CIMCO OXE Diesel 125 HP User manual

1

OXE 125/150/175/200 HP INSTALLATION MANUAL

INSTALLATION MANUAL 1.0

Publication No: ODM1003-B

DIESEL ENGINE

3

OXE 125/150/175/200 HP INSTALLATION MANUAL

PREFACE

ABOUT THIS MANUAL

This manual provides you with the information you need to install your

125/150/175/200 HP OXE diesel outboard.

When installing the OXE diesel outboard, it is recommended to have access to

- OXE diesel outboard Service Book

- OXE diesel outboard User’s Manual

- Apliccable accessory manuals, such as a Control Head and Display Manual.

NOTE! Specifications and descriptions are subject to change without notice.

!IMPORTANT!

Be sure to fill in the Commissioning Information Form at the rear of this manual

to activate your warranty.

Cimco Marine AB

PREFACE

Metallgatan 17 B

SE-262 72 Ängelholm, Sweden

+46 (0)431-371130

4

OXE 125/150/175/200 HP INSTALLATION MANUAL

5

OXE 125/150/175/200 HP INSTALLATION MANUAL

CONTENTS

Preface ________________________________________________________________________________ 3

About this manual___________________________________________________________________ 3

Warning signs and regulations _____________________________________________________________ 9

Levels of warnings __________________________________________________________________ 9

Regulations designed to prevent accidents _______________________________________________ 9

Prevent accidents with personal injury and damage to engine____________________________ 9

Prevent accidents with damage to engine ____________________________________________ 9

Prevent accidents with damage to the environment ___________________________________ 10

Important information ___________________________________________________________________ 12

Recommended fluids and grease______________________________________________________ 12

Avoiding fuel flow restrictions ________________________________________________________ 13

Technical data _____________________________________________________________________ 14

Unpacking instructions __________________________________________________________________ 15

Accessory box Content ______________________________________________________________ 17

Installation dimensions __________________________________________________________________ 18

Mounting the OXE outboard ______________________________________________________________ 21

General application _____________________________________________________________ 22

High speed application __________________________________________________________ 22

Installing Transom mount ___________________________________________________________ 23

Determining boat transom vertical centerline (C/L) ___________________________________ 24

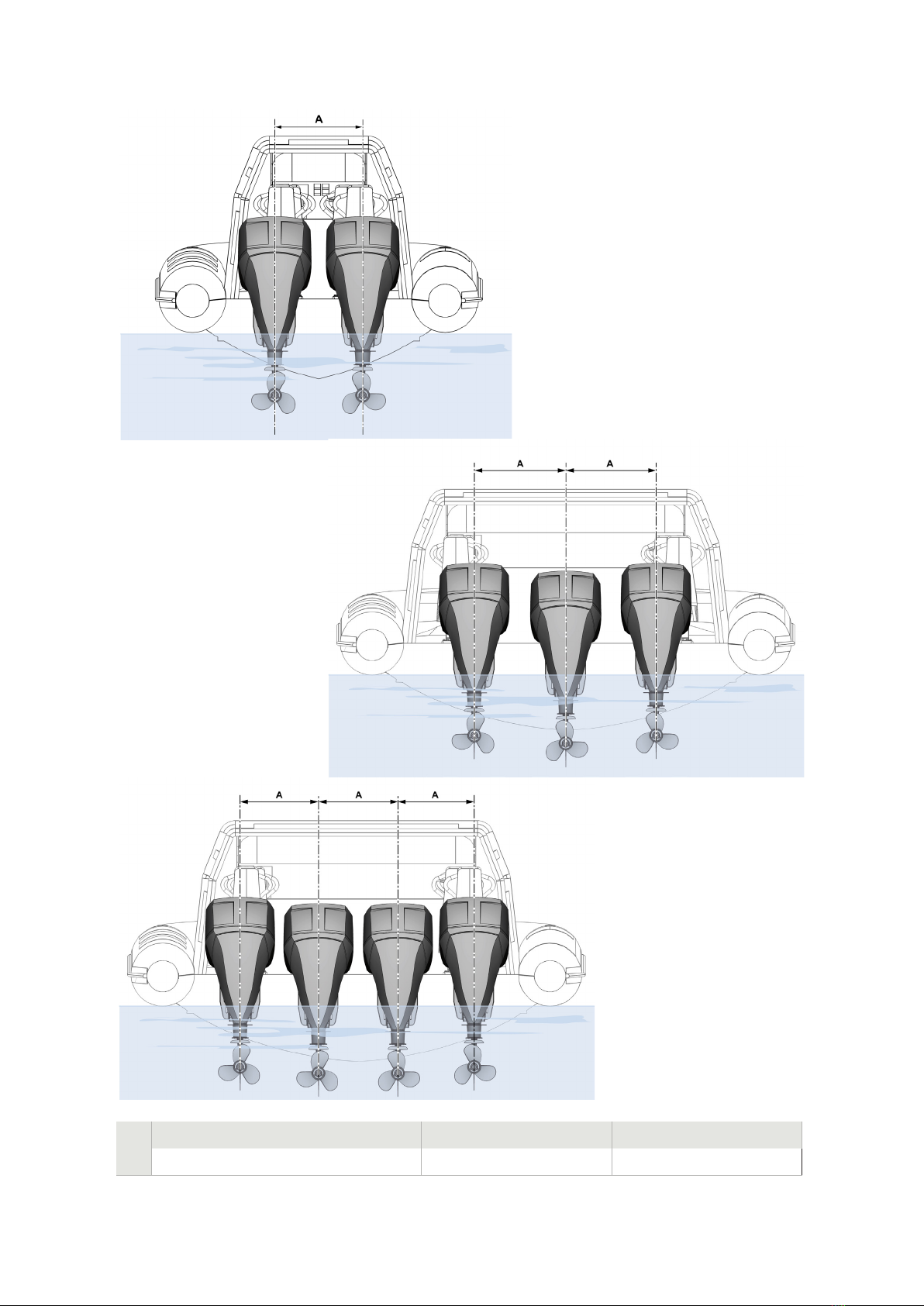

OXE outboard twin installation ____________________________________________________ 24

OXE outboard triple installation ___________________________________________________ 25

OXE outboard quad installation ___________________________________________________ 25

Steering ______________________________________________________________________________ 27

Electro Steering without joystick ______________________________________________________ 27

Electro Steering with joystick_________________________________________________________ 28

Power steering ____________________________________________________________________ 29

Power steering servo-assisted _______________________________________________________ 29

