Checkpoint 1250E Series User manual

This manual suits for next models

3

Table of contents

Other Checkpoint Water Pump manuals

Checkpoint

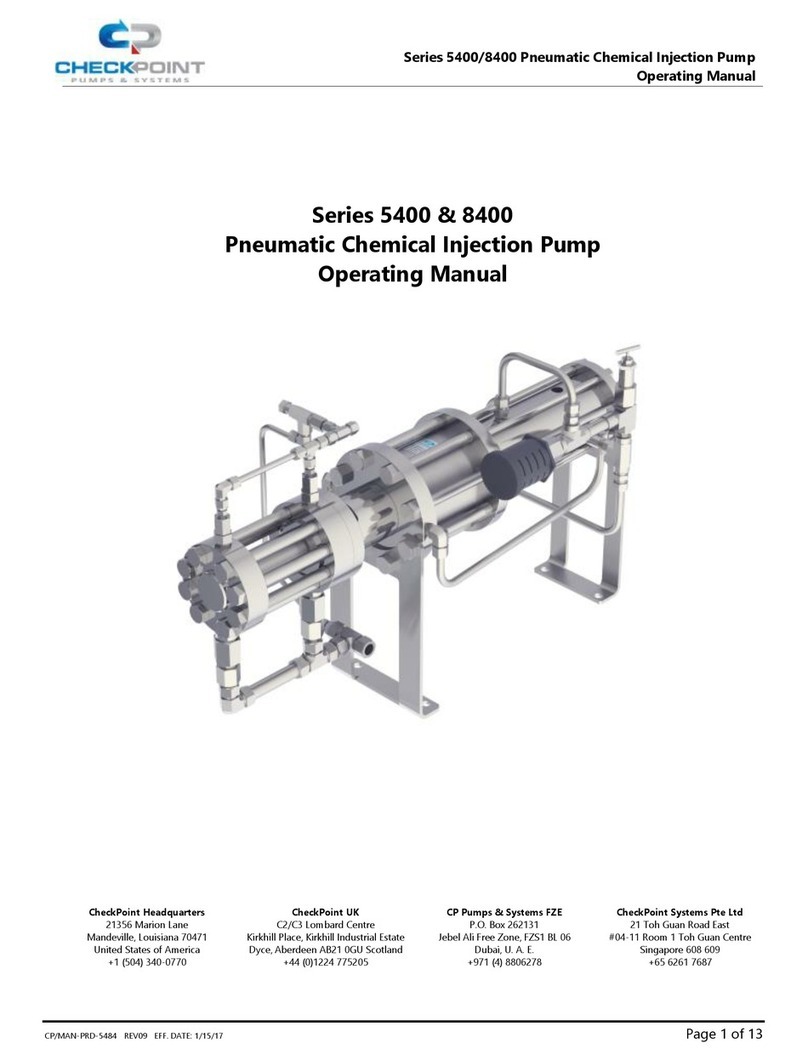

Checkpoint 5400 Series User manual

