CIAM CIAO Series User guide

ICE CREAM DISPLAY CABINET

CIAO series

Maintenance

And Use Manual

CIAM SPA

Viale dei Pini, 9

Petrignano d'Assisi

PG – Italy

tel. 075 80161

Fax 075 8016 15

http://www.ciamgroup.it

e-mail: info@ciamgroup.it

1. INTRODUCTION

PRESENTATION

Dear Client,

Ciam is pleased to number you among its customers and relies the bought machine will match your expectation. In order to get the best

performances of the machine, we recommend you to follow all suggestions and instructions, which are included in this manual.

1.2. HOW TO USE THE MACHINE

PERMITTED USES

This refrigerated display cabinet has been manufactured for ice cream presentation and sell.

NOT PERMITTED USES

It is absolutely forbidden the use of the refrigerated display cabinet for pharmaceutical products.

1.3. RESPECTED NORMS

The refrigerated display cabinet has been manufactured in respect of the safety issues relevant to the following norm:

Machinery Directive N° 2006/42/CE : CE marking for machinery

Directive N° 2006/95/CE : Low tension

Directive N° 2004/108/CE : Electro-magnetic Compatibility

Directive N° 97/23/EC (P.E.D.) : European Pressure Equipment

Norm CEI 17-13/1 (EN 60439/1) : Realization of Electric Installations

Norm CEI EN 60335-1 (CEI 61-150) : Safety of household and similar electrical appliances

Norm CEI EN 60335-2-24 (CEI 61-56) : Special norms for refrigerators, freezers and ice machines

For ETL marked cabinet:

UL471 / CAN/CSA C22.2 No. 120-M91

NSF/ANSI 7 - 2009

1.4. RESPONSIBILITY

CIAM spa declines any responsibility relevant to damages on persons, animals and/or products in case of:

•No respect of in force norms

•Installation, which is not conform to the instructions manual

•No observance of all maintenance operations, which are suggested in this manual

•No previously agreed change operations with the manufacturer

•

No proper use of the refrigerated display cabinet, for which the machine has been produced.

1.5. WARNING

Anytime CIAM spa reserves the right to up-date the content of this manual and/or to modify the product in order to improve its quality and

performance, without any previous notice and/or communication.

2. DISPLAY CASE DATA PLATE

2.1. DATA PLATE CONTENT

1. Commercial name of the unit

2. Identification number

3. Production date

4. Voltage

5. Phases

6. Frequency

7. Compressor type

8. Number of compressor

9. Refrigerant type

10. Refrigerant weight

11. Climatic rate (Cl.3 = +25°C/60% U.R.; Cl. 4 = +30°C/55% U.R.)

12. Test pressure – system high pressure side

13. Test pressure – system low pressure side

14. Nominal power/current absorbed during defrost

15. Max. power absorbed during defrost

16. Nominal power absorbed by heating elements (only if higher than 100W)

17. Lighting nominal power

3. TECHNICAL FEATURES

CIAO GEL GEL 12 GEL 18 GEL 24

Load limit height

H (mm)

Ice cream pans

5

,

2

dm

3

(

360

x16

5

x1

2

0 mm)

12

18

24

6,5

dm

3

(25

0x

360

x

8

0 mm)

8

12

16

Display ca

binet

weight

(kg)

210

280

320

Display cabinet

performances

Climatic class

-

Environment

(°F/%

R.

H.

)

85 / 55

Working temperature

(°

F

)

0

Electrical supply

(V/ph/Hz)

23

0

/

1

/

50

Refrigeration

Forced air circulation

Dfrosting

Automatic,

by reverse cycle

Refrigera

ting gas

R 404A

Glasses

Heated

side glasses,

hetaed

front glass

Standard internal

compressor

Type

Hermetic single phase

No.

1

1

1

Nominal power

(W)

600

725

2 x 560

Power/current of display cabinet

(W/A)

1800

/

10,0

2

.

05

0/

11,5

2.250/13

,

5

Closing for refrifgerated area

Sliding doors

4. LOAD LIMITS

In the following figure are shown the load limits for the displayed product.

The product should be exposed in order to ensure right air flow ! So it's necessary to comply with the load before

showed.

ATTENTION! The manufacturer is not liable for failures caused by improper use of equipment!

5. INSTALLATION

5.1. MACHINE HANDLING

The ice cream display cabinet handling, from the truck to the final place, has to be made

by any truck-lift, which is proper to its weight. The display cabinet shall be always

balanced in order to ensure personnel integrity and machine functionality

The cabinet can be shipped with or without wood packaging, in case wood crate will be

used, will have a pallet base for an easy fork-lift handling. The pallet, however should be

handle in the central position

During the shipment, it is necessary to avoid any crash or/and shake of the display

cabinet in order to not damage its frame, especially its glasses.

Do not drag the display cabinet on the floor and do not push it on the upper glasses

.

5.2 STOCK OF THE DISPLAY CABINET

Whenever the cabinet has to be stoked, follow carefully what suggested before.

Environmental temperature during the cabinet stock can have following range -15°C and + 55°C and humidity between 30% and 90%.

The display cabinet has always to be protected by sunrays and raining.

In case the display cabinet has to remain in stock quite long time before its use, keep it with its packaging in order to maintain its protection.

5.3. PACKAGING REMOVE

Before getting the display cabinet from the forwarding agent, check its conditions. In case it will be some damages, inform the driver and sign it on

shipping documents. Eventual damages relevant to the shipment and/or to the wrong stock, have not to be ascribed to the manufacturer.

5.4. DISPLAY CABINET POSITION

The refrigerated display cabinet needs particular environmental conditions in order to offer the right performance, so that the area where it will be

used has to respect following indications

Floor has to be l

evelled perfectly, on the contrary keep the display cabinet on the horizontal

position in order to guarantee a perfect defrosting water drain and avoid boring compressor

noises.

The display cabinet has to not be under the

sun

-

rays in order to have its better refrigeration

performance, has to remain inside the local or to be sheltered by window curtain. If what

described above is not observed, it can determinate an increase of temperature of displayed

product and an increasing power consume.

The display cabinet has not to be under air currents due to open doors or windows, or under

roof ventilators or under air condition outlets.

In case will be not respected the above suggestions it can arise an increasing of temperature

of the displayed product and/or an increasing ice phenomena on the evaporator and internal

fans, which compromise the correct cold air circulation and product consistence

The display cabinet has not to be placed close any heat source as heaters, oven

s, etc

The display cabinet has to have a sufficient place in order to ensure a correct custom service,

to make an easy maintenance operation, to guarantee the right air flow necessary to make

cold the condenser. Besides the warm air which flows out has to no have any obstacle or to

invest other equipments in order to not reduce the correct functions.

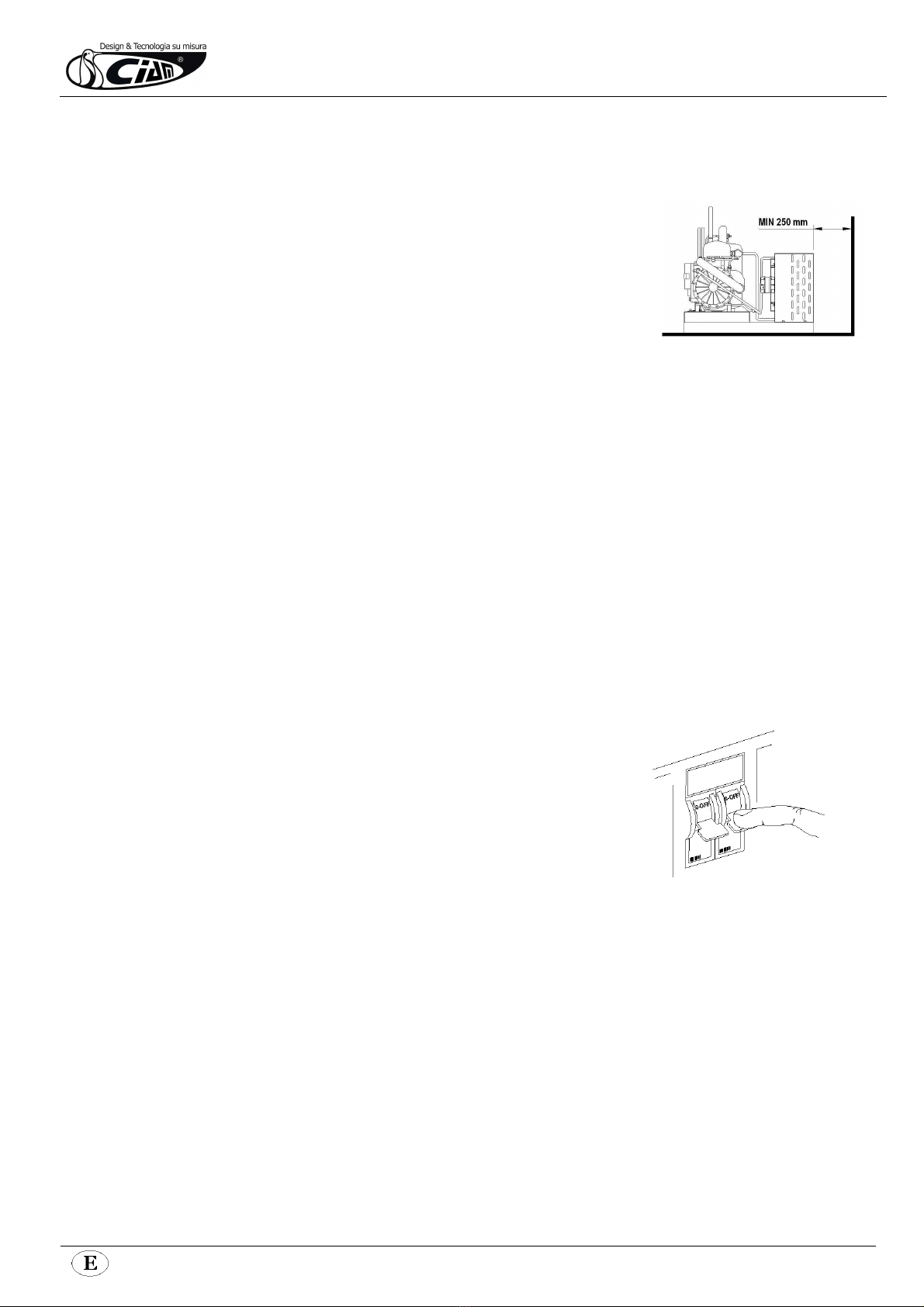

5.5. REMOTE CONDENSING UNIT PLACING

According to the model of ice cream display cabinet you have No.1 or No.2 internal, or remote, condensing units.

