China ZQ127-25Y User manual

MODEL ZQ127/25Y

DRILL PIPE POWER TONG

PARTS OPERATION AND

MAINTENACE MANUAL

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

SAFETY CAUTION

1.Operators should read and understand this manual before operation.

2.Operators should wear protective clothing, hard hat and safety boots.

3.Tie the back guy according to the instructions.

4.Make sure to operate at the side of the tong opening.

5.Close the safety door in make-up/break-out operation.

6.Keep hands away from rotating parts.

7.Keep sundries out of the operation range.

8.Cut off the hydraulic source and move the tong off the wellhead during maintenance,

changing dies or other parts.

9.Never use the power tong under over-pressure or over-torque conditions, otherwise

the tubing will be damaged and so the planetary gear of the tong will be damaged.

10.Keep the tong turning center according to the center of tubing before

make-up/break-out, otherwise the planetary gear of the tong would be damaged.

11.Don’t dismantle or add parts to the tong.

12.Please adopt the original fitting parts made by TEDA.

If the manual is changed or revised later, we have no obligation to notify any

person.

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

TABLE OF CONTENTS

1 . S ummary ………………………………………………………………1

2 . Te chni c al paramete r……………………………………………………1

3 . Ins tal l ati o n……………………………………………………………1

3 . 1 l i fti ng …………………………………………………………………1

3 . 2 l e v el i ng ………………………………………………………………1

3.3 Tie the bac k guy………………………………………………………1

4. Operation Instruction……………………………………………………2

4.1 The Choice of Die Seats………………………………………………2

4.2 The Choice of Die………………………………………………………2

4.3 Note of break out operation……………………………………………2

5. Maintenance and lubrication……………………………………………3

6. Common troubles and remedy……………………………………………4

7. Attached figures and part list……………………………………………5

8 . Eas y - damag e d parts l i s t……………………………………………23

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

1. Summary

Model ZQ127-25Y Drill Pipe Tong is mouth-opening type power tong used for make up and break out 2

3/8"-3 1/2"drill pipe, 3 1/2"-4 1/2"tubing and 4 1/2"-5 1/2"casing in the oil field well workover operation.

2. Technology Parameter

2.1 Application Range

2 3/8"-3 1/2"drill pipe, 3 1/2"-4 1/2" tubing and 4 1/2"-5 1/2"casing

2.2 Rated Oil Supply Pressure 16Mpa

2.3 Rated Oil Supply Amount 120 lpm

2.4 Rated High Gear Torque 5.1 KN.m

2.5 Rated Low Gear Torque 25 KN.m

2.6 Rated Rotation Speed at High Gear 43 rpm

2.7 Rated Rotation Speed at Low Gear 8 rpm

2.8 Overall Weight 680 kg

2.9 Dimension of Combination tongs 1270×770×780mm

3. Installation

3.1 Lifting

Connect the lifting bucket to the lifting bar of the master tong, lift the drill pipe tong at the well servicing

rig. The lifting point is supposed to be 15m above the wellhead. In the state of free suspension, the center of

the tong head is 0.5m away from the wellhead. The suspension height is appropriate when the backup tong

clamps the drill pipe connector or the coupling of tubing, or casing.

3.2 Leveling

Adjusting the adjusting screws on the lifting bar to keep the drill pipe level, if not, the clamping will fail to

work.

3.3 Tie the back guy

Tie one end of the back guy to the rig, the other end to the seat of the back guide pole of the drill pipe

tong, the back guy is supposed to be able to bear load of 50 KN. When the drill pipe is in the making-up state,

the back guy should be vertical to the drill pipe so as to make the operator safety.

1

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

4.Operation Instruction

4.1 The Choice of Die Seats

Part No.

Part Name

Application Range

Steel

Mark

Note

ZQ25.1.1-7(1)

Die Seat (1)

2 3/8"drill pipe, 3 1/2"tubing

3 1/2"

ZQ25.1.1-7(2)

Die Seat (2)

2 7/8"drill pipe, 4"tubing

4"

ZQ25.1.1-7(3)

Die Seat (3)

4 1/2" tubing, 3 1/2" tubing coupling,

4 1/2"casing

4 1/2"

For

selection

ZQ25.1.1-7(4)

Die Seat (4)

3 1/2" drill pipe, 4" tubing coupling,

5"casing, 4 1/2" casing coupling

5"

ZQ25.1.1-7(5)

Die Seat (5)

4 1/2" tubing coupling, 5 1/2" casing,

5"casing coupling

5 1/2"

ZQ25.1.1-7(6)

Die Seat (6)

5 1/2"casing coupling

6 1/8"

For

selection

Choose die seats according to the seat marks and part numbers.

4.2 Choice of dies

Part No.

Part Name

Application Range

Steel Mark

Note

XYQ12.Z-01.12(2)

Die

2 3/8"-3 1/2" drill pipe, 3 1/2"-4 1/2"

tubing, 3 1/2" tubing coupling, 4 1/2"

casing

89-114

XYQ12.Z-01.12(3)

Die

3 1/2" drill pipe, 4"-4 1/2" tubing

coupling, 5"-5 1/2" casing, 5"-5 1/2"

casing coupling

121-156

Choose dies according to the steel marks and part numbers.

4.3 Note of break out operation

The pin axle of the guide pole must be moved to the lowest hole when break out operation.

2

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

5. Maintenance and lubrication

5.1 Before work, the fastening screws must be checked to see whether they are loose, if loose, the screws

must be tightened.

5.2 Before work, enough lubricating grease should be added to each transmitting part.

5.3 After each use, the tong body must be check to clean up water or oil stain in time.

5.4 After each well operation is over, the tong must be cleaned with diesel fuel, and lubricating grease must

be added to each transmitting part after cleaning.

