Chore-Time W400B1-CT User manual

DIRECT DRIVE BELT WINCH

INSTRUCTION MANUAL - P2

Part Number / Partie n°

W400B1-CT & W400B3-CT

MF2499B

SANGLE DE COMMANDE DIRECTE DE TREUIL

MANUEL D’UTILISATION - P16

CTB, Inc.

PO Box 2000

Milford, Indiana 46542-2000 USA

Phone (574) 658-4101 Fax (877) 730-8825

Internet: www.choretime.com

CTB ref: 56929 & 57084

2

CHORE-TIME WARRANTY

LIMITED WARRANTY

CTB, Inc. (“Chore-Time”) warrants the new CHORE-TIME Direct Drive Winch to be free from defects in material or

workmanship under normal usage and conditions, for One (1) year from the date of installation by the original purchaser

(“Warranty”). Chore-Time provides for an extension of the aforementioned Warranty period (“Extended Warranty Period”)

with respect to certain Product parts. If such a defect is determined by Chore-Time to exist within the applicable period,

Chore-Time will, at its option, (a) repair the Product or Component Part free of charge, F.O.B. the factory of manufacture or

(b) replace the Product or Component Part free of charge, F.O.B. the factory of manufacture. This Warranty is not

transferable, and applies only to the original purchaser of the Product.

CONDITIONS AND LIMITATIONS

THIS WARRANTY CONSTITUTES CHORE-TIME’S ENTIRE AND SOLE WARRANTY AND CHORE-TIME EXPRESSLY

DISCLAIMS ANY AND ALL OTHER WARRANTIES, INCLUDING, BUT NOT LIMITED TO, EXPRESS AND IMPLIED

WARRANTIES, INCLUDING, WITHOUT LIMITATION, WARRANTIES AS TO MERCHANTABILITY OR FITNESS FOR

PARTICULAR PURPOSES.

CHORE-TIME shall not be liable for any direct, indirect, incidental, consequential or special damages which any purchaser

may suffer or claim to suffer as a result of any defect in the Product. Consequential or Special Damages as used herein

include, but are not limited to, lost or damaged products or goods, costs of transportation, lost sales, lost orders, lost

income, increased overhead, labor and incidental costs, and operational inefficiencies. Some jurisdictions prohibit limitations

on implied warranties and/or the exclusion or limitation of such damages, so these limitations and exclusions may not apply

to you. This warranty gives the original purchaser specific legal rights. You may also have other rights based upon your

specific jurisdiction.

Compliance with federal, state and local rules which apply to the location, installation and use of the Product are the

responsibility of the original purchaser, and CHORE-TIME shall not be liable for any damages which may result from non-

compliance with such rules.

• The following circumstances shall render this Warranty void:

• Modifications made to the Product not specifically delineated in the Product manual.

• Product not installed and/or operated in accordance with the instructions published by the CHORE-TIME.

• All components of the Product are not original equipment supplied by CHORE-TIME.

• Product was not purchased from and/or installed by a CHORE-TIME authorized distributor or certified

representative.

• Product experienced malfunction or failure resulting from misuse, abuse, mismanagement, negligence, alteration,

accident, or lack of proper maintenance, or from lightning strikes, electrical power surges or interruption of electricity.

• Product experienced corrosion, material deterioration and/or equipment malfunction caused by or consistent with the

application of chemicals, minerals, sediments or other foreign elements.

• Product was used for any purpose other than for the care of poultry and livestock.

The Warranty and Extended Warranty may only be modified in writing by an officer of CHORE-TIME. CHORE-TIME shall

have no obligation or responsibility for any representations or warranties made by or on behalf of any distributor, dealer,

agent or certified representative.

Effective: April 2014

3

TABLE OF CONTENTS

CONTENTS

CHORE-TIME WARRANTY ............................................................................................................................................2

TABLE OF CONTENTS....................................................................................................................................................3

SAFETY AND GENERAL INFORMATION .......................................................................................................................4

SPECIFICATIONS............................................................................................................................................................4

DIMENSIONS...................................................................................................................................................................5

INTRODUCTION AND PLANNING ..................................................................................................................................6

MOUNTING......................................................................................................................................................................7

ELECTRICAL CONNECTION...........................................................................................................................................9

SETUP AND ADJUSTMENT..........................................................................................................................................11

MANUAL OPERATION ..................................................................................................................................................12

ELECTRICAL OPERATION............................................................................................................................................12

MAINTENANCE ............................................................................................................................................................13

SERVICE PARTS ...........................................................................................................................................................14

TROUBLESHOOTING....................................................................................................................................................14

PART NUMBERS

Direct Drive Winch

Single Phase

Part No. W400B1-CT

CTB ref: 56929

Three Phase

Part No. W400B3-CT

CTB ref: 57084

Wall Control

Single Phase

Part No. RG37612P-CT

CTB ref: 56930

Wall controls are available separately

Three Phase

Part No. RG37812P-CT

CTB ref: 57085

4

Signal words are used in conjunction with the safety–alert symbol to identify the severity of the warning.