Checkpoint

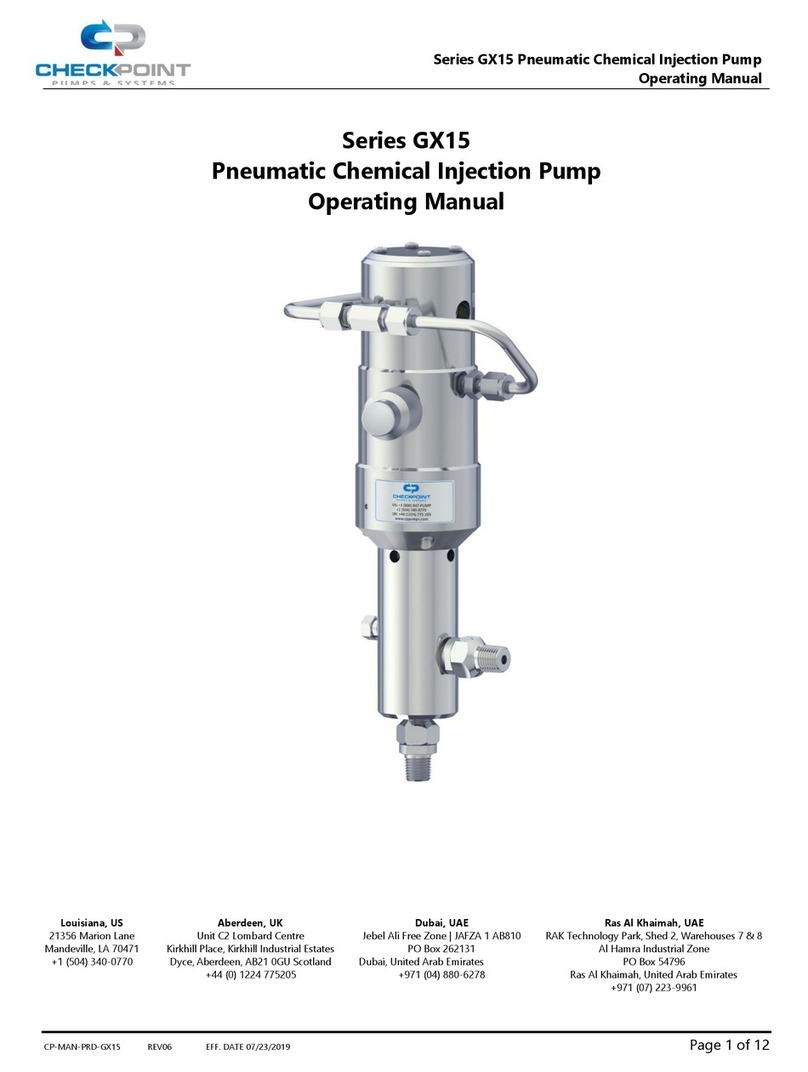

Checkpoint GX15G11C3 Series User manual

Checkpoint

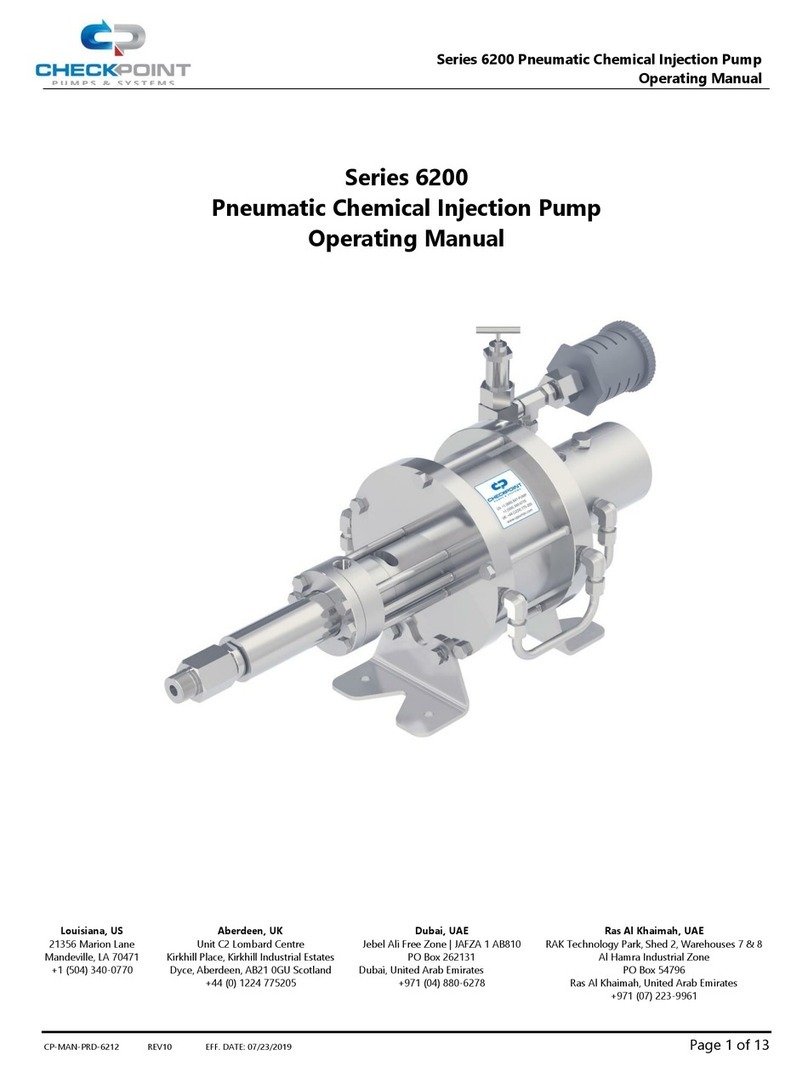

Checkpoint 6200 Series User manual

