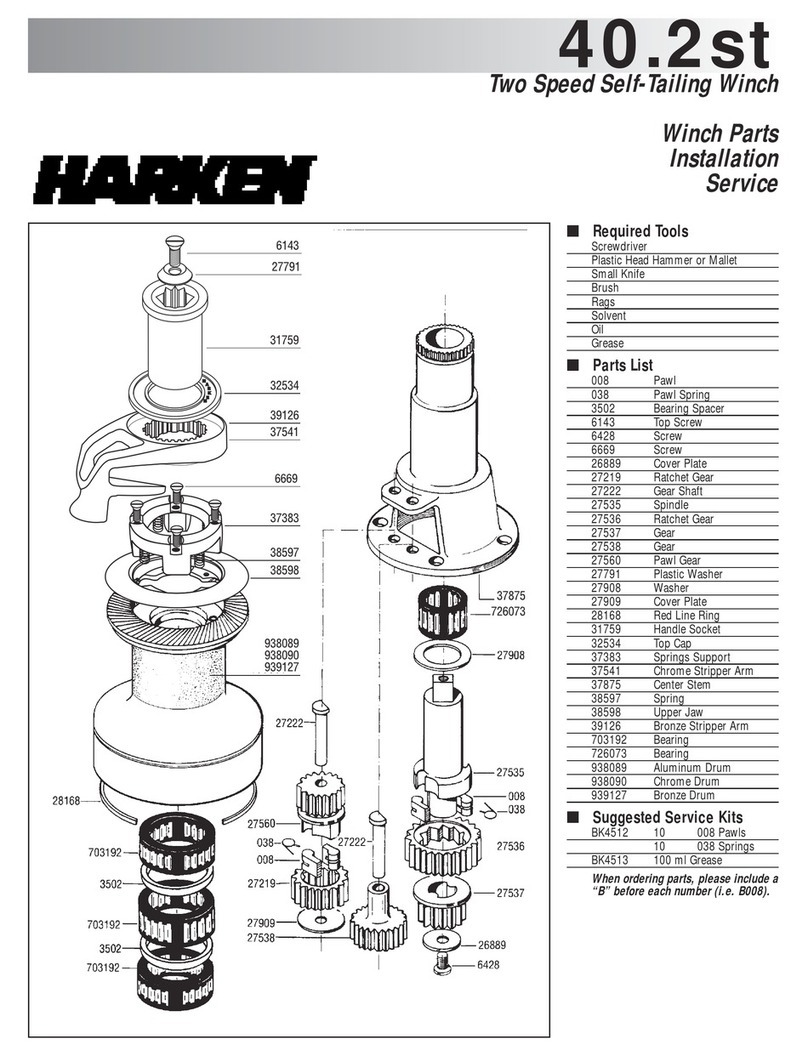

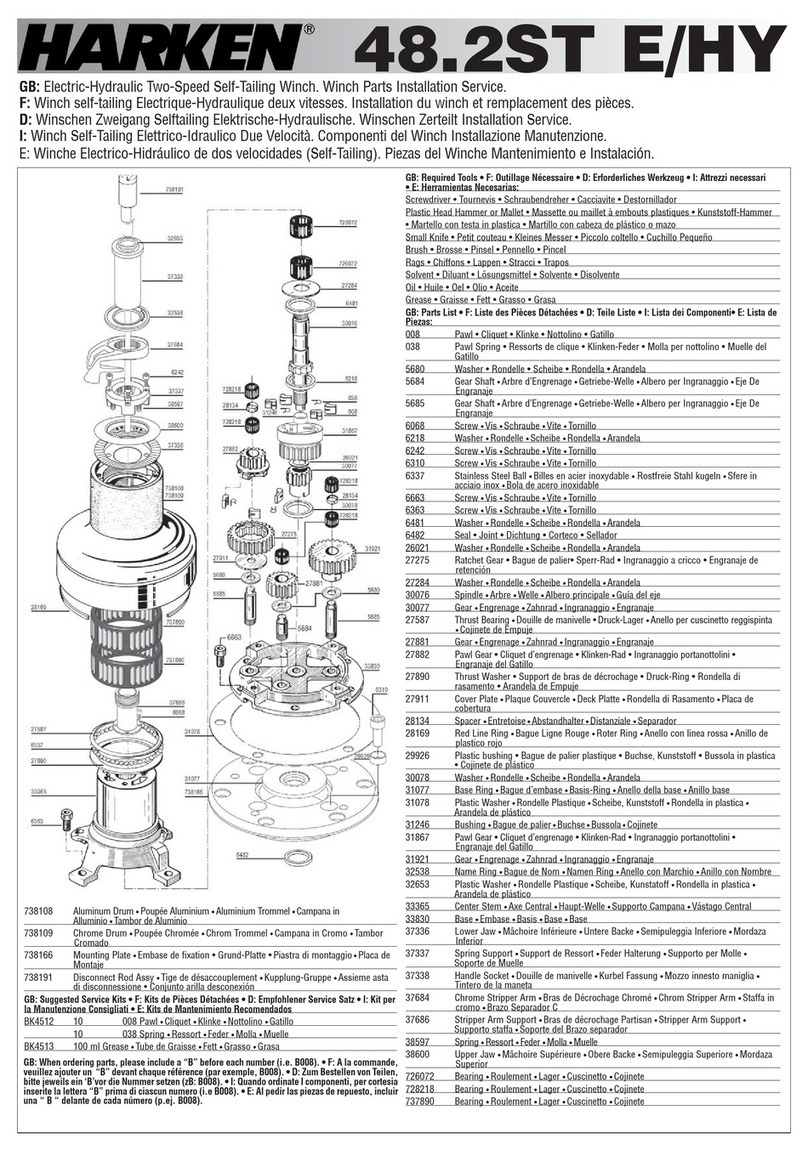

Adjusting Self-Tailer

If lines slip in the self-tailer, be sure that there are four

or five wraps on the drum, then consider closing the jaws

by pressing down on the upper jaw 33602 and turning

counterclockwise.

The 33666 shimming washer must be removed to

use small line.

The winch is more efficient when the jaw opening

matches line size, so close the jaws only if you are

using smaller line.

Positioning StripperArm

Loosentop screw

Remove handle socket

Lift stripper arm and position as desired

Opening Winch

Remove top screw

Lift of f d rum

On self-tailing winches, lift off stripper arm with drum

Servicing Winch

Remove bearings from center stem

Remove allen screws holding center stem to base

Remove center stem carefully

Remove pawls and springs - service as below

Remove all bearings, gear shafts and gears

Clean all parts with rags and solvent

Use a brush to lubricate all gears, gear shafts, bearings, teeth

and all moving parts lightly with grease

Replace pawls and springs and lubricate lightly with oil

Reassemble and close winch

Servicing Pawls

Catch spring with knife and hold against pawl

Lift ou t p awl

Clean and check for wear

Place spring against pawl with straight leg against pawl

Hold spring closed and slip pawl into pawl socket

Lubricate pawls using oil

Fittingon Boat

Make sure mounting surface is flat

Check sheet entry angle

Open winch

Position winch on deck with drive gear where sheet enters

winch drum and mark holes

Remove winch and drill holes

Mount using five 5/16" (8mm) flat head machine screws

Ap ply bedding compound and bo lt winch to bo at

Clean excess bedding compound from base drain holes

Lubricate and reassemble winch

Recommended Service Cycle – Service winch before the sailing season and once during.