DANGER indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

SAFETY AND GENERAL INFORMATION

SPECIFICATIONS

CAUTION, WARNING AND DANGER DECALS have been placed on the equipment to warn of potentially

dangerous situations. Care should be taken to keep this information intact and easy to read at all times. Replace missing or

damaged safety decals immediately.

SAFETY–ALERT SYMBOL

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual and on your equipment safety signs. Follow recommended precautions

and safe operating practices.

Keep safety signs in good condition. Replace missing or damaged safety signs.

THIS IS A SAFETY–ALERT SYMBOL. When you see this symbol on your equipment, be alert to the

potential for personal injury. This equipment is designed to be installed and operated as safely as possible...

however, hazards do exist.

Understanding Signal Words

Direct Drive Belt Winch General Specification

Lift Capacity Max. (lbs) 885

Max Lift Speed (ft/min) ~10.1

Drum Torque (ft-lbs) 177

Drum Diameter (inch) 2.62 (min) 5.5 (Max)

Maximum Lift Height (ft) 12.8

Belt Size (mm x mm) 40 X 1.5

Mounting Bolt Spec 4 X M12 HT

Limits 2 X NC Micro Switch

IP Code IP55

Manual Operation USE 13mm Socket

Weight (lbs) 73

Suitable Controller Single Phase

RG37612P-CT Wall Control

(sep. avail.) CTB Ref: 56930

Three Phase

RG37812P-CT Wall Control

(sep. avail.) CTB Ref: 57085

Operating Temperature 10°C - 40°C / 50°F - 104°F

Application Indoor use only

Single Phase Electrical Specification

Motor Power 1.5Hp, 1.1kW

Full Load Current 7.1 Amp

Voltage 230V

Phase 1 (2 X Hot Wire)

Frequency 60Hz

Capacitor( Uf) Run-35 / Start 200

Motor Fuse 12 Amp Slow Blow

Three Phase Electrical Specification

Motor Power 1.5Hp, 1.1kW

Full Load Current 5.5 Amp

Voltage 230V 3-Phase

Phase 3

Frequency 60Hz

5

DIMENSIONS

8.130in

206.50mm

9.921in

252mm

0.512in

13mm

0.059in

1.50mm

19.961in

507mm

13 mm Hex(A/F)

[Approx:1/2"]

11.850in

301mm

1.535in

39mm

8.406in

213.50mm

6.492in

164.88mm

153.540in

3900mm

1.969in

50mm

4.528in

115mm

1.218in

30.93mm

7.992in

203mm

6

INTRODUCTION AND PLANNING

INTRODUCTION

Congratulations on your purchase of the Chore-Time Direct Drive Belt Winch. This winch stands alone in the market as the

fastest and most robust winch of its kind. The installation of a Direct Drive Belt Winch ensures extreme longevity and trouble

free operation.

PLANNING

The Direct Drive Belt Winch is designed to be installed inside livestock buildings to lift drinker lines (and other similar

systems) between the ground level and ceiling space.

The Direct Drive Belt Winch features a single phase motor coupled to a drive system comprising two cam activated limit

switches to allow stopping at the fully lowered and raised positions.

Suitable controls will be required to switch the motor direction and accept the limits switch inputs.

HANDLING

Ensure you wear personal protection equipment (proper clothing, gloves, dust masks). Never use your hands at dangerous

locations (eg cables, sharp edges etc). In order to safely lift the Direct Drive Belt Winch, use an approved M12 or 1/2" lifting

eye or strap as shown below:

Use an M12 or 1/2" lifting eye as

shown to allow lifting into the proximity

of the final mounting location

7

MOUNTING

An electrician must disconnect electric

power to the winch and control before

removing or opening covers.

CEILING MOUNTING

The Direct Drive Belt Winch is designed to be

mounted to a concealed or web truss structure in

livestock buildings. The roof truss structure must be

engineered to ensure mounting of the winch and the

relevant applied loads will be adequately supported.

Refer to page 5 for mounting bolt hole spacing and

size for fabrication of a suitable mounting structure.

Refer below for mounting examples.

CONCEALED TRUSS MOUNT

WEB TRUSS MOUNT

Mounting

plate

Mounting

plate

Truss braces

Truss braces

Ensure the belt wraps on to the

drum on the side closest to the

structural member as shown.

8

MOUNTING

An electrician must disconnect electric

power to the winch and control before

removing or opening covers.

FLAG MOUNTING

Mount the Belt winch in flag configuration using at least 2 x M12

High Tensile (Grade 8.8) bolts and locking nuts to secure the

winch to a suitably engineered vertical or horizontal structural

member as shown below. Tighten to a torque of 40-45Nm.

