chatron miiBIO User manual

1

miiBIO

miiBIO

Instruction

manual for

installation of

Biocooler

Smart Solar

2

miiBIOmiiBIO

Instruction

manual for

installation of

Biocooler

Smart Solar

3

BIOCOOLER

Solar Power Installation

Index

1. Introduction Page.3

2. Warnings Page.3

3. System Page. 4

4. Installation Page. 7

5. Connections Page. 9

6. Maintenance Page. 13

7. Faults Page. 14

Annex A – esquema quadro de energia

Annex B – inversor solar

1 - Introduction

To obtain the maximum level of service and sa-

tisfaction of our Solar Biocooler, please read this

manual carefully before installation.

2 - Warnings

Please read the warnings. They are listed for the

protection of people and the product. Neglecting or

ignoring these warnings can result in death or serious

injury and ends with the warranty. The system must be

installed by people with knowledge of electricity.

• The system must be installed and operated only by quali-

fied personnel. Make sure all power sources are turned off

when handling the installation wires.

• Prevent the control equipment from being exposed to di-

rect sunlight or other sources of heat.

• Install a ground system suitable for safety and protection

against lightning. A well-sized ground system can reduce

the chances of severe damage.

• Follow the recommendations for power cables. Undersized

cables may cause fan malfunction or even cable melting.

• To test, avoid joining wires to create spark. Use a multime-

ter to check the voltages.

• There are potential hazards when handling any heavy me-

chanical assembly. If you have questions about your ability

to perform manual installation safely, hire an installer. Do

not use a winch or a vehicle.

• In case of fire, notify the fire department of the existence of

photovoltaic installations.

3 - System

The Solar Biocooler is an air cooling unit, which

uses photovoltaic solar energy or mains electrici-

ty. For this purpose it uses 4 photovoltaic panels

(PV) and a monobloc frame with the necessary

elements.

Figure 1 - Solar Biocooler system scheme.

The photovoltaic panels provide energy for the Biocoo-

ler to function, however on cloudy days or during night

time, when there is less light, the power relay from the

mains can be activated.

If you do not wish to supply the mains power, you

must switch the cut-off switch on the switchboard off.

It should be noted that the supply of support must

be activated during the day, as the switching system

requires the 24VDC provided by the photovoltaic sys-

tem.

3.1 Technical characteristics

The Biocooler is an evaporative cooling unit that

allows to lower the temperature of the air by increasing

its humidity.

The model used can reach a pressure up to 194 pa

and an air flow up to 18000 m³ / h.

3.2 Monoblock with electrical equipment

The monobloc contains the essential equipment for

the operation of the system. This can be divided into

two subsystems depending on the power source, the

photovoltaic subsystem and the supportive supply

subsystem.

In the photovoltaic subsystem two equipments are pre-

sent; a voltage booster (DC BOOSTER) and a pho-

tovoltaic inverter (INV SOLAR1). It should be noted

that the voltage lift will provide a voltage of 440 VDC

to the inverter. This generates a three-phase voltage of

380V / 50 Hz and will power a second inverter (SO-

LAR INV. 2).

A power cut-off switch (BT) and a protective circuit

breaker (D) are present in the network support subsys-

tem.

Two contactors (K1, K2) are present for switching

between the two supply subsystems. There is an elec-

trical interlock to ensure that only one contactor is

actuated.

+ +

_ _

+ +

_ _

+_+_

+_+_

+_

Sinais

Motor

Placa

Monobloco

Gestão

Energia Rede

(400VAC)

4

A transformer (TRAN) converts the 380 VAC (supplied

by the mains or the first inverter) to 230 VAC, needed

to power the control board, water pump and discharge

valve.

A second inverter (INV SOLAR2) is used to power the

“Biocooler” fan motor. This will receive two signals,

from the control board, to control the speed of rota-

tion.

Figure 2 - monoblock with electrical equipment.

Warning: On the outside of the electrical board door

should contain a warning signal about the existence of

two sources of energy, one of which is photovoltaic.

This signal is important for whoever installs and main-

tains the equipment.

To activate the photovoltaic system there is a se-

lector (S1) that starts the solar inverter.

Figure 3 - control selector of solar photovoltaic system.

• Turning the selector to “ON”, the solar inverter 1 is activa-

ted, powering the Biocooler with photovoltaic energy.

• When turning the selector switch to “OFF”, the

solar inverter 1 is deactivated, if it has power from

the network, the Biocooler will be powered by it.

Placed on the side of the electric panel is a cut-off

panel, which controls the mains supply.

Figure 4 - general network power cut-off panel.