Steering cylinder in single engine application ____________________________________________ 30

Steering cylinder and tie bar in Twin engine application ____________________________________ 30

Two Steering cylinders and one tie bar in Triple engine application ___________________________ 31

Two Steering cylinders and Two tie bars in Quad engine application __________________________ 31

Oxe outboard alignment, toe-in and toe-out position __________________________________ 32

CONTENTS

6

OXE 125/150/175/200 HP INSTALLATION MANUAL

Fuel system ___________________________________________________________________________ 33

Fuel pre-filter _________________________________________________________________ 33

External fuel feed pump _________________________________________________________ 33

Engine fuel filter _______________________________________________________________ 34

Fuel rail high-pressure pump_____________________________________________________34

Fuel rail assembly______________________________________________________________ 34

Fuel tank _____________________________________________________________________34

Fuel rail sensor ________________________________________________________________34

Fuel injectors__________________________________________________________________ 34

Quick-connect fitting ____________________________________________________________34

Fuel pipe O-rings_______________________________________________________________34

Installing fuel lines _________________________________________________________________ 35

bleeding the Fuel system ____________________________________________________________ 36

Propeller and gear ratio selection _________________________________________________________ 37

Selecting the correct gear ratio and propeller for your application________________________ 37

Upper (primary) belt housing _________________________________________________________ 37

Propeller rotation ______________________________________________________________ 38

Diameter and pitch _________________________________________________________________ 38

Diameter ____________________________________________________________________ 38

Pitch ________________________________________________________________________ 39

Propeller slippage _________________________________________________________________ 40

Slip examples _________________________________________________________________ 40

Propeller testing and optimisation ____________________________________________________40

Engine under or overloading _________________________________________________________ 41

Theoretical Speed calculations _______________________________________________________ 41

Example _____________________________________________________________________ 41

General propeller and application table _________________________________________________ 42

Propeller installation ____________________________________________________________________ 43

propeller anode installation __________________________________________________________ 46

CONTENTS

7

OXE 125/150/175/200 HP INSTALLATION MANUAL

CONTENTS

Installation wiring ______________________________________________________________________ 47

Identification of wiring harness generations _____________________________________________ 47

NMEA2000, 1A (F101) FUSE __________________________________________________________48

Single Engine Configuration ______________________________________________________48

Multiple Engine Configuration_____________________________________________________ 48

User ignition signal, 1A (F102) FUSE ___________________________________________________48

Engine - Helm harness Engine connector _______________________________________________ 49

12V Electrical power connection ______________________________________________________ 50

G3.5 - Single engine application _______________________________________________________ 51

G3.5 - Twin engine application ________________________________________________________ 52

G3.5 - Triple application _____________________________________________________________ 53

G3.5 - Quad engine application________________________________________________________ 54

Reference, installation wiring G3.5_____________________________________________________ 55

Color codes, cable harness_______________________________________________________ 55

G4 - Single engine application ________________________________________________________ 56

G4 - Twin engine application__________________________________________________________ 57

G4 - Triple engine application _________________________________________________________ 58

G4 - Quad engine application _________________________________________________________ 59

Reference, installation wiring G4 ______________________________________________________ 60

Color codes, cable harness_______________________________________________________ 60

Controlhead throttle and shi behavior _________________________________________________ 61

Triple outboard application _______________________________________________________ 61

Quad outboard application _______________________________________________________ 61

Electrical Components ______________________________________________________________ 62

Engine setup___________________________________________________________________________ 65

Setting engine rotation, location and number of engines ___________________________________ 65

Setting Engine rotation __________________________________________________________ 65

Setting Engine Location _________________________________________________________ 66

Setting Number of Engines_______________________________________________________ 66

Start/test running on land________________________________________________________________ 67

Options _______________________________________________________________________________ 69

Cabin Heater installation ____________________________________________________________ 69

Notes_________________________________________________________________________________ 70

Delivery and warranty registration_________________________________________________________ 73

Harbor Acceptance Checklist (HAT) ____________________________________________________ 75

Sea trial checklist (SAT) _____________________________________________________________ 79

Report form ___________________________________________________________________________ 81

8

OXE 125/150/175/200 HP INSTALLATION MANUAL

9

OXE 125/150/175/200 HP INSTALLATION MANUAL

WARNING SIGNS AND REGULATIONS

WARNING SIGNS AND REGULATIONS

LEVELS OF WARNINGS

Important instructions which concern technical safety and protection of persons

are emphasised as shown below.

!WARNING

A warning indicates a hazardous situation which, if ignored, could result in

death or serious injury.

!DANGER

This refers to working and operating procedures which must be complied

with in order to prevent damage to or destruction of material.

!CAUTION

A caution indicates special precautions that must be taken to avoid damage

to the products or other property.

NOTE! Explanatory descriptions which help in understanding the relevant work

or operating procedure to be carried out.

REGULATIONS DESIGNED TO PREVENT ACCIDENTS

Prevent accidents with personal injury and damage to engine

- Installation work may only be performed by authorized and skilled

personnel.

- Keep area surrounding the outboard, ladders and stairways free

from oil and grease. Accidents caused by slipping can have serious

consequences.

- Persons must not stand under an engine suspended on a crane hook.

Use certified liing equipment and check for any damage.

- Wear close-fitting working clothes.

- Wear safety work clothes and footwear.

- During installation work, switch off the battery master switch.

- The engine may only be started and operated by authorized personnel.

Prevent accidents with damage to engine

- Always use genuine OXE parts. Installation of “equally” good parts from other

suppliers may cause severe damage for which the workshop carrying out the

work is responsible.

- Use only OXE diesel-approved service products (fuel, engine oil, antifreeze

and anti-corrosion agent).

Pay attention to cleanliness. Diesel fuel must be free of water.

10

OXE 125/150/175/200 HP INSTALLATION MANUAL

Prevent accidents with damage to the environment

Engine oil and filter elements/cartridges, fuel/fuel filter

- Dispose of used oil according to local environmental legislation.

- Take strict precautions to ensure that no oil or diesel fuel contaminate soil or

drainages.

!CAUTION

Risk of contamination of drinking water.

- Filter elements are classed as dangerous waste and must be treated as such.

Coolant

- Treat undiluted anti-corrosion agents and/or antifreeze as

hazardous waste.

- When disposing of used coolant, the environmental legislation issued by the

relevant local authorities must be adhered to.