Checkpoint

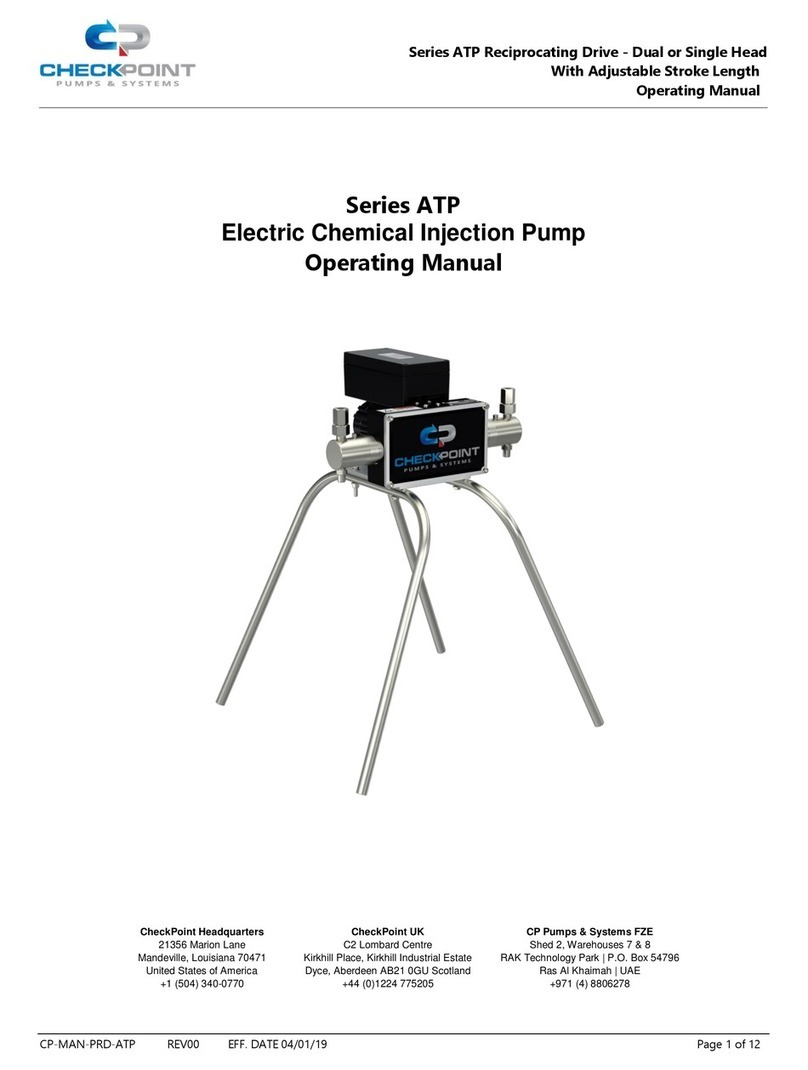

Checkpoint ATP Series Specification sheet

Checkpoint

Checkpoint ATP Series User manual

Checkpoint

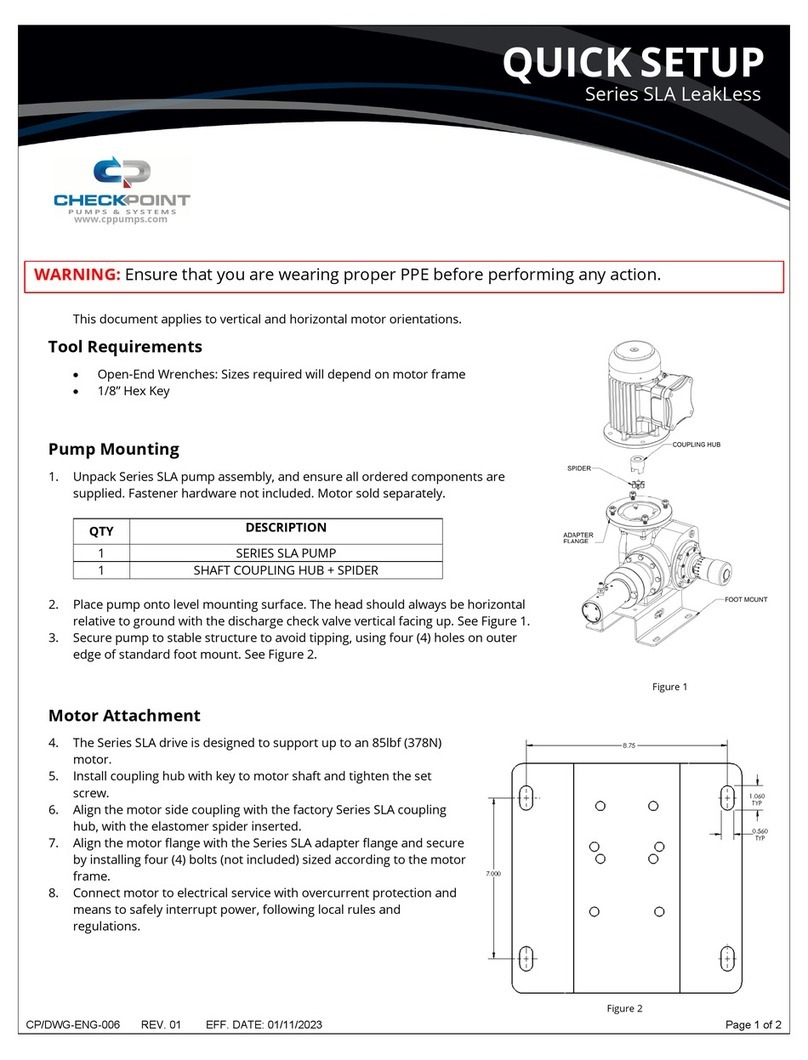

