Chemtrac Auto Clean UV254 User manual

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 1

Chemtrac, Inc.

1555 Oakbrook Dr. Suite 100

Norcross, GA 30093

(770) 449-6233

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 2

1 Contents

2Overview_____________________________________________________________________________3

3Safety _______________________________________________________________________________4

3.1 Safety Instructions _________________________________________________________________4

4Technical Specifications_________________________________________________________________5

5Installation____________________________________________________________________________5

5.1 Unpacking and Inspection ___________________________________________________________5

5.2 Assembly ________________________________________________________________________6

5.3 Mounting_________________________________________________________________________6

5.4 Plumbing_________________________________________________________________________7

5.4.1 Connecting a UV254 Analyzer ____________________________________________________8

5.5 Electrical and Communication ________________________________________________________9

6Start Up and Operation_________________________________________________________________10

6.1 Start Up_________________________________________________________________________10

6.2 Operation _______________________________________________________________________11

7Cleaning ____________________________________________________________________________12

8Cleaning Configuration_________________________________________________________________13

8.1 UVM5000 Organics Monitor Menu ____________________________________________________14

9Maintenance _________________________________________________________________________15

10 Parts and Accessories _________________________________________________________________15

11 Cabinet Dimensions and Clearance_______________________________________________________16

12 Warranty ____________________________________________________________________________17

List of Tables

Table 1: Automatic Cleaning Module Specifications _______________________________________________5

Table 2: Items and quantity list for unpacking ____________________________________________________5

Table 3: Commercial cleaning solutions________________________________________________________12

Table 4: Menu functions and configuration for Auto Clean System ___________________________________13

Table 5: UVM5000 menu selection of cleaning configuration _______________________________________14

Table 6: Maintenance tasks and frequency for Auto Clean system___________________________________15

Table 7: Spare parts for Auto Clean system_____________________________________________________15

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 3

2 Overview

Thank you for purchasing from Chemtrac, Inc.

The Automatic Cleaning Module is a chemical cleaning system for use with the

Chemtrac UVM5000 UV254 Organics Monitor, and the UV1 UV254 Organics

Sensor. The purpose of the system is to reduce and clean any deposition/fouling

in the analyzer flow cell.

The Auto Clean and the UV254 analyzer are plumbed so that process water flows through the cleaning module

to the analyzer. When a cleaning cycle starts, the Auto Clean temporarily stops the flow of process water, and

instead pumps cleaning solution from its cleaning fluid bottle to the analyzer flow cell. This can be done on an

automated periodic schedule, or on an immediate basis through manual intervention.

A portion of cleaning fluid is recaptured and directed back into the bottle after a cleaning cycle is completed.

Analyzer measurement resumes after the tubing is rinsed of residual cleaning fluid by the reestablished flow of

process water.

The cleaning system is controlled through the Operator Interface of the Chemtrac UV254 analyzer. From here,

the system is enabled, and a cleaning frequency is selected.

Cleaning of the flow cell is best achieved when cleaning frequency and cleaning fluid work in unison to prevent

the accumulation of fouling agents inside the flow cell.

On schedule,

cleaning fluid drawn

from bottle by

pump.

Cleaning fluid to

flow cell for a

10-minute hold

time.

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 4

3 Safety

3.1 Safety Instructions

Please read and follow all safety instructions outlined in this owner’s manual prior to

installation and/ or operation.

1. Visually inspect the device prior to operation. If it seems broken or damaged in any way, do not use.

Contact Chemtrac, Inc. for a replacement.