Notes on safety in handling used engine oil

Prolonged or repeated contact between the skin and any kind of engine oil dries

out and increases the risk of skin-related illnesses such as eczema. Common

effects to the exposed skin are dry sensations, irritation and inflammation. Drying,

irritation or inflammation of the skin may therefore occur. Used engine oil also

contains hazardous substances that have caused skin cancer in tests on animals. If

the basic principles of work safety and hygiene are followed, handling used engine

oil does not represent a health hazard.

WARNING SIGNS AND REGULATIONS

11

OXE 125/150/175/200 HP INSTALLATION MANUAL

Precautionary measures to protect your health

- Avoid prolonged or repeated skin contact with used engine oil.

- Protect your skin by means of suitable agents (creams etc.) or wear

protective gloves.

- Clean skin which has been in contact with engine oil.

- Wash thoroughly with soap and water. A nail brush provides effective

assistance here.

- Special hand cleaning agents make it easier to clean dirty hands.

- Do not use gasoline (petrol), diesel fuel, gas oil or solvents as

washing agents.

- Aer washing apply a fatty skin cream to the skin.

- Change clothing and shoes that are soaked in oil.

- Do no put oily cloths in your pockets.

Ensure that used engine oil is disposed of in appropriate manner. Engine oil

is a substance that endangers the water supply.

For this reason do not let engine oil get into the ground, waterways, the drains or

the sewers. Violations of local environmental legislation are punishable by law.

Carefully collect and dispose of used engine oil. Information on collection points

can be obtained from retailers, the supplier or the local authorities.

WARNING SIGNS AND REGULATIONS

12

OXE 125/150/175/200 HP INSTALLATION MANUAL

IMPORTANT INFORMATION

!WARNING

The OXE diesel outboard is normally delivered without any fluids and has to be filled up before start-up.

Use fluids of quality and volume listed in table below.

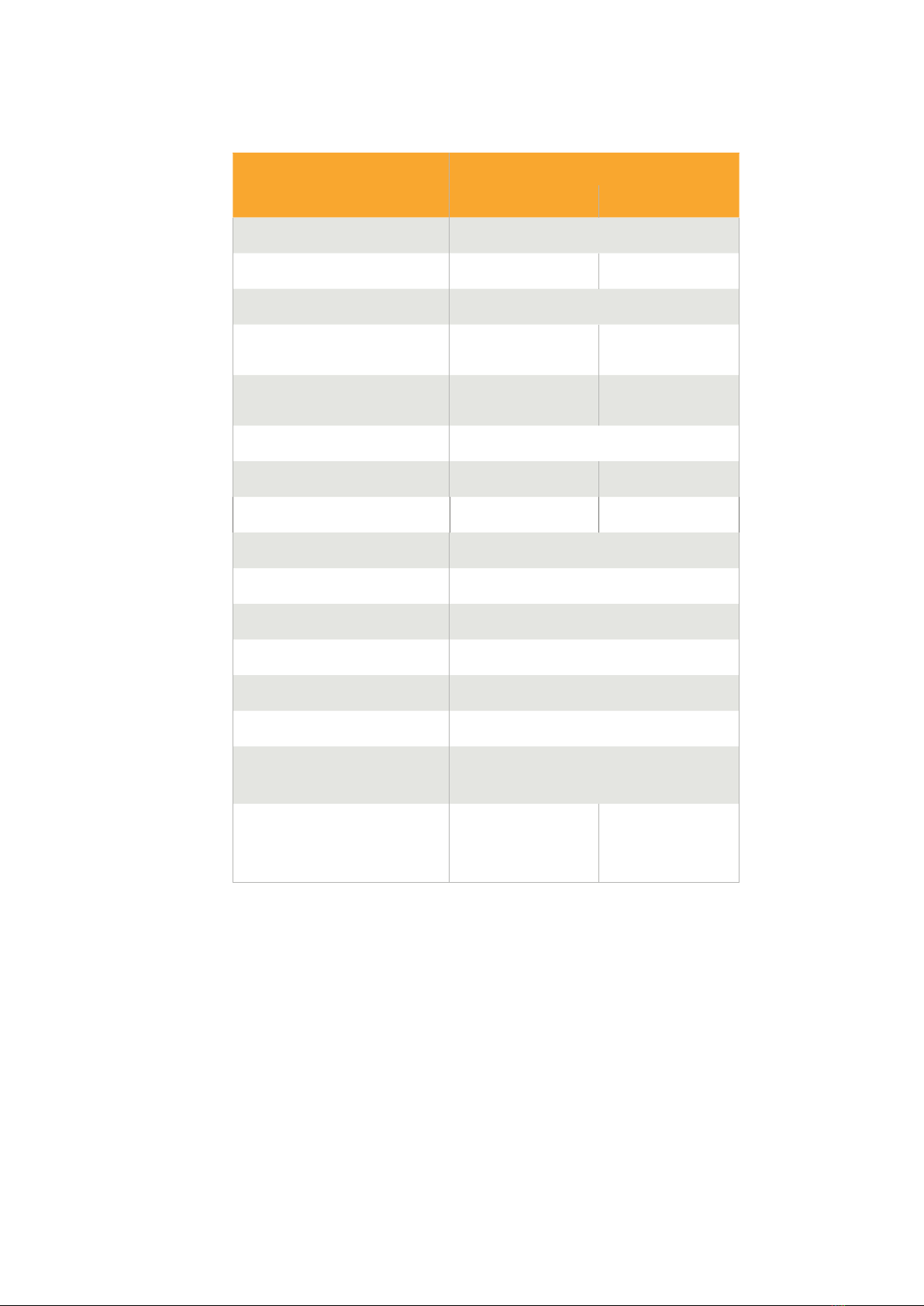

RECOMMENDED FLUIDS AND GREASE

Quantity

Fluid Quality Metric US units

Fuel

EN 590 (with national environmental and cold weather

standards)

ASTM D 975 No. 1 and No. 2

JIS KK 2204

NATO Code F54 and F75

- -

Engine oil OXE Engine Oil or

5w-30 dexos2 API SM/CF GM-LL-A025/ B025 ACEA A3/B4 2)

5.5 liters 1) 3)

7.0 liters 1) 4)

5.8 quarts 1) 3)

7.4 quarts 1) 4)

Gear box oil OXE Gearbox Oil or

Fully Synthetic Dual Clutch Transmission Fluid - DCT 2.0 liters 1) 2.1 quarts

Coolant

OXE Coolant or

GM Long-Life Coolant - Specification B040 1065/Distilled water

(min 30/70)

6.0 liters 6.3 quarts

Grease OXE Grease or

DIN 51502:KP2.5K-20 ISO 6743: ISO-L-XBCEB2.5 - -

Power trim and tilt unit,

PTT

OXE PTT Oil or

ATF Dexron II 0.5-0.7 liters 0.52-0.73 quarts

Upper belt oil OXE Belt Transmission Oil or

Fully Synthetic Transmission Fluid - ATF / Dexron HP 0.33 liters 0.34 quarts

Lower belt oil OXE Belt Transmission Oil or

Fully Synthetic Transmission Fluid - ATF / Dexron HP 2 liters 2.1 quarts

NOTE! The fuel must meet national and international standards.