The remote condensing unit has to be checked by specialised technicians and according to the required refrigerating power and their position

respect the cabinet. The condensing unit has to be placed following these points:

The condensing unit h

as to be located at least 250 mm from any eventual wall.

(pic.

5

.

1

)

Air flow direction has to be from the eventual wall towards compressor.

The local, in case will be closed, has to be with enough air circulation.

By the condenser has to be guaranteed in any case as much as possible cold air.

In case will be necessary it has to be foreseen a forced air exchange by any fan according to the

air flow of condenser.

The condensing units of display cabinets have to be fixed properly.

The generated noise has not exceed the admitted noise levels relevant to the public places,

especially in case of domestic buildings.

It is always necessary a sufficient place along the four sides of the display cabinet in order to make

easy any type of check and maintenance operations.

When the condensing units are external will be necessary a frame holder that has to be fixed in a

proper way and eventually added with amortising elements. Besides this frame has to be closet with

no-water protection grid and sufficient opening holes for ventilation.

5.6 PIPING CONNECTION BETWEEN DISPLAY CABINET AND REMOTE CONDENSING UNITS.

The liquid and suction piping exit from the base of the display cabine; the choice of piping diameter and insulation thickness has to be taken by

specialised technical personnel, who know specific parameters.

The choice of piping diameter and insulation thickness has to be taken by specialised technical personnel, who know specific parameters.

The piping length has to be as short as possible.

The piping arrangement has to be made on purpose by qualified personnel in order to guarantee the main functionalities as the right inclination,

to have some siphons on the base of suction piping on the way up, and eventually on the intermediate elevation.

WARNING!

A wrong connection may occur serious damages on the display cabinet, especially on the compressor. The display cabinet

manufacturer cannot be responsible of any damage, which can arise from a wrong connection made by third parties.

5.7 ELECTRICAL CONNECTION

Before proceeding with electrical connection, be sure that the available electric power and tension are what is required on technical label of the

cabinet.

The electric connection has to be made by qualified personnel and following manufacturer’s instructions taking into

consideration the relevant norms in force.

The display cabinet has already a general switch, however it is necessary an omni

polar switch, with a minimum distance among the contacts of 3mm.

It is obligatory that the display cabinet will be connected properly with an efficient

ground socket.

WARNING!

A wrong connection may occur always to persons, animals and things,

where the manufacturer cannot be considered as responsible.

WARNING!

The display cabinet has no main switch breaking both the phases.

Before any maintenance operation disconnect the electrical supply of the

display cabinet (see label on the rear of the display cabinet). (pic.5.2).

pic.5.1

pic.5.

2

5.8 – ELECTRICAL CONNECTION – REMOTE CONDENSING UNIT

In case the display cabinet has a remote condensing unit, the electric control panel is supplied separately; in case the display cabinet is without condensing

unit, the machine can be supplied without external control panel. However the electrical connection has to be made in the point indicating in the pic. 5.3.

In this point 5 connecting terminal are not fixed; they are numbered and represent:

1-2 Electrical supply

3-4 Compressor switch

5-6 Defrosting switch

Ground connecting terminal

5.9. IDRAULIC CONNECTION

In case the display cabinet has an internal condensing unit by air, it is not necessary any water system connection.

In case the display cabinet has a dipper well, it is necessary make the connection of its water outlet with the main water drain outlet; besides it is

necessary set a load water tube to the dipper well, to the operator side, to the right or to the left, according to customer’s choice.

In case the display cabinet has condensing unit working fully or partially by water, it is necessary to connect the load water tube (this is the tube with

thermo insulation) with the unload water tube(this is the tube without thermo insulation), of condenser working by water, to the water line

5.10.

IDRAULIC CONNECTION

-

REMOTE CONDENSING UNIT

In the case then display cabinet has a remote condensing unit, it is necessary make the connection of defrosting water outlet with the main water

drain outlet. At the base of cabinet you can find a female pipe-fitting with a rapid receptacle for a tube Ø 32 mm

pic

.

5.3

6. ROUTINE MAINTENANCE AND PERIODIC CHECKS

These kinds of operations are at client’s expenses.

In case some malfunctioning of the unit are observed, please make sure this is not due to non-maintenance reasons, before you apply to qualified

assistance.

The accurate and periodic cleaning of the unit will reduce the risk of damages to the unit itself and to the products stored within.

See following tab for reference.

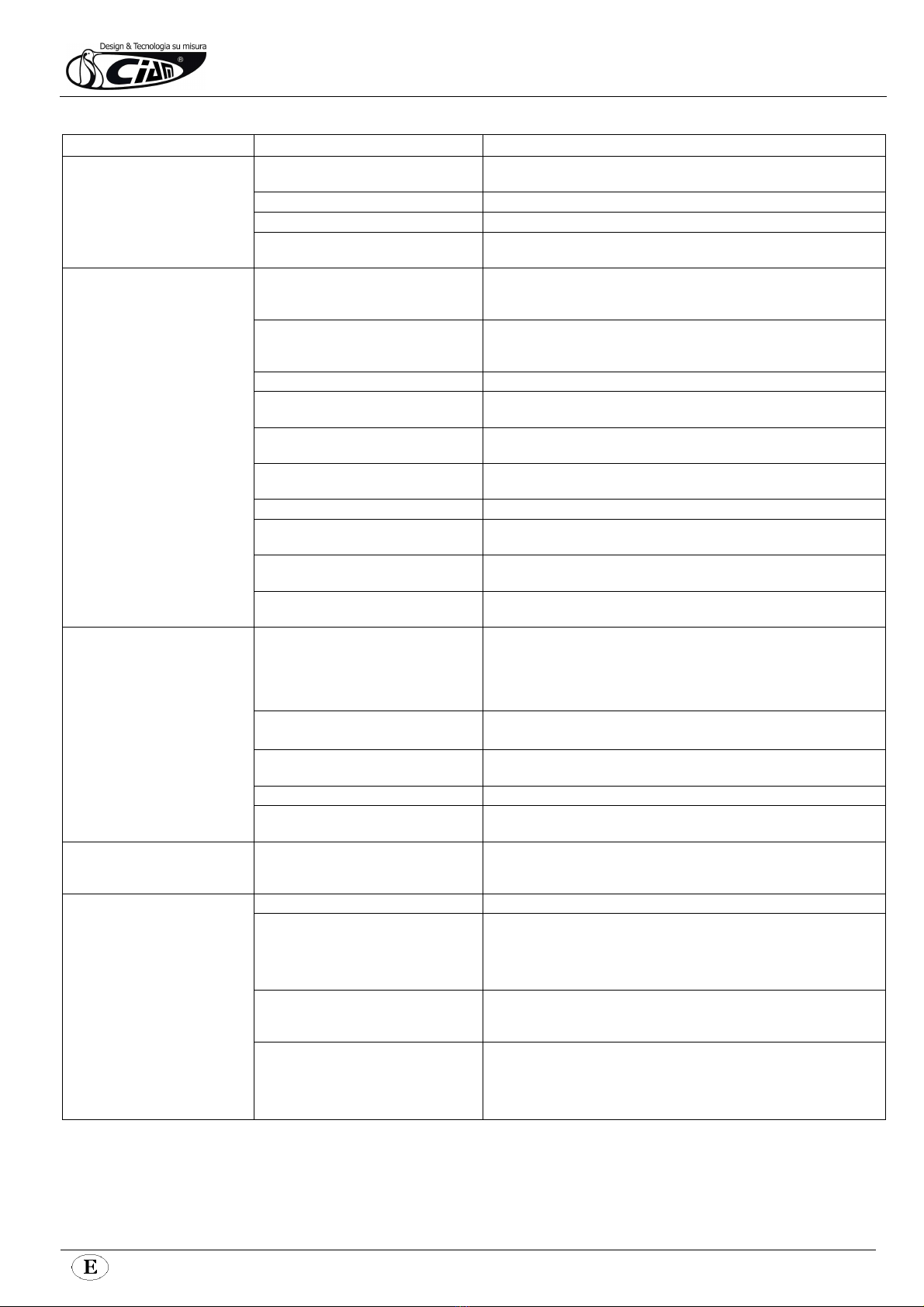

ATTENTION !

Before starting any maintenance and cleaning operation make sure you operate on the

main switch in order to deactivate tension (pic. 6)

(pic 6)

MAINTENANCE OPERATIONS AND THIR FREQUENCY. A SUMMARY TAB.

OPERATION DESCRIPTION FREQUENCY

Surfaces’ cleaning •Wash exclusively with warm water and neutral soup; rinse abundantly and wipe off with a soft

cloth.

•Do not use abrasive products

weekly

Plastic surfaces’ cleaning •Wash exclusively with warm water and neutral soup; rinse abundantly and wipe off with a soft

cloth.

•Do not use alcohol, acetone and any solvent that might spoil the look and structure of the

material.

weekly

Glass surfaces’ cleaning •Use only specific products for glass cleaning

•Using water alone might lead to calcareous deposits on the glass surfaces

daily

Wooden surfaces’ cleaning •Use exclusively a wet cloth. weekly

Additional defrost

•Under particular conditions of temperature and humidity, the frost that normally forms on the

evaporator and fans might increase in volume, so leading to a faulty functioning the unit.

•If these conditions should last, the assistance of a qualified technician shall be needed. Waiting

for this service, it is suggested to operate one or more defrost cycles (despite the damages this

might cause to the stored product)

Waiting for

qualified

assistance

Periodic defrost

•In order to obtain the best performance from the cooling system, we suggest to operate an

extended defrost cycle.

•Before you do that, please remove displayed products from inside the cabinet; always operate

an additional defrost cycle in order to remove from the evaporator the largest possible amount

of frost or ice. Turn the main switch off for 5 hours (min.)

•Before re-starting the unit, make sure that frost has totally melted and wipe carefully.

max. 15 DAYS

ATTENTION! DO NOT CLEA

N THE UNIT WITH WATER JETS

7. EXTRAORDINARY MAINTENANCE

This type of operation has to be made by qualified technician only.

ATTENTION!

Before operating any maintenance, make sure the tension is deactivated. (pic.11).

Lamps’ replacement: qualified technician needed.

Air condenser cleaning: qualified technician needed. When the fan is switched off you can clean the condenser

with a compressed air jet. Never use metallic brushes. Use protection gloves (pic.7).

(Pic.7.)