2. Ensure that all responsible personnel carefully read this manual before installing or servicing the device.

3. Failure to properly install and maintain this device may impact its effectiveness and warranty.

4. Improper use of this device may cause injury.

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 5

4 Technical Specifications

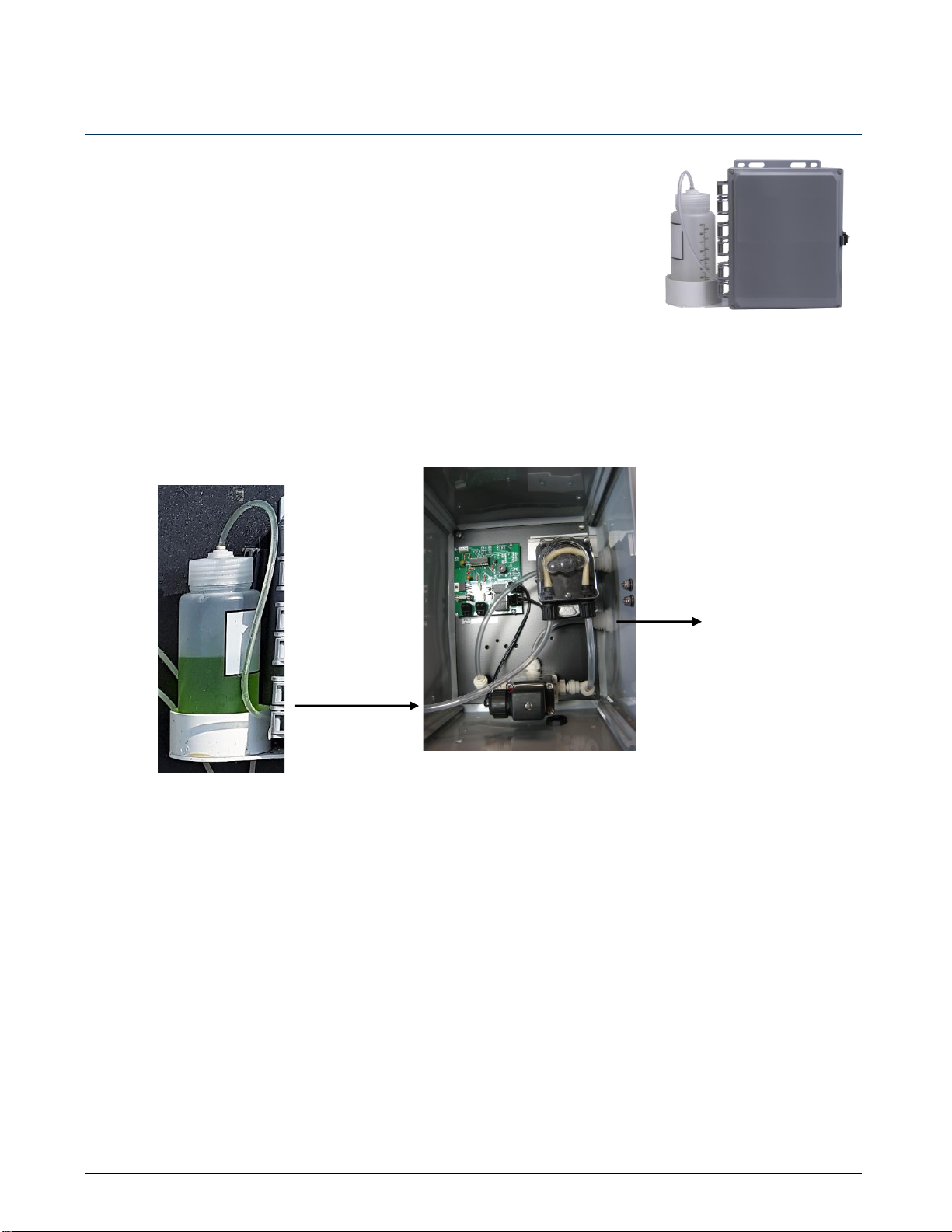

Table 1: Automatic Cleaning Module Specifications

CHARACTERISTIC

TECHNICAL DATA

CLEANING FREQUENCY

User configurable cleaning cycle

CLEANING CAPACITY

1L cleaning fluid bottle

DIMENSIONS

10”high x 18” wide x 6” deep (25 cm x 46 cm x 15 cm)

ENCLOSURE

Wall mountable

FLUID CONNECTIONS

¼” (6 mm) push-to-connect fittings and flex tubing

ELECTRICAL

Operates from 24 VDC

STORAGE TEMP.

-20°C to +60°C (-4°F to +140°F)

OPERATING TEMP.

0°C to 45°C (32°F to 113°F)

WEIGHT

10 lb (4.5 kg)

WETTED MATERIAL

Polypropylene, Marprene

WARRANTY

1-year limited warranty

5 Installation

5.1 Unpacking and Inspection

To begin, remove the Auto Clean system from the packaging and

carefully inspect the product to ensure that no visible damage has

occurred during shipping. The following items will be packed inside

the box:

Table 2: Items and quantity list for unpacking

ITEM

Automatic Cleaning Module

1L Cleaning Fluid Bottle

Bottle Holder

Power and Communication Cable

Owner’s Manual

Please ensure all items are unpacked and accounted for before moving on to assembly.