(Note: Fasteners are not supplied). Weld fixing may be suitable if

carried out in accordance with proper structural advice and by a

suitably qualified person.

9

ELECTRICAL CONNECTION

THE DIRECT DRIVE BELT WINCH MUST:

• BE CONNECTED IN ACCORDANCE WITH THE WIRING RULES OF THE COUNTRY IN

WHICH IT IS INSTALLED

• NOT HAVE ENCLOSURES LEFT OPEN FOR EXTENDED PERIODS (EXCESS DUST WILL

VOID WARRANTY)

ELECTRICAL CONNECTION

The Direct Drive Cable Winch is designed to be operated with the Chore-Time reversing

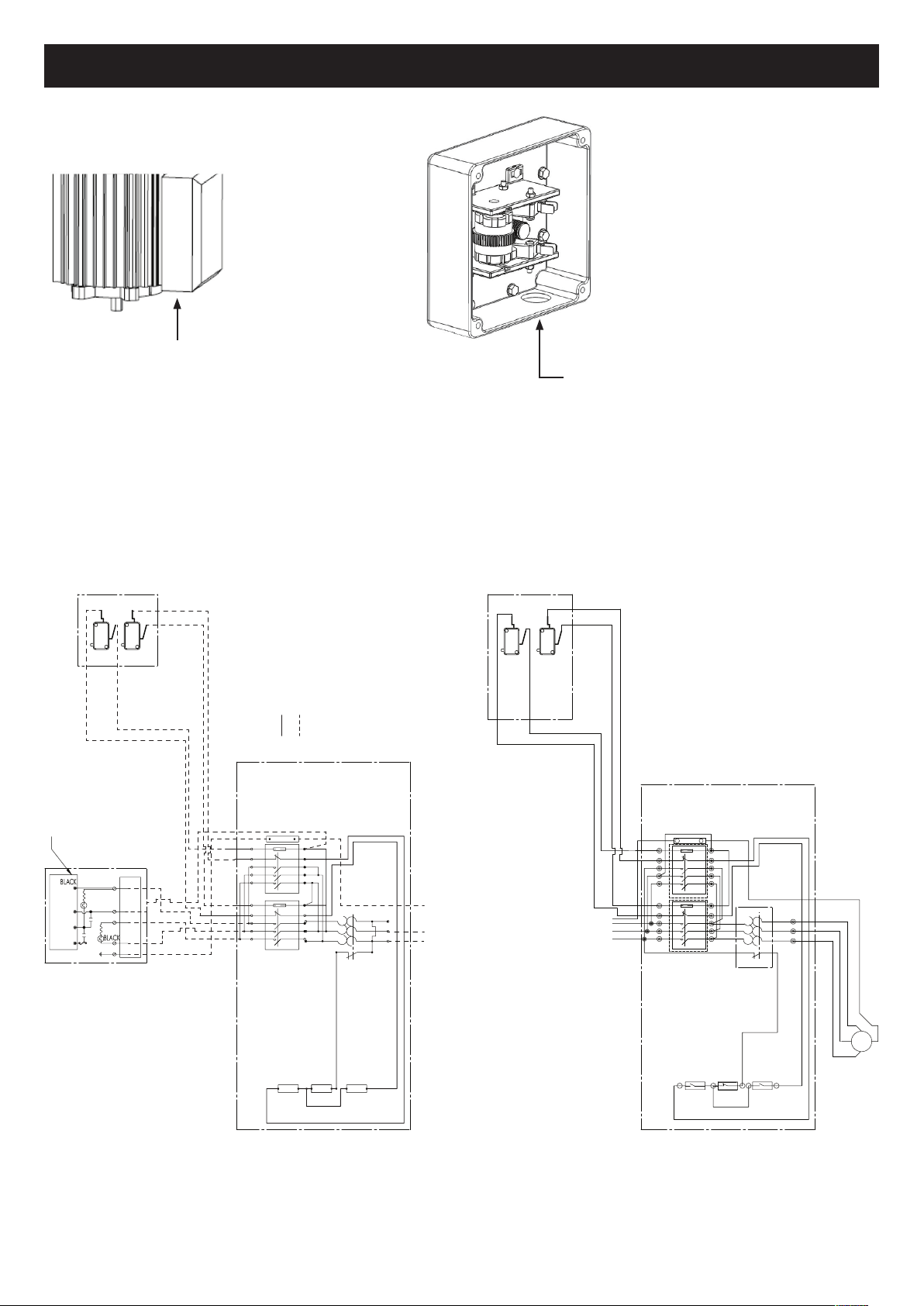

starter controls. The internal connection diagram is shown below:

L2L1

L2

F

L1

R

E

MAINS

UP LIMIT

DOWN LIMIT

E

M

230V SUPPLY IN

Operation of the above control

panels is via a simple two position

control as shown below.

