-CONTENTS-

❐INTRODUCTION / REQUESTS /

WARRANTY / NOTICES·······································1

FOR SAFE USE··············································· 2

WARNING ························································ 3

❐MAIN FEATURES AND FUNCTIONS ·········· 4

1. BEFORE USE ··················································· 5

1.1 Model Check and Information························· 5

1.2 Attachments and Consumable Parts············· 8

1.3 Flow Chart to Startup······································ 10

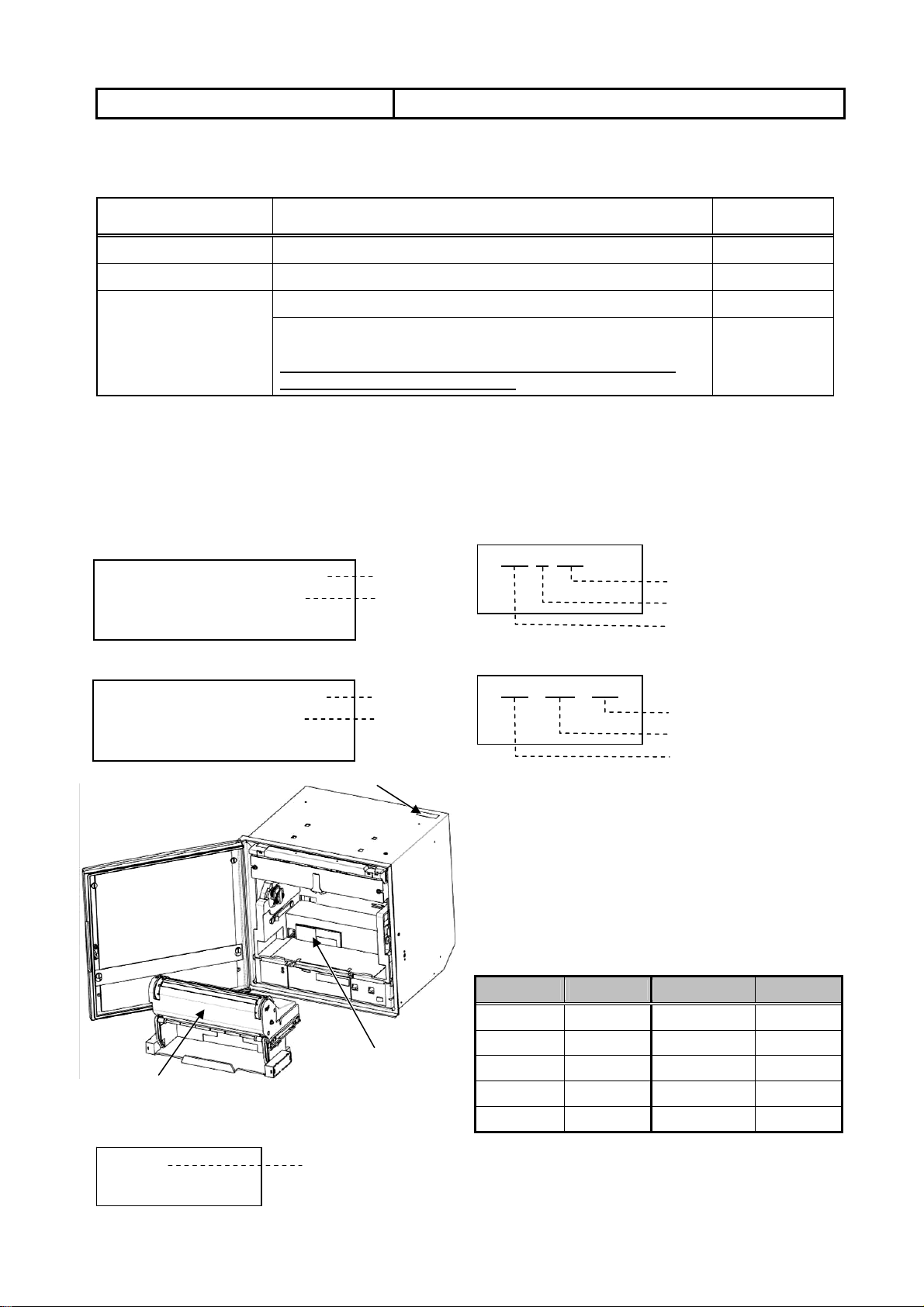

2. INSTALLATION··············································· 11

2.1. Mounting Place ·············································· 11

2.2 External Dimensions ······································ 12

2.3 Mounting Method on Panel

····················· 13

2.4 Release of Shipping Status

····················· 14

3. FRONT····························································· 16

3.1 Names of Front Portions

·························· 16

3.2 Display Operation Part

····························· 17

4. CONNECTIONS ············································· 19

4.1 Terminal Board

·········································· 19

4.2 Cautions on Connection

·························· 20

4.3 Power Supply & Protective Conductor

Terminals

··················································· 21

4.4 Measuring Input Terminals

······················ 22

4.5 Alarm Output Terminals (Optional)

········· 26

5. LOADING························································· 28

5.1 Inkpad Loading (For dot-printing type)

··· 28

5.2 Cartridge Pen Loading (For pen type)

······ 31

5.3 Chart Loading

············································ 34

6. OPERATION/SETTING································· 37

6.1 Turning Power On/Off ···································· 37

6.2 Operation/Setting Change····························· 40

6.3 Chart Feed Operation

······························ 44

6.4 Recording Operation (AUTO CH/

INDICATE Switch)··········································45

6.5 Pen Marker (Only for 2/3 pen type)

·········47

6.6 Chart Speed Change ·····································48

6.7 Alarm Specifications ·······································50

6.8 Alarm Setting ···················································51

6.9 Operation/Setting Function Depending on

Application

·················································58

7. OPERATION····················································60

7.1 Recording Operation (Pen type) ···················60

7.2 Alarm Activation/Reset and Behavior···········61

7.3 Behavior on Abnormal Input··························63

8. OPTION····························································64

8.1 Shunt Resistor for Current Input

··············64

8.2 Dotting Interval 3 Seconds (Dot-printing

type option)······················································65

9. ADJUSTMENT ················································66

9.1 User Indication Adjustment/Indication

Check

·························································66

9.2 Shift Programming··········································75

10. MAINTENANCE············································80

10.1 Routine Inspection

··································80

10.2 Troubleshooting

······································83

1

0.3 Recommended Parts Replacement

Intervals

······················································85

11. SPECIFICATIONS········································86

11.1 Detailed Specifications ·································86

11.2 Option Specifications····································88

11.3 Accuracy Rating List·····································89

12. DISPOSAL ·····················································91

The items marked with

in titles contain and . Read these items without fail.

Caution

Warning