Checkpoint SLA Series Specification sheet

Checkpoint

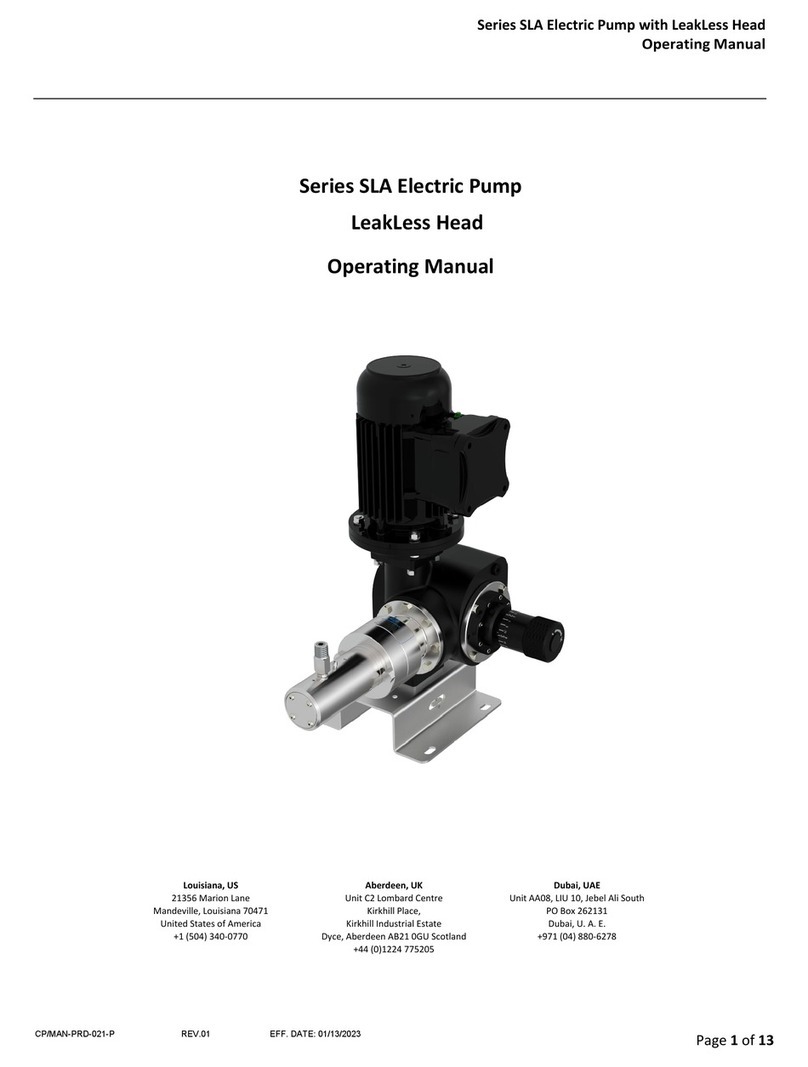

Checkpoint SLA Series User manual

Checkpoint

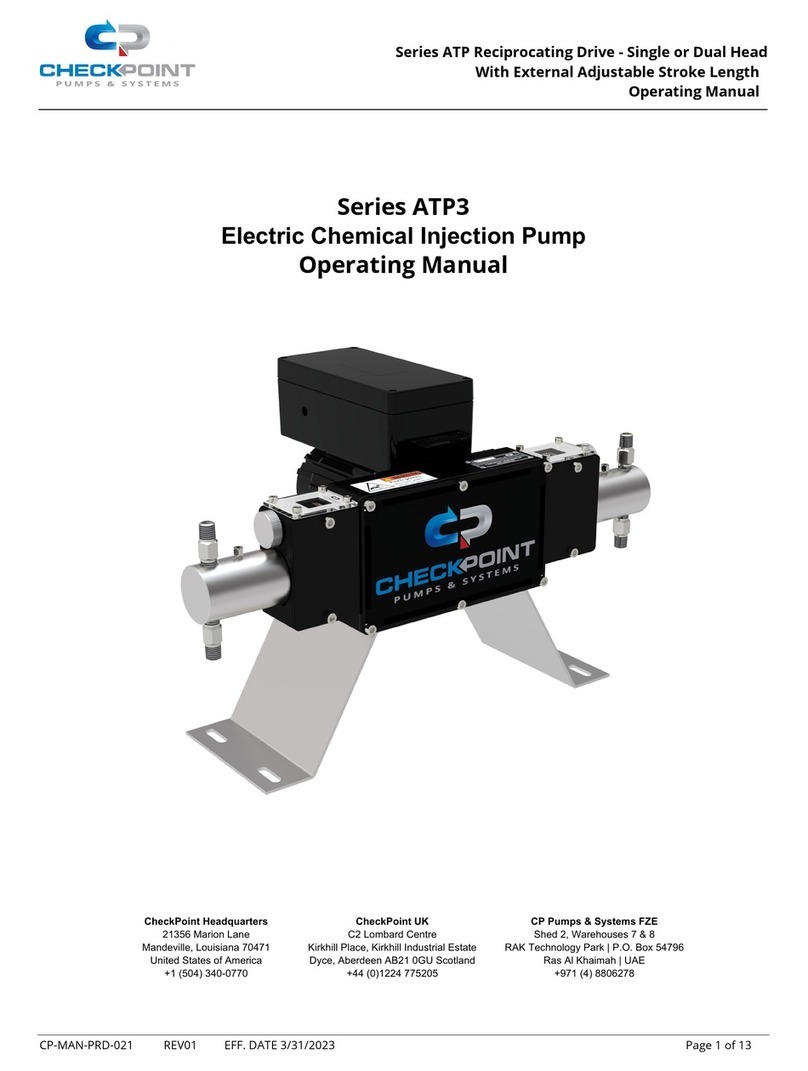

Checkpoint ATP3 Series User manual

Checkpoint

Checkpoint 1250 Series User manual

Popular Water Pump manuals by other brands

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS T3A61S-B Installation, operation and maintenance manual