NOTE! Only use fuels, lubricants etc. in accordance with Cimco Marine AB regulations. Otherwise the

manufacturer’s liability for defects will not apply!

Also refer to User’s manual and Workshop Manual, section Recommended Fluids and grease.

IMPORTANT INFORMATION

3) Volumes for engines 125 and 150 HP

4) Volumes for engines 175 and 200 HP

1) Refer to Workshop Manual

2) For cold climate, select viscosity according to table Oil Viscosity.

13

OXE 125/150/175/200 HP INSTALLATION MANUAL

DIESEL FUEL

The composition of the fuel is vital for operation of the OXE diesel engine, its

service life, and emissions. To meet the performance specified and to run the

boat cleanly and quietly, it is important that fuel as recommended in table

Recommended fluids and grease is used.

If national emission regulations permit, OXE diesel engines can be operated on

commercially available diesel fuels with less than 0.05% sulfur content.

Fuel sulfur content ≤0.05% (≤500 ppm) >0.05% - 0.5% (>500-5000 ppm2))

Engine oil change intervals 200 h or one year 100 h or one year 1)

1) If the sulfur content is higher than 0.05%, the intervals between engine oil changes should be halved

or determined by frequent oil sampling.

2) If the sulfur content is higher than 0.1% an engine lubrication oil with suitable TBN shall be used.

NOTE! Do not use fuel with more than 0.5% sulphur content!

Using fuel with high sulfur content will increase the OXE diesel engine’s emission

levels and cause excessive wear and shorter life time.

Large differences in composition occur in local fuel specification. This can result in

higher fuel comsumption, higher emissions and less power output.

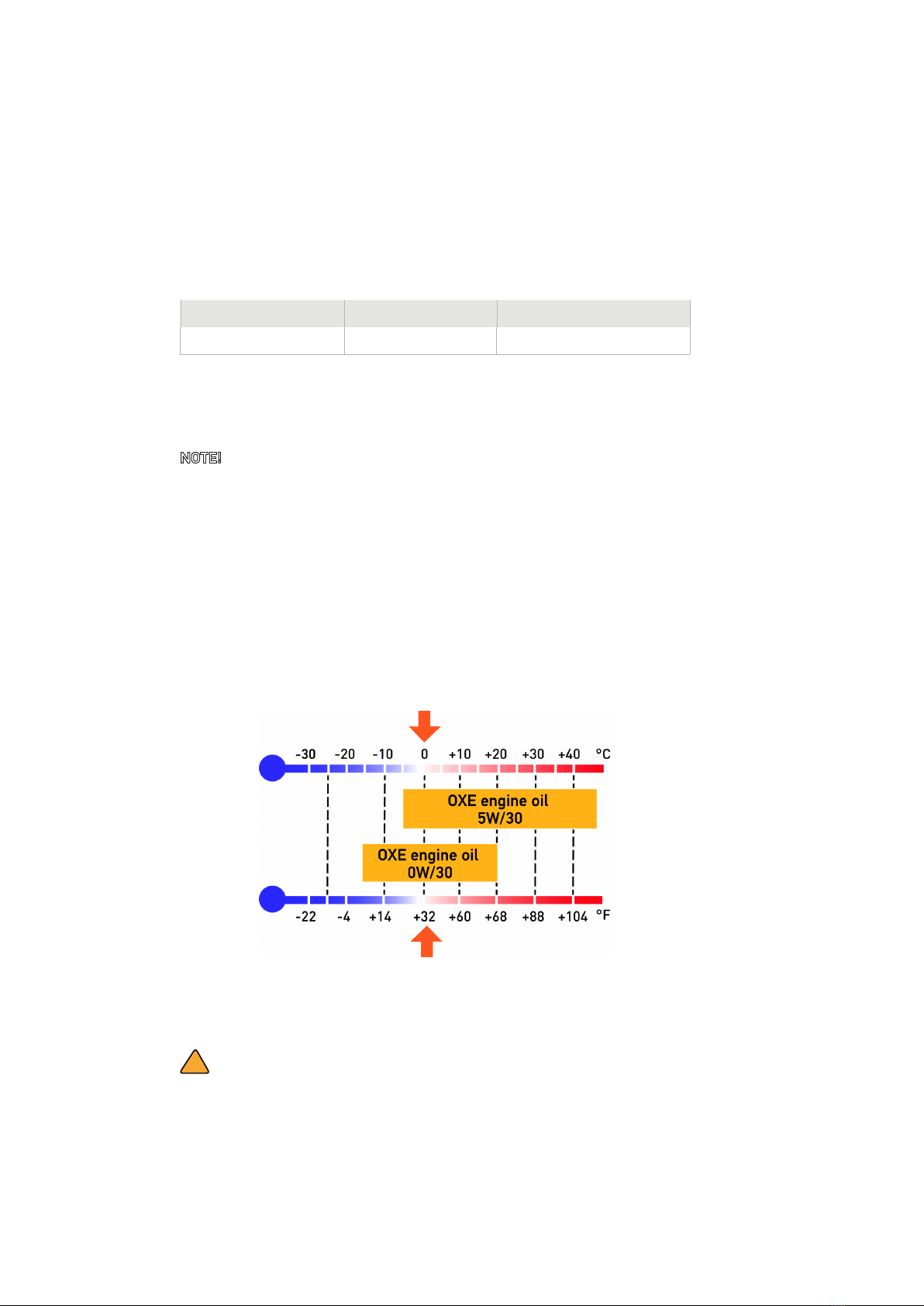

ENGINE OIL VISCOSITY

Select viscosity according to diagram below.

The temperature values refer to stable ambient temperatures.

AVOIDING FUEL FLOW RESTRICTIONS

!WARNING

Adding additional components to the fuel supply system such as filters,

valves, fittings, etc. may restrict the fuel flow. This could cause engine

stalling at low speed, and/or a lean fuel condition at high RPM, that could

cause engine damage.