Further information is given in annexes A and B, the

electrical diagrams are presented and a description of

the operation of the solar inverter is made.

It is also recommended to consult the operating ma-

nual of the Biocooler.

4 - Installation

To produce maximum energy, photovoltaic panels

should be properly aligned with the sun and clean (wi-

thout accumulation of litter or dust).

Panel performance improves with colder temperatures.

4.1 Location of photovoltaic panels

The photovoltaic panels should be installed in order

to maximize exposure to the sun. If necessary, the fan

panels can be separated.

5

However, the greater the distance, the greater the sec-

tion of electrical cables.

Caution: if there is shade on the PV panels there will

be a reduction in fan speed or even a stop. Any cell

that is shaded works as a resistor and reduces the

power of the entire PV array.

4.2 Solar Orientation

For better performance, care must be taken to ensure

the orientation of the photovoltaic panels.

In the installation one must look to orient the photo-

voltaic panels in relation to the equator line. (Northern

hemisphere - South direction), (Southern hemisphere

- North direction).

Small adjustments in the EAST or WEST direction do

not significantly affect system performance.

4.3 Inclination of the panels

Attention should also be given to the angle of inclina-

tion of the panels. In each season of the year, there

is a variation in the angle of solar incidence, which

affects the energy production.

In a simple way it can be considered that the inclina-

tion angle of the photovoltaic panels is related to the

latitude of the installation site. An adjustment can also

be made at the incline angle in order to maximize the

yield depending on the season:

• Ideal slope in summer: latitude -15º

• Ideal slope in winter: latitude + 15º

• Ideal year-round slope: latitude -5º

4.4 Distance between rows of panels

When placing the photovoltaic panels in rows; must

take into account the distance between rows to avoid

shading and consequent yield losses.

4.5 Support structure of photovoltaic panels

Caution: A structure designed to withstand wind, easy

to assemble, and most important, safe must be used.

You should follow good practices and defined care for

support structure.

Where roofs do not provide the sun exposure or incli-

nation necessary for the effectiveness of the system,

it may be assumed that it is installed at ground level.

Always consider minimum ground clearance, avoid

shading elements, observe safety conditions.

If you have questions about the structure of support

and display, consult a civil engineer with knowledge of

the site or companies dedicated to the installation of

photovoltaic panels. For better quality and economy,

factory racks are recommended.

5 - System Connections

All connections must be made by qualified personnel

in accordance with local laws, regulations and good

practice.

In order to make the connections, it is recommended

to consult chapter 6 (maintenance) and follow the pro-

cedures indicated therein.

5.1 Connections of the monobloc

+ +

_ _

+ +

_ _

+_+_

+_+_

+_

Signals

Motor

Board

Monoblock

of Energy

Management Network

(400VAC)

Figure 5 - connection diagram of the monoblock.

Make sure that the cables are not in tension when

making connections.

Warning: Make sure you connect the cables of each

element to their terminals. Follow the signs.

Caution: Check the connections in the diagram shown

in this manual. Connecting the cables incorrectly can

damage the system. Use a multimeter to check polarity

and voltage.

5.1.1 Network connection

You must make sure that all phases and ground are

correctly connected. (It is not necessary to connect the

neutral conductor)

Figure 6 - Network cable indication.

5.1.2 Connection of photovoltaic panels

Warning: Photovoltaic panels can generate dangerous

voltages. A 48 V panel can generate close to 100 V

when it is disconnected from the load.

To avoid the risk of electric shock or damage to equip-

ment while working on the installation, cover the photo-

voltaic panels with opaque material (eg card) and leave

a cable off in order to interrupt the electrical circuit.

6

Any damage caused by inattention to these notices

will not be covered by the warranty.

+ +

_ _

+ +

_ _

+_+_

+_+_

+_

MC4

Multibreach

Connector

MC4

Multibreach

Connector

Figure 7 - Connection diagram of photovoltaic panels

The photovoltaic panels used to power the

Biocooler have a nominal power of 250Wp at

270Wp. They are connected in a parallel of two

series (positive terminal with negative) and can

produce about 76 VDC, open.

It is recommended to use MC4 type connectors

and suitable cable for photovoltaic installations

with UV protection, with a minimum cross-section

of 4 mm2. The greater the distance between the

fan and the photovoltaic panels the greater the

section should be, to avoid large voltage drops.

5.1.3. Biocooler links

In order for Biocooler to work in the right direction, you

must make sure to connect:

• The motor power cable to the respective motor terminals,

in the frame of the Biocooler (U, V, W), please check the

direction of rotation, if necessary change a phase;

• The power cable of the control board to the terminals of

the board, in the frame of the Biocooler (F, N, T);

• The motor speed signal cable to the signal terminals on the

Biocooler board (AV, BV, COM), together with the interfa-

ce relays.