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 6

5.2 Assembly

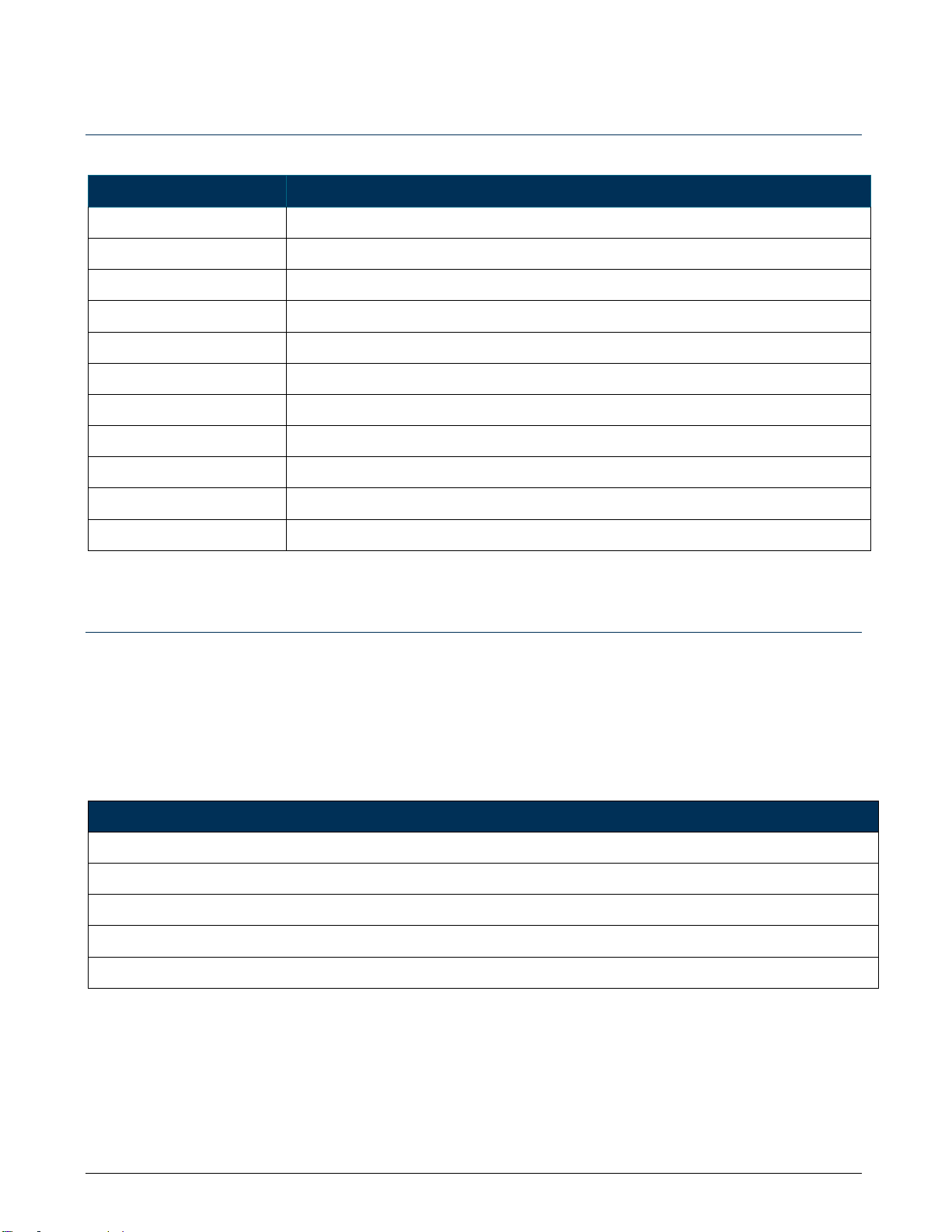

BThe cleaning fluid bottle holder must be mounted onto the Auto

Clean system from the underside of the enclosure as shown in

Figure 5.1. Fittings are supplied with the holder.

After mounting the enclosure, fill the 1L bottle with cleaning fluid.

Recommended fluids are outlined in Section 7 –Cleaning. Connect

the tubing from the system to the spout on the bottle.

5.3 Mounting

The system is enclosed in a wall-mountable cabinet.

The cabinet should be attached at all four of the

mounting holes provided (top left and right; bottom left

and right in Figure 5.2).

Use screws and washers that are sturdy enough to

support the cabinet weight of approximately 10 lbs.

Cabinet dimensions are to the nearest 1/8 inch. Refer

to Section 11, Cabinet Dimensions and Clearance for

drawings of dimensions and clearance.

The expanded view at right (Figure 5.3) shows

an example of a ¼” bolt and washer inserted in

the front side of the cabinet.

The system should be mounted in a convenient

location near the UV254 analyzer to be cleaned

(less than 2 ft.).

Figure 5.1: Cleaning fluid bottle

holder

Figure 5.2: Mounting cabinet

Figure 5.3: Sample bolt and washer

for attachment

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 7

5.4 Plumbing

Process water from a pressurized source flows through the Auto Clean system and into the connected

instrument for measurement.

Piping is required to be ¼” OD flex tubing of whatever pressure rating is needed for the particular site. Figure

5.4 displays the two push-to-connect inlet and outlet ports on the side of the Auto Clean system.

The Auto Clean system is connected in series with the instrument to be cleaned. It is preferred to keep the

tubing between the Auto Clean and instrument less than 2 feet. Configurations for the UV254 analyzer are

outlined in Figure 5.6.

Note: If installing with a Dual Feed system, the Auto Clean will be installed prior to the Dual feed on the Stream

1 port (See Figure 5.5). Refer also to the Dual Feed manual for further instructions.

Figure 5.4: Auto Clean system ports

From Process

To Analyzer

To Stream 1

From Process

To Analyzer

Figure 5.5: Auto Clean plumbing with Dual Feed

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 8

5.4.1 Connecting a UV254 Analyzer

1. Connect ¼” OD flex tubing from a pressurized source to

the IN port on the Auto Clean system.

2. Connect ¼” tubing from the OUT port on the Auto Clean

to the IN port on the side of the analyzer.

3. Connect ¼” tubing to the OUT port on the analyzer and

divert to drain.

IMPORTANT: The test water must be allowed to flow unrestricted to

drain so that no significant pressure will occur inside the flow cell.