8. DEFECTS AND REMEDIES

DEFECT PROBABLE CAUSES POSSIBLE REMEDIES

The unit does not work Automatic switch released due to

absorption overload

Re-start the automatic switch

Main switch off Turn the main switch on

Refrigeration switch off Turn the refrigeration switch on

Electrical black-out in the building If the black-out does not end in a reasonable time frame, it become

necessary to move the displayed product in another refrigerator

The temperature inside the display

area does not get enough cold

The evaporator(s) is blocked by ice

forming

Operate a complete defrost cycle after having displaced the products in

another refrigerator.Do not put the product back in the cabinet until the real

defect has been identified

The internal fans are damaged or not

working

Replace the damaged fans. If the fans are not damaged, an electrical defect

must be identified. If the fans are replaced, the blades’ inclination have to be

maintained unchanged

Excess of internal ventilation Replace the fans and make sure that blades’ inclination is kept unchanged

The pre-set temperature of the digital

control panel is wrong

Set the correct temperature

The digital control is not working Replace the slave module or the temperature sensor, after you made clear

which one is faulty

The display area is crossed by draught or

exposed to direct/reflected sunbeams

Eliminate draughts and try to avoid sunbeams interference in any way

Air condenser is clogged by dust or dirt Clean the condenser with accuracy

The cooling air flow of the condenser is not

sufficient

Remove everything that might obstacle the air flow through the condenser

Refrigerant gas not sufficient inside the

cooling system

Find and remove the leak inside the system. Refill the system with the

refrigerant

The cooling water flow of the water

condenser is not sufficient

Check that water supply is operating. In case it is, just regulate (or replace)

the regulation valve

The product gets too hard next to

air outlet and too soft next to air

intake

Front evaporator blocked by frost Verify the efficiency of the gasket seal (relatively to the glass superstructure).

Verify that the display area is not crossed by draughts. Verify that backsliders

(or night blind) are always closed, peak hours excepted. Verify that internal

ventilation is sufficient and that the product does not exceed 10mm above

the pans level. Act accordingly

Front evaporator blocked by ice All the a.m. checks are required

Verify, in addition, the defrost cycle efficiency

Back evaporator blocked by ice Verify that the refrigerating and electric systems of the unit are working

properly

Internal fans are not efficient Restore the efficiency of the fans by replacing the damaged ones

The basket seal of the glass

superstructure is not sufficient

Verify the seriousness of the defect and make sure the draughts are

minimized

Some of the products tend to

soften, while some other keep the

right consistence

The temperature inside the display area is

not fit for the products that get too soft

Since the storage temperature cannot be appropriate for any gelato product,

based on different flavours and compositions, it is suggested to display only

similar products together

The compressor does not start or it

does not hold operating

There is no electrical supply Verify there is no black-out in progress. Turn all the power switches on.

The supply tension is too low Verify that nominal tension at connecting clamps is 220V; a tension between

198V and 242V will be acceptable. If the tension does not reach 198V, the

compressor might have problems in starting. Verify the efficiency of electric

installation including the connecting clamps to the compressor

The pre-set temperature on the thermostat

is too high

If the preset temperature is higher than in the display area, the compressor is

not going to work. Change the settings if you verify that the preset

temperature is not enough low

The intervention of the max pressure valve

(where present)

Identify the probable cause among the following:

The air condenser is blocked - The cooling fan of the air condenser is not

working - The room temperature is too high - Lack of cooling water in the

water condenser - The pressure valve is broken - Remove the cause

DEFECT PROBABLE CAUSES POSSIBLE REMEDIES

The compressor works constantly

or for too long periods

The temperature inside the room is too

high

The compressor can only work constantly if there is no chance of decreasing

room temperature (for instance with a.c. system)

The temperature of the compressors’ room

is too high (remote comp.)

See above

The air condenser is blocked Clean the condenser carefully

Cooling air flow of the water condenser is

not sufficient

Check the efficiency of the regulation valve and make sure that taps are

turned on

Lack of refrigerant Identify the eventual leak and refill with refrigerant

Internal ventilation is not sufficient Restore a proper ventilation by replacing the faulty fans or by removing the

eventual obstacle

Evaporators are extremely clogged Operate a complete defrost cycle

The temperature set on the thermostat is

too low

Adjust temperature settings

Temperature is not displayed on

the digital panel

Flat battery Replace battery

Sensor does not work properly Replace digital thermostat

Faulty electronics Replace digital thermostat

Defrost water missing Water drain pipes are blocked Remove the obstacle

Defrost cycle is not efficient Verify the efficiency of control panel (slave module, sensor, solenoid valve..)

and the position of the end cycle sensor

Lighting is not working The switch is off Turn the switch on

The neon lamp is not properly fitted in its

case

Ad just the lamp by rolling it

Exhausted lamp Replace the lamp

Ballasts or starter are not efficient Replace faulty components

The unit is too noisy Vibrations of internal plates Tighten all the fixing screws

Internal fans are not fixed well See above

Fans’ blades are not fixed well Replace faulty fans. If there is friction between the blades and some ice

formation, then act on defrost cycle settings

Pipes are in contact with other parts of

equipment

Avoid any contact between pipes and other parts; a constant rubbing might

wear the pipes out and give way to refrigerant leaking

The unit is not well levelled Adjust the levelling

Condensation water forming on the

glasses

Transformer is not working Check that the transformer is correctly supplied - Verify the correct

