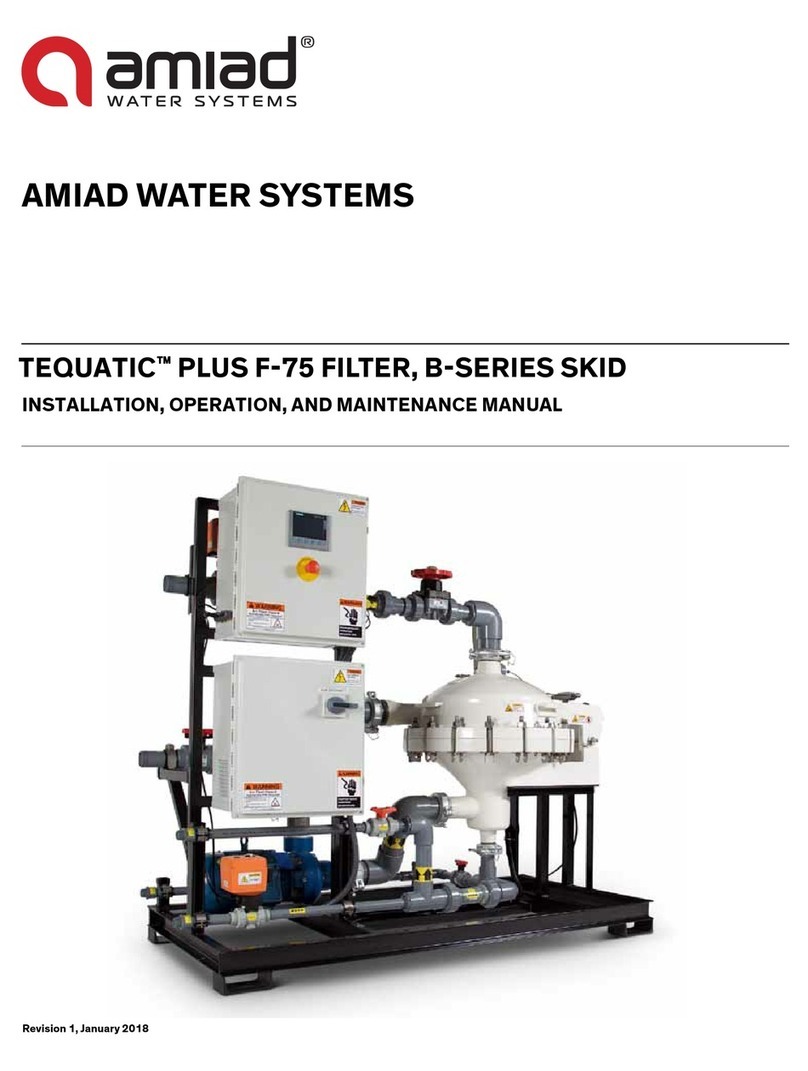

amiad

amiad TEQUATIC PLUS F-75 Installation, operation and maintenance manual

Sullair

Sullair OWS-88 User & service manual

Watts

Watts PWDWUV3 Installation, operation and maintenance manual

OptiPure

OptiPure FX-21 Installation, operation & maintanance manual

Brita

Brita On tap Instructions for use