5.5 After each operation, the steam is prohibited to clean the power tong for it could cause the grease lost.

5.6 The temperature of the hydraulic should be kept below 65℃, overheating may lead to the failure of the

hydraulic system sealing.

5.7 The hydraulic oil must be kept clean to guarantee the normal filtering of the oil filter, if the oil is dirty, it

should be replaced in time.

5.8 The choice of hydraulic oil

5.8.1 YC-N46 low freezing hydraulic oil, suitable ambient temperature: -20℃-+40℃.

5.8.2 YB-N46 wear resistant hydraulic oil, suitable ambient temperature: -10℃-+40℃.

5.8.3 YA-N46 ordinary hydraulic oil, suitable ambient temperature: 0℃-+40℃.

3

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

6. Common troubles and remedy

Common troubles

Reason

Remedy

Tong dies slip

Die groove fill with hard objects

Cleaning up sundries in the

groove

Dies over worn

Replace new dies

Tong body not level

Adjusting tong level (master

tong and backup tong)

Master tong head backup

tong head not in alignment

with the opening

Retaining pin can’t be contained by

reset knob axle

Turn the reset knob and reset

again

Master tong clamps well

while backup tong slips

The turning direction of jaw plate

frame of backup tong opposite to

the turning direction of the master

tong

Exchange the positions of the

two hoses.

4

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

7. Attached figures and part list.

7.1 General assembly (Fig1. Table1)

Fig1. General assembly

Table1. Detailed table for General assembly

Item

Purchase No.

Part No.

Part name and Description

QTY

1

ZQ25-1

ZQ25.1

Master tong

1

2

ZQ25-3

ZQ25.3

Front guide pole assembly

2

3

ZQ25-2

ZQ25.2

Backup tong

1

4

ZQ25-4

ZQ25.4

Back guide pole assembly

1

5

ZQ25-5

XYQ12.YD-01.1

Hydraulic bucket

1

5

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

7.2 Master tong (Fig2. Table2)

Fig2. Master tong

Table2. Detailed table for Master tong

Item

Purchase No.

Part No.

Part name and Description

QTY

1

Shell assembly and parts

1

2

tong head assembly and brake

mechanism

1

3

ZQ25-30

Hydraulic motor J6K-625

1

4

Hand control valve and lift valve

1

5

Drive gear assembly and parts

1

6

ZQ25-21

ZQ25.1.6

Shift mechanism assembly

1

6

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

7.2.1 Shell assembly and parts (Fig3. Table3)

Fig3. Shell assembly and parts

7

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

Table3. Detailed table for Shell assembly and parts

Item

Purchase No.

Part No.

Part name and Description

QTY

1

ZQ25-47

GB70

Hexagon socket head cap screw M10×25

29

2

ZQ25-111

GB93

Washer 10

23

3

ZQ25-126

ZQ25.1.9-1

Safety door shaft

1

4

ZQ25-127

GB91

Cotter pin 5×35

1

5

ZQ25-53

Tension spring(Φ17×95)

1

6

ZQ25-125

ZQ25.1.9.1

Main body of safety door

1

7

ZQ25-121

ZQ25.1.8-6

Pin shaft

1

8

ZQ25-116

ZQ25.1.8-1

Tong head cover

1

9

ZQ25-12

ZQ25.1-2

Tong body

1

10

ZQ25-8

XYQ3C.Z.3

Fore handle(RH)

1

11

ZQ25-6

ZQ25.1-1

Fore support seat

2

12

ZQ25-7

GB70

Hexagon socket head cap screw M12×25

4

13

ZQ25-202

GB93

Washer 12

4

14

ZQ25-10

GB5781

Hex head bolt M10×20

6

15

ZQ25-177

GB65-85

Slotted cylinder head screw M6×10

12

16

ZQ25-203

ZQ25.1-14A

Name plate

1

17

ZQ25-48

ZQ25.1.7

Hanging rod

1

18

ZQ25-51

GB70

Hexagon socket head cap screw M12×100

2

19

ZQ25-204

ZQ25.1.7-1A

Hanging caput

2

20

ZQ25-50

GB91

Cotter pin 4×30

2

21

ZQ25-49

ZQ25.1-16

Hanging pin shaft

2

22

ZQ25-29

GB1152

Oil cup M10×1

2

23

ZQ25-46

ZQ25.1-13A

hanging seat

2

24

ZQ25-9

XYQ3C.Z.4

Fore handle(LH)

