Cimon Touch T12FS User manual

www.kdtsys.com

Installation Guide

You can refer to this guide to use CIMON-PPC

Essential Safety Precautions

WARNING

System Design

Do not create TOUCH gra hic objects that could ossibly endanger the safety of equi ment

and ersonnel. Damage to the TOUCH can cause an out ut signal to remain ON or OFF

continuously and can cause a major accident. Therefore, design all monitoring circuits using

limit switch to detect incorrect device movement.

Do not create TOUCH gra hic objects that control machine safety o erations, such as an

emergency sto . Switches to control machine safety o erations must be installed as

se arated hardware switches.

Design your system so that a communication fault between the TOUCH/PPC and the

controller of the equi ment can not make the equi ment malfunction.

Do not use the TOUCH/PPC as a warning device for critical alarms that can cause serious

o erator injury, machine damage or roduction sto age.

The TOUCH/PPC is not a ro riate for use with aircraft control devices, aeros ace

equi ments, central trunk data transmission (communication) devices, nuclear ower control

devices, or medical life su ort equi ment, due to these devices’ inherent requirements of

extremely high levels of safety and reliability.

When using the TOUCH/PPC with trans ortation vehicles (trains, cars and shi s), disaster

and crime revention devices, various ty e of safety equi ment, non-life su ort related

medical devices, etc. redundant and/or failsafe system designs should be used to ensure the

ro er degree of reliability and safety.

After the backlight of the TOUCH/PPC burns out, the touch anel of the TOUCH/PPC is still

active. If an o erator does not notice that the backlight burned out and touches the anel, a

otentially dangerous machine miss-o eration can occur. Therefore, do not use the TOUCH

gra hic objects for the control of any equi ment safety mechanisms, such as Emergency

Sto switches, etc. that rotect humans and equi ment from injury and damage.

If the backlight of LCD suddenly turns OFF, use the following ste s to determine if the

backlight is actually burned out.

Ste 1. If your TOUCH/PPC is not set to “Standby Mode” and the screen has gone

blank, the backlight of LCD is burned out.

Ste 2. Or, if your TOUCH/PPC is set to “Standby Mode” but touching the screen

can not wake TOUCH/PPC u , your backlight is burned out.

Installation

High voltage runs through the TOUCH/PPC. Do not disassemble the TOUCH/PPC. Otherwise

an electric shock can occur.

Do not modify the TOUCH/PPC unit, since the modified TOUCH/PPC cause a fire or an

electric shock.

Do not use the TOUCH/PPC in flammable gasses, since o erating the TOUCH/PPC in

flammable gasses may cause an ex losion.

Wiring

To revent an electric shock, be sure to confirm that the ower cord of the TOUCH/PPC is

not connected to the main ower before connecting any cord, cables or line to the

TOUCH/PPC.

Do not use ower beyond the s ecified voltage range of the TOUCH/PPC. Doing so may

cause a fire or an electric shock.

Maintenance

The TOUCH/PPC uses a lithium battery to back u its internal clock data. If the battery is

incorrectly re laced, the battery may ex lode. To revent this, lease do not re lace the

battery yourself. When the battery needs to be re laced, lease contact your local

TOUCH/PPC distributor.

CAUTIONS

Installation

Be sure to securely connect all cable connectors to the TOUCH/PPC. A loose connection may

cause incorrect in ut or out ut.

Wiring

Ground the FG line of the TOUCH/PPC se arately from FG lines of other units. Putting these

FG lines too close may cause an electric shock or unit malfunction. Be sure to use a

grounding resistance of 100

Ω

or less and a 2

㎟

or thicker wire, or a licable standard of

your country.

Correctly wire the TOUCH/PPC, be sure that the rated voltage and terminal layout are within

the designated range. If the voltage su lied differs from the rated voltage, or incorrect

wiring or grounding is erformed, it may cause a fire or unit malfunction.