functioning of the transformer fuse - Replace the transformer

Heating circuit interrupted Replace the glasses

Leg.Man.Uso Man.ENG-CIAM-13/2012-R02

REFRIGERATION AND ELECTRICAL SYSTEM CABLE CONNECTION GUIDE

AGD

AEL

AP

CA

CAR

CE

CN

CO

D

DEV

DR

EM

EV

F

FD

FLU

FR

HL

I

IEC

IGD

II

IL

IMC

INV

IR

IRP

IV

KM

LF

LI

LIA

LIG

LIP

MDIG

MM

MUC

PA

PD

PO

QE

QF

R

RADD

RE

REL

REP

RES1

RES2

RES3

RES4

RES5

RES6

RES7

RES8

RES9

RES10

RES11

RES12

RES13

RES14

RES15

RES16

RES17

RES18

RES19

RES20

RES21

RES22

RES23

RES24

RES25

RES26

RES27

DIGITAL FLAVOURS DISPLAY FEEDER

ELECTRONIC BALLAST

SERVICE VALVE

SUPPLY CABLE

AIR CONDENSER

ELECTRONIC CONTROL

MULTIPOLAR CONNECTOR

COMPRESSOR

DIOD

SHUNT

REMOTE DISPLAY

PHOTOCELL EMITTER

EVAPORATOR

FUSE

FILTER DRIER

WATER FLOW SWITCH

COMPRESSOR THERMAL PROTECTION

COMPRESSOR ALARM LIGHT

GENERIC SWITCH

WATER EVAPORATION BIN SWITCH

DIGITAL FLAVOURS DISPLAY

LIGHTING SWITCH

SIGHT GLASS

WARM SHELF SWITCH

INVERTER

REFRIGERATION SWITCH

LIGHT REFRIGERATION SWITCH

INTERNAL FAN SWITCH

CONTACTOR

FRONT LIGHTING

INTERNAL UPPER LIGHTING

FRONT LIGHTING

FLAVOURS DISPLAY LIGHTING

REAR LIGHTING

DIGITAL MODULE FOR FLAVOURS DISPLAY

SPINNING SHELVES ELECTRIC MOTOR

CONDENSING UNIT ELECTRIC CONNECTIONS

HIGH PRESSURE CONTROL

HIGH-LOW PRESSURE CONTROL

WATER PUMP

EXTERNAL ELECTRIC PANEL

MAGNETIC-THERMIC SWITCH

LIGHTING BALLAST

RECTIFIER

GENERIC RELAY

ELECTRONIC BALLAST

ELECTRONIC CONTROL TEMPERATURE REPEATER

COLD AIR DISCHARGE HEATING ELEMENT

FRONT PROFILE HEATING ELEMENT

RIGHT/LEFT GLASS HEATING ELEMENT

FRONT GLASS HEATING ELEMENT

DEFROST HEATING ELEMENT

WATER EVAPORATION HATING ELEMENT

TOP LIGHTING FIXTURE HEATING ELEMENT

LATERAL GLASS SUPPORT HEATING ELEMENT

FRONT BAND HEATING ELEMENT

COUPLING BAND HEATING ELEMENT

SERVICE TOP HEATING ELEMENT

UPPER BAND/DOOR FRAME HEATING ELEMENT

HOT DRY/BAIN MARIE DISPLAY HEATING ELEMENT

ANTI-FOG SUCTION AIR BAND HEATING ELEMENT

WARM SHELF HEATING ELEMENT

SIDE BANDS/ FRONT GLASS HINGE HEATING ELEMENT

DEHUMIDIFICATION HEATING ELEMENT

DEFROSTING WATER DRAIN HEATING ELEMENT

RING FRAME HEATING ELEMENT

SIDE BAND HEATING ELEMENT

SUCTION AIR GLASS HEATING ELEMENT

OUTLET AIR HEATING ELEMENT

REAR GLASS HEATING ELEMENT

INTERNAL GLASS HEATING ELEMENT

FRONT GLASS UPPER FRAME HEATING ELEMENT

FRONT GLASS LATERAL/LOWER FRAME HEATING

ELEMENT

FRONT GLASS LATERAL FRAME HEATING ELEMENT

RES28

RES29

RES30

RES31

RES32

RES33

RES34

RES35

RES36

RES37

RES38

REV

REVC

RI

RIC

RICV

RIS

RL

RLA

RO

SAA

SC

SD

SDC

SE

SEC

SFV

SIDG

SL

SLA

SPC

SPMC

SPR

SPS

SS

ST

STR

SU

T

TI

TC

TE

TER

TF

TMC

TP

TRA

TRC

TREV

TS

TVC

V

VC

VEC

VES

VI

VPA

VR

VRA

VRE

VS

VSA

VSAB

VSIC

VSL

VSS

VT

VV

X1

X2

X3

FRONT GLASS LOWER FRAME HEATING ELEMENT

FRONT GLASSES COUPLING PROFILE HEATING ELEMENT

DOORS FRAME MIDDLE POST HEATING ELEMENT

GLASSES PERIMETRAL FRAME HEATING ELEMENT

HEATED DOORS HEATING ELEMENTS

WATER DRAIN HEATING ELEMENT

DOORS FRAME HEATING ELEMENT

COMPRESSOR CRANKCASE HEATING ELEMENT

FRONT GLASS FRAME HEATING ELEMENT

CABINET FRAME HEATING ELEMENT

HOT COMPARTMENT HEATING ELEMENT

CONDENSER FAN SPEED CONTROL

CONDENSER FAN RELAY

REFRIGERANT TAP

COMPRESSOR DELAYER

PHOTOCELL RECEIVER

RESERVE , ANTI-FOG HEATER ELEMENT

LIQUID RECEIVER

WATER LEVEL ELECTRONIC CONTROL

OIL HEATER ELEMENT

ABSENCE OF WATER LIGHT

CONDENSER PROBE

TERMINAL BOX

COMPRESSOR TERMINAL BOX

PROXIMITY SENSOR

MAIN SWITCH

TANK BOTTOM HEATING COIL

FLAVOURS DISPLAY DIGITAL SYSTEM

LIQUID SEPARATOR

WATER LEVER PROBE

COMPRESSOR LIGHT

WARM SHELF LIGHT

ELECTRIC SUPPLY LIGHT

DEFROSTING LIGHT

DEFROSTING PROBE

TEMPERATURE PROBE

LIGHTING STARTER

HUMIDITY PROBE

TEMPERATURE CONTROL

WINTER THERMOSTAT

CAPILLARY TUBE

TIMER

THERMOMETER

FUSIBLE PLUG

WARM SHELF THERMOSTAT

LIGHTING FIXTURES REGRIGERATOR THERMOSTAT

TRANSFORMER

ELECTRONIC CONTROL TRANSFORMER

WATER EVAPORATION HEATER ELEMENT THERMOSTAT

SECURITY THERMOSTAT

CONDENSER FAN THERMOSTAT

COMPRESSOR FAN / GENERAL USE

CONDENSER FAN

WATER EVAPORATION BIN

EXPANSION VALVE

INTERNAL FAN

CONDENSING PRESSURE CONTROL WATER VALVE

CHECK VALVE

SUCTION PRESSURE REGULATION VALVE

EVAPOTATING PRESSURE REGUTATION VALVE

GENERAL USE SOLENOID VALVE

SOLENOID WATER VALVE

BY-PASS SOLENOID WATER VALVE

REVERSING CYCLE SOLENOID VALVE

LIQUID SOLENOID VALVE

DEFROSTING SOLENOID VALVE

POWER REGULATOR

GLASS FAN

CABINET CONNECTIONS

EXTERNAL ELECTRIC PANEL CONNECTIONS

CONDENSING UNIT CONNECTIONS

,QVWDOOLQJDQG2SHUDWLQJ,QVWUXFWLRQV

UHO FRG

UHO FRG

1592009030 XW271 GB_1.doc

;:/ ;:/

1/4

::,1*

;:/ ;:/

;:/ ;:/

1. GENERAL WARNING

1.1 PLEASE READ BEFORE USING THIS MANUAL

• This manual is part of the product and should be kept near the instrument for easy and quick reference.

• The instrument shall not be used for purposes different from those described hereunder. It cannot be

used as a safety device.

• Check the application limits before proceeding.

1.2 SAFETY PRECAUTIONS

• Check the supply voltage is correct before connecting the instrument.

• Do not expose to water or moisture: use the controller only within the operating limits avoiding sudden

temperature changes with high atmospheric humidity to prevent formation of condensation

• Warning: disconnect all electrical connections before any kind of maintenance.

• Fit the probe where it is not accessible by the End User. The instrument must not be opened.

• In case of failure or faulty operation send the instrument back to the distributor or to “Dixell s.r.l.” (see

address) with a detailed description of the fault.

• Consider the maximum current which can be applied to each relay (see Technical Data).

• Ensure that the wires for probes, loads and the power supply are separated and far enough from each

other, without crossing or intertwining.

• In case of applications in industrial environments, the use of mains filters (our mod. FT1) in parallel with

inductive loads could be useful.

2. GENERAL DESCRIPTION

Models XW270L and XW271L, 38x185 mm format, are microprocessor based controllers suitable for

applications on medium or low temperature refrigerating units. They are provided with six relay outputs to

control compressor, defrost - which can be either electrical or hot gas - the evaporator fans, the lights, the

alarm and an auxiliary output. In XW271L the auxiliary output is configured as anti-condensing heater.

They arealso provided with three NTC probe inputs, one for temperature control,one to control the defrost end

temperature of the evaporator and the third, optional, for the display.There are two digital inputs (free contact)

for the door switch and configurable by parameter.

The standard TTL output allows the user to connect, by means of a TTL/RS485 external module, a ModBUS-

RTU compatible monitoring system and to programme the parameter list with the “Hot Key”.

An optional output for remote display “XW-REP” is available.

3. CONTROLLING LOADS

3.1 THE COMPRESSOR

The regulation is performed according to the temperature measured by the thermostat probe with a positive

differential from the set point: if the temperature increases and reaches set point plus differential the

compressor is started and then turned off when the temperature reaches the set point value again.

In case of fault in the thermostat probe the start and stop of the compressor are timed through parameters

“COn” and “COF”.

3.2 FAST FREEZING

When defrost is not in progress, it can be activated the keypad by holding the

X

X

key pressed for about 3

seconds. The compressor operates in continuous mode for the time set through the “CCt” parameter. The cycle

can be terminated before the end of the set time using the same activation key,

X

X

for about 3 seconds.

3.3 DEFROST

Three defrost modes are available through the “tdF” parameter: defrost with electrical heater, hot gas or

thermostatic defrost. The defrost interval is control by means of parameter “EdF”: (EdF=in) the defrost is made

every “IdF” time, (EdF=Sd) the interval “IdF” is calculate through Smart Defrost algorithm (only when the

compressor is ON and the evaporator temperature is bigger than “SdF” parameter).

At the end of defrost the drip time is controlled through the “Fdt” parameter.

3.4 CONTROL OF EVAPORATOR FANS

The fan control mode is selected by means of the “FnC” parameter:

FnC=C-n fans will switch ON and OFF with the compressor and not run during defrost:;

FnC=C-y fans will run continuously, but not during defrost

After defrost, there is a timed fan delay allowing for drip time, set by means of the “Fnd” parameter.

FnC=O-n fans will switch ON and OFF with the compressor and run during defrost;

FnC=O-y fans will run continuously also during defrost

An additional parameter “FSt” provides the setting of temperature, detected by the evaporator probe, above

which the fans are always OFF. This can be used to make sure circulation of air onlyifhistemperature is lower

than set in “FSt”.

3.5 AUXILIARY OUTPUT

The auxiliary output is switch ON and OFF by means of the corresponding button on the keyboard.

The auxiliary output of the XW271L model controls the anti-condensing heater and it is automatically activated

if the room temperature is lower than the “SAA” parameter.

4. KEYBOARD

To displayandmodifytarget setpoint; in programming mode it selects a parameter or confirm an

operation.

By holding it pressed for 3s when max or min temperature is displayed it will be erased.

To see the max. stored temperature; in programming mode it browses the parameter codes or

increases the displayed value. By holding it pressed for 3s the fast freezing cycle is started.

To see the min stored temperature; in programming mode it browses the parameter codes or

decreases the displayed value.

By holding it pressed for 3s the defrost is started.

Switch ON and OFF the cold room light.

By holding it pressed for 3s Energy Saving function is started or stopped.

For XW270L model. Switch ON and OFF the auxiliary output.

For XW271L model. Switch ON and OFF the anti-condensing heater output.

Switch ON and OFF the instrument.

KEY COMBINATIONS

+ To lock and unlock the keyboard.

+ To enter the programming mode.

+ To exit the programming mode.

4.1 USE OF LEDS

Each LED function is described in the following table.

LED MODE Function

ON The compressor is running

FLASHING - Programming Phase (flashing with LED )

- Anti-short cycle delay enabled

ON The fan is running

FLASHING Programming Phase (flashing with LED )

ON The defrost is enabled

FLASHING Drip time in progress

ON The Fast Freezing cycle is enabled

ON - ALARM signal

- In “Pr2” indicates that the parameter is also present in “Pr1”

ON (Present only in ’XW271L)

The Anti-condensing heater relay (Aux) is ON.

Function of the LEDs placed on the left top side of buttons:

BUTTON MODE FUNCTION

SET FLASHING The Set point is displayed and it can be modified

SET FAST FLASHING The Energy Saving is enabled

DEFROST ON The Manual Defrost is activated

ENERGY SAVING ON The Energy Saving is enabled

LIGHT ON The Light is ON

AUX ON The Auxiliary output is ON (XW270L)

HEATER ON The Anti-condensing heater is ON (XW271L)

ON/OFF ON The instrument is OFF

4.2 HOW TO SEE THE MIN TEMPERATURE

1. Press and release the

W

W

key.

2. The “Lo” message will be displayed followed by the minimum temperature recorded.

3. By pressing the

W

W

key or waiting for 5s the normal display will be restored.

4.3 HOW TO SEE THE MAX TEMPERATURE

1. Press and release the

X

X

key.

2. The “Hi” message will be displayed followed by the maximum temperature recorded.

3. By pressing the

X

X

key or waiting for 5s the normal display will be restored.

4.4 HOW TO RESET THE MAX AND MIN TEMPERATURE RECORDED

To reset the stored temperature, when max or min temperature is displayed :

1. Press SET key until “rST” label starts blinking.

N.B. After the installation RESET the temperature stored .

HOW TO SEE AND MODIFY THE SET POINT

1. Push and immediately release the SET key: the display will show the Set point value;

2. The SET LED start blinking;

3. To change the Set value push the

X

X

or

W

W

arrows within 10s.

4. To memorise the new set point value push the SET key again or wait 10s.

,QVWDOOLQJDQG2SHUDWLQJ,QVWUXFWLRQV

UHO FRG

UHO FRG

1592009030 XW271 GB_1.doc

;:/ ;:/

2/4

TO START A MANUAL DEFROST

1. Push the DEF key for more than 2 seconds and a manual defrost will start.

TO ENTER IN PARAMETERS LIST “PR1”

To enter the parameter list “Pr1” (user accessible parameters) operate as follows:

1. Enter the Programming mode by pressing the Set and DOWN key for few

seconds ( and start blinking).

2. The instrument will show the first parameter present in “Pr1”

TO ENTER IN PARAMETERS LIST “PR2”

To access parameters in “Pr2”:

1. Enter the “Pr1” level.

2. Select “Pr2” parameter and press the “SET” key.

3. The “PAS” flashing message is displayed, shortly followed by “0 - -” with a flashing zero.

4. Use

X

X

or

W

W

to input the security code in the flashing digit; confirm the figure by pressing “SET”. The

security code is “321“.

5. If the security code is correct the access to “Pr2” is enabled by pressing “SET” on the last digit.

Another possibility is the following: after switching ON the instrument the user can push Set and DOWN keys

within 30 seconds.

NOTE: each parameter in“Pr2” can be removed or put into “Pr1” (user level) by pressing “SET” +

W

W

. When a

parameter is present in “Pr1” LED is on.