IMPORTANT INFORMATION

14

OXE 125/150/175/200 HP INSTALLATION MANUAL

TECHNICAL DATA

Application

Specification

Metric US units

Engine type Diesel, L4

Displacement 1956 cc 122 cu in

Intake VGT turbocharged, intercooled

Max. power

at engine speed 4100 RPM 92/110/129/147 kW 125/150/175/200 HP

Max. engine torque

at engine speed at 2500 rpm 376/380/380/415 Nm 510/515/515/563 lb

Fuel Diesel

Dry weight 350 kg 772 lbs

Wet weight 358 kg 789 lbs

Alternator output 130 A

Rig length 25" or 33"

Cooling Closed cooling circuit, heat exchanger/seawater

Starting Electric

Shi Electro-hydraulic

Clutch Hydraulic multi-friction plate

Gear ratios High speed - 1.73:1

High speed torque - 2.17:1

Dimensions, L x H x W

25" leg

33” leg

994 x 1880 x 678 mm

994 x 2083 x 678 mm

39 x 74 x 27 in

39 x 82 x 27 in

SELECTING ACCESSORIES FOR THE OXE OUTBOARD

Genuine Cimco Marine parts and accessories have been specifically designed and

tested for OXE outboards.

Some accessories, not manufactured or sold by Cimco Marine, may not be

designed to be safely used with OXE outboards or OXE outboard operating system.

Acquire and read the Installation, Operation, Maintenance and Accessories

manuals for all selected accessories.

IMPORTANT INFORMATION

15

OXE 125/150/175/200 HP INSTALLATION MANUAL

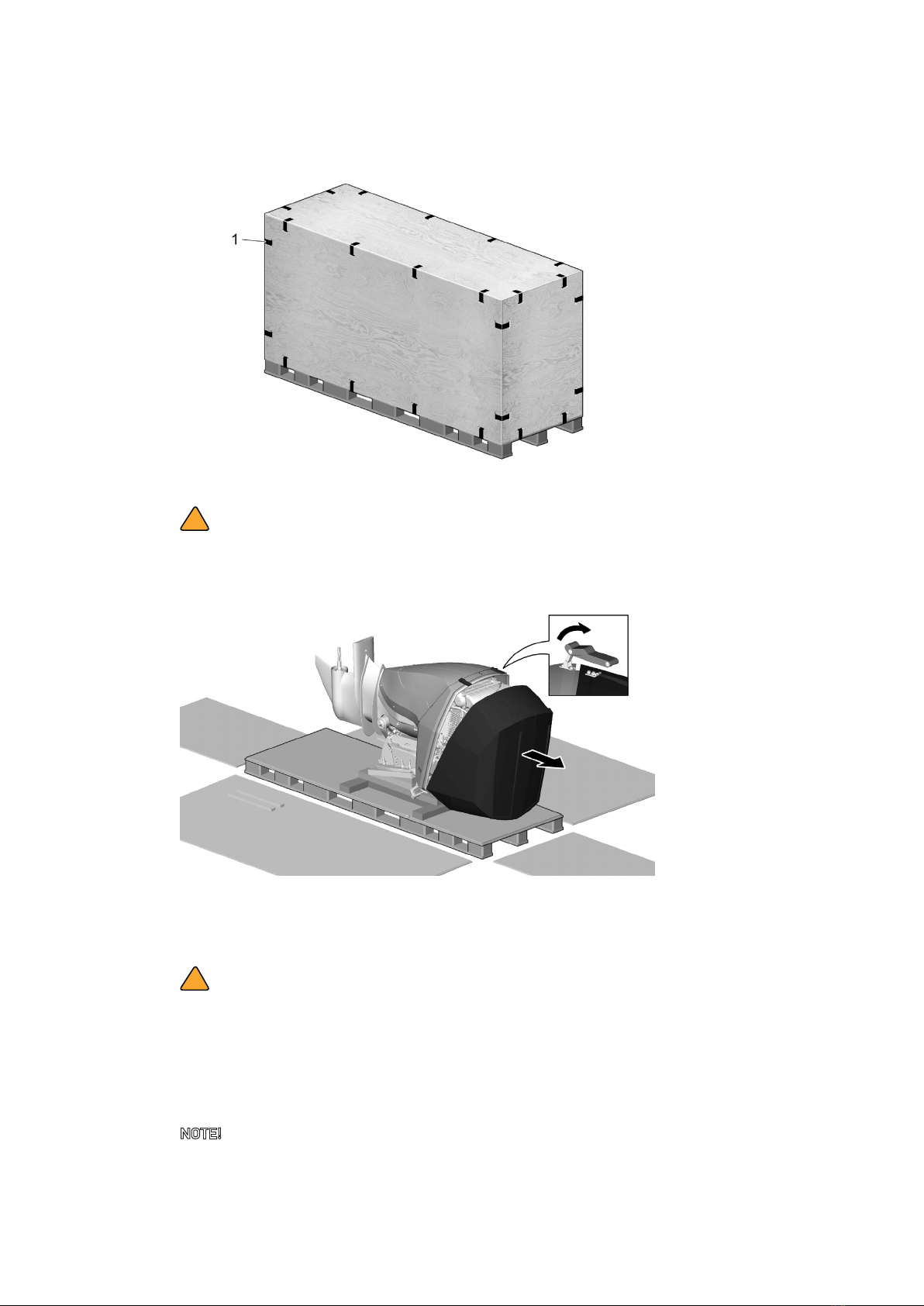

UNPACKING INSTRUCTIONS

UNPACKING INSTRUCTIONS

1. Move the OXE outboard box by means of a pallet/forkli truck.

!CAUTION

Follow instructions on the OXE outboard box.

2. Remove the lid and side parts from the pallet.

3. Remove and take care of the box containing installation accessories.

!CAUTION

Do not damage the outboard surface.

4. Remove the OXE outboard top cowling.

5. Remove and take care of the document folder placed on the right side of the

engine.

NOTE! These documents shall be delivered with the OXE outboard and always

passed on to the next owner!