®

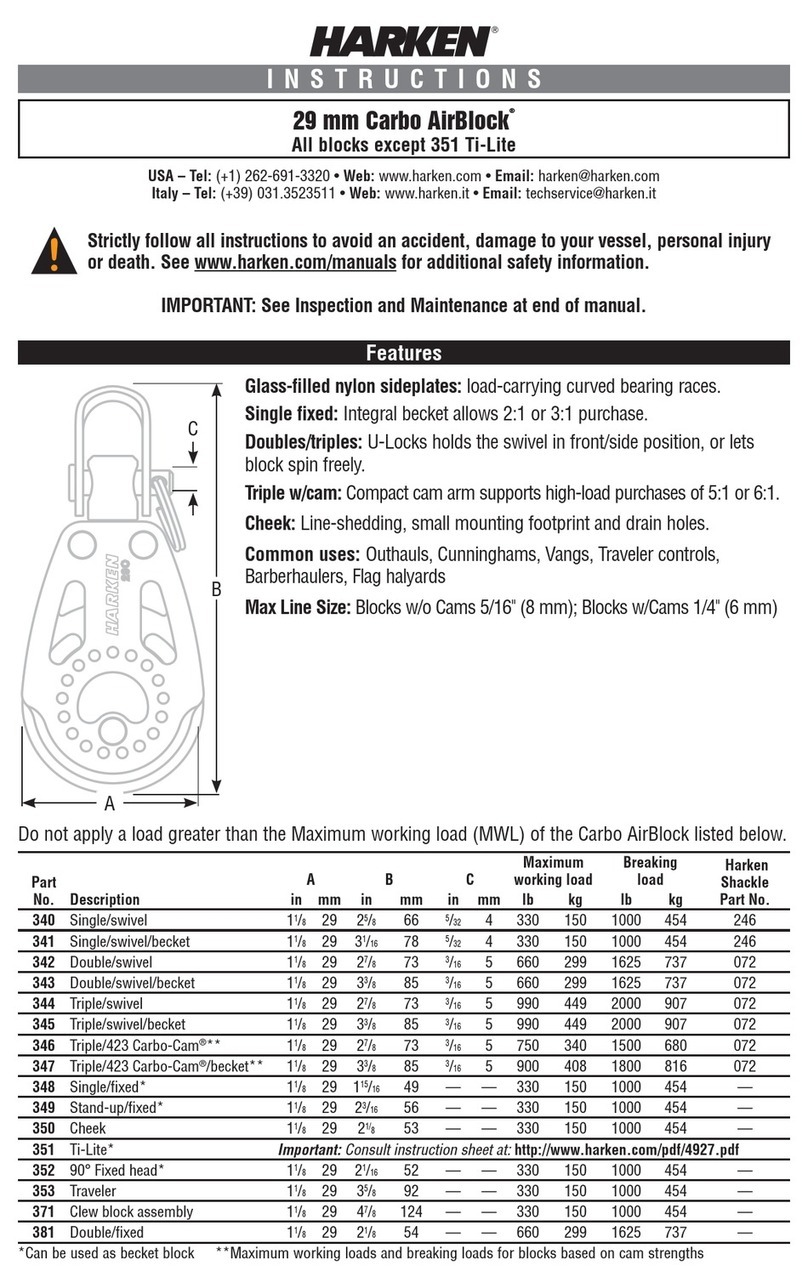

Adjusting Self-Tailer

Correct opening: Sheet fits completely

in to ja w an d re sts a gain st d rum .

Servicing WinchServicing PawlsFitting on Boat

Attention: R atchet gear mounted

b ackw a rds w il l ca use w inc h to slip.

Grease lightly and spread grease

e ven ly. Use a br ush .

Use knife to free captive s pring.

Position drive gear where sheet

e nter s w inc h dr um.

➊

➋

Press

Turn

SHEET

DRIVE GEAR

Insert spring with straight leg against

pawl. Use oil for lubrication.

46.2st

Two Speed Self-Tailing Winch

Winch Parts and Service Instructions

Right Wrong

Pressand turn to adjust self-tailer.

Clean all parts with solvent.

8

Sheet entry must be at least 8°.

When ordering parts for service, please include a "B" before each number (i.e. B008).

H4605-5/98

1251 E. Wisconsin Ave., Pewaukee, WI 53072 USA •Tel: (414) 691-3320 •Fax: 414-6913008

Vi a Della Cerca, 12/14, 22070 Lurago Mari none, Como, Italy •Tel: (39) 31.938840 •Fax:(39) 31.3520031

RIGHT WRONG