HOW TO CHANGE THE PARAMETER VALUE

1. Enter the Programming mode.

2. Select the required parameter with

X

X

or

W

W

.

3. Press the “SET” key to display its value ( and LED starts blinking).

4. Use

X

X

or

W

W

to change its value.

5. Press “SET” to store the new value and move to the following parameter.

To exit: Press SET + UP or wait 15s without pressing a key.

NOTE: the new programming is stored even when the procedure is exited by waiting the time-out.

HOW TO LOCK THE KEYBOARD

1. Keep the

X

X

and

W

W

keys pressed together for more than 3 s the

X

X

and

W

W

keys.

2. The “POF” message will be displayed and the keyboard is locked. At this point it is only

possible the viewing of the set point or the MAX o Min temperature stored and to switch

ON and OFF the light, the auxiliary output and the instrument.

TO UNLOCK THE KEYBOARD

Keep the

X

X

and

W

W

keys pressed together for more than 3s.

ON/OFF FUNCTION

By pushing the ON/OFF key, the instrument shows “OFF” for 5 sec. and the ON/OFF LED is

switched ON.

During the OFF status, all the relays are switched OFF and the regulations are stopped; if a

monitoring system is connected, it does not record the instrument data and alarms.

N.B. During the OFF status the Light and AUX buttons are active.

TO SEE THE PROBE VALUES

1. Enter in “Pr2” level.

2. Select “Prd” parameter with

X

X

or

W

W

.

3. Press the “SET” key to display “Pb1” label alternate with Pb1 value.

4. Use

X

X

and

W

W

keys to display the other probe values.

5. Press “SET” to move to the following parameter.

PARAMETER LIST

REGULATION

Hy Differential: (0,1÷25,5°C; 1÷45°F): Intervention differential for set point, always positive. Compressor

Cut IN is Set Point Plus Differential (Hy). Compressor Cut OUT is when the temperature reaches the set

point.

LS Minimum set point limit: (-50,0°C÷SET; -58°F÷SET) Sets the minimum acceptable value for the set

point.

US Maximum set point limit: (SET÷110°C; SET÷230°F) Set the maximum acceptable value for set point.

OdS Outputs activation delay at start up: (0÷255 min) This function is enabled at the initial start up of the

instrument and inhibits any output activation for the period of time set in the parameter. (AUX and Light

can work)

AC Anti-short cycle delay: (0÷30 min) interval between the compressor stop and the following restart.

CCt Thermostat override: (0min ÷23h 50min) allows to set the length of the continuous cycle. Can be used,

for instance, when the room is filled with new products.

Con Compressor ON time with faulty probe: (0÷255 min) time during which the compressor isactive in case

of faulty thermostat probe. With COn=0 compressor is always OFF.

COF Compressor OFF time with faulty probe: (0÷255 min) time during which the compressor is off in case of

faulty thermostat probe. With COF=0 compressor is always active.

DISPLAY

CF Temperature measurement unit: °C = Celsius; °F = Fahrenheit . When the measurement unit is

changed the SET point and the values of the regulation parameters have to be modified

rES Resolution (for °C): (in = 1°C; de = 0,1°C) allows decimal point display.

de = 0,1°C

in = 1 °C

Lod Local display : select which probe is displayed by the instrument:

P1 = Thermostat probe

P2 = Evaporator probe

P3 = auxiliary probe

1r2 = difference between P1 and P2 (P1-P2)

Red Remote display : select which probe is displayed by the remote display (XW-REP)

P1 = Thermostat probe

P2 = Evaporator probe

P3 = auxiliary probe

1r2 = difference between P1 and P2 (P1-P2)

DEFROST

tdF Defrost type:

rE = electrical heater (Compressor OFF)

rT = thermostat defrost. During the defrost time “MdF”, the heater switches On and OFF depending on

the evaporator temperature and “dtE” value.

in = hot gas (Compressor and defrost relays ON)

EdF Defrost mode:

in = interval mode. The defrost starts when the time “Idf” is expired.

Sd = Smartfrost mode. The time IdF (interval between defrosts) is increased only when the compressor

is running(even non consecutively)and only if the evaporator temperature is less than the value in "SdF”

(set point for SMARTFROST).

SdF Set point for SMARTFROST: (-30÷30 °C/ -22÷86 °F) evaporator temperature which allows the IdF

counting (interval between defrosts) in SMARTFROST mode.

dtE Defrost termination temperature: (-50,0÷110,0°C; -58÷230°F) (Enabled only when the evaporator

probe is present) sets the temperature measured by the evaporator probe which causes the end of

defrost.

IdF Interval between defrosts: (1÷120h) Determines the time interval between the beginning of two defrost

cycles.

MdF (Maximum) duration of defrost: (0÷255 min) When P2P = n, no evaporator probe, it sets the defrost

duration, when P2P = y, defrost end based on temperature, it sets the maximum length for defrost.

dFd Display during defrost:

rt = real temperature;

it = temperature reading at the defrost start;

Set = set point;

dEF = “dEF” label;

dEG = “dEG” label;

dAd Defrost display time out: (0÷255 min) Sets the maximum time between the end of defrost and the

restarting of the real room temperature display.

Fdt Drain down time: (0÷60 min.) time interval between reaching defrost termination temperature and the

restoring of the control’s normal operation. This time allows the evaporator to eliminate water drops that

might have formed due to defrost.

dPO First defrost after start-up:

y = Immediately;

n= after the IdF time

dAF Defrost delay after fast freezing: (0min÷23h 50min) after a FastFreezing cycle,the first defrost will be

delayed for this time.

FANS

FnC Fan operating mode:

C-n = running with the compressor, OFF during the defrost;

C-y = running with the compressor, ON during the defrost;

O-n = continuous mode, OFF during the defrost;

O-y = continuous mode, ON during the defrost;

Fnd Fan delay after defrost: (0÷255 min) The time interval between the defrost end and evaporator fans start.

FSt Fan stop temperature: (-50÷110°C; -58÷230°F) setting of temperature, detected by evaporator probe,

above which the fan is always OFF.

ALARMS

ALC Temperature alarm configuration

rE = High and Low alarms related to Set Point

Ab = High and low alarms related to the absolute temperature.

ALU High temperature alarm setting:

ALC= rE, 0 ÷50°C or 90°F

ALC= Ab, ALL ÷110°C or 230°F

when this temperature is reached and after the ALd delay time the HA alarm is enabled.

ALL Low temperature alarm setting:

ALC = rE , 0 ÷50 °C or 90°F

ALC = Ab , - 50°C or -58°F ÷ALU

when this temperature is reached and after the ALd delay time, the LA alarm is enabled,.

AFH Temperature alarm and fan differential: (0,1÷25,5°C; 1÷45°F) Intervention differential for temperature

alarm set point and fan regulation set point, always positive.

ALd Temperature alarm delay: (0÷255 min) time interval between the detection of an alarm condition and

the corresponding alarm signalling.

dAO Delay of temperature alarm at start-up: (0min÷23h 50min) time interval between the detection of the

temperature alarm condition after the instrument power on and the alarm signalling.

EdA Alarm delay at the end of defrost: (0÷255 min) Time interval between the detection of the temperature

alarm condition at the end of defrost and the alarm signalling.

dot Delay of temperature alarm after closing the door : (0÷255 min) Time delay to signal the temperature

alarm condition after closing the door.

doA Open door alarm delay:(0÷255 min) delay between the detection of the open door condition and its

alarm signalling: the flashing message “dA” is displayed.

tbA Buzzer and alarm relay silencing: by pushing one of the keypad buttons.

n= Only the Buzzer is silenced;

y=Buzzer and relay are silenced.

nPS Pressure switch number: (0 ÷15) Number ofactivation of the pressure switch, during the “did” interval,

before signalling the alarm event (I2F= PAL).

PROBE INPUTS

Ot Thermostat probe calibration: (-12.0÷12.0°C/ -21÷21°F) allows to adjust possible offset of the

thermostat probe.

OE Evaporator probe calibration: (-12.0÷12.0°C/ -21÷21°F) allows to adjust possible offsets of the

evaporator probe.

,QVWDOOLQJDQG2SHUDWLQJ,QVWUXFWLRQV

UHO FRG

UHO FRG

1592009030 XW271 GB_1.doc

;:/ ;:/

3/4

O3 Auxiliary probe calibration: (-12.0÷12.0°C/ -21÷21°F) allows to adjust possible offsets of the

evaporator probe.

P2P Evaporator probe presence:

n= not present: the defrost stops only by time; y= present: the defrost stops by temperature and time.

P3P Auxiliary probe presence: n= not present; y= present.

HES Temperature increase during the Energy Saving cycle : (-30,0°C ÷30,0°C / -22÷86°F) sets the

increasing value of the set point during the Energy Saving cycle.

DIGITAL INPUTS

odc Compressor and fan status when open door:

no = normal;

Fan = Fan OFF;

CPr = Compressor OFF;

F_C = Compressor and fan OFF.

I1P Door switch input polarity:

CL : the digital input is activated by closing the contact;

OP : the digital input is activated by opening the contact.

I2P Configurable digital input polarity:

CL : the digital input is activated by closing the contact;

OP : the digital input is activated by opening the contact

I2F Digital input operating mode: configure the digital input function:

EAL = generic alarm;

bAL = serious alarm mode;

PAL = Pressure switch;

dFr = Start defrost;

AUS = Relay AUX actuation;

Es = Energy Saving;

onF = remote On/OFF.

did Time interval/delay for digital input alarm:(0÷255 min.) Time interval to calculate the number of the

pressure switch activation when I2F=PAL. If I2F=EAL or bAL (external alarms), “did” parameter defines

the time delay between the detection and the successive signalling of the alarm.

SAA Set Point for anti-condensing heater: (-50,0÷110,0°C; -58÷230°F) defines the room temperature

setpoint to switch on the anti-condensing heater.

OTHER

Adr RS485 serial address (1÷247): Identifies the instrument address when connected to a ModBUS

compatible monitoring system.

Rel Release software: (read only) Software version of the microprocessor.

Ptb Parameter table: (read only) it shows the original code of the

parameter map.

Prd Probes display: (read only) display the temperature values of the evaporator probe Pb2 and the

auxiliary probe Pb3.

Pr2 Access to the protected parameter list (read only).

DIGITAL INPUTS

The Wing series can support up to 2 free contact digital inputs. One is always configured as door switch, the

second is programmable in seven different configurations by the “I2F” parameter.

DOOR SWITCH INPUT

It signals the door status and the corresponding relay output status through the “odc” parameter:

no = normal (any change);

Fan = Fan OFF;

CPr = Compressor OFF;

F_C = Compressor and fan OFF.