16

OXE 125/150/175/200 HP INSTALLATION MANUAL

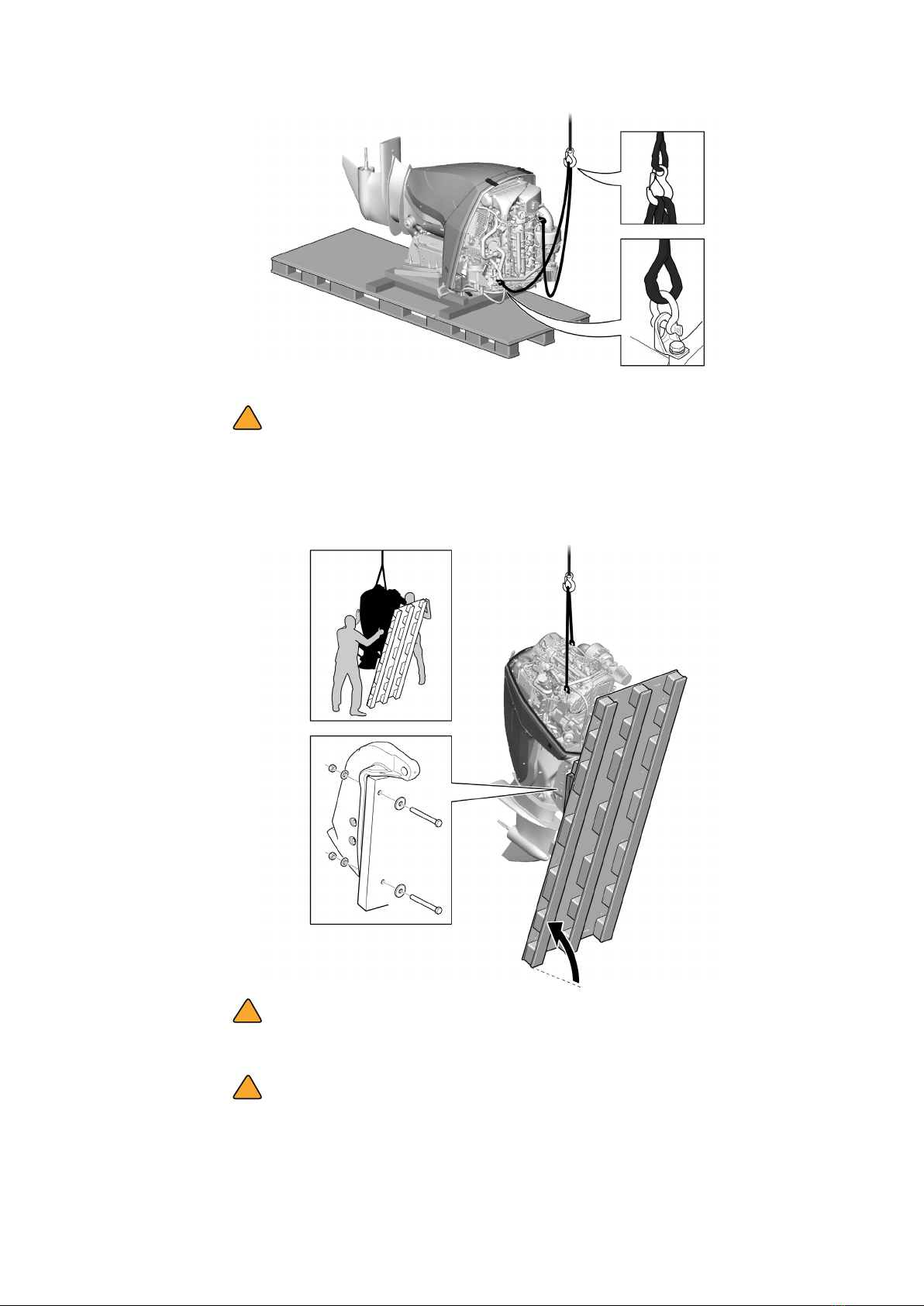

!DANGER

Do not unbolt the OXE outboard from the pallet.

6. Mount shackles and liing straps, certified according to weight, to the liing

eyes.

!DANGER

Do not remove the OXE outboard from the pallet before liing operation.

!CAUTION

This is a two person operation.