1

25

ZQ25-55

XYQ3C.Z-37

Back handle

2

26

ZQ25-26

XYQ12.Z-62

Tail guy pin

1

27

ZQ25-27

GB91

Cotter pin 5×35

1

28

ZQ25-24

ZQ25.1-4

Back guide rod seat

1

29

ZQ25-25

GB1096

Parallel key 12×40

2

30

ZQ25-23

XYQ3C.Z-21

spring

1

31

ZQ25-22

XYQ12.Z.1-21

Locating block

1

32

ZQ25-100

ZQ25.1.5-8

Bearing cover

1

33

ZQ25-20

GB70

Hexagon socket head cap screw M8×25

6

8

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

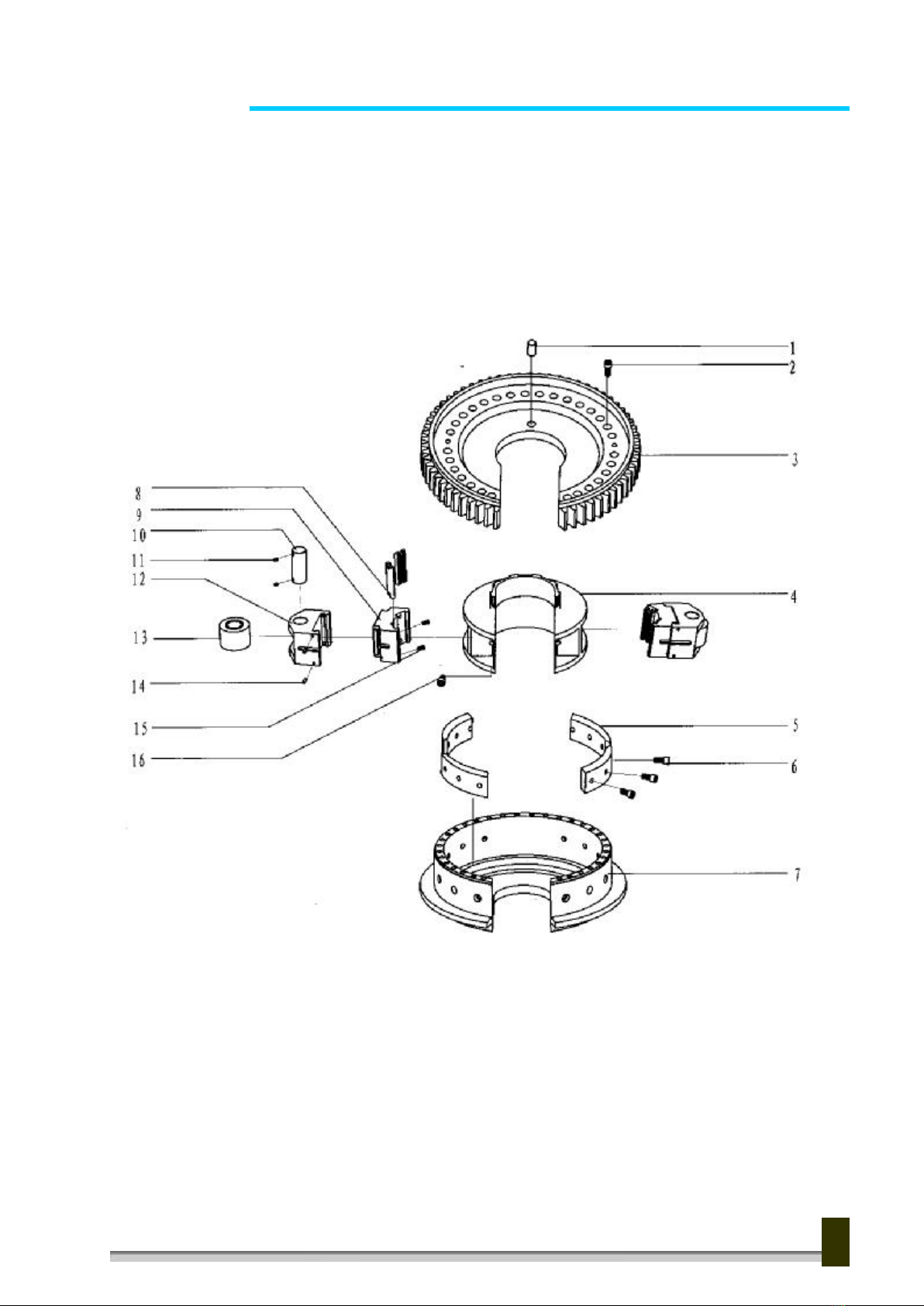

7.2.2 Tong head assembly(Fig4. Table4)

Fig4. tong head assembly

9

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

Table4. Detailed table for tong head assembly

Item

Purchase No.

Part No.

Part name and Description

QTY

1

ZQ25-69

ZQ25.1.1-9

Retainer pin

1

2

ZQ25-70

GB70

Hexagon socket head cap screw M12×30

30

3

ZQ25-68

ZQ25.1.1-8

Open gear

1

4

ZQ25-58

ZQ25.1.1-3

Jaw set bracket

1

5

ZQ25-57

ZQ25.1.1-2

Ramp

4

6

ZQ25-7

GB70

Hexagon socket head cap screw M12×25

12

7

ZQ25-56

ZQ25.1.1-1

Main body

1

8

ZQ25-65

XYQ12.Z-01.12(2-3)

Die (2-3)

Each

for 4

9

ZQ25-64

ZQ25.1.1-7(1-5)

Die seat(1-5)

