7

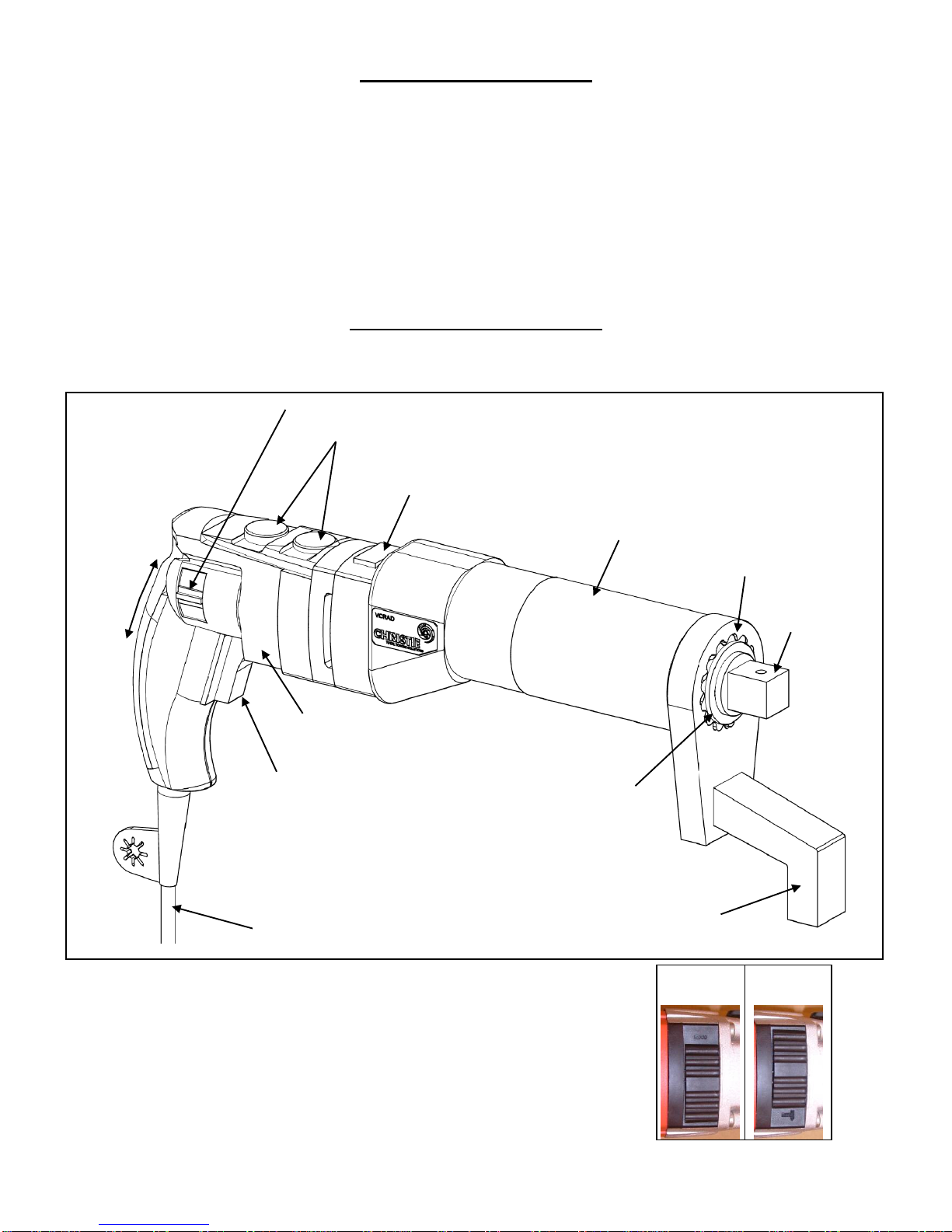

OPERATING THE WRENCH

1. Fit the wrench with the correct size impact socket to suit the bolt to be tightened and retain with

ring and pin system.