BUSCH

BUSCH COMBI COBRA DS 8161 F instruction manual

GORMAN-RUPP PUMPS

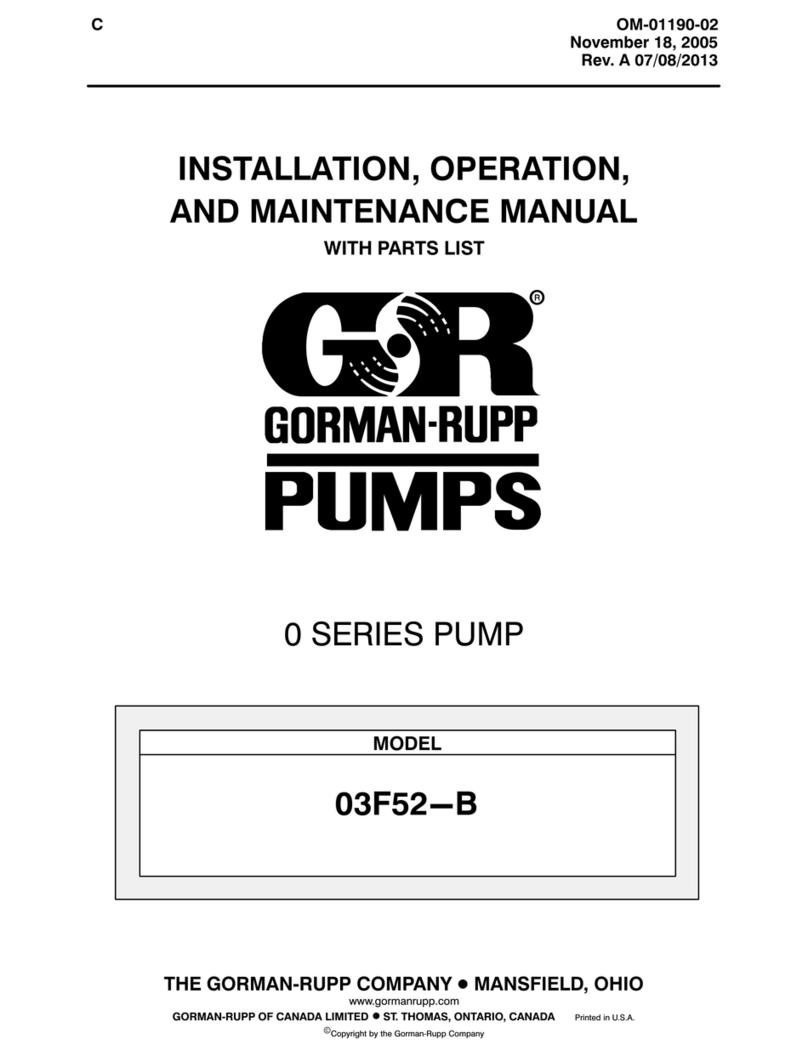

GORMAN-RUPP PUMPS 03F52-B Installation, operation, and maintenance manual with parts list