Each

for 2

10

ZQ25-62

ZQ25.1.1-6 Roller shaft

2

11

ZQ25-63

GB71 Slotted cone end fastening screw M8×10

4

12

ZQ25-59

ZQ25.1.1-4

Jaw set

2

13

ZQ25-61

ZQ25.1.1-5

Roller 2

14

ZQ25-60

GB119

Cylindrical pin 6×18

4

15

ZQ25-66

XYQ12.Z-01.11

Screw retainer pin

20

16

ZQ25-67

XYQ12.B-10

Set screw

2

10

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

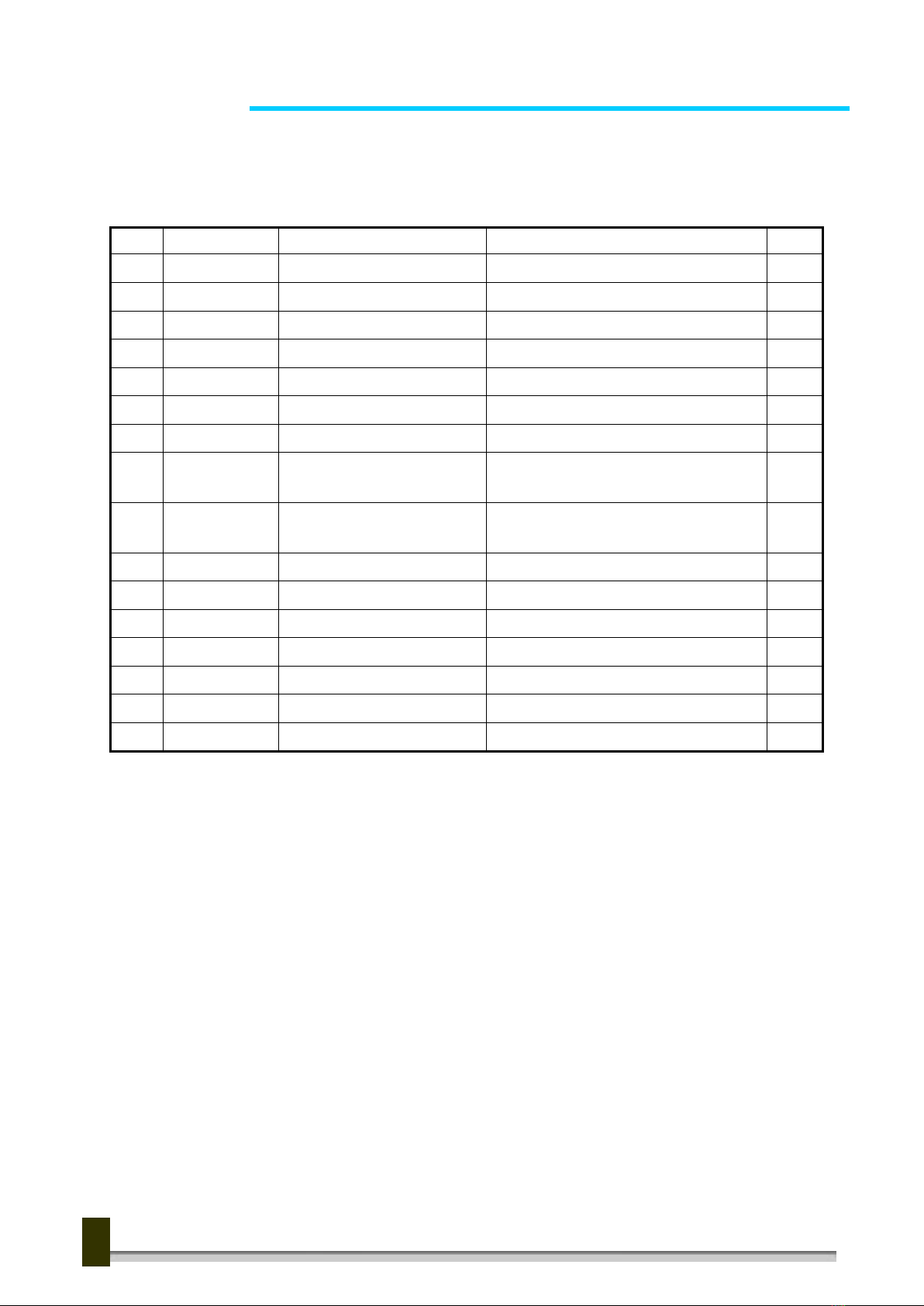

7.2.3 Tong head brake mechanism(Fig5. Table5)

Fig5. tong head brake mechanism

11

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

Table5. Detailed table for tong head brake mechanism

Item

Purchase No.

Part No.