Since the door is opened, after the delay time set through parameter “dOA”, the alarm output is enabled and

the display shows the message “dA”. The alarm stops as soon as the external digital input is disabled again.

During this time and then for the delay “dot” after closing the door, the high and low temperature alarms are

disabled.

CONFIGURABLE INPUT - GENERIC ALARM (EAL)

As soon as the digital input is activated the unit will wait for “did” time delay before signalling the “EAL” alarm

message. The outputs status don’t change. The alarm stops just after the digital input is de-activated.

CONFIGURABLE INPUT - SERIOUS ALARM MODE (BAL)

When the digital input is activated, the unit will wait for “did” delay before signalling the “BAL” alarm message.

The relay outputs are switched OFF. The alarm will stop as soon as the digital input is de-activated.

CONFIGURABLE INPUT - PRESSURE SWITCH (PAL)

If during the interval time set by “did” parameter, the pressure switch has reached the number of activation of

the “nPS” parameter, the “PAL” pressure alarm message will be displayed. The compressor and the regulation

are stopped. When the digital input is ON the compressor is always OFF.

CONFIGURABLE INPUT - START DEFROST (DFR)

It executes a defrost if there are the right conditions. After the defrost is finished, the normal regulation will

restart only if the digital input is disabled otherwise the instrument will wait until the “Mdf” safety time is expired.

CONFIGURABLE INPUT - RELAY AUX ACTUATION (AUS)

This function allows to turn ON and OFF the auxiliary relay by using the digital input as external switch.

CONFIGURABLE INPUT - ENERGY SAVING (ES)

The Energy Saving function allows to change the set point value as the result of the SET+ HES (parameter)

sum. This function is enabled until the digital input is activated.

CONFIGURABLE INPUT - REMOTE ON/OFF (ONF)

This function allows to switch ON and OFF the instrument.

DIGITAL INPUTS POLARITY

The digital inputs polarity depends on “I1P” and “I2P” parameters.

CL : the digital input is activated by closing the contact.

OP : the digital input is activated by opening the contact

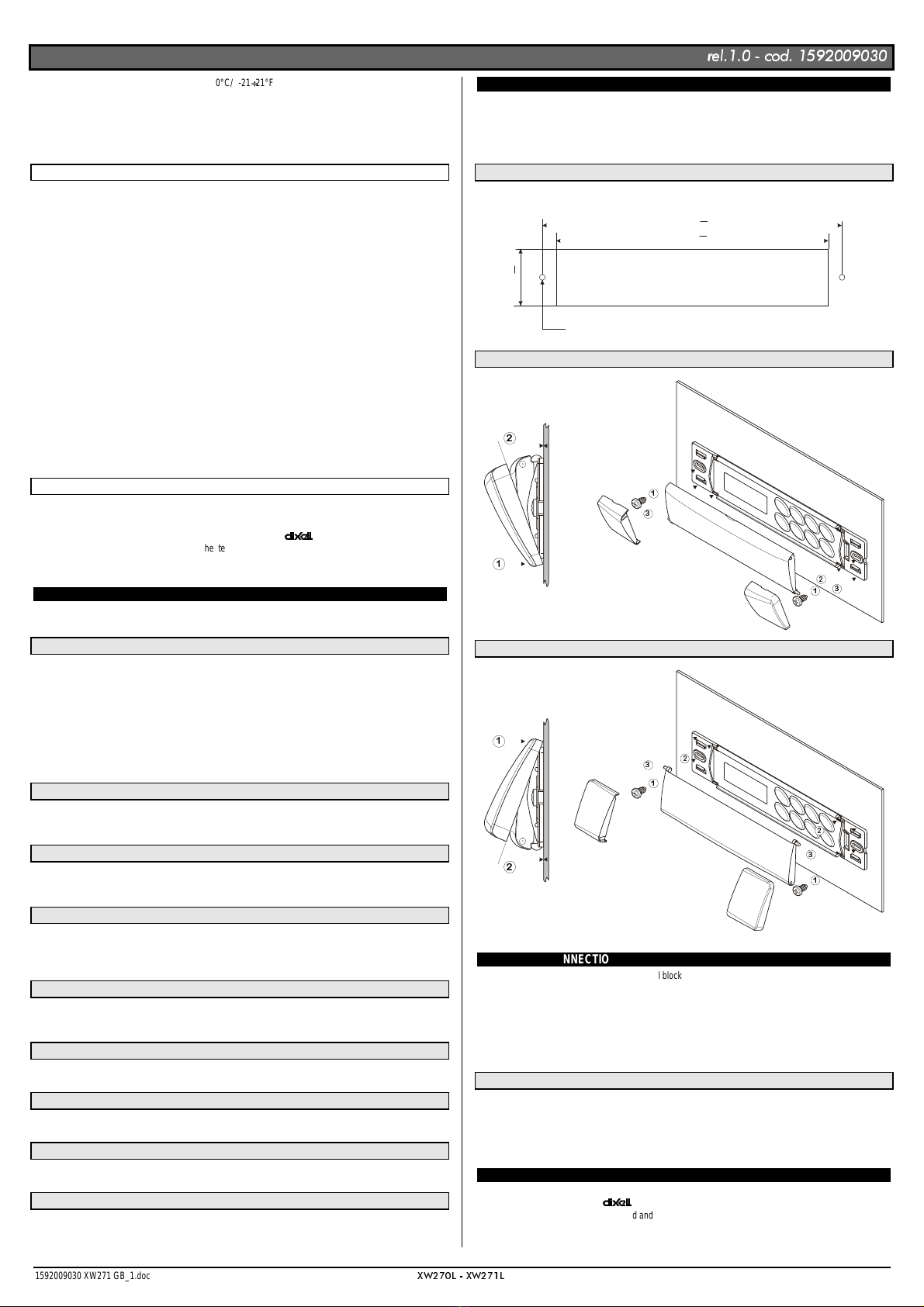

INSTALLATION AND MOUNTING

Instruments XW270L, XW271L shall be mounted on vertical panel, in a 150x31 mm hole, and fixed using two

screws ∅3 x 2mm. To obtain an IP65 protection grade use the front panel rubber gasket (mod. RG-L). The

temperature range allowed for correct operation is 0 - 60 °C. Avoid places subject to strong vibrations,

corrosive gases, excessive dirt or humidity. The same recommendations apply to probes. Let the air circulate

by the cooling holes.

CUT OUT

165

150

31

+0.5

-0

+0.5

-0

+1

-1

Ø3 x2

MOUNTING WITH KEYBOARD COVER OPENING DOWNWARD

CLICK!

MOUNTING WITH KEYBOARD COVER OPENING UPWARD

CLICK!

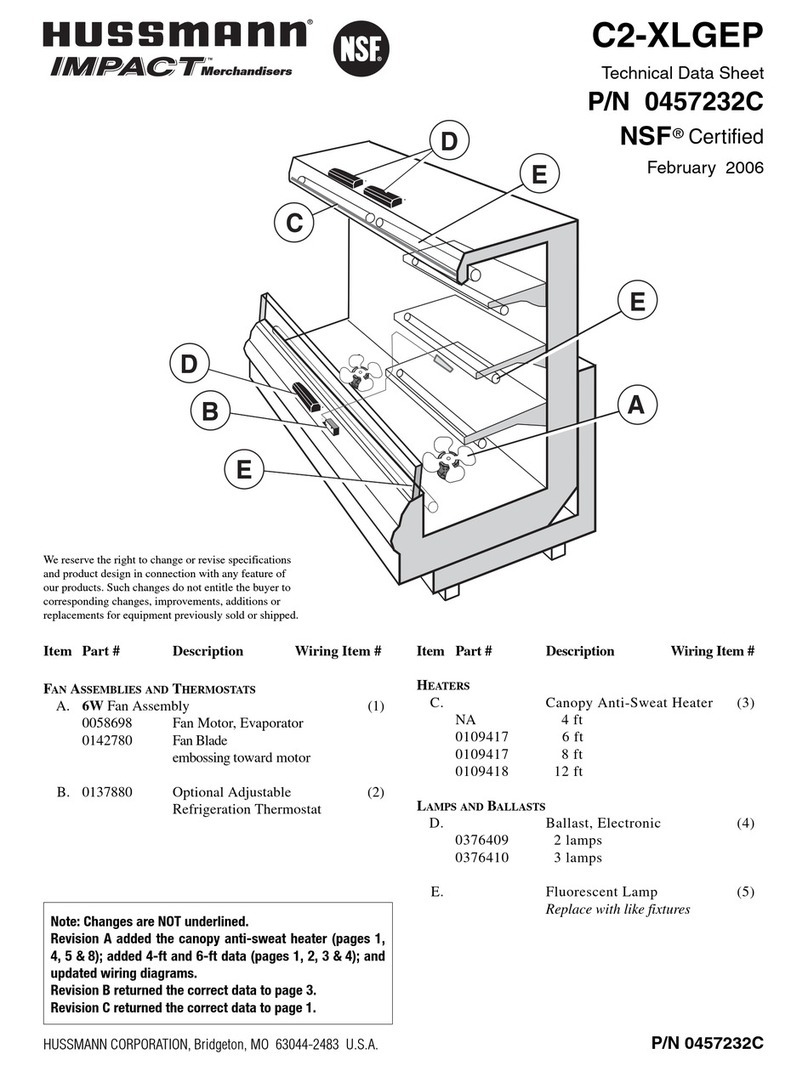

ELECTRICAL CONNECTIONS

The instruments are provided with screw terminal block to connect cables with a cross section up to 2,5 mm2 for

the digital and analogue inputs. Relays and power supply have a Faston connection (6,3mm). Heat-resistant

cables have to be used. Before connecting cables make sure the power supply complies with the instrument’s

requirements. Separate the probe cables from the power supply cables, from the outputs and the power

connections. Do not exceed the maximum current allowed on each relay, in case of heavier loads use a

suitable external relay.

N.B. Maximum current allowed for all the loads is 20A.

PROBE CONNECTIONS

The probes shall be mounted with the bulb upwards to prevent damages due to casual liquid infiltration. It is

recommended to place the thermostat probe away from air streams to correctly measure the average room

temperature. Place the defrost termination probe among the evaporator fins in the coldest place, where most

ice is formed, far from heaters or from the warmest place during defrost, to prevent premature defrost

termination.

TTL SERIAL LINE

The TTL connector allows, by means of the external module TTL/RS485, to connect the unit to a network line

ModBUS-RTU compatible as the

monitoring system XJ500 (Version 3.0).

The same TTL connector is used to upload and download the parameter list of the “HOT KEY“.