REVERSING

STARTER

WALL

CONTROL

SINGLE PHASE ELECTRICAL CONNECTION THREE PHASE ELECTRICAL CONNECTION

STOP

UP

DOWN

L2L1 L3

L2L1

L3

E

MAINS

230V 3~

UP LIMIT

DOWN LIMIT

E

M

NO

NC

NO

E

10

ELECTRICAL CONNECTION

CABLE ENTRY

SYSTEM WIRING DIAGRAM

SINGLE PHASE THREE PHASE

Connect with min. 18 gauge wire using conduit or gland to

meet min IP55.

Suitable UL listed Liquid Tight Cordgrips (glands) must be

used; cable diameter 0.260” (Minimum) to 0.545” (Maximum).

Connect with min. 18 gauge wire using

conduit or gland to meet minimum IP55 (If

rubber grommet is fitted, remove and

discard to allow use of cable gland).

Sw

GREY

BLUE

RED

L2

F

EARTH

R

L1

Rw

Cr

Cs

RED

BLUE

WHITE

RECS-220P

L2

L1 L2

F

L1

NC- E-STOP

NO- UP

NO-DOWN

Winch Limits

WINCH

MOTOR

R

DOWN

CONTACTOR Pre-wired

Installer to wire

UP

CONTACTOR

E

Electronic Centrifugal

Switch

Controller

SPLIT PHASE

MAINS SUPPLY

LI-115V, L2-115V

NC

NC

Mains supply

230V/60Hz/3 Phase

with No Neutral

E

NC

NC

NC

NO

NO

Winch Limits

DOWN

Contactor

UP

Contactor

E

M

L1 L2 L3 E

Overload

Contactor

Up

Down

E-Stop

L1

L2

L3

11

With primary connection of the winch complete in accordance with relevant control box, it is time to test the operation.

Carefully follow the next steps to ensure safe setup:

1) Ensure the winch is properly secured and the lift cables clamped accordingly.

2) Check and make sure both limit cams are positioned away from their relevant micro switches.

3) Secure all covers, and supply mains power.

CHECKING OPERATIONAL DIRECTION

4) Operate the winch momentarily in one direction to check that the UP switch will lift the load.

5) If incorrect, isolate mains power and proceed as follows: (ref page 10)

- Swap F and R on the single phase model

- Swap L1 and L2 on the three phase model

6) Secure covers, supply power to the system, and check for correct operational direction.

SETTING LIMITS

WARNING: Limits are sensitive; a small cam movement may correspond to a large amount winch travel.

- Position one cam to depress a switch (the other should be well clear of the switch)

- Note the switch that you have activated

- Supply power and activate in up direction momentarily

- If the winch lifts up then the limit switch noted above is the lower limit

- If the winch doesn't move it is the upper limit (momentarily activate in the close direction to confirm this)

- Proceed to adjust each friction held cam and operate the winch to achieve the required set positions.

SETUP AND ADJUSTMENT

Friction held limit cams.

Use a small flat blade

screwdriver to adjust

12

MANUAL OPERATION

13mm or 1/2"

Hex Socket

NOTE: 13mm or 1/2"

Hex Socket is not

supplied with the winch

Isolate mains power before using the manual crank feature as shown below.

Use a 13mm (1/2 in) hex socket with a suitable drive bit (not included) to operate the winch manually.

Rotation of the socket will operate the winch in either direction.

In operation the winch will require the user to hold the controlling switch to raise or lower the load.

The winch should operate quietly with only the hum of the motor, and perhaps some pulley noise depending on the

condition and/or lubrication of the various pulleys connected to the load.

If the winch produces any abnormal noises such as grinding, rattling or squeaking, cease use immediately and isolate the

power. Refer to Troubleshooting on page 14, and/or contact a suitably qualified technician to inspect and/or repair.

ELECTRICAL OPERATION

13

MAINTENANCE

DANGER!

Power MUST be turned off before servicing or adjusting the winch. Isolate the supply when cleaning!

Any works requiring access to electrical connections or junction boxes must be carried out by

a qualified electrician!

WINCH MODEL

The Direct Drive Belt Winch is built for extreme service life and does not need

any internal maintenance. Only trained and competent persons should carry

out maintenance.

Certain mechanical aspects of the installation should be routinely checked

and rectified by a qualified fitter or electrician.

Any works requiring access to electrical connections or junction boxes must

be carried out by a qualified electrician.

If the winch has exceeded the stated working life, replacement is

recommended. All inspections must be monthly beyond the working life.

DISPOSAL

If disposal is required, it should be done using the most up-to-date recycling

technology according to local regulations and laws. Drain oil via the plug

provided on the gearbox, and contain it for safe disposal at a suitable

recycling yard.

