ChemInstruments DDM-206A-S User manual

CHEMINS INSTRUMENT CO., LTD Rev2020-04 1 / 11

www.chemins-tech.com

DDM-206A-S Online Salinity Sensor

User Manual

YANTAI CHEMINS INSTRUMENT CO., LTD.

Tel:0535-3463801 0571-89870583

E-mail:service@chemins-tech.com service@chemins-env.com

Website:www.chemins-tech.com

Address: No. 15, Entrepreneurship Base, Development Zone, Zhaoyuan City,

Shandong Province

CHEMINS INSTRUMENT CO., LTD Rev2020-04 2/11

www.chemins-tech.com

User Notes

Please read this manual carefully before use and save it for reference.

Please follow the operating procedures and precautions in this manual.

When receiving the instrument, please carefully open the package and check

whether the instrument and accessories are damaged due to shipping. If any

damage is found, please inform the manufacturer and distributor immediately,

and keep the package for return.

When the instrument fails, do not repair it yourself. Please contact the

maintenance department of the manufacturer directly.

CHEMINS INSTRUMENT CO., LTD Rev2020-04 3/11

www.chemins-tech.com

Content

User Notes.......................................................................................................2

Ⅰ、 Application environment................................................................................4

Ⅱ、 Technical performance and specifications.....................................................4

1. Technical parameters.................................................................................... 4

2. Dimensional drawing....................................................................................5

Ⅲ、 Installation and electrical connection............................................................5

1. Installation...................................................................................................5

2. Electrical connection................................................................................... 5

Ⅳ、 Maintenance and maintenance..................................................................... 6

1. Use and maintenance...................................................................................6

2. Calibration..................................................................................................... 6

Ⅴ、 Quality and service.........................................................................................6

1. Quality assurance........................................................................................ 6

2. Accessories and spare parts........................................................................7

3. After-sales service commitment.................................................................7

Appendix data communication.................................................................................. 8

CHEMINS INSTRUMENT CO., LTD Rev2020-04 4/11

www.chemins-tech.com

Ⅰ、Application environment

Sea water / heavy salt water / various water supply / industrial water treatment.

Signal output: RS-485 (Modbus/RTU protocol).

Convenient connection to third-party equipment such as PLC, DCS, industrial control computer,

general controller, paperless recording instrument or touch screen.

Immersion installation with 3/4 NPT pipe thread for easy submersible installation or installation

in pipes and tanks.

IP68 protection grade.

Ⅱ、Technical performance and specifications

1. Technical parameters

Model

DDM-206A-S

Measuring range

0~70.0PSU

Resolution

0.1PSU

Precision

±1.5%F.S.,±0.5℃

Working temperature

0~65℃

Working pressure

<0.6MPa

Power supply

12~24VDC

Signal output

RS-485(Modbus/RTU)

Wetted material

ABS(Default)/ POM

Mounting method

Immersion mounting, 3/4 NPT thread

Cable length

5 meters, other lengths can be customized

Temperature compensation

Auto temperature compensation(Pt1000)

Calibration

Two-point calibration

Power consumption

0.2W@12V

Protection grade

IP68

CHEMINS INSTRUMENT CO., LTD Rev2020-04 5/11

www.chemins-tech.com

2. Dimensional drawing

Ⅲ、Installation and electrical connection

1. Installation

Note: At least 2 cm from the bottom and side walls of the container during installing and testing.