Figure 8 - Identification of cables and terminals to be connected in the Biocooler.

5.2 Earth connection, lightning protection

Due to their exposure PV systems are subject to the

effect of direct atmospheric discharges or surges due

to indirect discharges in the vicinity of the installation.

Precautions should be taken to prevent or limit the da-

mage caused by them.

Caution: Local laws, regulations and good practices

for protection against direct and indirect atmospheric

discharges should be followed.

To mitigate the effects of indirect lightning strikes:

• Connect all metallic structural elements of the photovol-

taic panels to each other and the ground bus, in order to

create an equipotential bond between all the elements.

Proper grounding is important, allowing static electricity

to discharge to the earth - preventing lightning.

• It is recommended to use connecting conductors with a

minimum cross-section of 10 mm2 (copper).

• It is recommended that the conductive wires of the pho-

tovoltaic panels be put together in order to avoid inducti-

ve phenomena of indirect discharges.

• It is recommended that the elements of the photovoltaic

panels be separated from the atmospheric discharge

systems.

• It is recommended to use shielded cables in exposed

locations and / or over long cable distances.

If the building does not have a lightning protection

system, the support structure of the photovoltaic

generator must be connected to the ground bus

and incorporated in the equipotential bonding.

If there is a protection system against direct at-

mospheric discharges already implemented in

the building, all metallic structural elements of the

photovoltaic panels must be connected to it and

by the shortest possible path. The goal is to pre-

vent the beam from being able to directly reach

the photovoltaic module. The distance between

the photovoltaic generator and the shaft should

be greater than 2 meters in order to avoid lateral

discharge to the generator.

6 - Maintenance

Caution: All maintenance must be carried out by qua-

lified personnel in accordance with local laws, regula-

tions and good practice.

Each photovoltaic panel produces a voltage greater

than 35V, even without load. Care must be exercised

when handling all elements that are in contact with

their terminals.

On the electric panel will be a DC Booster that will

raise the photovoltaic voltage to about 440 Vdc. There

is danger of serious injury, even death. There is a war-

ning sign on the equipment.

7

Figure 10 - Hazard sign, voltage on photovoltaic panels.

Whenever maintenance work is required, all power

sources (photovoltaic panels, mains, etc.) must be

switched off or disconnected to avoid risk of electric

shock.

Make sure that:

• Turns off the equipment at the control;

• Turn off the disconnecting switches, the photovoltaic pa-

nels, the electricity grid, the equipment present;

• Cover the photovoltaic panels with opaque material (eg

card) and disconnect one of the power cables to ensure

that the circuit is interrupted.

Figure 11 - Warning signal, with installation / maintenance procedure.

7 - Failures

Table 2 - possible Biocoller failures

Faults: Verify: Solution:

Biocooler will

not start

The power switch is set to “ON”

The connections and cables are in

good condition

Check connections,

replace cables

PVs are shaded Remove elements that

cause shadow

Solar inverter has errors Reset the Inverter

Controller is on Check connections

Biocooler

only works

with network

support

PVs are shaded Remove elements that

cause shadow

The connections and cables are in

good condition

Check connections,

replace cables

Solar inverter is faulty Reset the Inverter

The status of the contactor (can

be glued) Contactor Replacement

Biocooler

only works

with PV

The power switch is set to “ON”

Circuit Breaker Check circuit breaker

The status of the contactor (can

be glued) Contactor Replacement

In case of another type of fault that can not be solved,

please contact CHATRON.

In more specific cases you can refer to Appendix B,

where a brief description of the errors of the solar in-

verter is made.