It is recommended that the winch be taken to a scrap metal recycling yard.

MAINTENANCE LOG

MONTHLY

Inspect for signs of wear or damage to

lifting equipment

Check proper operation of the winch (lift/

lower)

QUARTERLY

Check tightness of fixing bolts and

tighten if needed (ref page 7)

Check mounting structure, including

welds / fasteners etc

Check for any abnormal noises

Brush down and wipe over the winch

with a damp cloth

MONTHLY DATE CHECKED / COMPLETE (SIGN)

Inspect for signs of wear or damage to lifting belt

Check proper operation of the winch (lift/lower)

MONTHLY DATE CHECKED / COMPLETE (SIGN)

Inspect for signs of wear or damage to lifting belt

Check proper operation of the winch (lift/lower)

MONTHLY DATE CHECKED / COMPLETE (SIGN)

Inspect for signs of wear or damage to lifting belt

Check proper operation of the winch (lift/lower)

QUARTERLY DATE CHECKED / COMPLETE (SIGN)

Check tightness of fixing bolts and tighten if needed (ref pg 7)

Check mounting structure, including welds / fasteners etc

Check for any abnormal noises

Brush down and wipe over the winch with a damp cloth

MONTHLY DATE CHECKED / COMPLETE (SIGN)

Inspect for signs of wear or damage to lifting belt

Check proper operation of the winch (lift/lower)

MONTHLY DATE CHECKED / COMPLETE (SIGN)

Inspect for signs of wear or damage to lifting belt

Check proper operation of the winch (lift/lower)

MONTHLY DATE CHECKED / COMPLETE (SIGN)

Inspect for signs of wear or damage to lifting belt

Check proper operation of the winch (lift/lower)

QUARTERLY DATE CHECKED / COMPLETE (SIGN)

Check tightness of fixing bolts and tighten if needed (ref pg 7)

Check mounting structure, including welds / fasteners etc

Check for any abnormal noises

Brush down and wipe over the winch with a damp cloth

(Copy multiples of this blank

form for future record keeping)