Part name and Description

QTY

1

ZQ25-124

ZQ25.1.8-9

Brake blot

11

2

ZQ25-123

ZQ25.1.8-8

Brake spring

11

3

ZQ25-117

ZQ25.1.8-2

Friction disc

3

4

ZQ25-16

GB68

Slotted countersunk screw M5×10

63

5

ZQ25-109

ZQ25.1.6-2

shim

1

6

ZQ25-118

ZQ25.1.8-3

Brake steel plate

1

7

ZQ25-119

ZQ25.1.8-4

Knob shaft

1

8

ZQ25-14

XYQ12.Z-03

Centralizing roller

21

9

ZQ25-13

ZQ25.1-3

Centralizing roller shaft

21

10

ZQ25-116

ZQ25.1.8-1

Tong head cover

1

11

ZQ25-122

ZQ25.1.8-7

Brake disc

1

12

ZQ25-87

GB70

Hexagon socket head cap screw M6

×10

1

13

ZQ25-120

ZQ25.1.8-5

knob

1

14

ZQ25-47

GB70

Hexagon socket head cap screw M10

×25

4

15

ZQ25-55

XYQ3C.Z-37

Back handle

2

16

ZQ25-121

ZQ25.1.8-6

Pin shaft

1

12

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

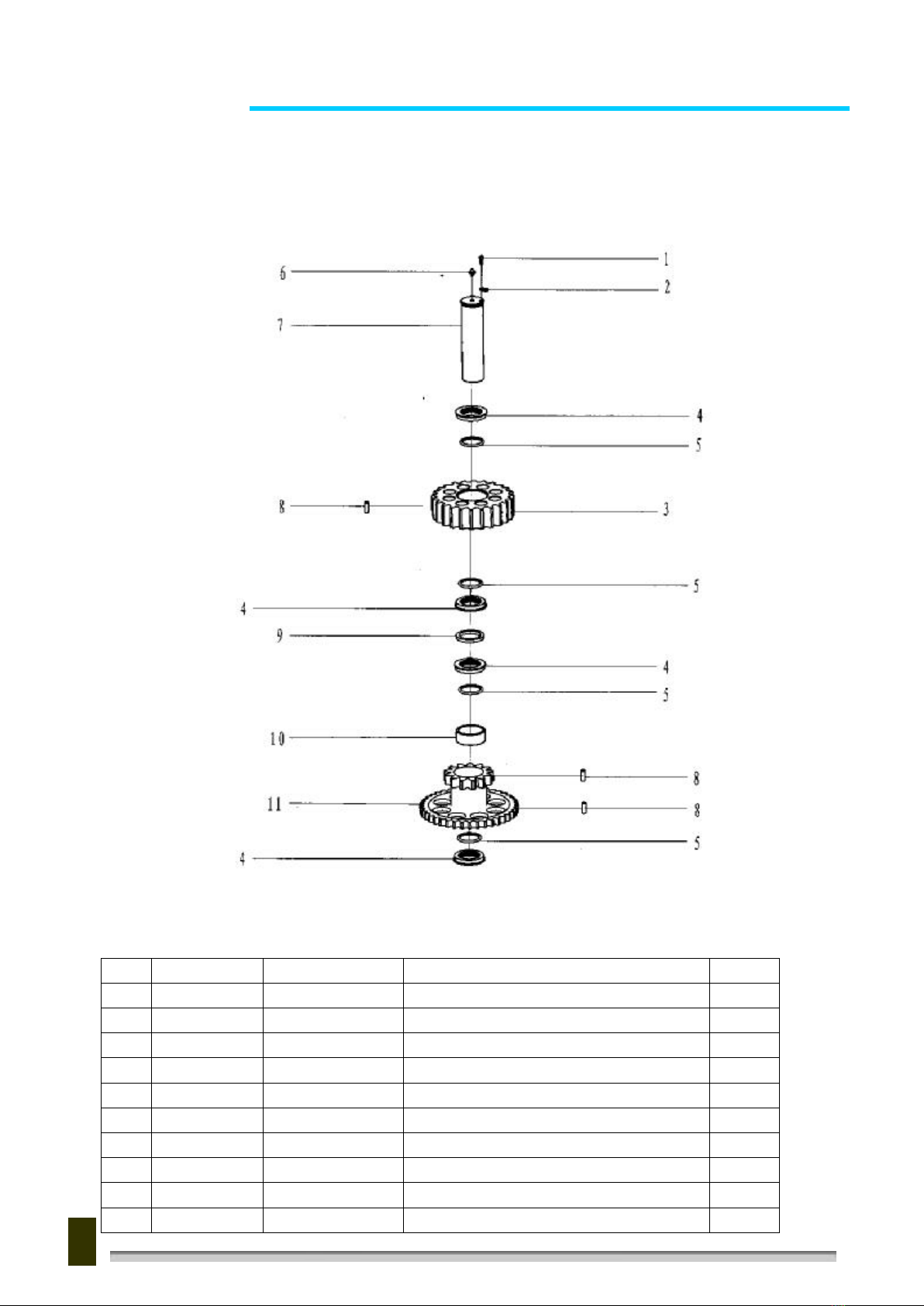

7.2.4 Idle shaft assembly (Fig6. Table6)

Fig6.Idle shaft assembly

Table6. Detailed table for Idle shaft assembly

Item

Purchase No.

Part No.

Part name and Description

QTY

1

ZQ25-86

XYQ3C.Z-5

Locating disc

2

2

ZQ25-80

ZQ25.1.3-4

Idler shaft

2

3

ZQ25-76

ZQ25.1.3-2

Seal ring(1)

4

4

ZQ25-77

GB1235-76

O ring 63×5.7

4

5

ZQ25-75

ZQ25.1.3-1

idler(1)

2

6

ZQ25-78

Roller Φ10×30

40

7

ZQ25-79

ZQ25.1.3-3

Shaft sleeve(1)