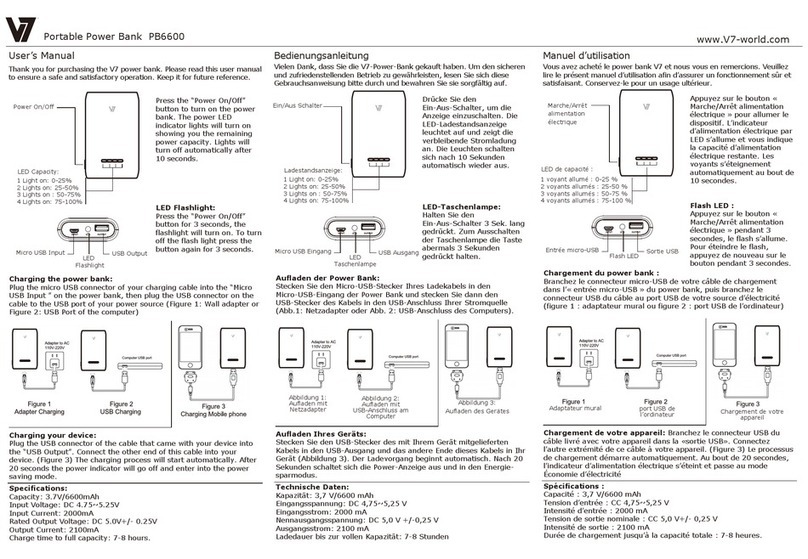

2. Electrical connection

a) Red line - power cord (12 ~ 24V)

b) Black line - ground (GND)

c) Blue line - 485A

d) white line - 485B

After wiring is completed, it should be carefully checked to avoid incorrect connections before

CHEMINS INSTRUMENT CO., LTD Rev2020-04 6/11

www.chemins-tech.com

powering up.

Cable specification: Considering that the cable is immersed in water (including sea water) for a long

time or exposed to the air, the cable has certain corrosion resistance. The outer diameter of the

cable is Φ6 mm and all interfaces are waterproof.

Ⅳ、Maintenance And Maintenance

1. Use and maintenance

Conventional electrodes require periodic cleaning and calibration, and the maintenance cycle is

determined by the customer based on his or her own operating conditions. Cleaning method for

conventional electrode: Remove the attached material with a soft brush (be careful to avoid

scratching the surface of the electrode), then rinse with distilled water, and then perform

calibration.

Electrode cleaning method:

The inductive salinity electrode is basically maintenance-free, and its normal operation will not

be affected by pollution or slight scaling of the shell.

If it needs clean, use a soft brush or sandpaper to remove attachments, and then clean with

distilled water, calibration after operation.

Because the inductive electrode often works in the environment which is easy to scale or dirty,

the cleaning strength can be increased appropriately. Slight scratches on the electrode surface

will not affect the normal operation of the electrode, but it is necessary to avoid penetrating

the electrode shell.

2. Calibration

a) Zero calibration

Rinse the sensor with distilled water and blot the liquid with filter paper. Place the sensor on the

power supply and place it in the air for about 3 minutes. After the value is stable, perform zero

calibration.

b) Slope calibration

Place the electrode vertically in a standard solution (20% full scale - full scale). Note that the

electrode is at least 2 cm from the bottom and side walls of the vessel for slope calibration. The

calibration instructions are detailed in the appendix.

Ⅴ、Quality and service

1. Quality assurance

The quality inspection department has standardized inspection procedures, advanced and

perfect testing equipment and means, and strictly in accordance with the regulations, to do

CHEMINS INSTRUMENT CO., LTD Rev2020-04 7/11

www.chemins-tech.com

72-hour aging test and stability test on the product, and not to allow one unqualified product to

leave the factory.

The receiving party directly returns the product batch with a failure rate of 2%, and all the costs

incurred are borne by the supplier. The reference standard refers to the product description

provided by the supplier.

Guarantee the quantity of goods and the speed of shipment.

2. Accessories and spare parts

This product includes:

1 sensor

1 copy of the instruction manual

1 certificate

Calibration solution (optional)

3. After-sales service commitment

The company provides local after-sales service within one year from the date of sale, but does not

include damage caused by improper use. If repair or adjustment is required, please return it, but

the shipping cost must be conceited. Damaged on the way, the company will repair the damage of

the instrument for free.

CHEMINS INSTRUMENT CO., LTD Rev2020-04 8/11

www.chemins-tech.com

Appendix Data Communication

1. Data format

The default data format for Modbus communication is: 9600, n, 8, 1 (baud rate 9600bps, 1 start bit,

8 data bits, no parity, 1 stop bit).