14

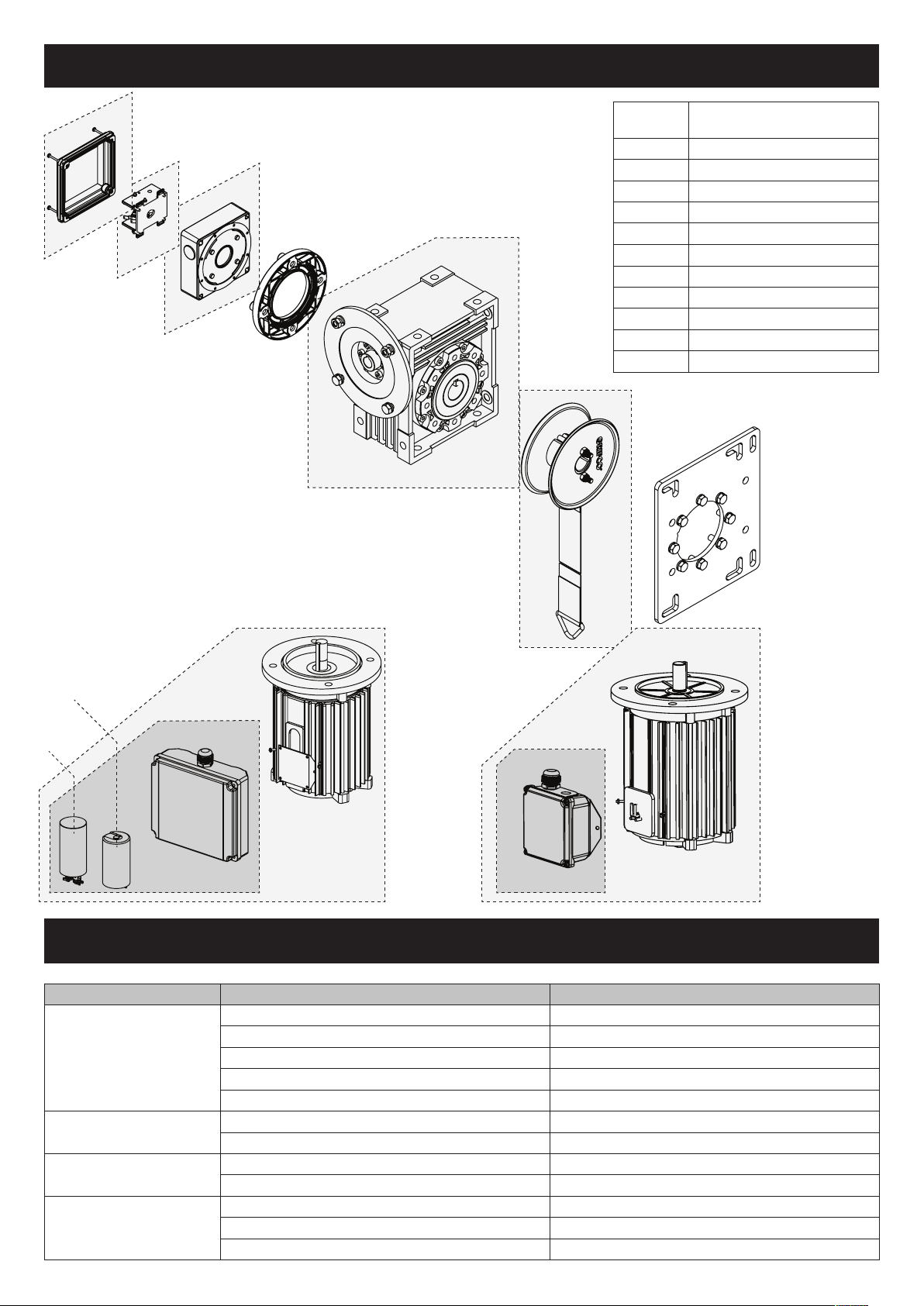

SERVICE PARTS

Part

Number

Description

56949 Limit switch box cover

56950 Limit switch box base

56951 Limit switch assembly

56931 Gearbox assembly

56932 Motor 230V 60Hz Single Phase

57086 Motor 230V 60Hz Three Phase

56952 Motor terminal box Single Phase

57091 Motor terminal box Three Phase

56954 Motor Run Capacitor

56955 Motor Start Capacitor

56953 Belt Hub and Belt

56931

56953

56950

56951

56949

Problem Possible Cause Action

Winch does not raise or lower No power Restore power supply

Both limit cams activated Check / adjust limit switches

Excess load - thermal overload tripped Reduce load, reset / adjust overload in control

Excess use - motor overheated Allow to cool

Electrical fault Check all electrical connections

Winch does not raise Upper limit activated Check / adjust limit switch

Electrical fault Check all electrical connections

Winch does not lower Lower limit activated Check / adjust limit switch

Electrical fault Check all electrical connections

Winch makes noise Belt misalignment Check/adjust belt alignment as it lays on to the hub

Motor to gearbox coupling loose Remove winch and return to Chore-Time for inspection

Internal gearbox noise Remove winch and return to Chore-Time for inspection

TROUBLESHOOTING

56952

56955

56954

Single Phase

Three Phase

5708657091

15

NOTES

16

GARANTIE CHORE-TIME

GARANTIE LIMITÉE

CTB, Inc. («Chore-Time») garantit que le nouveau treuil à entraînement direct CHORE-TIME ne présente pas de défauts

concernant les matériaux ou la fabrication et qu’il peut être utilisé dans des conditions normales durant un (1) an à partir de

la date d’installation par l’acheteur initial («Garantie»). Chore-Time fournit une extension de la période de garantie sus-

mentionnée («Extension de la période de garantie») pour certaines pièces du produit. Si Chore-Time établit qu’un défaut

existe dans les limites du délai applicable, Chore-Time procèdera, à sa discrétion, (a) à la réparation du produit ou de la

composante gratuitement, F.A.B. l’usine de fabrication, ou (b) au remplacement du produit ou de la composante,

gratuitement, F.A.B. l’usine de fabrication. Cette garantie ne peut être transférée et ne s’applique qu’à l’acheteur d’origine

du produit.

CONDITIONS ET RESTRICTIONS

CETTE GARANTIE CONSTITUE LA SEULE GARANTIE COMPLÈTE ET CHORE-TIME EXCLUT EXPRESSÉMENT TOUTE

AUTRE GARANTIE, NOTAMMENT MAIS PAS EXCLUSIVEMENT LES GARANTIES EXPRESSES ET IMPLICITES,

COMPRENANT SANS S’Y LIMITER LES GARANTIES DE QUALITÉ MARCHANDE ET D’ADAPTATION À UN USAGE

PARTICULIER.

CHORE-TIME ne peut être tenu responsable des dommages directs, indirects, accidentels, consécutifs ou spéciaux, que

l’acheteur pourrait subir ou constater, résultant d’un défaut du produit. Les dommages consécutifs ou spéciaux tels

qu’utilisés dans la présente comprennent sans s’y limiter la perte de produits ou biens et l’endommagement de ces

derniers, les frais de transport, les ventes et commandes perdues, la perte de revenus, l’augmentation des frais généraux,

des coûts accessoires et de ceux liés à la main d’œuvre et les inefficacités opérationnelles. Certaines juridictions interdisent

les limitations des garanties implicites et/ou l’exclusion ou la limitation desdits dommages, par conséquent ces limitations et

exclusions peuvent ne pas s’appliquer à votre cas. Cette garantie donne à l’acheteur d’origine des droits juridiques

spécifiques. Vous pourriez bénéficier d’autres droits selon votre juridiction.