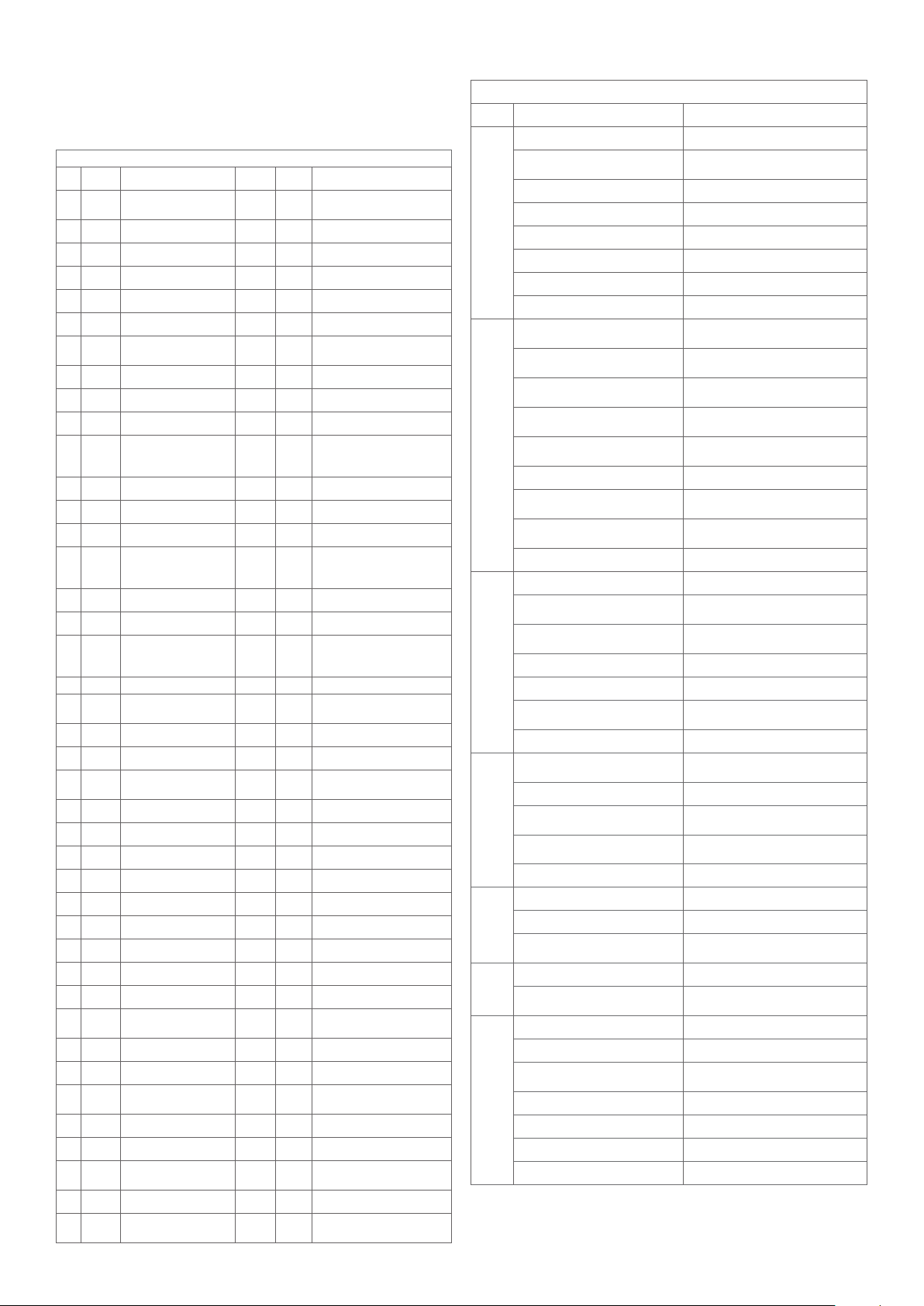

Appendix A - System Wiring Diagram

The system contains the essential equipment for its

operation and will be powered by two sources of ener-

gy. For a better understanding, electrical schematics of

the power and control circuits are presented.

7

Photovoltaiccell

EM12-SP

+10VAI1 AO1 485+ DI1 DI2 DI3 DI4 DI5 HDI

GND AI2 AO2 485- GND COM CME COM +24V COM

TA TB TC

FM DO1 COM

OFF

ON

JP2 J P6

CME

COM

V

I

JP3JP4

1

3

2

1

3

2

1

3

2

1

3

2

JP8

1

3

2

+ (R)

- (T) AC input

Diagram3-2 EM12-SP control circ uit and main circuit wiring

+

+

+

+

Photovoltaic Panels

DC

Booster K1

K2D1

S1

K2

21

22

+

-

+

-

21

22

K2

K1

K1

R1

Inv.

R2

Inv.

D1

(Run Stop

Command)

DI1

(Inverter)

(Always Run)

DI2

(Inverter)

(Low)

DI3

(Inverter)

(High V.)

BT2

COM

COM COM

RC BV RC AV

COM

TA1

TC1

TA2

TB2

Grid

COM (PV System)

Inverter 1

Source

Inverter 2

Source

M

Board

Tran.