2. Rotate the handle to convenient position relative to the reaction arm.

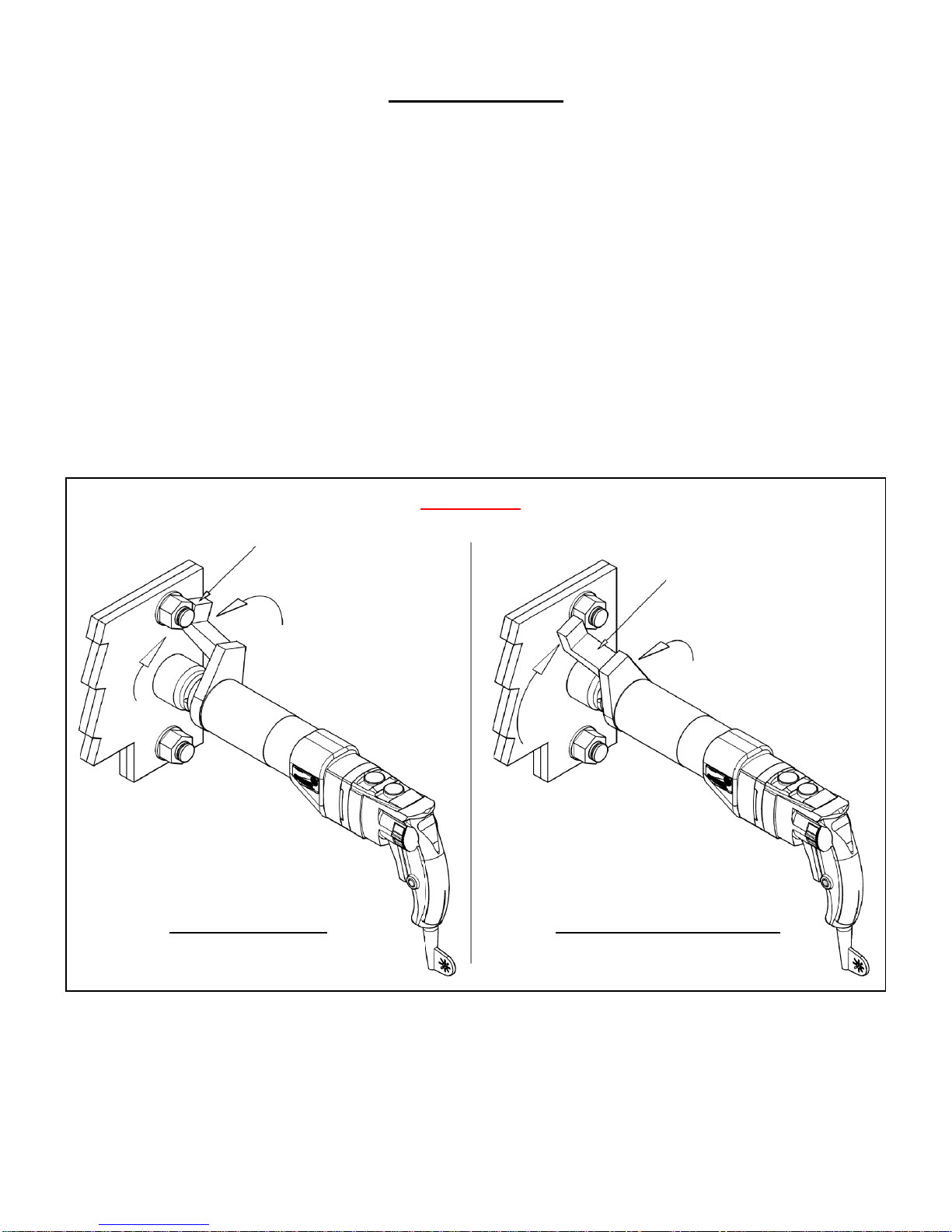

3. Fit the tool onto the bolt to be tightened with the reaction arm adjacent to the reaction point (See

“Torque Reaction” Page)

4. Move the direction selector switch (D) from the neutral position and into either forward or reverse

as required.

5. Squeeze the trigger (C) to bring the reaction arm into contact with the reaction point.

6. Fully press the trigger (C) and keep pressed until the tool stalls (when tightening) or the fastener is

released (when un-tightening). If the trigger is released before the wrench stalls, full torque will

not be applied to the bolt. Once the motor stalls do not “blip” the trigger, or incorrect torque will

be applied.

IMPORTANT: IF A FASTENER WILL NOT UN-TIGHTEN WHEN THE TOOL IS SET TO

MAXIMUM, DO NOT “BLIP” THE TRIGGER, USE TOOLING OF HIGHER

TORQUE OUTPUT.

7. Release the soft start trigger (C) and remove tool from bolt.

CAUTION: IN USE THIS TOOL MUST BE SUPPORTED AT ALL TIMES IN ORDER TO

PREVENT UNEXPECTED RELEASE OF A FASTENER OR COMPONENT

FAILURE.

IMPORTANT: IF BREAKDOWN, MALFUNCTION OR DAMAGE OCCURS DO NOT

ATTEMPT TO REPAIR, CONTACT W. CHRISTIE (IND) LTD

IMMEDIATELY.

MAINTENANCE AND RECALIBRATION

To prevent premature failure and ensure confidence in torque supply, it is recommended that this

equipment is serviced and calibrated at least on an annual basis, by W. Christie (Ind) LTD.

There are no user serviceable parts. If any failures occur then the wrench should be returned to W.

Christie (Ind) LTD for evaluation.