L’acheteur d’origine est tenu de se conformer aux règles fédérales, nationales et locales s’appliquant à l’emplacement,

l’installation et l’utilisation du produit. CHORE-TIME ne peut pas être tenu responsable en cas de préjudice résultant d’une

non conformité auxdites lois.

• Les circonstances suivantes invalideront cette garantie:

• Des modifications apportées au produit non spécifiquement décrites dans le mode d’emploi.

• L’installation et/ou utilisation du produit de manière non-conforme aux instructions publiées par CHORE-TIME.

• Une ou plusieurs composantes du produit sont différentes de l’équipement d’origine fourni par CHORE-TIME.

• Le produit n’a pas été acheté de et/ou installé par un représentant accrédité ou un distributeur agréé

CHORE-TIME.

• Une mauvaise utilisation, un traitement inadéquat, une mauvaise gestion, une négligence, une altération,

un accident ou un mauvais entretien, la foudre, le survoltage ou des surtensions électriques ou une interruption de

l'alimentation électrique ayant entraîné un dysfonctionnement ou une casse du produit.

• Le produit a subi une corrosion, une détérioration et/ou un dysfonctionnement des équipements causés par ou

compatibles avec l’application d’agents chimiques, minéraux, dépôts ou d’autres éléments étrangers.

• Le produit a été utilisé à des fins autres que l’élevage de volailles et de bétail.

La garantie et l’extension de garantie peuvent être modifiées uniquement par écrit par un agent de CHORE-TIME. CHORE-

TIME n’a aucune obligation ou responsabilité quant aux déclarations faites ou garanties données au nom d’un distributeur,

du revendeur, de l’agent ou représentant accrédité.

Prend effet en : avril 2014

17

TABLE DES MATIÈRES

TABLE DES MATIÈRES

GARANTIE CHORE-TIME .............................................................................................................................................16

TABLE DES MATIÈRES .................................................................................................................................................17

SÉCURITÉ ET INFORMATIONS GÉNÉRALES..............................................................................................................18

CARACTÉRISTIQUES TECHNIQUES ...........................................................................................................................18

DIMENSIONS.................................................................................................................................................................19

INTRODUCTION ET PLAN ............................................................................................................................................20

ASSEMBLAGE...............................................................................................................................................................21

RACCORDEMENT ÉLECTRIQUE..................................................................................................................................23

INSTALLATION ET RÉGLAGE .......................................................................................................................................25

ACTIONNEMENT À COMMANDE MANUELLE ............................................................................................................26

FONCTIONNEMENT ÉLECTRIQUE ..............................................................................................................................26

ENTRETIEN ...................................................................................................................................................................27

PIÈCES DÉTACHÉES ....................................................................................................................................................28

DÉPANNAGE..................................................................................................................................................................28

NUMÉROS D’IDENTIFICATION DES PIÈCES

Treuil à entraînement direct

Monophasé

Pièce N° W400B1-CT

Code CTB : 56929

Triphasé

Pièce N° W400B3-CT

Code CTB : 57084

Commande murale

Monophasé

Pièce N° RG37612P-CT

Code CTB : 56930

Les commandes murales sont vendues séparément

Triphasé

Pièce N° RG37812P-CT

Code CTB : 57085

18

Des mentions d'avertissement sont utilisées en parallèle avec les symboles de sécurité et d’alerte afin d’identifier la

gravité de l’avertissement.

DANGER indique une situation de danger imminent qui, si elle n’est pas évitée, PROVOQUERA la mort ou une

blessure grave.

AVERTISSEMENT indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, PEUT

provoquer la mort ou une blessure grave.

ATTENTION indique une situation de danger qui, si elle n’est pas évitée, POURRAIT provoquer une blessure

mineure ou modérée.

SÉCURITÉ ET INFORMATIONS GÉNÉRALES

CARACTÉRISTIQUES TECHNIQUES

DES ÉTIQUETTES DE MISE EN GARDE, D’AVERTISSEMENT ET DE DANGER ont été placées sur les

équipements afin de signaler des situations potentiellement dangereuses. Veillez à maintenir ces informations intactes et

lisibles à tout moment. Remplacez immédiatement toute étiquette de sécurité manquante ou abîmée.

SYMBOLES DE SÉCURITÉ ET D’ALERTE

VEUILLEZ SUIVRE LES CONSIGNES DE SÉCURITÉ

Lisez attentivement tous les messages d'avertissement de sécurité du présent manuel et les signaux de sécurité de vos

équipements. Suivez les mesures de précautions et les pratiques recommandées pour une utilisation sécuritaire.