2

13

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

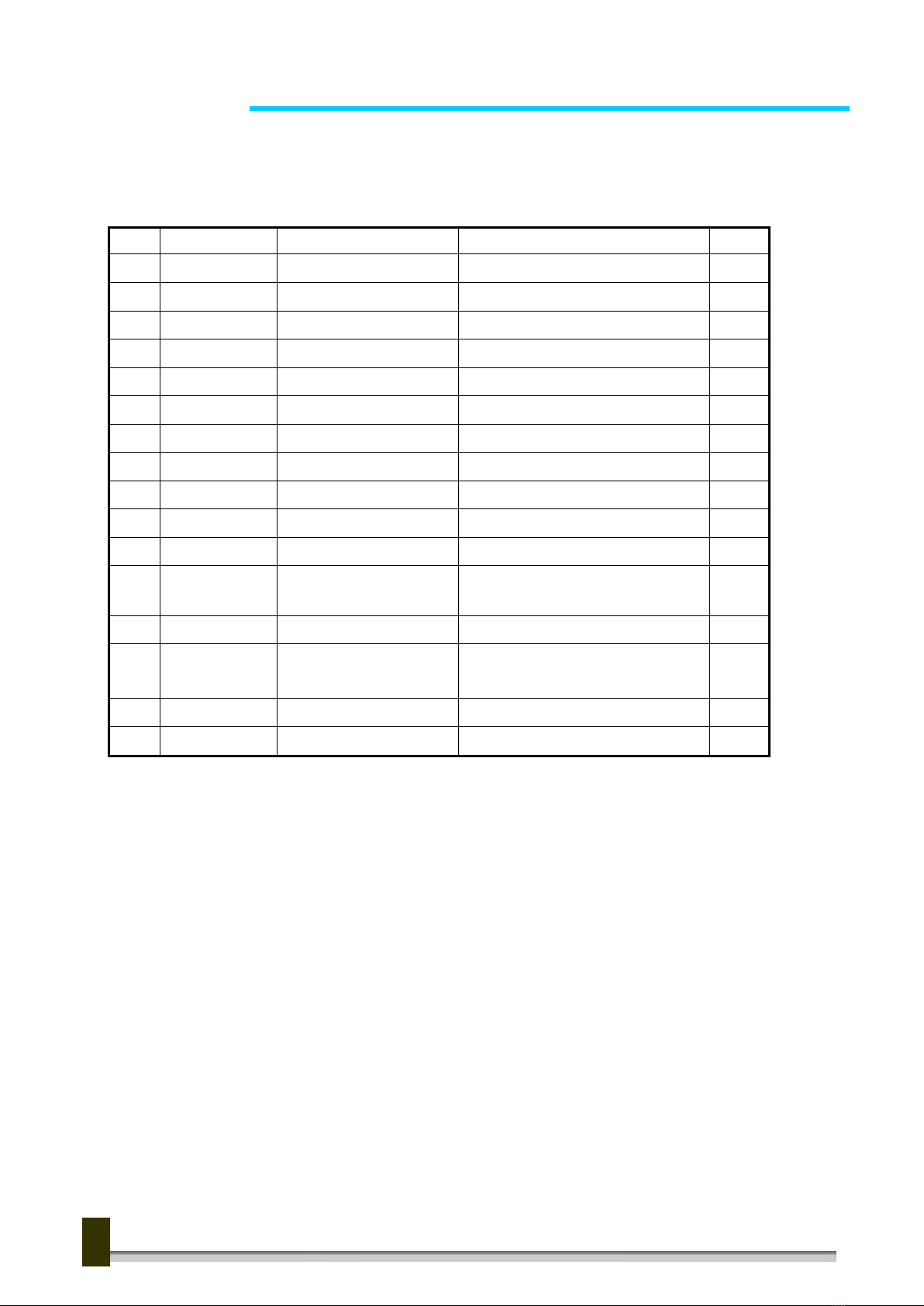

7.2.5 Duplex gear assembly (Fig7. Table7)

Fig7. Duplex gear assembly

Table7. Detailed table for Duplex gear assembly

Item

Purchase No.

Part No.

Part name and Description

QTY

1

ZQ25-87

GB70

Hexagon socket head cap screw M6×10

1

2

ZQ25-86

XYQ3C.Z-5

Locating disc

1

3

ZQ25-84

ZQ25.1.4-4

Idler (2)

1

4

ZQ25-76

ZQ25.1.3-2

Seal ring(1)

4

5

ZQ25-77

GB1235-76

O ring 63×5.7

4

6

ZQ25-29

GB1152

Oil cup M10×1

1

7

ZQ25-85

ZQ25.1.4-5

Duplex shaft

1

8

ZQ25-78

Roller Φ10×30

60

9

ZQ25-83

ZQ25.1.4-3

shim

1

10

ZQ25-82

ZQ25.1.4-2

Shaft sleeve(2)

1

14

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

11

ZQ25-81

ZQ25.1.4-1

Duplex gear(1)