IMPORTANT: If system was supplied with Dual Feed Option, be sure

to review the Dual Feed manual for additional plumbing information.

Figure 5.6: UV254 Analyzer and Auto Clean plumbing connections

Water In

Water Out

(To Drain)

Auto Clean System

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 9

5.5 Electrical and Communication

The power and communication line from the UV254

analyzer feeds into the Auto Clean system via an

electrical conduit fitting at the bottom of the cabinet. The

system is powered and controlled through the

connected UV254 analyzer.

Connections at the analyzer are shown in Figure 5.7.

•White and green wires to terminal 7 and 8 (Clean

Out). Polarity is not important.

•Black wire to terminal 9 (24 VDC Out -).

•Red wire to terminal 10 (24 VCD Out +).

The terminal block connections at the Auto Clean

system control board are shown in Figure 5.8.

1. Connect the white and green wires leading from

the UV254 analyzer to the right terminal block.

Polarity is not important.

2. Connect the power wires leading from the

analyzer to the left terminal block. The black

power wire connected to the left (-) terminal and

red wire to the right (+) terminal.

Figure 5.8: Auto Clean system communication and power

connections

Figure 5.7: UV254 Analyzer connections

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 10

6 Start Up and Operation

6.1 Start Up

Once plumbing and electrical connections have been made, you need to enable the cleaning system and enter

settings for cleaning configuration. This is accomplished through the UVM5000 Operator Interface. Section 8

gives more detail on menu selections.

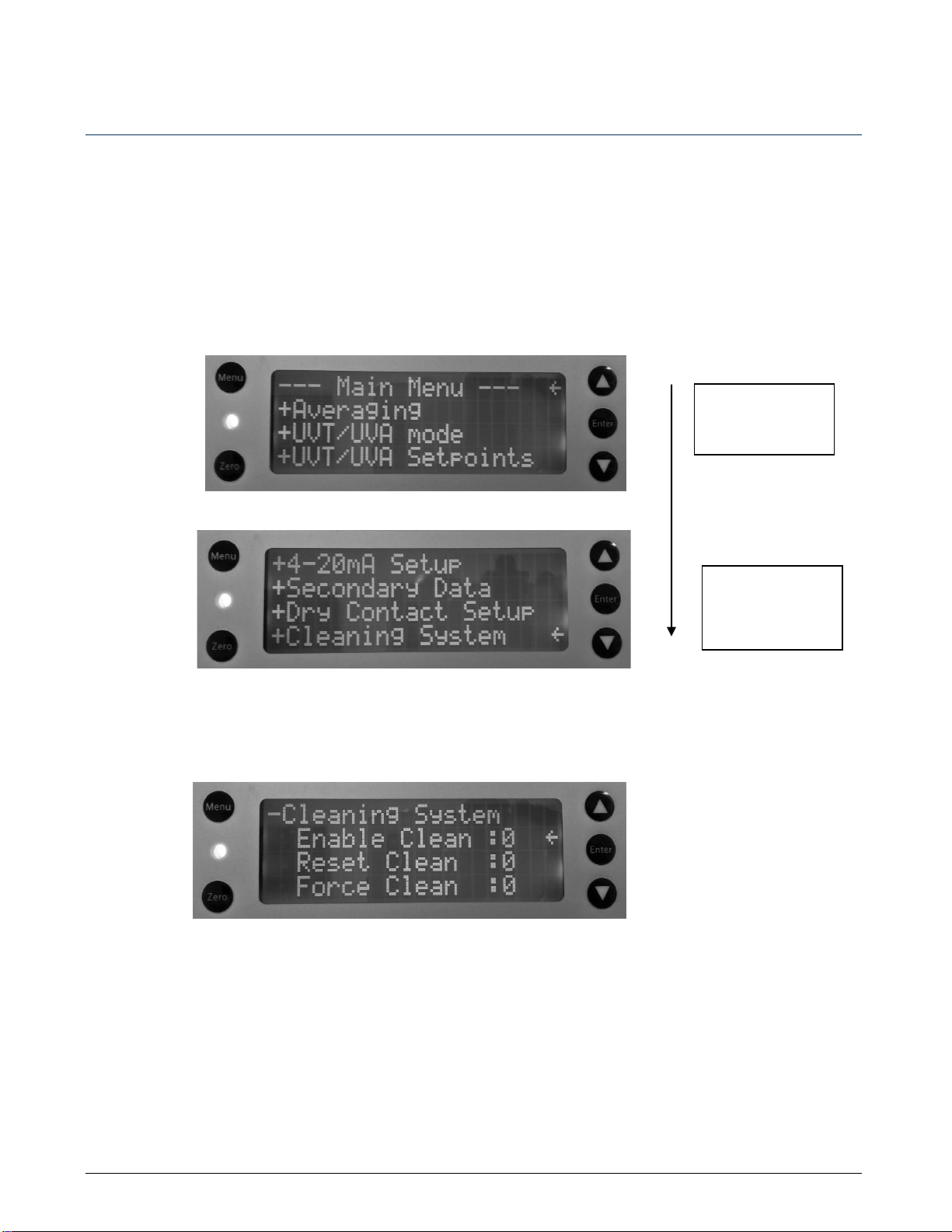

From the main menu, press the down arrow button to scroll to the +Cleaning system menu. Access the Main

Menu page by pressing the Menu button. You may need to press the button more than once to have the screen

displayed.