,QVWDOOLQJDQG2SHUDWLQJ,QVWUXFWLRQV

UHO FRG

UHO FRG

1592009030 XW271 GB_1.doc

;:/ ;:/

4/4

USE OF THE PROGRAMMING “HOT KEY “

The Wing units can UPLOAD or DOWNLOAD the parameter list from its own E2 internal memory to the “Hot

Key” and vice-versa.

DOWNLOAD (FROM THE “HOT KEY” TO THE INSTRUMENT)

1. Turn OFF the instrument by means of the ON/OFF key, remove the TTL serial cable if present, insert

the “Hot Key” and then turn the Wing ON.

2. Automatically the parameter list of the “Hot Key” is downloaded into the Wing memory, the “DoL”

message is blinking. After 10 seconds the instrument will restart working with the new parameters.

3. Turn OFF the instrument remove the “Hot Key”, plug in the TTL serial cable, then turn it ON again.

At the end of the data transfer phase the instrument displays the following messages:

“end “ for right programming. The instrument starts regularly with the new programming.

“err” for failed programming. In thiscase turn the unit off and then on if you want to restart the download again

or remove the “Hot key” to abort the operation.

UPLOAD (FROM THE INSTRUMENT TO THE “HOT KEY”)

1. Turn OFF the instrumentbymeansofthe ON/OFF key and remove the TTL serial cable if present; then

turn it ON again.

2. When the Wing unit is ON, insert the “Hot key” and push

X

key; the "uPL" message appears.

3. Push “SET” key to start the UPLOAD; the “uPL” message is blinking.

4. Turn OFF the instrument remove the “Hot Key”, plug in the TTL serial cable, then turn it ON again.

At the end of the data transfer phase the instrument displays the following messages:

“end “ for right programming.

“err” for failed programming. In this case push “SET” key if you want to restart the programming again or

remove the not programmed “Hot key”.

ALARM SIGNALS

Message Cause Outputs

“P1” Thermostat probe failure Alarm output ON; Compressor output according to

parameters “COn” and “COF”

“P2” Evaporator probe failure Alarm output ON; Other outputs unchanged

“P3” Auxiliary probe failure Alarm output ON; Other outputs unchanged

“HA” Maximum temperature alarm Alarm output ON; Other outputs unchanged

“LA” Minimum temperature alarm Alarm output ON; Other outputs unchanged

“EE” Data or memory failure Alarm output ON; Other outputs unchanged

“dA” Defrost timeout alarm Alarm output ON; Other outputs unchanged

“dAL” Door switch alarm Alarm output ON; Other outputs unchanged

“EAL” External alarm Alarm output ON; Other outputs unchanged

“BAL” Serious external alarm Alarm output ON; Other outputs OFF

“PAL” Pressure switch alarm Alarm output ON; Other outputs OFF

The alarm message is displayed until the alarm condition is recovery.

All the alarm messages are showed alternating with the room temperature except for the “P1” which is flashing.

To reset the “EE” alarm and restart the normal functioning press any key, the “rSt” message is displayed for

about 3s.

SILENCING BUZZER / ALARM RELAY OUTPUT

If “tbA = y”, once the alarm signal is detected the buzzer and the relay are is silenced by pressing any key.

If “tbA = n”, only the buzzer is silenced while the alarm relay is on until the alarm condition recovers.

“EE” ALARM

The

instruments are provided with an internal check for the data integrity. Alarm “EE” flashes when a

failure in the memory data occurs. In such cases the alarm output is enabled.

ALARM RECOVERY

Probe alarms : “P1” (probe1 faulty), “P2” and “P3”; they automatically stop 10s after the probe restarts normal

operation. Check connections before replacing the probe.

Temperature alarms “HA” and “LA” automatically stopas soon as the thermostat temperature returns to normal

values or when the defrost starts.

Door switch alarm “dA” stop as soon as the door is closed.

External alarms “EAL”,“BAL” stop as soon asthe external digital input isdisabled “PAL” alarm is recovered by

switching OFF the instrument.

TECHNICAL DATA

Housing: self extinguishing ABS.

Case: facia 38x185 mm; depth 76mm

Mounting : panel mounting in a 150x31 mm panel cut-out with two screws. ∅3 x 2mm.

Distance between the holes 165mm

Protection: IP20.

Frontal protection: IP65 with frontal gasket mod RG-L. (optional)

Connections: Screw terminal block ≤2,5 mm2heat-resistant wiring and 6,3mm Faston

Power supply: 230Vac or. 110Vac ±10%

Power absorption: 7VA max.

Display: 3 digits, red LED, 14,2 mm high.

Inputs: 3 NTC probes

Digital inputs: 2 free voltage

Relay outputs: Total current on loads MAX. 20A

compressor: relay SPST 20(8) A, 250Vac

light: relay SPST 16(3) A, 250Vac

fans: relay SPST 8(3) A, 250Vac

defrost: relay SPST 8(3) A, 250Vac

alarm: SPST relay 8(3) A, 250Vac

auxiliary: SPST relay 16(3) A, 250Vac

Other output : alarm buzzer

Serial output : TTL standard

Communication protocol: Modbus - RTU

Data storing: on the non-volatile memory (EEPROM).

Kind of action: 1B.

Pollution grade: normal

Software class: A.

Operating temperature: 0÷60 °C.

Storage temperature: -25÷60 °C.

Relative humidity: 20÷85% (no condensing)

Measuring and regulation range: NTC probe: -40÷110°C (-58÷230°F)

Resolution: 0,1 °C or 1°C or 1 °F (selectable).

Accuracy (ambient temp. 25°C): ±0,5 °C ±1 digit

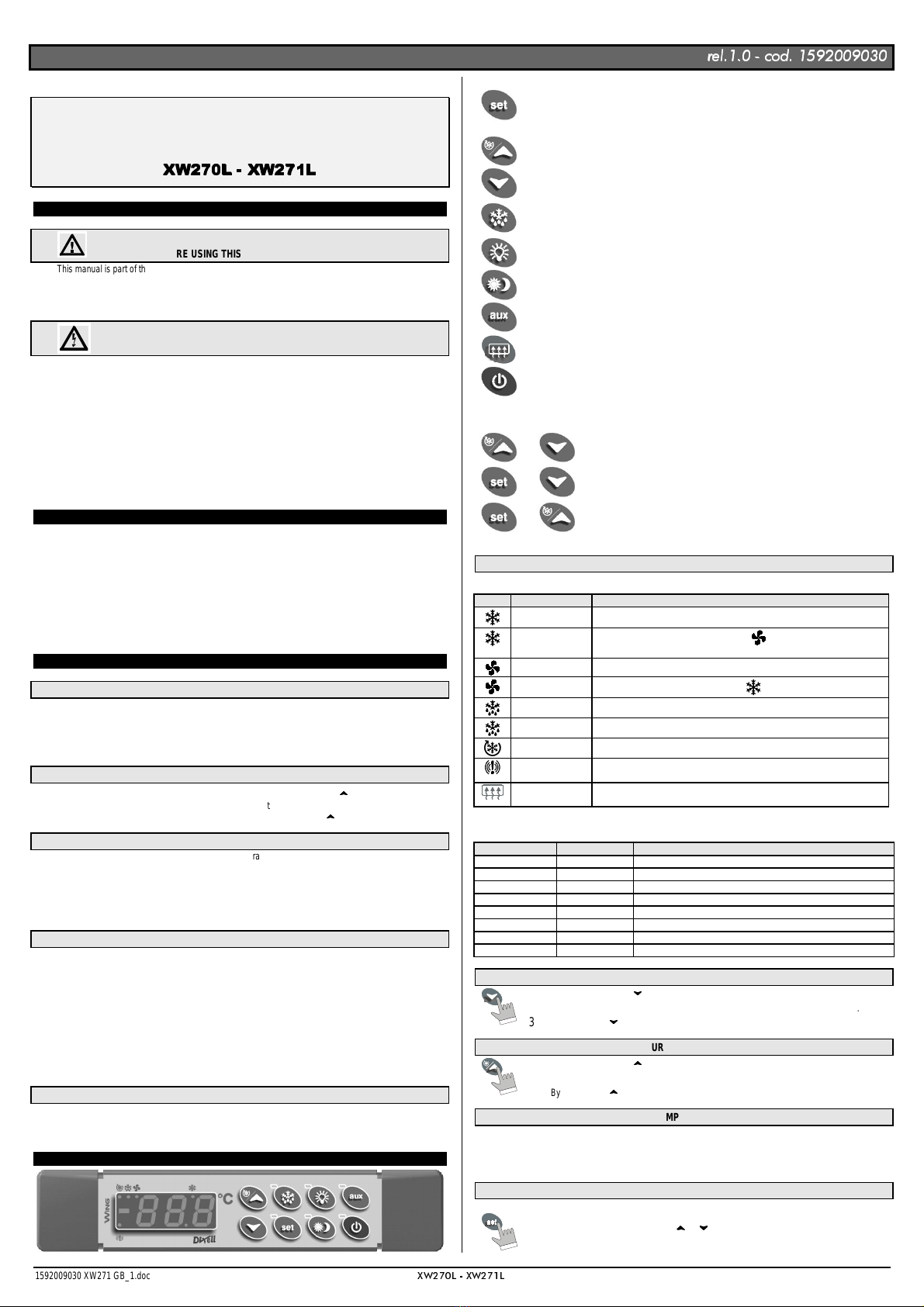

CONNECTIONS

XW270L/XW271L

(*) In XW271L, AUX is an anticondensing heater

Common

Door switch

Digital inp.

Def.