1 2

3 4

5 6

1 2

3 4

5 6

DC

DC

Solar

Inv. 1

Solar

Inv. 2 Biocooler

400V AC

400V AC

230V AC

+/R W

V

-/TV U

R

S

T

+/R W

V

-/TV U

Power circuit: A1- power circuit

Table No. A1 - description of the elements present in the power circuit

Des. Equipment Function

BT Disconnector 25 A Network support power button

DBreaker Protection

K2 Contactor I = 9A 3P Uc = 24 V Selection of network support

Tran Transf. S = 100VA Is = 0.43A 400V AC to 230VAC converter

K1 Contactor I = 9A 3P Uc = 24 V Selection of photovoltaic panels

K2 Contactor I = 9A 3P Uc = 24 V Power grid selection

PV + Positive from solar panels Positive terminal of photovoltaic panels

PV - Negative from solar panels Negative terminal of photovoltaic panels

DC booster DC booster Tension lift

Inv.Solar1 Solar Inverter Pot. 2,2KW Photovoltaic inverter for power

Inv.Solar2 Solar Inverter Pot. 2,2KW Photovoltaic inverter for motor

MBiocooler motor 380V Biocooler Fan

Board Biocooler board230V Biocooler Control

Circuito de comando do inversor solar 1 (controlo da

parte fotovoltaica).

A2 - solar inverter control circuit 1

7

Photovoltaiccell

EM12-SP

+10VAI1 AO1 485+ DI1 DI2 DI3 DI4 DI5 HDI

GND AI2 AO2 485- GND COM CME COM +24V COM

TA TB TC

FM DO1 COM

OFF

ON

JP2 JP6

CME

COM

V

I

JP3JP4

1

3

2

1

3

2

1

3

2

1

3

2

JP8

1

3

2

+ (R)

- (T) AC input

Diagram3-2 EM12-SP control circuit and main circuit wiring

+

+

+

+

Photovoltaic Panels DC

Booster K1

K2D1

S1

K2

21

22

+

-

+

-

21

22

K2

K1

K1

R1

Inv.

R2

Inv.

D1

(Run Stop

Command)

DI1

(Inverter)

(Always Run)

DI2

(Inverter)

(Low)

DI3

(Inverter)

(High V.)

BT2

COM

COM COM

RC BV RC AV

COM

TA1

TC1

TA2

TB2

Grid

COM (PV System)

Inverter 1

Source

Inverter 2

Source

M

Board

Tran.

1 2

3 4

5 6

1 2

3 4

5 6

DC

DC

Solar

Inv. 1

Solar

Inv. 2 Biocooler

400V AC

400V AC

230V AC

+/R W

V

-/TV U

R

S

T

+/R W

V

-/TV U

8

Table A2 - description of the elements present in the control circuit of the

solar inverter 1.

Des. Equipment Function

S1 Command selector Active (“RUN”) of solar inverter 1

R1 Relay # 1 (TA1-TC1) of the solar

inverter

Contact “NO” is closed inverter

ready

R2 Relay # 2 (TA2-TB2) of the solar

inverter

Contact “NF” is Open Inverter

Ready

K1 K1 contactor control coil Selection of photovoltaic panels

K2 K2 contactor control coil Power grid selection

Inv. 1 source Solar inverter 24VDC source It feeds the contactor K1

Inv. 2 source Solar inverter 24VDC source Power the contactor K2

COM Common Source Point Contactor supply, signals

DI1 Input signal port # 1 Inverter outdoor activation signal 1

Solar inverter control circuit 2 (Biocooler motor control).

A3 - solar inverter control circuit 2

7

Photovoltaiccell

EM12-SP

+10VAI1 AO1 485+ DI1 DI2 DI3 DI4 DI5 HDI

GND AI2 AO2 485- GND COM CME COM +24V COM

TA TB TC

FM DO1 COM

OFF

ON

JP2 JP6

CME

COM

V

I

JP3JP4

1

3

2

1

3

2

1

3

2

1

3

2

JP8

1

3

2

+ (R)

- (T) AC input

Diagram3-2 EM12-SP control circuit and main circuit wiring

+

+

+

+

Photovoltaic Panels DC

Booster K1

K2D1

S1

K2

21

22

+

-

+

-

21

22

K2

K1

K1

R1

Inv.

R2

Inv.

D1

(Run Stop

Command)

DI1

(Inverter)

(Always Run)

DI2

(Inverter)

(Low)

DI3

(Inverter)

(High V.)

BT2

COM

COM COM

RC BV RC AV

COM

TA1

TC1

TA2

TB2

Grid

COM (PV System)

Inverter 1

Source

Inverter 2

Source

M

Board

Tran.