1. To enable the cleaning system, scroll down to ‘Enable Clean’ and press Enter to enable the cleaning

system. The 0 turns to 1, which signifies the item has been selected and therefore, enabled.

Scroll down by

pressing the down

arrow repeatedly.

Press Enter to

expand the

+Cleaning System

menu.

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 11

2. Scroll down from the last entry until the +Clean Frequency menu is displayed. Expand the menu by

pressing the Enter button. Seven selections are available. The default is 4: 3 days. De-select a

frequency by scrolling to it, and then pressing Enter to remove the checkmark. Conversely, select an

option by scrolling the arrow to it, and then press Enter to place a checkmark beside it.

Implementing these two settings is the minimum you need for set up. The system is ready for use. For all other

functions, refer to Section 8, Cleaning Configuration. If the system encounters any problems, associated alarms

or warnings are displayed on the Operator Interface of the UVM5000.

To turn the Auto Clean system off, disable the device by removing the checkbox opposite Enable Clean

(reverse of step 1).

6.2 Operation

The system consists of a 3-way stainless solenoid valve, a peristaltic pump, and a 1L chemical cleaner storage

container. The cleaning process is initiated automatically on a preselected time interval or can be manually

triggered.

The cleaning process consists of the following steps:

1. Solenoid shuts off the process water flow to the analyzer flow cell (LED turns on).

2. Solenoid opens flow from peristaltic pump to the analyzer flow cell.

3. Peristaltic pump turns on and pumps cleaning solution into the analyzer flow cell.

4. The pump turns off and the system waits to allow the chemical cleaning solution to remove fouling and

staining present on the walls of the quartz flow cell.

5. The pump turns on in the opposite direction to re-capture the cleaning chemical.

6. Solenoid valve opens the water flow from the process to purge out the cleaning solution (LED turns off).

The process is now complete.

During the cleaning cycle, the measured UVA/UVT value shown on the M series instrument is held to the last

value measured before the cycle started and released after the purge time is complete.

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 12

7 Cleaning

The Auto Clean system comes with a 1L chemical storage bottle. After

a cleaning cycle, approximately 85% of the used cleaning fluid is

pumped back into the bottle reducing the need to replenish the fluid

on a regular basis.

