Points to consider before use

Section 1

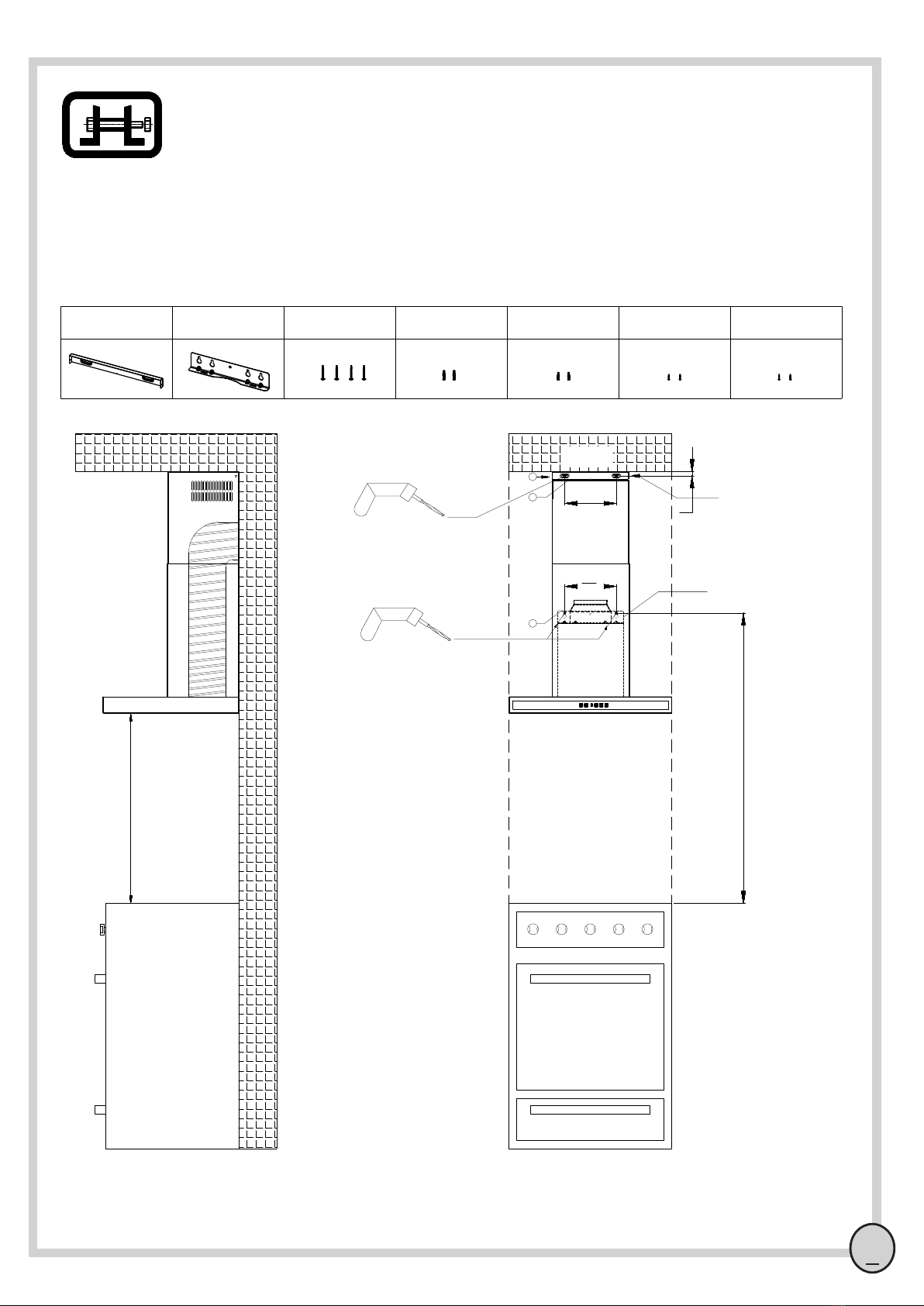

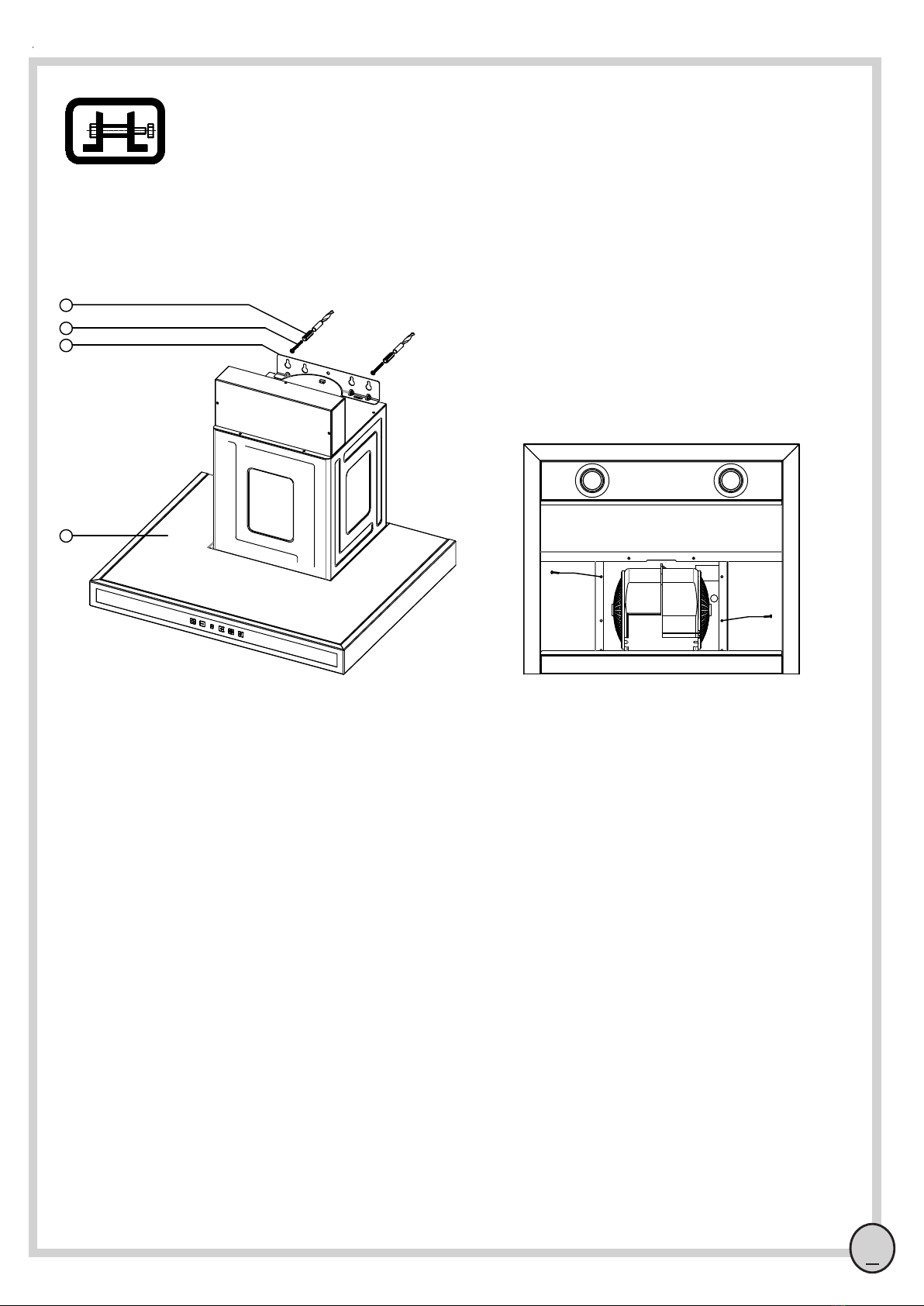

1....Electrical connections and installation of the product must be done by qualified service personnel.

In contrary, the product's efficiency may be reduced and serious risks such as noise,

vibration and electricity leakage may occur. In addition, the warranty becomes null.

2....Operating voltage is 200-230 Volt. Do not use under lower or higher voltages.

In contrary, it leads to burnout with the motor windings, failure with the light bulbs and

damages other electrical connection members.