1 2

3 4

5 6

1 2

3 4

5 6

DC

DC

Solar

Inv. 1

Solar

Inv. 2 Biocooler

400V AC

400V AC

230V AC

+/R W

V

-/TV U

R

S

T

+/R W

V

-/TV U

Table A3 - description of the elements present in the control circuit of the

solar inverter 2.

Des. Equipment Function

RC BV Low speed interface relay Low speed indication to inverter 2

RC AV High-speed interface relay High speed indication to inverter 2

COM Common Source Point Contactor supply, signals

DI1 Input signal port # 1 Inverter outdoor activation signal 2

DI2 Input signal port # 2 Low speed outdoor signal inverter 2

DI3 Input signal port # 3 High speed outdoor signal inverter 2

For more information on solar inverters, please

refer to Annex B.

Annex B - Solar Inverter

The solar inverter converts the DC current of the pho-

tovoltaic panels into AC power in three phases with

about 380 V and a nominal power of 2200W.

Security information:

• Access and handling of the inverter must be carried out by

suitably qualified persons.

• When servicing the inverter ensure that the photovoltaic

panels are plugged in and the power cables disconnected.

• Do not touch the terminals with your hands.

• Do not change the values of the parameters in the solar

inverter, it can cause them to fail and consequently to mal-

function.

7

Photovoltaiccell

EM12-SP

+10VAI1 AO1 485+ DI1 DI2 DI3 DI4 DI5 HDI

GND AI2 AO2 485- GND COM CME COM +24V COM

TA TB TC

FM DO1 COM

OFF

ON

JP2 J P6

CME

COM

V

I

JP3JP4

1

3

2

1

3

2

1

3

2

1

3

2

JP8

1

3

2

+ (R)

- (T) AC input

Diagram3-2 EM12-SP control circuit and main circuit wiring

+

+

+

+

Photovoltaic Panels DC

Booster K1

K2D1

S1

K2

21

22

+

-

+

-

21

22

K2

K1

K1

R1

Inv.

R2

Inv.

D1

(Run Stop

Command)

DI1

(Inverter)

(Always Run)

DI2

(Inverter)

(Low)

DI3

(Inverter)

(High V.)

BT2

COM

COM COM

RC BV RC AV

COM

TA1

TC1

TA2

TB2

Grid

COM (PV System)

Inverter 1

Source

Inverter 2

Source

M

Board

Tran.

1 2

3 4

5 6

1 2

3 4

5 6

DC

DC

Solar

Inv. 1

Solar

Inv. 2 Biocooler

400V AC

400V AC

230V AC

+/R W

V

-/TV U

R

S

T

+/R W

V

-/TV U

B1- basic inverter diagram.

In the power circuit you have:

• terminals + (R) and - (T) for connection of the panels

• photovoltaic;

• terminals U (T1), V (T2), W (T3) for motor connection.

• In the control circuit you have:

• (+ 24V COM), for external sensors and input, up to

200mA,

• digital inputs (DI1 DI6) for inverter control,

• two relays with normally open contacts (TA 1/2 TB 1/2)

and normally closed contacts (TA 1/2 TC 1/2).

The solar inverter display shows the following configu-

ration:

Indicators:

• RUN - inverter status indication (OFF, off, ON);

• LOCAL - inverter control type indication (OFF -

panel, ON - terminal);

• DIR - indication of the direction of rotation of the

motor (OFF - reverse, ON - direct);

• TRIP - torque control (always ON), adjustment in-

dication (blinks slowly), error / fault (blinks quickly).

Button Diagram:

• PGR / ESC - menu entry and exit;

• DATA / ENTER - parameter entry and confirmation of settin-

gs;

• “Up arrow” - increments values, navigates through the

menu;

• “Down arrow” - decrements values, navigates through the

menu;

• “Right arrow” - selects the displayed parameter numbers,

• RUN - start of inverter (on control panel);

9

• STOP / RESET - inverter stop, error / fault clearing;

• MF.K- performs a pre-selected function.