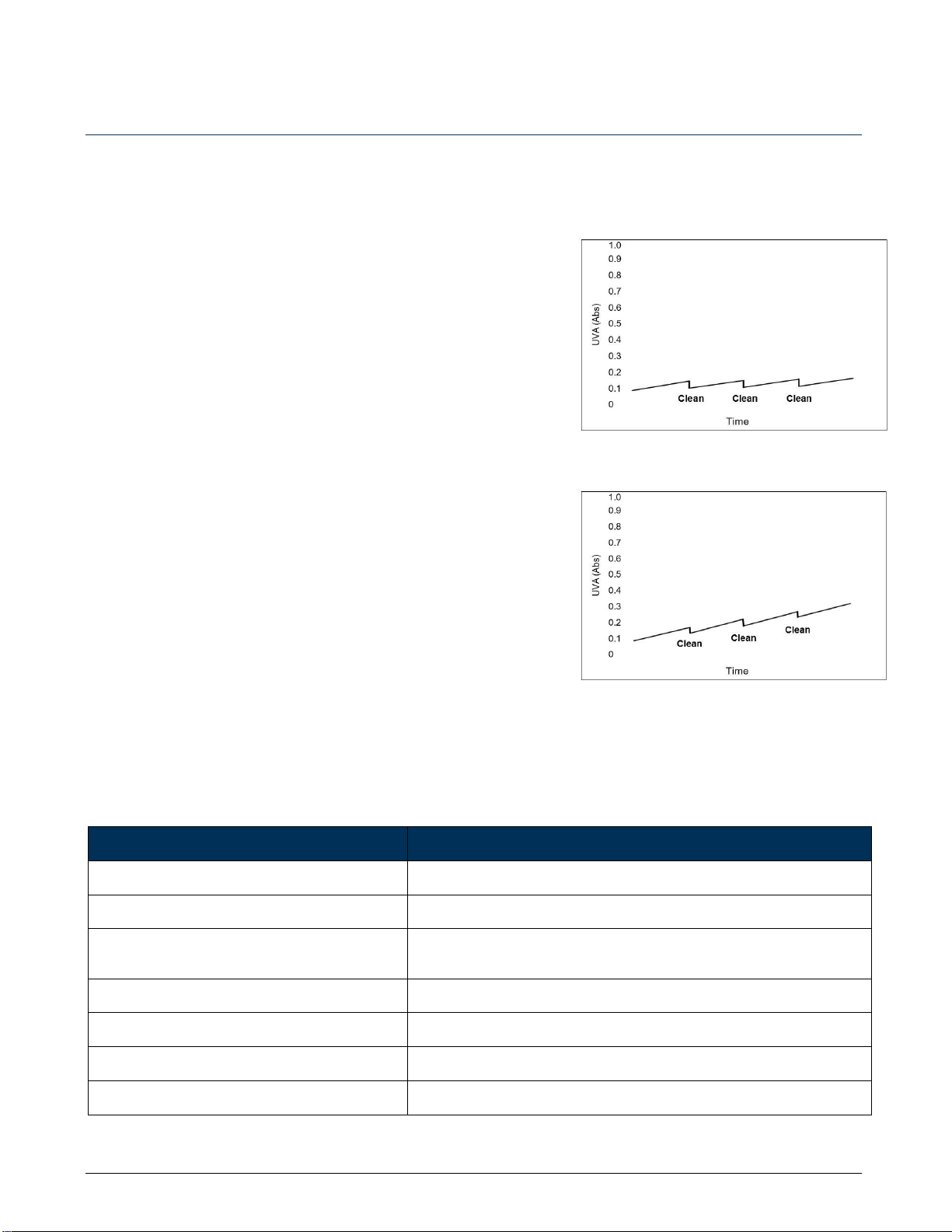

Two important factors that affect the sensor performance are the

cleaning fluid used to clean the flow cell, and how often the flow cell

is cleaned (cleaning frequency).

Cleaning Frequency

The optimum frequency of cleaning is quite variable depending on

the amount and type of fouling agents in the water. This will be

dependent on the application and installation point.

For wastewater, a higher frequency will be required (ex. 1-24hrs)

whereas high purity water will require a lower frequency (ex. once a

month). Each installation will be different and require configuration

onsite.

Once in operation, observe the flow cell for signs of fouling prior to

the first cleaning cycle. If fouling is present, increase the cleaning

frequency accordingly. The measured data can also be observed for

signs of a saw tooth effect as shown in Figure 7.1. If the saw tooth

shows an upward trend, as shown in Figure 7.2, the sensor is drifting

and cleaning frequency must be increased.

Cleaning Fluid

Selecting an effective cleaning solution is essential for optimal

performance. The following commercial cleaning solutions and acids

are readily available to remove common fouling agents.

Table 3: Commercial cleaning solutions

SOLUTION

FOULING AGENTS

Lactic Acid <20% solution (CLR®)

Removes lime, calcium, rust, magnesium, and other dissolved minerals

Sulfamic Acid <10% solution (Lime Away®)

Removes lime, calcium, rust, magnesium, and other dissolved minerals

Phosphoric Acid <30% solution (Rust Off,

Hagasen Blue)

Removes lime, calcium, rust and color staining

Citric Acid <20% solution

Removes mineral scaling

Sodium Hypochlorite <6% solution (Not bleach)