Display

Room

;:/;:/

ALARM

AUX

(*) Def. Comp

Fan Light

Line

Neutral

20A

250Vac MAX

20A

8A

250Vac 16A

250Vac

8A

250Vac 8A

250Vac

16A

250Vac

DEFAULT SETTING VALUES

Label Name Range Default Level

REGULATION °C/°F XW270L XW271L

Set Set point LS÷US -5 Pr1 Pr1

Hy Differential 0,1÷25,5 °C / 1÷45°F 2 Pr1 Pr1

LS Minimum set point -50,0°C÷SET / -58°F÷SET -30 Pr2 Pr2

US Maximum set point SET ÷ 110°C / SET ÷ 230°F 20 Pr2 Pr2

OdS Outputs activation delay at start up 0÷255 min. 1 Pr2 Pr2

AC Anti-short cycle delay 0÷30 min. 1 Pr1 Pr1

CCt Compressor ON time during fast

freezing 0 ÷ 23h 50 min. 0 Pr2 Pr2

COn Compressor ON time with faulty probe 0÷255 min. 15 Pr2 Pr2

COF Compressor OFF time with faulty probe 0÷255 min. 30 Pr2 Pr2

DISPLAY

CF Temperature measurement unit °C ÷ °F °C Pr2 Pr2

rES Resolution (integer/decimal point) in ÷ de de Pr1 Pr1

Lod Local display P1 ÷ 1r2 P1 Pr2 Pr2

Red Remote display P1 ÷ 1r2 P1 Pr2 Pr2

DEFROST

tdF Defrost type rE, rT, in rE Pr1 Pr1

EdF Defrost mode In, Sd In Pr2 Pr2

SdF Set point for SMART DEFROST -30 ÷ +30°C / -22÷+86°F 0 Pr2 Pr2

dtE Defrost termination temperature

(1°Evaporator) -50,0÷110°C/ -58÷230°F 8 Pr1 Pr1

IdF Interval between defrost cycles 1÷120h 6 Pr1 Pr1

MdF (Maximum) length for 1° defrost 0÷255 min. 30 Pr1 Pr1

dFd Displaying during defrost rt, it, SEt, dEF, dEG it Pr2 Pr2

dAd MAX display delay after defrost 0÷255 min. 30 Pr2 Pr2

Fdt Draining time 0÷60 min. 0 Pr2 Pr2

dPO First defrost after start up n ÷ y n Pr2 Pr2

dAF Defrost delay after fast freezing 0 ÷ 23h 50 min. 2 Pr2 Pr2

FANS

FnC Fans operating mode C-n, C-y, O-n, O-y O-n Pr2 Pr2

Fnd Fans delay after defrost 0÷255 min. 10 Pr2 Pr2

FSt Fans stop temperature -50,0÷110°C/ -58÷230°F 2 Pr2 Pr2

ALARMS

ALC Temperature alarms configuration rE÷Ab rE Pr2 Pr2

ALU MAXIMUM temperature alarm -50,0÷110°C/ -58÷230°F 10 Pr1 Pr1

ALL minimum temperature alarm -50,0÷110°C/ -58÷230°F 10 Pr1 Pr1

AFH Temperature alarm and fan differential 0,1÷25,5 °C / 1÷45°F 2

ALd Temperature alarm delay 0÷255 min. 15 Pr2 Pr2

dAO Delay of temperature alarm at start up 0 ÷ 23h 50 min. 1,3 Pr2 Pr2

EdA Alarm delay at the end of defrost 0÷255 min. 30 Pr2 Pr2

dot Delay of temperature alarm after closing

the door 0÷255 min. 15 Pr2 Pr2

dOA Open door alarm delay 0÷255 min. 15 Pr2 Pr2

tBA Alarm relay silencing y ÷ n y Pr2 Pr2

nPS Pressure switch activation number 0÷15 0 Pr2 Pr2

ANALOGUE INPUTS

Ot Thermostat probe calibration -12,0÷12,0°C / -21÷21°F 0 Pr1 Pr1

OE Evaporator probe calibration -12,0÷12,0°C / -21÷21°F 0 Pr2 Pr2

O3 Auxiliary probe calibration -12,0÷12,0°C / -21÷21°F 0 Pr2 Pr2

P2P Evaporator probe presence n ÷ y y Pr2 Pr2

P3P Auxiliary probe presence n ÷ y n Pr2 Pr2

HES Temperature increase during the Energy

Saving cycle -30÷30°C / -22÷86°F 0 Pr2 Pr2

DIGITAL INPUTS

Odc Open door control no, Fan, CPr, F_C Fan Pr2 Pr2

I1P Door switch polarity CL÷OP CL Pr2 Pr2

I2P Configurable digital input polarity CL÷OP CL Pr2 Pr2

i2F Digital input configuration EAL, bAL, PAL, dFr,

AUS, ES, OnF EAL Pr2 Pr2

dId Digital input alarm delay 0÷255 min. 5 Pr2 Pr2

SAA Set point for anti-condensing heater -50,0÷110°C/ -58÷230°F -20.0 - - - Pr2

OTHER

Adr Serial address 0÷247 1 Pr1 Pr1

rEL Software release - - - 1.0 Pr2 Pr2

Ptb Map code - - - - - - Pr2 Pr2

Prd Probes display Pb1÷Pb3 - - - Pr2 Pr2

Pr2 Access parameter list - - - - - - Pr2 Pr2

Dixell s.r.l. Via dell’Industria, 27 - 32010 Z.I Pieve d’Alpago (BL) ITALY

tel. +39 - 0437 - 98 33 - fax +39 - 0437 - 98 93 13 -

(PDLOGL[HOO#GL[HOOFRP KWWSZZZGL[HOOFRP

This manual suits for next models

3

Table of contents

Popular Merchandiser manuals by other brands

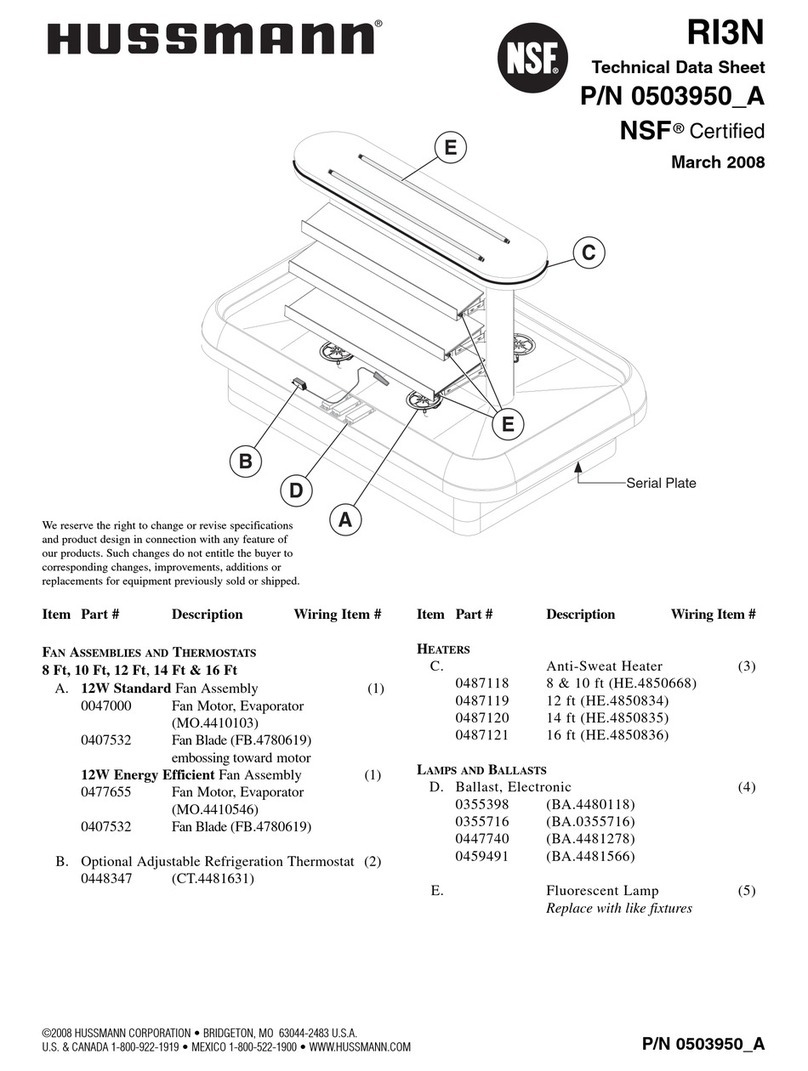

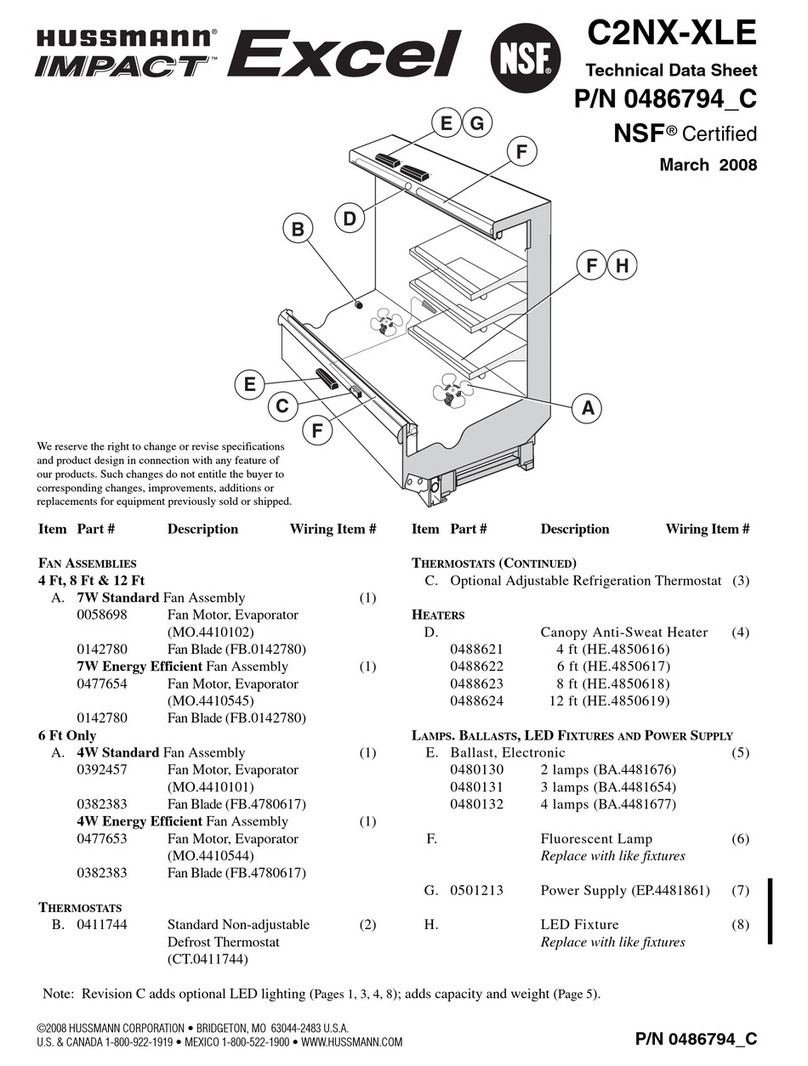

Hussmann

Hussmann Impact Excel C2X-LGEP Technical data sheet

Hussmann

Hussmann RI2-E Technical data sheet

Hussmann

Hussmann RI3-N Technical data sheet

Hussmann

Hussmann Impact C2-XLE Technical data sheet

Alto-Shaam

Alto-Shaam ITM2-48/STD Installation & operation instruction

Goldmedal

Goldmedal Sterno Pretzel Warmer instruction manual