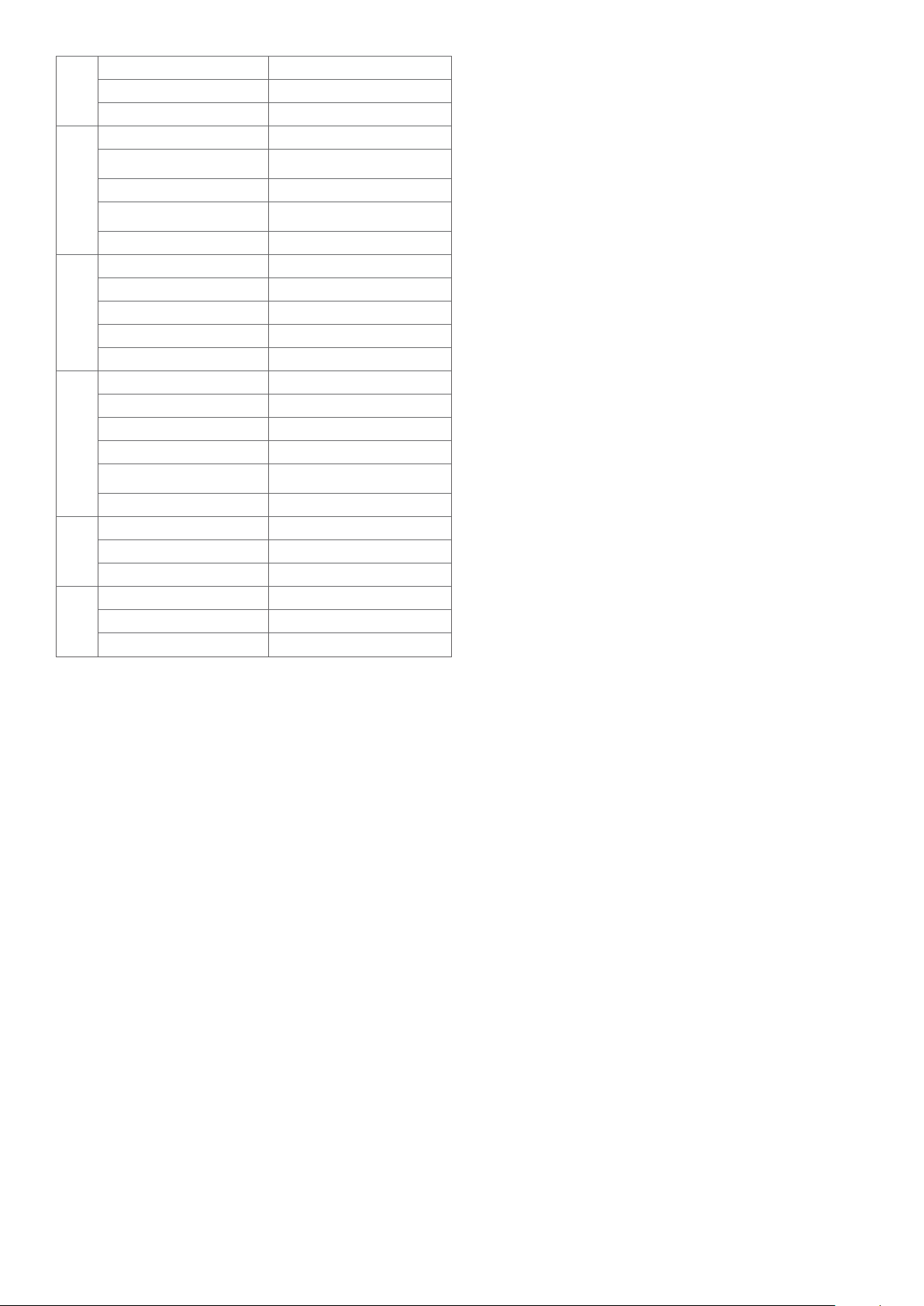

Table No. B1 - list of parameterized functions in solar inverters

description inv. 1 inv. 2 Definition

F0 Basic functions of the

inverter

F0-00 Binary curve selection 1 2 For fan

F0-02 Inverter control 1 1 Terminal Control

F0-03 Inverter control 6 Outside speed control

F0-17 Binary curve selection 20 20 For fan

F0-18 Inverter control 35 20 Terminal Control

F1 Motor parameter assign-

ment functions

F1-01 Rated motor power 1,5 1,2

F1-02 Rated motor voltage 410 380

F1- 03 Rated motor current 21,5

F4

Parameter setting

functions of the inverter

inputs

F4-00 Digital input # 1 1 1 RUN Command Entry

F4-01 Digital input # 2 12 RUN Command Entry

F4-02 Digital input # 3 13 RUN Command Entry

F5

Parameter setting

functions of the inverter

outputs

F5-02 Relay # 1 1 Active when inverter is running

F5-03 Relay # 2 1 Active when inverter is running

F9

Parameter assignment

functions for inverter

faults

FC Inverter control func-

tions

FC-01 Percentage of speed 1 30 Percentage at low speed

FC-02 Percentage of speed 2 75 High Speed Percentage

FE Parameterizing functions

of the solar system

FE-03 Engine type 0 0 Single-phase motor

FE-16 Sleepiness 370 V 250 V Voltage Disabling Inverter

FE-17 Activation voltage 420 V 350 V Voltage that activates inverter

FE-18 Activation time 3600s 0s Time for inverter activation

UO Monitoring

U0-00 Frequency (Hz)

U0-02 Input Voltage

U0-03 Output Voltage

U0-04 Output Current

U0-05 Power of photovoltaic

panels

U0-06 Input current

U0-07 Status of entries

U0-12 Open circuit input

voltage

Ar Alarms

Ar.01 Sleepiness

Ar.02 Low frequency pro-

tection

Ar.04 Overload protection

A4.05 Minimum power pro-

tection

Table No. B2 - list of error codes present in solar inverters.