1

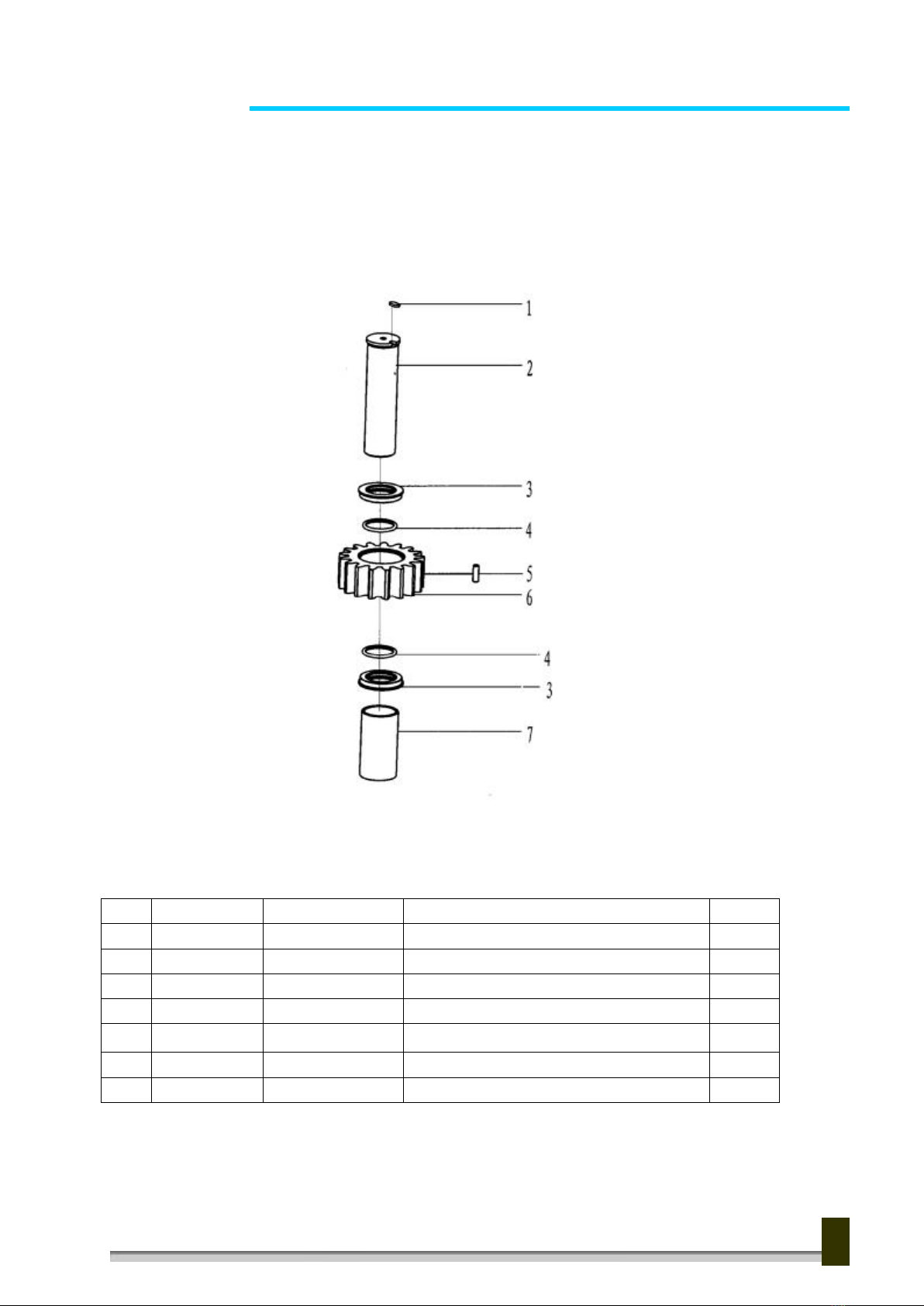

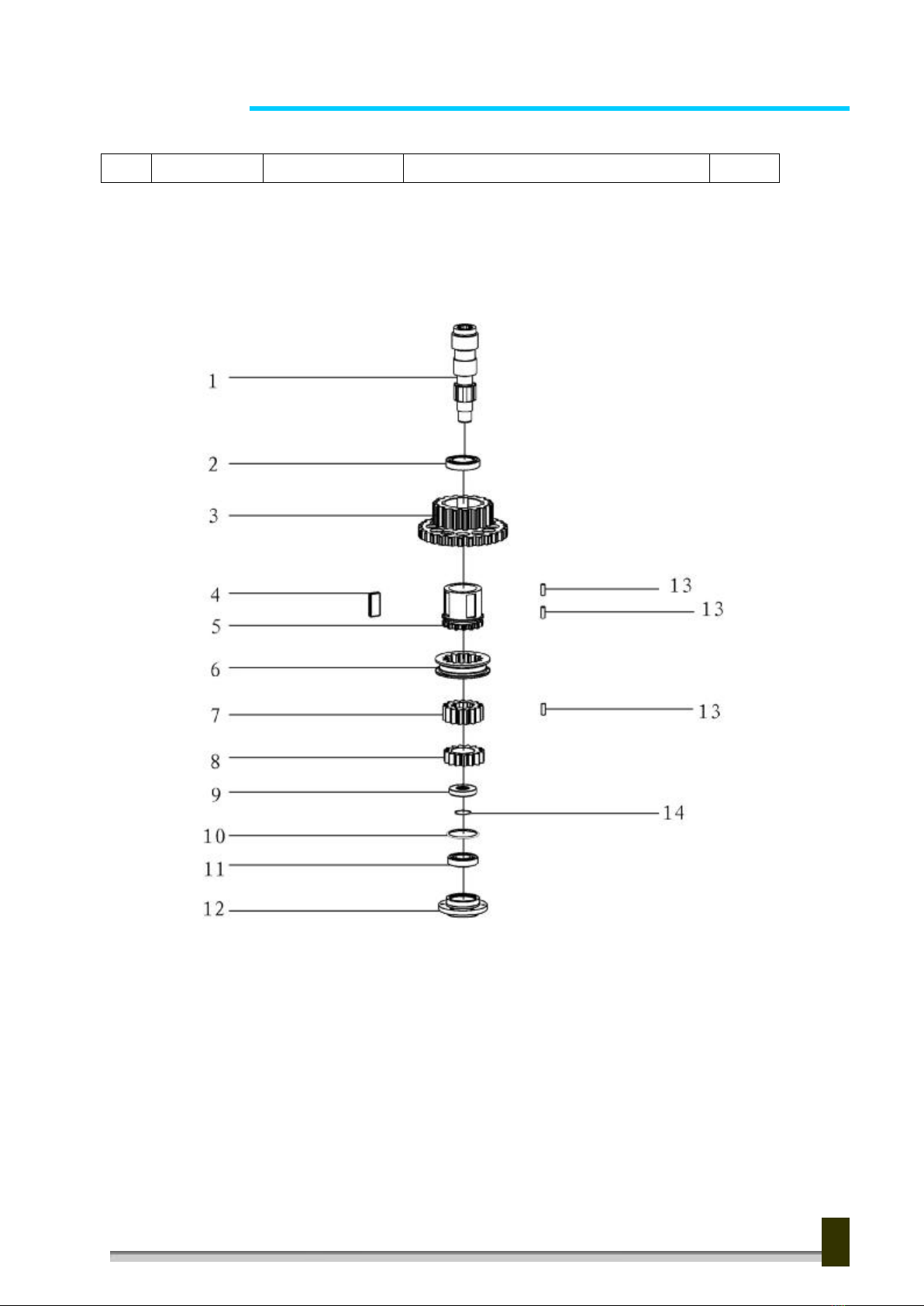

7.2.6 Power input shaft assembly (Fig8. Table8)

Fig8. Power input shaft assembly

15

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

Table8. Detailed table for Power input shaft assembly

Item

Purchase No.

Part No.

Part name and Description

QTY

1

ZQ25-88

ZQ25.1.5-1

Power input shaft

1

2

ZQ25-89

GB276

Deep groove ball bearing 112

1

3

ZQ25-92

ZQ25.1.5-3

Duplex gear(2)

1

4

ZQ25-91

GB1567

Thin flat key 28×10×63

4

5

ZQ25-90

ZQ25.1.5-2

Clutch gear

1

6

ZQ25-94

ZQ25.1.5-5

Inner gear sleeve

1

7

ZQ25-93

ZQ25.1.5-4

Inner spline gear

1

8

ZQ25-95

ZQ25.1.5-6

Shifting gear

1

9

ZQ25-96

ZQ25.1.5-7

Seal ring(2)