Removes oil, grease and biofilm

Acetic Acid <20% solution

Removes oil and grease

Sulfuric Acid <10% solution

Removes oil and grease

Figure 7.1: Effective cleaning

Figure 7.2: Inadequate cleaning

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 13

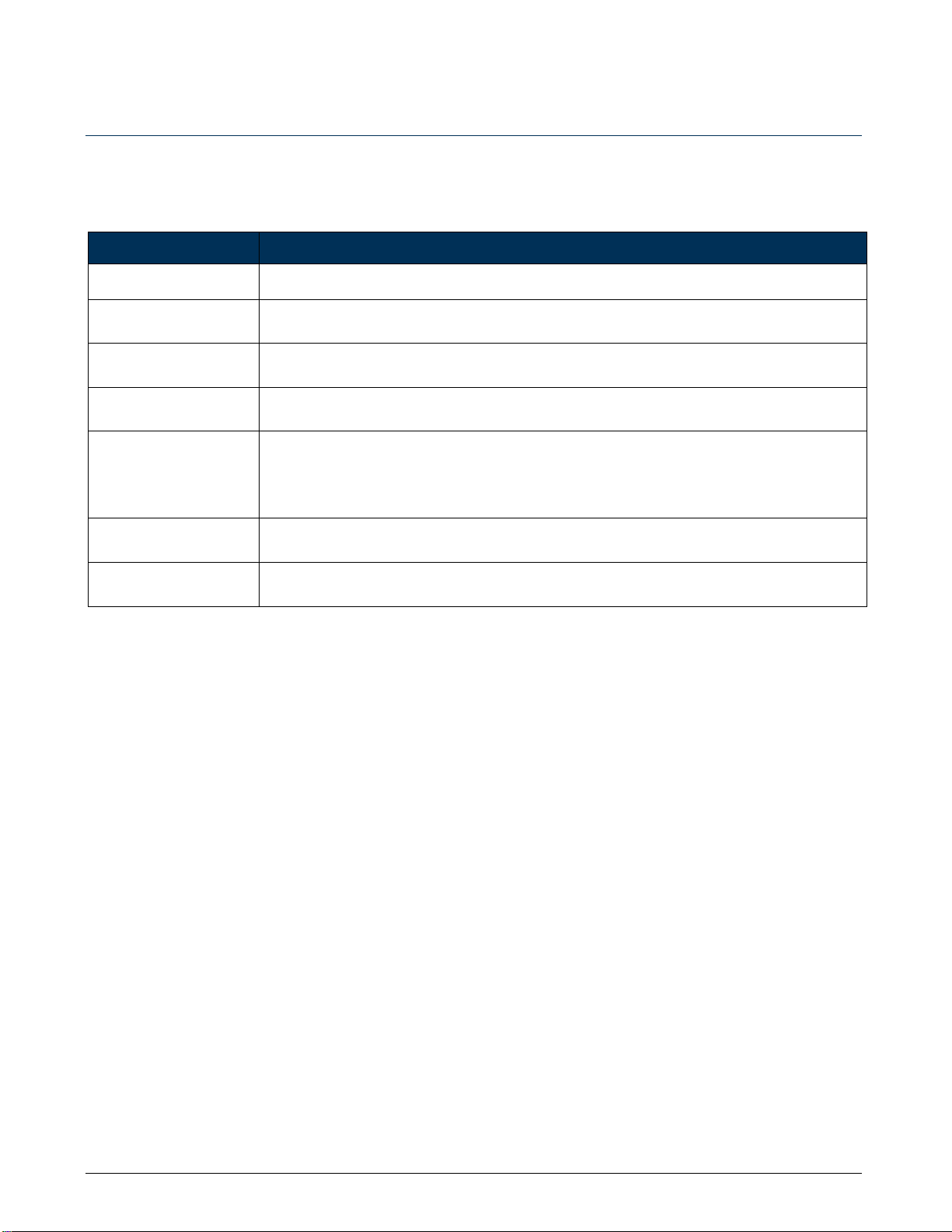

8 Cleaning Configuration

The Auto Clean system is controlled and configured through the M series analyzer. Below is a general

summary of the functions and configurations for the system.

Table 4: Menu functions and configuration for Auto Clean System

MENU

DESCRIPTION

-Cleaning System

Enable Clean

Cleaning must be enabled for the Auto Clean system to operate.

Reset Clean

When the cleaning fluid is changed or refilled, the user must do a Reset to reset the counter on

the cleaning bottle.

Force Clean

At any time, the user can trigger a cleaning cycle by selecting force clean. This does not

interfere with the normal cleaning schedule.

Pumping Time

Pumping Time allows for configuration of time (in seconds) the cleaning system pumps

cleaning fluid to the sensor. The pumping time should be configured to ensure the cleaning

fluid reaches and fills the quartz flow cell prior to the 10-minute holding period. Longer

distances between the cleaning system and sensor will require a longer pumping time. Default

setting is 120 seconds, suitable for a tube length of 24-36 inches.

-Clean Frequency

Clean Frequency allows the frequency of cleaning to be configured i.e. hour, day, week, or

month. Default is 3 days.

-Alarms

If enabled, alarm conditions are displayed on the main menu.