UNPACKING INSTRUCTIONS

17

OXE 125/150/175/200 HP INSTALLATION MANUAL

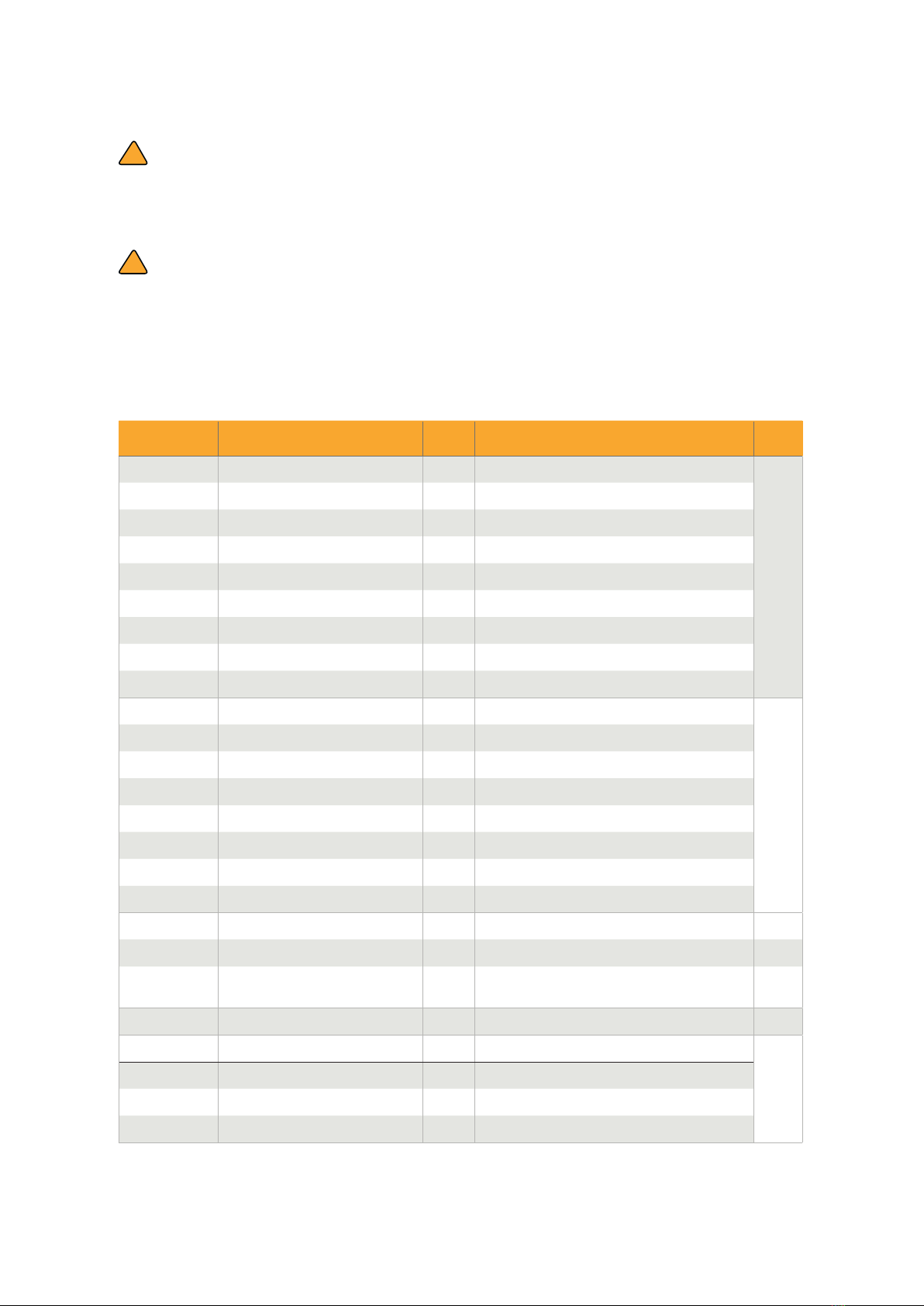

7. Slowly li the OXE outboard and pallet into upright position.

!CAUTION

Do not damage the paint coat of the transom unit.

8. Remove screws, spacers and nuts carefully.

!CAUTION

This is a two person operation.

9. Carefully remove the pallet from outboard. Hold the outboard in order to keep it from swinging.

ACCESSORY BOX CONTENT

Part number Description QTY Reference Kit

30-0114-444 Pump, External Fuel pump 1 Refer to Installation Manual, Fuel system.

• 30-0114-458 • Fuel pump bracket 1 Refer to Installation Manual, Fuel system.

• 30-0116-132 • Harness for External Fuel Pump 1 Refer to Installation Manual, Electrical components.

• 30-0122-254 • Connector for fuel hose 2 Refer to Installation Manual.

• 30-0122-049 • Hose clamp 2 For the external pump

• 30-0121-052 • Copper washer 2 Used in installation with 30-0122-254.

• 30-0130-270 • Nut M6, Nylock 1 Used with 30-0114-458.

• 30-0130-191 • Washer M6 1 Used with 30-0114-458.

• 30-0130-292 • Bolt M6 x 40 1 Used with 30-0114-458.

30-0190-006 Prefilter Fuel Assembly 1 Refer to Installation Manual.

• 30-0122-280 • Rubber p-clip M6x16x20 W5 2 Refer to Installation Manual.

• 30-0130-041 • Bolt M8x20 1 Used with 30-0122-280 in installation.

• 30-0130-192 • Washer 8.4 x16 M8 1 Used with 30-0122-280 in installation.

• 30-0122-049 • Hose clamp 2 Refer to Installation Manual

• 30-0114-462 • Fuel feed hose 5M 1 Refer to Installation Manual

• 30-0114-464 • Fuel return hose 5M 1 Refer to Installation Manual

• 30-0114-497 • ¼” UF to 10mm hose connector 2 Refer to Installation Manual

30-0140-032 Man overboard switch, kill cord 1 Set as normally closed.

30-0122-246 Cable tie 10 Used for installation on Fuel hose

30-0190-011 Loctite 542 1 Used to seal and secure fitting when installing to the

external prefilter, external fuel pump.

30-0140-100 Rigging sleeve (hose) incl. flange 1 Refer to Installation Manual.

Doc. kit Documents and servicebook kit 1

• 30-0160-036 • Drill template 1 Refer to Installation Manual.