Table of errors / failures

Code description Solution

Err01

Inverter protection

1. Short-circuit or earthing at the

outlet 1. Eliminate external failures

2. The connecting cable is very 2. Install a filter on the outlet

3. Heating the IGBT 3. Check the air filter and cooling fan

4. Disappearance of terminals 4. Connect the cables properly

5. Control card failure 5. Ask for technical help

6. Power board failure 6. Ask for technical help

7. Failure of IGBTs 7. Ask for technical help

Err02 /

04

Overload during acceleration /

constant speed

1. Short-circuit or earthing at the

outlet 1. Eliminate external failures

2. Motor parameterization is not

performed 2. Perform the parameterization

3. The acceleration time is too short 3. Increase the acceleration time

4. The V / F curve is not the most

appropriate 4. Perform curve adjustment

5. The voltage is too low 5. Set to normal value

6. The start of the operation is carried

out with a rotating motor

6. Select the restart rotation or start the

engine when it stops.

7. A charge was added during

acceleration 7. Remove the added load

8. The power of the inverter is small 8. Select a higher power inverter

Err03

Overload during deceleration

1. Short-circuit or earthing at the

outlet 1. Eliminate external failures

2. Motor parameterization is not

performed 2. Perform the parameterization

3. The deceleration time is too short 3. Increase the deceleration time

4. The voltage is too low 4. Set to normal value

5. A load was added during dece-

leration 5. Remove the added load

6. Braking unit not installed 6. Install the braking unit

Err05 /

06

Overvoltage during acceleration /

deceleration

1. Very high input voltage 1. Set to normal value

2. An external force pulls on the

engine during acceleration

2. Eliminate the external force or install a

braking unit

3. The acceleration / deceleration

time is too short

3. Increase the acceleration / decelera-

tion time

4. Braking unit not installed 4. Install the braking unit

Err07

Constant speed overvoltage

1. Very high input voltage 1. Set to normal value

2. An external force pulls on the

engine during deceleration

2. Eliminate the external force or install a

braking unit

Err08 Power unit failure

The input voltage is not within the

defined range Set the input voltage for the

Err09

Low tension

1. Inverter input failure 1. Clear fault

2. The input voltage is not within the

defined range 2. Set the input voltage for the

3. Out-of-normal DC bus voltage 3. Ask for technical help

4. Rectifying Bridge Failure 4. Ask for technical help

5. Board failure 5. Ask for technical help

6. Main board failure 6. Ask for technical help

10

Err10 Inverter Overload

1. Very high load, locked rotor 1. Reduce load, check engine condition

2. The power of the inverter is small 2. Select a higher power inverter

Err12

Input phase failure

1. Failure of the inputs of the three

phases 1. Eliminate the fault

2. Control board failure 2. Ask for technical help

3. Discharge Protection Board

Failure 3. Ask for technical help

4. Control main board failure 4. Ask for technical help

Err13

Output phase failure

1. Motor cable fault 1. Eliminate the fault

2. The three phases are not balanced 2. Check the motor windings

3. Control board failure 3. Ask for technical help

4. IGBT module failure 4. Ask for technical help

Err14

Overheating in the IGBT module

1. Very high ambient temperature 1. Lower the ambient temperature

2. Air filter blocked 2. Clean the air filter

3. Cooling fan damaged 3. Replace the fan

4. The IGBT module thermistor is

damaged 4. Replace the thermistor

5. The IGBT module is damaged 5. Replace the module

Err18 Current Detection Failure

1. Faulty current sensor 1. Replace sensor

2. Board failure 2. Replace board

Err22

Drive equipment failure

1. Overvoltage

2. Overload

In case of another type of fault that can not be solved,

please contact CHATRON.

11

miiBIOmiiBIO

Instruction

manual for

installation of

Biocooler

Smart Solar

12

miiBIO

miiBIO

Instruction

manual for

installation of

Biocooler

Smart Solar

Table of contents