Conservez les étiquettes de danger en bon état. Remplacez toute étiquette de danger manquante ou abîmée.

CECI EST UN SYMBOLE DE SÉCURITÉ ET D’ALERTE. Si vous voyez ce symbole sur votre

équipement, faites attention aux potentielles blessures. Cet équipement est conçu pour être installé et utilisé

en respectant le mieux possible les normes de sécurité... Toutefois, des risques existent.

Comprendre les mentions d'avertissement

Caractéristiques générales du treuil à entraînement direct par courroie

Capacité maximale de

levage (Kg)

401,429

Vitesse de levage maximale

(m/min)

~3,08

Couple de poupée de treuil

(N-m)

239,97978

Diamètre du tambour (m) 6,65 (min) 1,39 (max)

Hauteur de levage maxi (m) 39,01

Dimension de la courroie 40 X 1,5

Caractéristiques des boulons

de montage

4 X M12 HT

Limites 2 X Micro-interrupteur électrique NC

Code IP IP55

Actionnement à commande

manuelle

UTILISEZ une douille de 13mm

Poids (kg) 33,11

Contrôleur adapté Monophasé

Contrôle mural RG37612P-CT (vendu

séparément) Code CTB : 56930

Triphasé

Contrôle mural RG37812P-CT (vendu

séparément) Code CTB : 57085

Température normale de

fonctionnement

10°C - 40°C / 50°F - 104°F

Application Utilisation à l’intérieur seulement

Spécifications électriques : courant monophasé

Puissance du

moteur

1,5Hp, 1,1kW

Courant pleine

charge

7,1 Amp

Voltage 230V

Phase 1 (2 X fils chauds)

Fréquence 60Hz

Condensateur (UF) Fonctionnement 35/

Démarrage 200

Fusible moteur Fusion lente 12 Amp

Spécifications électriques : courant triphasé

Puissance du

moteur

1,5Hp, 1,1kW

Courant pleine

charge

5,5 Amp

Voltage 230V triphasé

Phase 3

Fréquence 60Hz

19

DIMENSIONS

8.130in

206.50mm

9.921in

252mm

0.512in

13mm

0.059in

1.50mm

19.961in

507mm

13 mm Hex(A/F)

[Approx:1/2"]

11.850in

301mm

1.535in

39mm

8.406in

213.50mm

6.492in

164.88mm

153.540in

3900mm

1.969in

50mm

4.528in

115mm

1.218in

30.93mm

7.992in

203mm

20

INTRODUCTION ET PLAN

INTRODUCTION

Félicitations pour votre achat de la commande murale du treuil à entraînement direct par courroie Chore-Time. Ce treuil se

distingue des autres produits sur le marché par sa rapidité et sa robustesse. L’installation d’un treuil à entraînement direct

par courroie vous assure le maximum de longévité et une exploitation sans défaillances.

PLAN

Le treuil à entraînement direct par courroie est conçu pour l’installation dans des bâtiments d’élevage pour l’élévation des

lignes d’abreuvoir (et autres systèmes similaires) entre le sol et le plafond.

Le treuil à entraînement direct par courroie se caractérise par un moteur monophasé couplé à un système de transmission

doté de deux interrupteurs de fin de course à came qui permettent l’arrêt dans les positions d’élévation et d’abaissement

maximum.

Des contrôles appropriés seront requis pour commuter le sens du moteur et détecter les entrées de fin de course.

PROCÉDURE

Assurez-vous de porter des équipements de protection (vêtements adaptés, gants, masques anti-poussières). N’approchez

pas vos mains d’endroits dangereux (par ex., les câbles, les bords tranchants etc.). Pour lever de manière sécurisée le treuil

à entraînement direct par courroie, veuillez utiliser un œilleton de levage M12 ou 1/2" ou une sangle homologués comme

illustré ci-dessous :

Utilisez un œilleton de levage M12 ou

1/2" comme illustré afin de permettre

un levage à proximité de

l’emplacement final de montage

This manual suits for next models

1

Table of contents

Languages:

Popular Winch manuals by other brands

Startax

Startax 9201-100192 User instructions

Columbus McKinnon

Columbus McKinnon Yale Mtrac Mini Translated Operating Instructions

1st-Relief

1st-Relief VERSACHOCK manual

HADEF

HADEF 108/22-EX Installation, Operating and Maintenance Instruction

POWERWINCH

POWERWINCH 712 owner's manual

Harken

Harken 46.2 Parts and service instructions

Paccar Winch

Paccar Winch BRADEN BA3A Installation maintenance and service manual

Huchez

Huchez PRIMO INOX BT 250 instruction manual

Lug-All

Lug-All 6000-15SH Operating, and servicing instructions

POWERWINCH

POWERWINCH PW46101 owner's manual

Stahl

Stahl SH Series Product information

Comeup

Comeup CWG-30075 manual