• 30-0160-033 • Acessory box, Content list 1

• ODM1006 • Service Book 1

UNPACKING INSTRUCTIONS

External fuel pump kit

Fuel prefilter kit

Doc. kit

18

OXE 125/150/175/200 HP INSTALLATION MANUAL

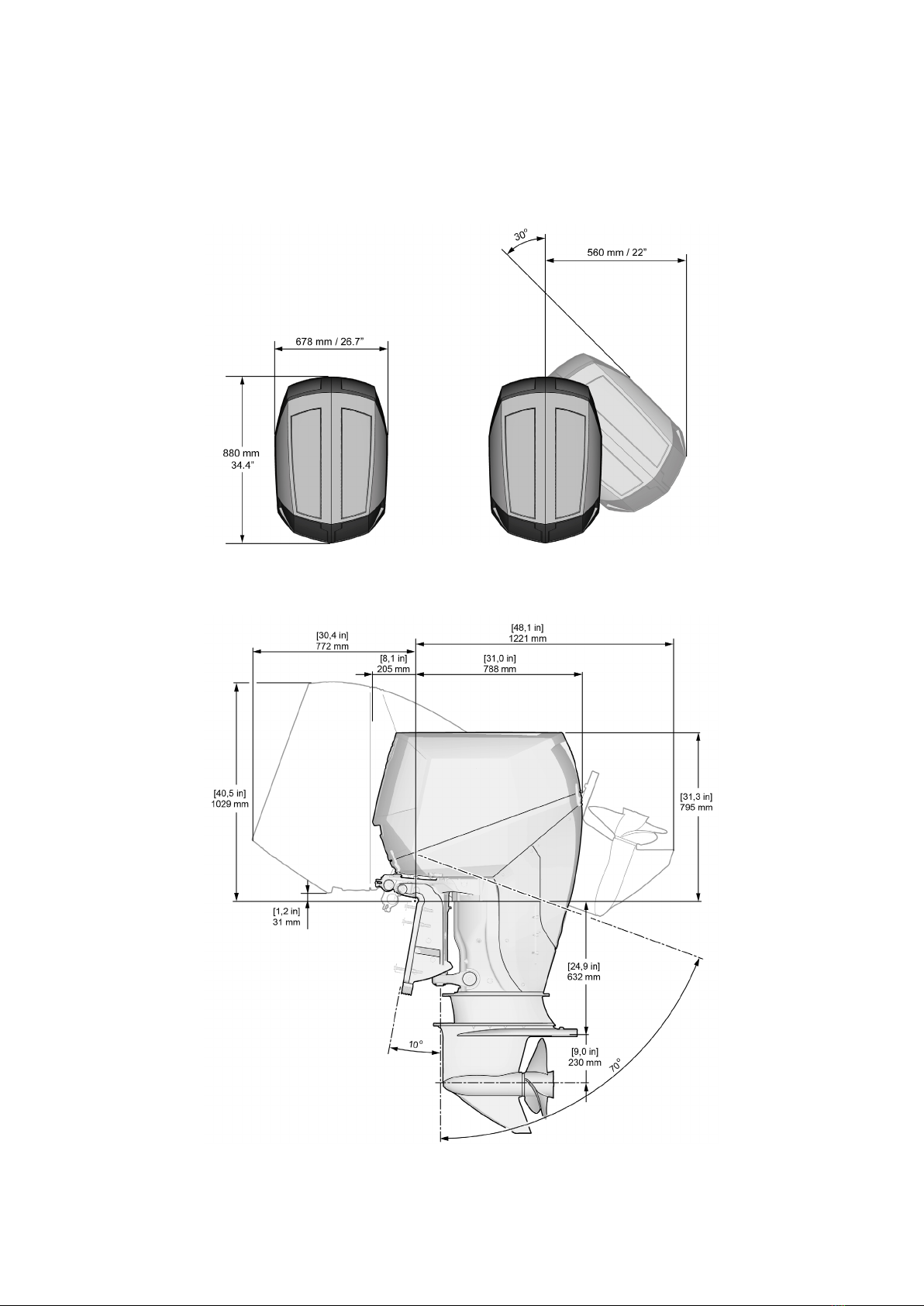

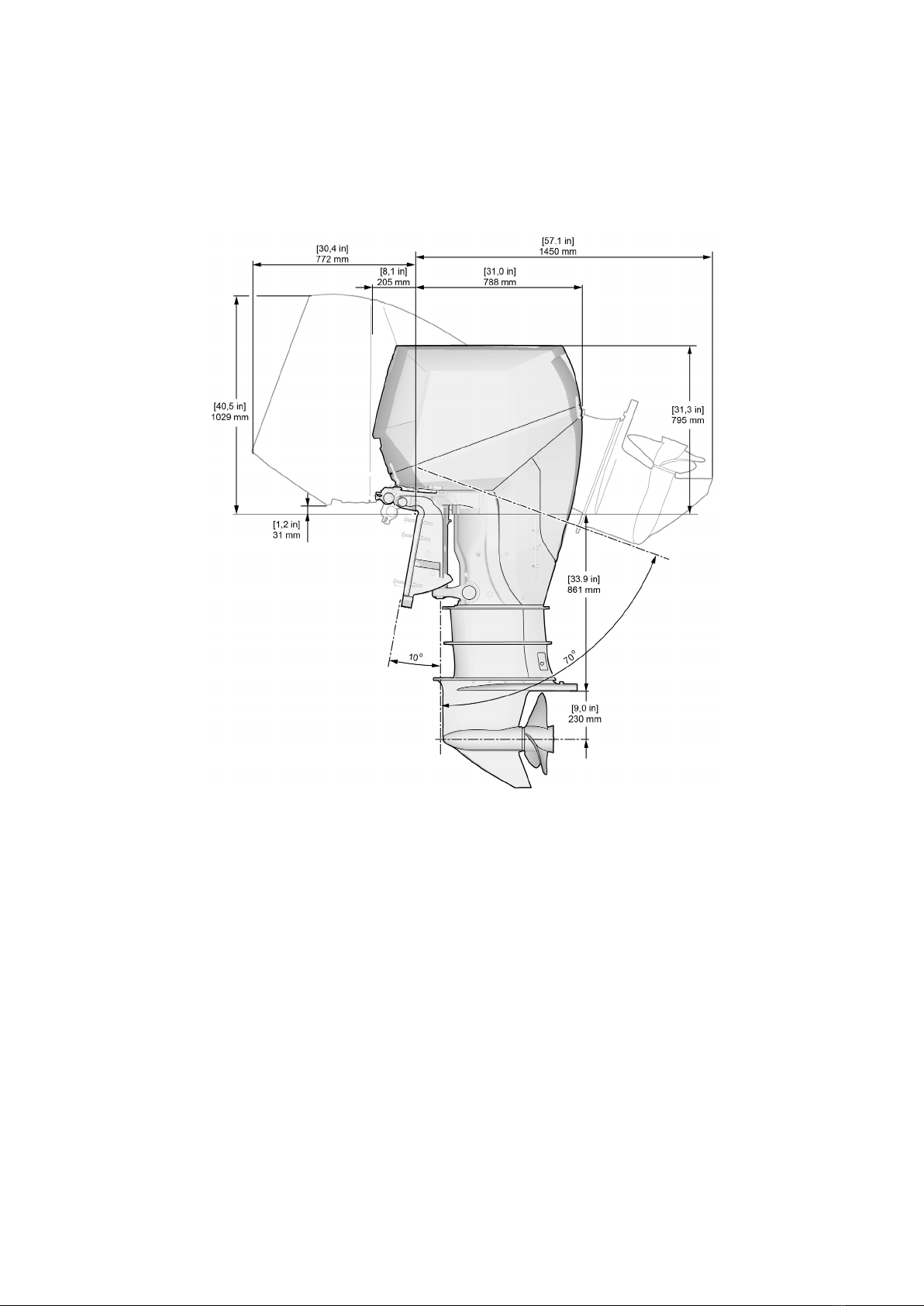

INSTALLATION DIMENSIONS

When mounting the OXE outboard, ensure there is clearance for the engine moving from port to starboard as

well as during trim and tilt operations.

Fig. 1 Clearance needed for the OXE outboard moving from port to starboard

Fig. 2 Clearance needed for the OXE outboard trim and tilt operation - rig 25”

INSTALLATION SPECIFICATIONS

19

OXE 125/150/175/200 HP INSTALLATION MANUAL

INSTALLATION SPECIFICATIONS

Fig. 3 Clearance needed for OXE outboard trim and tilt operation - rig 33”

20

OXE 125/150/175/200 HP INSTALLATION MANUAL

A

Min clearence between outboard centerline CL cm inch

Twin/Triple/Quad 81.3 32

INSTALLATION SPECIFICATIONS

This manual suits for next models

3

Table of contents

Popular Outboard Motor manuals by other brands

Sleipner

Sleipner SE-IP60 installation guide

Evinrude

Evinrude E-Tec Operator's guide

Torqeedo

Torqeedo Ultralight 402 operating manual

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS SIDE-POWER SE IP 60/185 S installation manual

Aqua-Marina

Aqua-Marina X series owner's manual

Pure Watercraft

Pure Watercraft Pure Outboard user guide