1

10

ZQ25-99

GB1235

O ring 80×3.1

1

11

ZQ25-98

GB276

Deep groove ball bearing 207

1

12

ZQ25-100

ZQ25.1.5-8

Bearing cover

1

13

ZQ25-78

Roller Φ10×30

68

14

ZQ25-97

GB1235

O ring 40×3.1

1

16

M o d e l Z Q 1 2 7 / 2 5 Y D r i l l P i p e P o w er T o n g

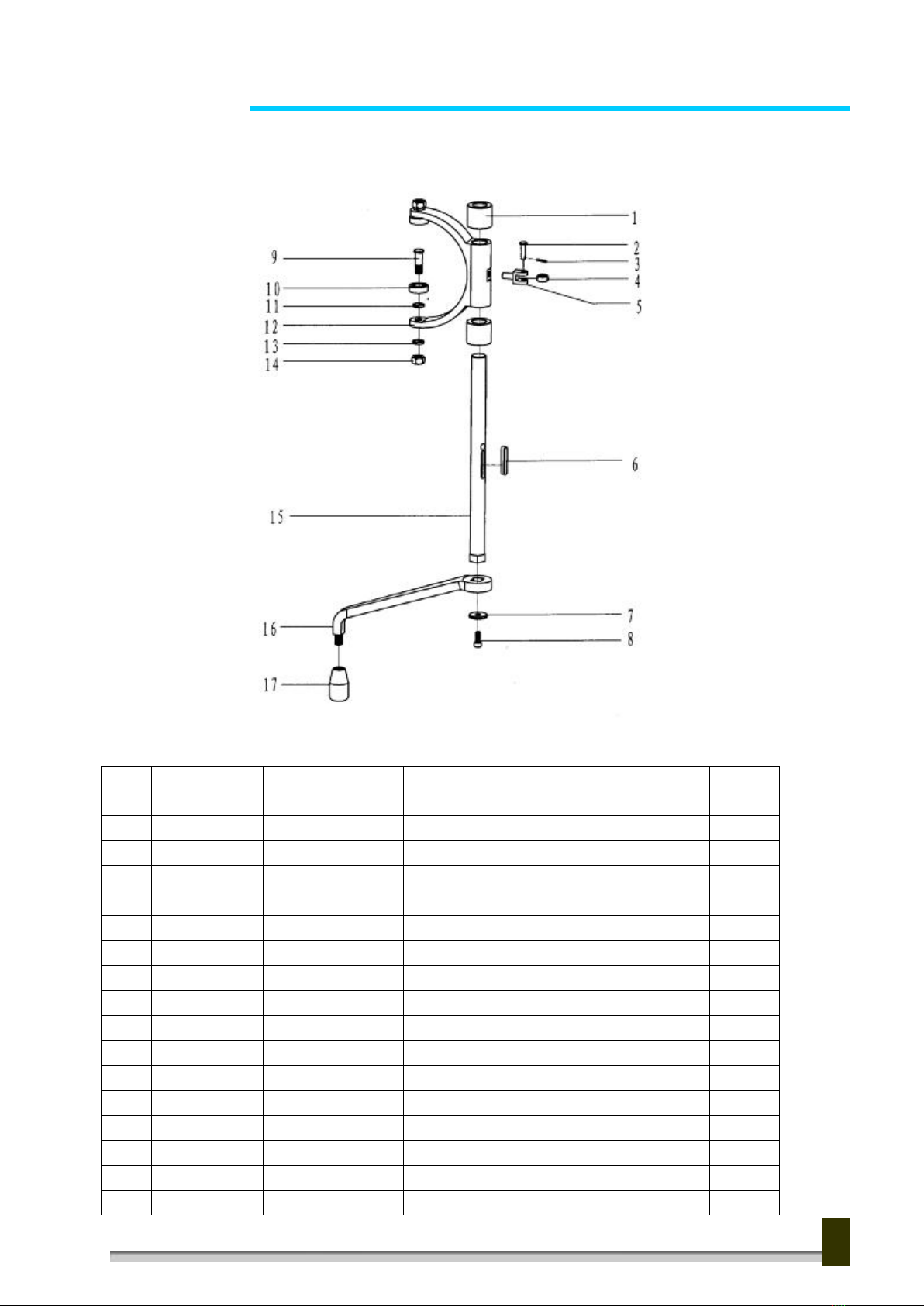

7.2.7 Shifting mechanism assembly (Fig9. Table9)

Fig9. Shifting mechanism assembly

Table9. Detailed table for Shifting mechanism assembly

Item

Purchase No.

Part No.

Part name and Description

QTY

1

ZQ25-101

XYQ12.Z-19.01

Shaft sleeve

2

2

ZQ25-104

XYQ3C.Z.6-4

Roller shaft

1

3

ZQ25-105

GB91

Cotter pin 2×10

1

4

ZQ25-103

XYQ3C.Z.6-3

roller

1

5

ZQ25-106

XYQ3C.Z.6-5

Roller support seat

1

6

ZQ25-107

GB1096

Flat key 6×6×40

1

7

ZQ25-109

ZQ25.1.6-2

shim

1

8

ZQ25-87

GB70

Hexagon socket head cap screw M6×10

1

9

ZQ25-112

XYQ12.Z-19.04

Bolt shaft

2

10

ZQ25-114

GB276

Deep groove ball bearing 100

2

11

ZQ25-113

GB848

Washer 10

2

12

ZQ25-102

XYQ12.Z-19.02

fork

1

13

ZQ25-111

GB93

Washer 10

2

14

ZQ25-110

GB6170

Nut M10

2

15

ZQ25-108

ZQ25.1.6-1

Fork shaft

1

16

ZQ25-115

ZQ25.1.6.1

Operating handle assembly

1

17

ZQ25-205

XYQ3C.Z.5-10

Handle

1

17

Table of contents

Popular Drill manuals by other brands

Makita

Makita DTS131 instruction manual

Hilti

Hilti TE 500-A36 Original operating instructions

Hitachi

Hitachi DS 10DFL2 Handling instructions

Ingersoll-Rand

Ingersoll-Rand 6L Series Product information

Cembre

Cembre SD-15PR-ECO Operation and maintenance manual

Harbor Freight Tools

Harbor Freight Tools Warrior 57383 Owner's manual & safety instructions