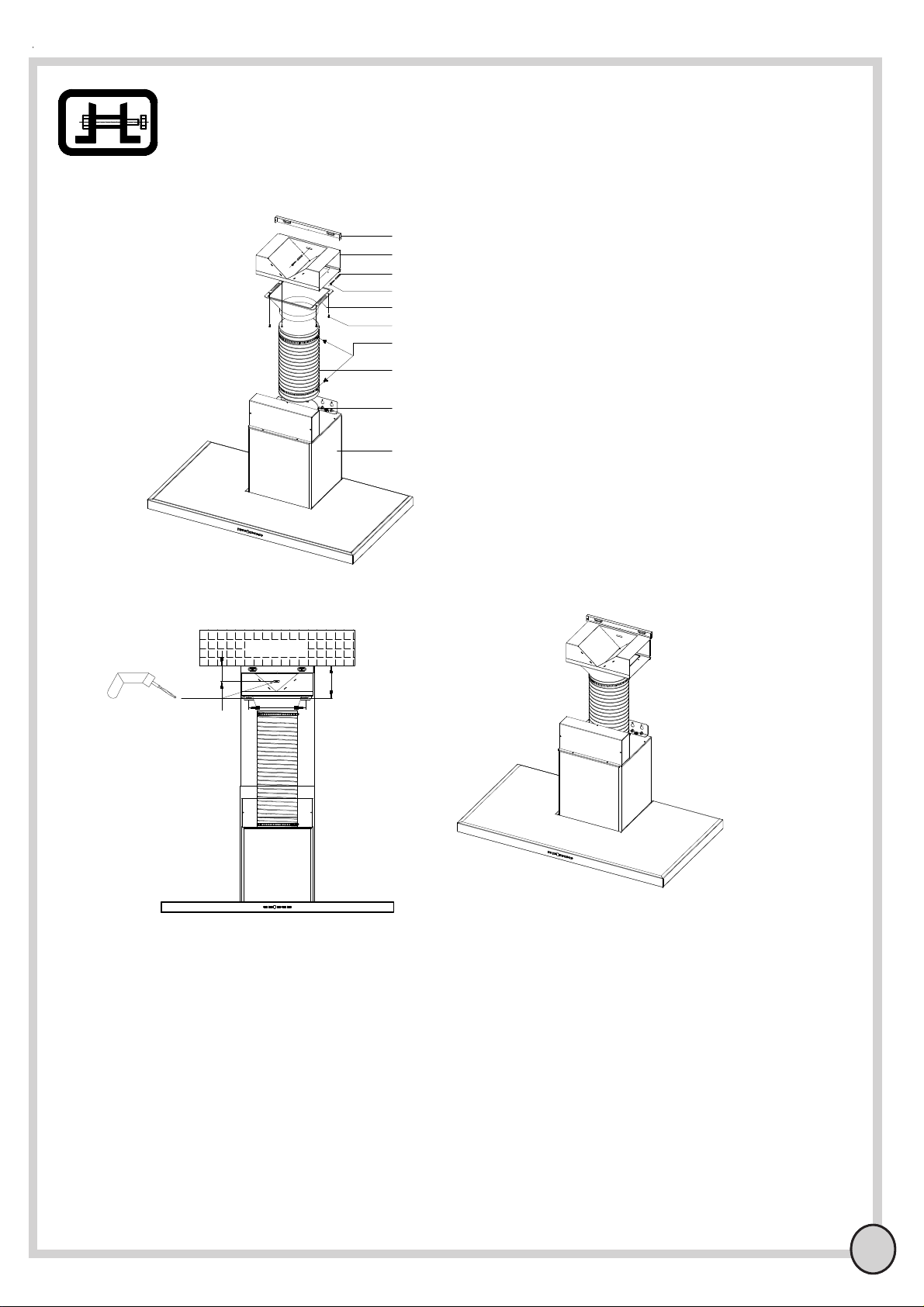

3....The exhaust connection of the product must be made to heating stove, natural gas, heater, ventilation duct.

In contrary, toxic gas leakage occurs or the high air pressure affects other environments.

4....The product must be connected to grounding plug.

In contrary, there is a risk of equipment damage and electrical shock.

5....Flammable food should not be cooked under the range hood.

In contrary, the equipment may take fire, electrical components and metal housing may be damaged.

6....Do not use replace the aluminium filter of the range hood with other materials.

In contrary, other materials may take fire, the suction power may be reduced in addition to the

reduction of service life.

7....Do not connect the range hood to power before completing the installation works.

In contrary, there is a risk of electrical, mechanical problems for the equipment, in addition,

electrical or mechanical accidents may take place.

8....Range hood is designed for use above the stoves in the kitchen of the houses. The product should

not be used out of its intended purpose.

In contrary, the manufacturer shall not assume any responsibility in connection with possible

problems and accidents. In addition, the warranty of the equipment becomes null.

9....Make sure that the wall where the range hood will be mounted is capable of bearing its load.

In contrary, negative consequences may occur.

10....Keep children away from the equipment and do not allow them to use it.

In contrary, negative consequences may occur.

11.... Do not touch the halogen lamp as it heats on the surface.

In contrary, various accidents may take place.