Parameters such as baud rate can be customized.

2. Information frame format

a) Read data instruction frame

06 03 xx xx xx xx xx xx

Address Function code Register address Number of registers CRC check code (low byte first)

b) Read data response frame

06 03 xx xx......xx xx xx

Address Function code Bytes Answer data CRC check code (low byte first)

c) Write data instruction frame

06 06 xx xx xx xx xx xx

Address Function code Register address Write data CRC check code(low byte first)

d) Write data response frame (same data command frame)

06 06 xx xx xx xx xx xx

Address Function code Register address Write data CRC check code (low byte first)

3. Register address

Register

address

Name

Instruction

Number of

registers

Access

method

40001

Measured value

4 double-byte integers, which

4(8 bytes)

Read

CHEMINS INSTRUMENT CO., LTD Rev2020-04 9/11

www.chemins-tech.com

(0x0000)

+ temperature

are the measured value, the

measured number of decimal

places, the temperature

value, and the decimal value

of the temperature value.

44097

(0x1000)

Zero calibration

Calibrate in the air, the read

data is 0.

1(2 bytes)

Write

44101

(0x1004)

Slope

calibration

Calibrated in a known

standard solution (20% full

scale - full scale), the read

value is actual value of

standard solution *10

1(2 bytes)

Write

44103

(0x1006)

Zero calibration

value

The data is read out as a zero

offset.

1(2 bytes)

Read

44105

(0x1008)

Slope calibration

value

The read data is the slope

value x 1000.

1(2 bytes)

Read

44113

(0x1010)

Temperature

value

Calibrated in solution, the

written data is the actual

temperature value x 10; the

read data is the temperature

calibration offset x 10 .

1(2 bytes)

Write/Rea

d

48195

(0x2002)

Device address

The default is 6, writing data

range 1-127.

1(2 bytes)

Write/Rea

d

48225

(0x2020)

factory reset

The calibration value is

restored to the default value

and the write data is 0. Note:

The sensor needs to be

calibrated again after

resetting.

1(2 bytes)

Write

4. Command example

a) Start measurement instructions

Function: Obtain the conductivity value and temperature of the measuring probe; the unit of

temperature is Celsius, and the value of conductivity is mS/cm (or uS/cm);

CHEMINS INSTRUMENT CO., LTD Rev2020-04 10 /11

www.chemins-tech.com

Request frame:06 03 00 00 00 04 45 BE

Response frame: 06 03 08 01 02 00 01 00 B0 00 01 90 48

Example of reading:

For example: Salinity value 01 02 means hexadecimal reading salinity value, 00 01 means

the salinity value has no decimal point , which is converted to the decimal value of 25.8.

The temperature value 00 B0 represents the hexadecimal reading temperature value, and

00 01 indicates that the temperature value has a decimal point and is converted to a decimal

value of 17.6.

b) Calibration instructions

Zero calibration

Function: Set the sensor's conductivity zero calibration value; here the zero calibration is

performed in the air;

Request frame: 06 06 10 00 00 00 8C BD

Response frame: 06 06 10 00 00 00 8C BD

Slope calibration

Function: Set the sensor's conductivity slope calibration value; here the slope value is based on

the actual standard solution value, and the calibration is taken as an example with 5000μS/cm;

Request frame: 06 06 10 04 01 F4 CD 6B

Response frame: 06 06 10 04 01 F4 CD 6B

c) Set the device ID address:

Function: set the Modbus device address of the sensor;

Change the device address 06 to 01. The example is as follows:

Request frame:06 06 20 02 00 01 E3 BD

Response frame: 06 06 20 02 00 01 E3 BD

5. Error response

If the sensor does not correctly execute the host command, it will return the following format

information:

Definition

Address

Function code

Code

CRC check

Data

ADDR

COM+80H

xx

CRC 16

Number of bytes

1

1

1

2

a) CODE: 01 –Function code error

03 – Data is wrong

Conductivity value

Temperature value

01 02 00 01

00 B0 00 01

Table of contents