ELECTRIC SHOCK HAZARD. Any installation involv-

ing electric heaters must be performed by a quali-

fied person and must be effectively grounded in

accordance with the National Electrical Code to

eliminate shock hazard.

1. Be sure line voltage matches heater voltage (on nameplate).

2. Electric wiring to heater must be installed in accordance with local

codes and the National Electrical Codes.

3. Because of the high operating temperatures expected, 250˚C wire

should be used.

4. Power controls must be used when heaters are rated 3 phase and

when the heater amperage exceeds the rating of the thermostat.

5. Refer to Wiring Diagram Table B, to properly connect the heater.

Table B — Wiring Diagrams

WIRING

240V 480V

Model 1ø 2-1ø 3ø 2-3ø 1ø 2-1ø 3ø

Fig. No. Fig. No. Fig. No. Fig. No. Fig. No. Fig. No.Fig. No.

GCH-60905 1 — 3 — 5 — 7

GCH-61205 — 2 3 — 5 — 7

GCH-62005 — 2 — 4 5 — 7

GCH-62505 — — — 4 — 6 7

GCH-63005 — — — 4 — — 7

GCHIS 4, 8 —— 8 ———9

12, 15,20 kW

INSTALLATION

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property dam-

age. Heater must be installed by a qualified person

in accordance with the National Electrical Code,

NFPA 70

.

FREEZE HAZARD. This unit is equipped with a ther-

mowell for process control or over-temperature

control. Do not allow moisture to accumulate in

thermowell. Freezing temperatures can cause

damage that may result in the heated medium

leaking into terminal enclosure.

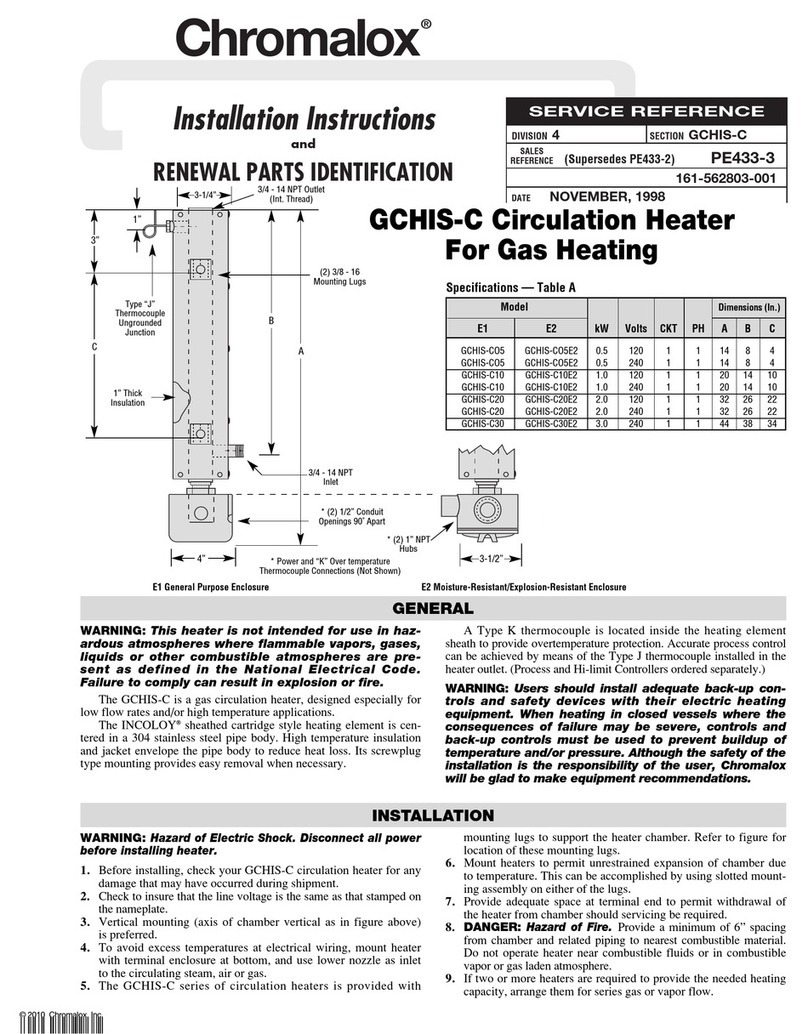

1. Vertical mounting (axis of chamber vertical as in photo on previ-

ous page) is preferred.

2. To avoid excess temperatures at electrical wiring, mount heater

with terminal enclosure at bottom and use lower nozzle as inlet to

the circulating steam, air or gas.

3. The GCH-GCHIS-6 series of circulation heaters are provided with

mounting lugs to support the heater chamber. Refer to photo on

previous page for location of these mounting lugs.

4. Mount heaters to permit unrestrained expansion of chamber due to

temperature. This can be accomplished by using a slotted mount-

ing assembly on either of the lugs.

FIRE HAZARD. Since heaters are capable of devel-

oping high temperatures, extreme care should be

taken to:

A. Provide minimum of 6” spacing from a chamber

and related piping to nearest combustible material.

B. Avoid operation of heater near combustible fluids

or in combustible vapor or gas laden atmosphere.

5. Provide adequate space at terminal end to permit withdrawal of the

heater from chamber should servicing be required.

6. If two or more heaters are needed to provide the needed heating

capacity, arrange them for series gas or vapor flow.

EXPLOSION HAZARD. When heating in closed vessels,

controls and back-up controls must be used to regu-

late build-up of temperature and/or pressure.

7. A pressure relief valve should be provided by customer at outlet

of vessel. There should be no other valving between vessel and