Giant

Giant LP200 Operating instructions/ repair and service manual

Regulus

Regulus CSE2 F W 1F Installation and operation manual

Stancor

Stancor SE Series Installation, operation and maintenance manual

Zoeller

Zoeller ProPak 507 Pre-Installation Checklist

Simplex

Simplex PET SERIES Operating & maintenance instructions

vacuubrand

vacuubrand VACUU-PURE 10C Instructions for use

Grundfos

Grundfos Liftaway B Installation and operating instructions

All-Flo

All-Flo C038 Operation & maintenance manual

Varian

Varian Turbo-V 2K-G instruction manual

PFT

PFT RITMO XL FU 230 operating instructions

cetoni

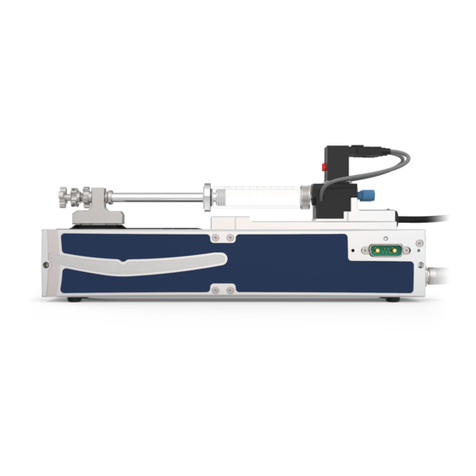

cetoni Nemesys S Hardware manual

Davey

Davey SJ35-04 Installation & operating instructions

BUSCH

BUSCH COBRA BC 0601 G instruction manual

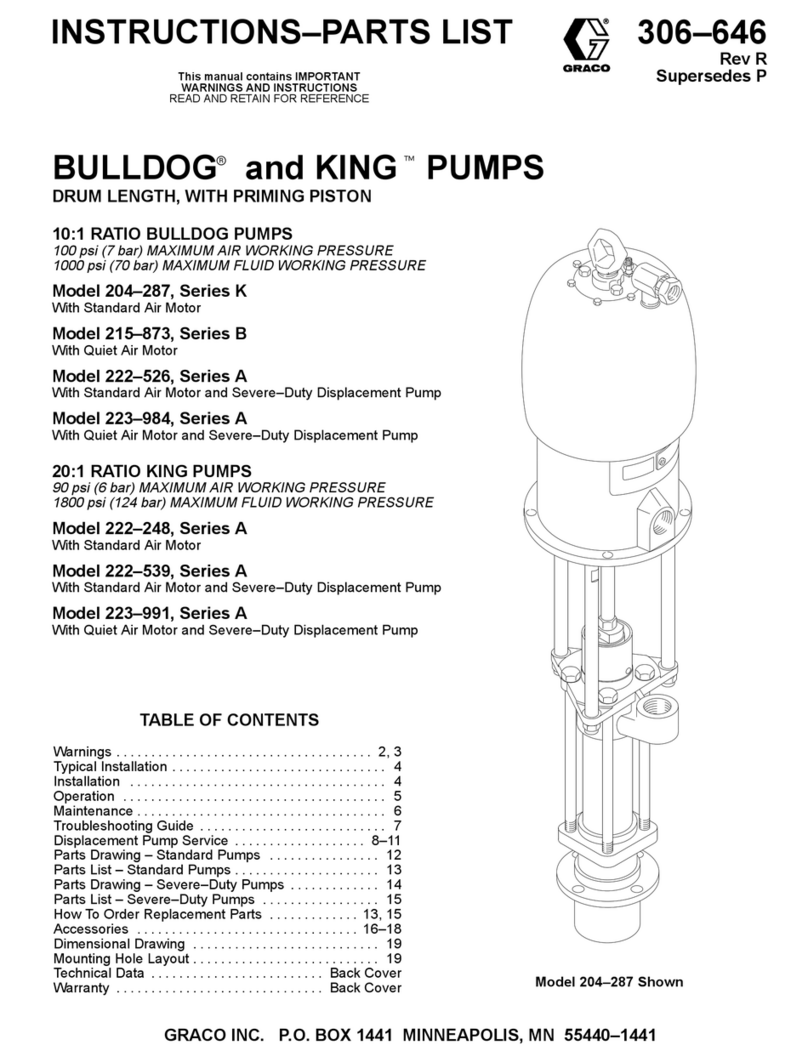

Graco

Graco BULLDOG 204-287, Series K Instructions-parts... instructions

ADEO Services

ADEO Services ZSPQ250-D instruction manual