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 14

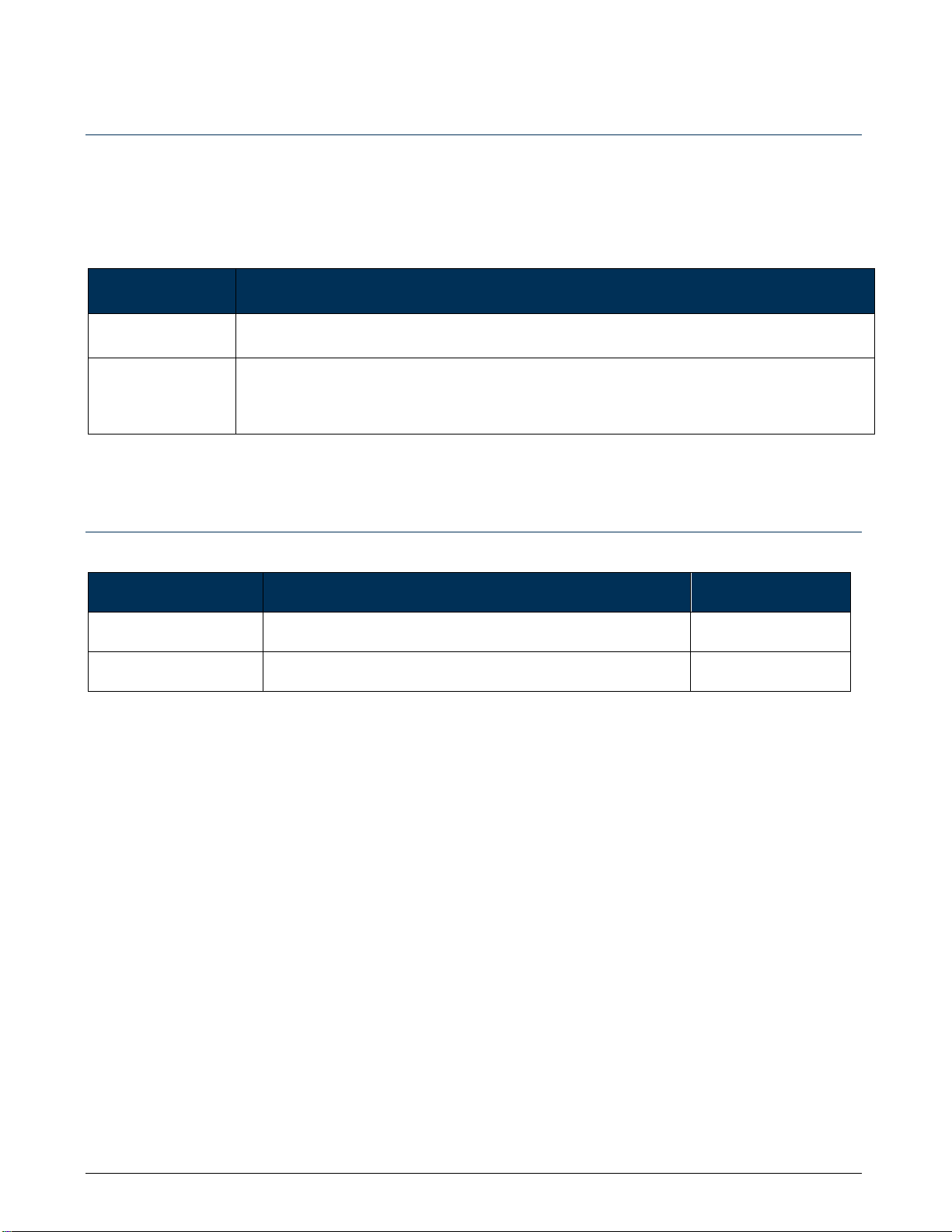

8.1 UVM5000 Organics Monitor Menu

Table 5: UVM5000 menu selection of cleaning configuration

MENU ITEM

DESCRIPTION

CLEANING SYSTEM

Enable Clean

Press Enter then up/down to select 0 or 1 to turn on automatic cleaning system

Reset Clean

Press Enter then up/down to select 0 or 1 to reset fluid alarms after refilling fluid

Force Clean

Press Enter then up/down to select 0 or 1 to force a cleaning cycle

Pumping Time

Press Enter then up/down to select 60, 90 or 120 seconds

CLEAN FREQUENCY

0: No Cleaning

1: 4 hours

2: 12 hours

3: 24 hours

4: 3 days

5: 1 week

6: 2 weeks

7: 1 month

Select

Press Enter then up/down to select cleaning frequency (value 0-7)

ALARMS

Cleaning

Alarm status (0= no alarm 1=alarm)

Clean Fluid Empty

Alarm status (0= no alarm 1=alarm)

Clean Fluid Low

Alarm status (0= no alarm 1=alarm)

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 15

9 Maintenance

Following the manufacturer’s recommended maintenance schedule will ensure optimal performance of the

product. Parts and accessories are outlined in Section 10.

A standard recommended maintenance schedule for the Auto Clean system is as follows:

Table 6: Maintenance tasks and frequency for Auto Clean system

FREQUENCY

TASK

Site Specific

•Automatic cleaning cycle configuration to ensure proper sensor cleaning

Weekly

•Visual inspection for leaks, corrosion or other issues.

•Inspect cleaning fluid levels. Replenish if necessary.

•View connected analyzer or controller display for configured cleaning alarms.

10 Parts and Accessories

Table 7: Spare parts for Auto Clean system

PRODUCT NAME

DESCRIPTION

PART NUMBER

Cleaning Fluid Bottle

1 Liter bottle for chemical fluid storage

25115

Chemical Pump Tubing

Replacement internal pump tubing for chemical pump

25120

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 16

11 Cabinet Dimensions and Clearance

The front, side, and back views of the cabinet are shown below to the nearest 1/8 inch. The back view gives the

dimensions relevant for spacing of screws to mount the cabinet. Allow a clearance of 6 inches around the

cabinet for unit connection.

Chemtrac UV Auto Clean - v 2.1

Chemtrac, Inc. 17

12 Warranty

Chemtrac, Inc. warrants its equipment to be free from defects in material and workmanship for a period of one

(1) year from date of shipment to the original purchaser. Upon receipt of written notice from purchaser, seller

shall repair or replace the equipment (at option of Chemtrac, Inc.).

Chemtrac, Inc. assumes no responsibility for equipment damage or failure caused by:

1. Improper installation, operation, or maintenance of equipment.

2. Abnormal wear and tear on moving parts caused by some processes.

3. Acts of nature (i.e. lightning, etc.)

This warranty represents the exclusive remedy of damage or failure of equipment. In no event shall Chemtrac,

Inc. be liable for any special, incidental, or consequential damage such as loss of production or profits.

For further assistance or service please contact:

Chemtrac, Inc.

1555 Oakbrook Dr.

Suite 100

Norcross, GA 30093

Tel: 770-449-6233

Tel: 800-422-8722 (toll-free in US)

Fax: 770-447-0889

Email: chemtrac@chemtrac.com

Website: chemtrac.com

Table of contents