12....Ventilation in the room must be at sufficient levels when the electrical range hood is used at the same time with the

equipment fuelled with gas or other fuels. (air-filtering equipment may be excluded)

In contrary, various accidents may take place.

13....Electrical range hood must be cleaned periodically, surfaces of the product must be clean.

In contrary, oil accumulates on the range hood surface and it may cause range hood to take fire.

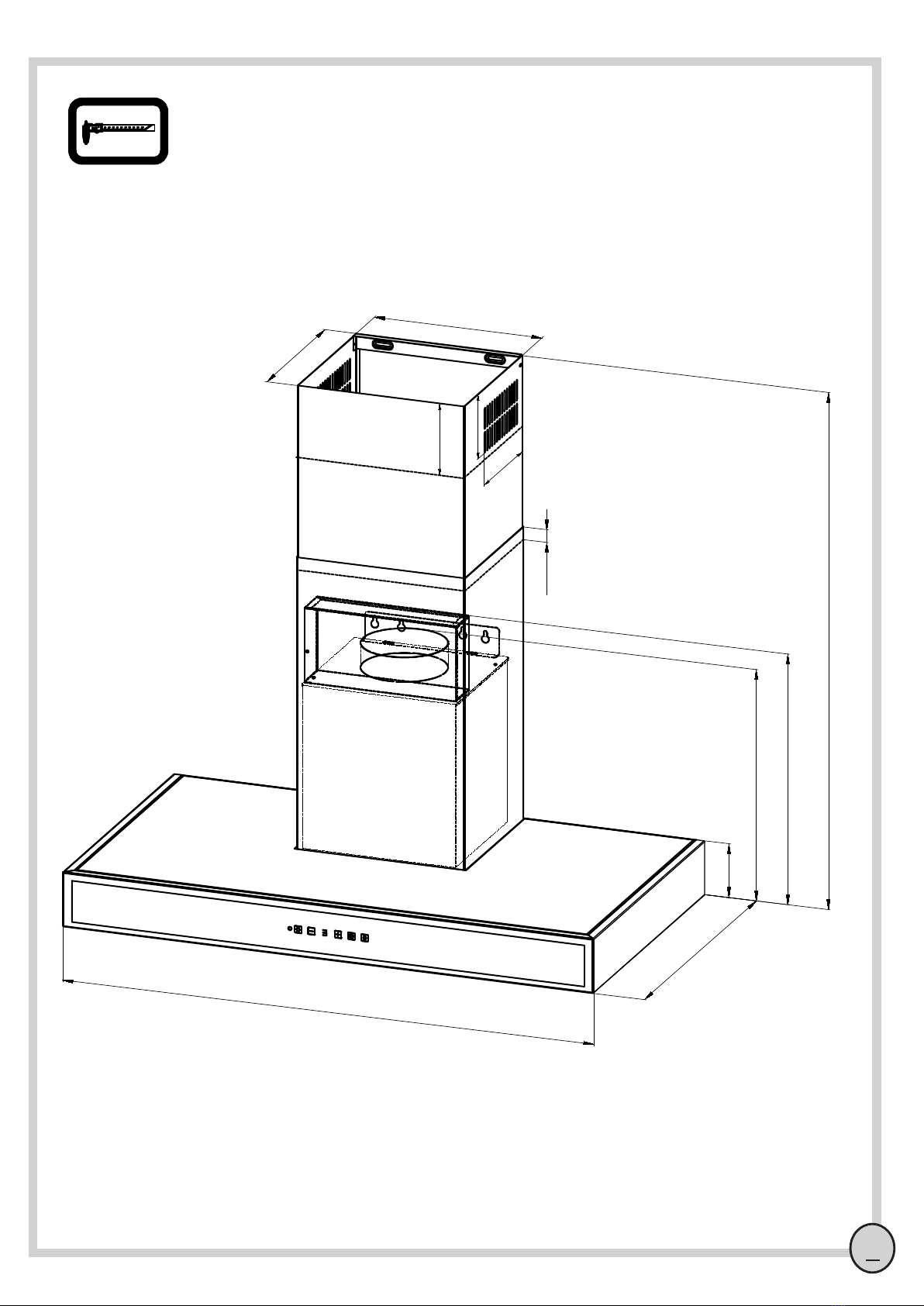

14....The product must be mounted on the wall in accordance with the dimensions specified in the mounting diagrams.

In contrary, the range hood may take fire, toxic gasses are not extracted and performance loss occurs.

2