Use only the designated torque to tighten terminal block screws of the TOUCH/PPC. If these

screws are not tightened firmly, it may cause a short circuit, fire or TOUCH/PPC malfunction.

Be careful that the metal filings and wiring debris do not fall into the TOUCH/PPC, since they

can cause a fire, TOUCH/PPC malfunction or incorrect o eration.

Maintenance

The LCD contains a owerful irritant and if for any reason the anel is damaged and this

liquid contacts any art of your body, be sure to wash that area with running water for 15

minutes. If any of this liquid enters your eye, flush your eye for 15 minutes with running

water and contact a hysician.

Unit Dis osal

When this unit is dis osed of, it should be done so according to your country’s regulation for

similar ty es of industrial waste.

General Safety Precautions

Do not strike the touch anel with a hard or ointed object, or ress on the touch anel with

too much force, since it may damage the touch anel or the dis lay.

Do not install the TOUCH/PPC where the ambient tem erature can exceed the allowed range.

Doing so may cause the TOUCH/PPC to malfunction or shorten its o eration life.

Do not restrict or limit naturally occurring rear-face ventilation of the TOUCH/PPC, or storing

or using the TOUCH/PPC in an environment that is too hot.

Do not use the TOUCH/PPC in areas where large, sudden tem erature changes can occur.

These changes can cause condensation to form inside the unit, ossibly causing the unit to

malfunction.

Do not allow water, liquids, metal or charged articles to enter inside the TOUCH/PPC, since

they can cause either a TOUCH/PPC malfunction or an electrical shock. The allowable

ollution degree is 2.

Do not store or use the TOUCH/PPC in direct sunlight, or in excessively dusty or dirty

environments.

Do not store or use the TOUCH/PPC where strong jolting or excessive vibration can occur.

Do not store or use the TOUCH/PPC where chemicals (such as organic solvents, etc.) and

acids can eva orate, or where chemicals and acids are resent in the air.

Do not use aint thinner or organic solvents to clean the TOUCH/PPC.

Do not store or o erate the LCD dis lay in areas receiving direct sunlight, since the sun's UV

rays may cause the LCD dis lay’s quality to deteriorate.

If you store the TOUCH/PPC in areas where the tem erature is lower than allowed level, the

liquid of the LCD will congeal and the LCD can be damage. Conversely, if the storage area’s

tem erature becomes higher than the allowed level, the liquid of the LCD will become

isotro ic, causing irreversible damage to the LCD. Therefore, be sure to store the anel only

in areas where tem eratures are within those s ecified in this manual.

After turning the TOUCH/PPC OFF, be sure to wait a few seconds before turning it ON again.

If the TOUCH/PPC started too soon, it may not start u correctly.

Due to the ossibility of unex ected accidents, you must back u the roject data of the

CIMON HMI regularly.

EWF: Enhanced Write Filter

The Enhanced Write Filter (EWF) rotects a volume from write access. The C:

volume of TOUCH/PPC is rotected by EWF of Windows XP Embedded.

When you will setu Windows, install rograms or write files on C: volume,

new data will be stored in EWF volume not in C: volume.

If you will restart TOUCH/PPC, old data will be restored in C: volume.

If you want to save new data, you must run EWF commit. Then the

TOUCH/PPC will be restart and new data will be saved.

After installing rogram, run EWF commit without reboot. If you

don’t, installed rogram will be removed.

After change Windows configuration, run EWF commit. If you don’t,

changed configuration will be removed.

After creating new files or folders, run EWF commit. If you don’t,

new files or folders will be removed.

Package Contents

The following items are contained in the ackage of the TOUCH/PPC. Before using the TOUCH/PPC,

lease confirm that all items listed here are resent.

TOUCH/PPC Unit Fastener

3P & 5P Connector

Installation Guide CD

This unit has been carefully acked, with s ecial attention to quality. However, should you find

anything damaged or missing, lease contact your local TOUCH/PPC distributor immediately.

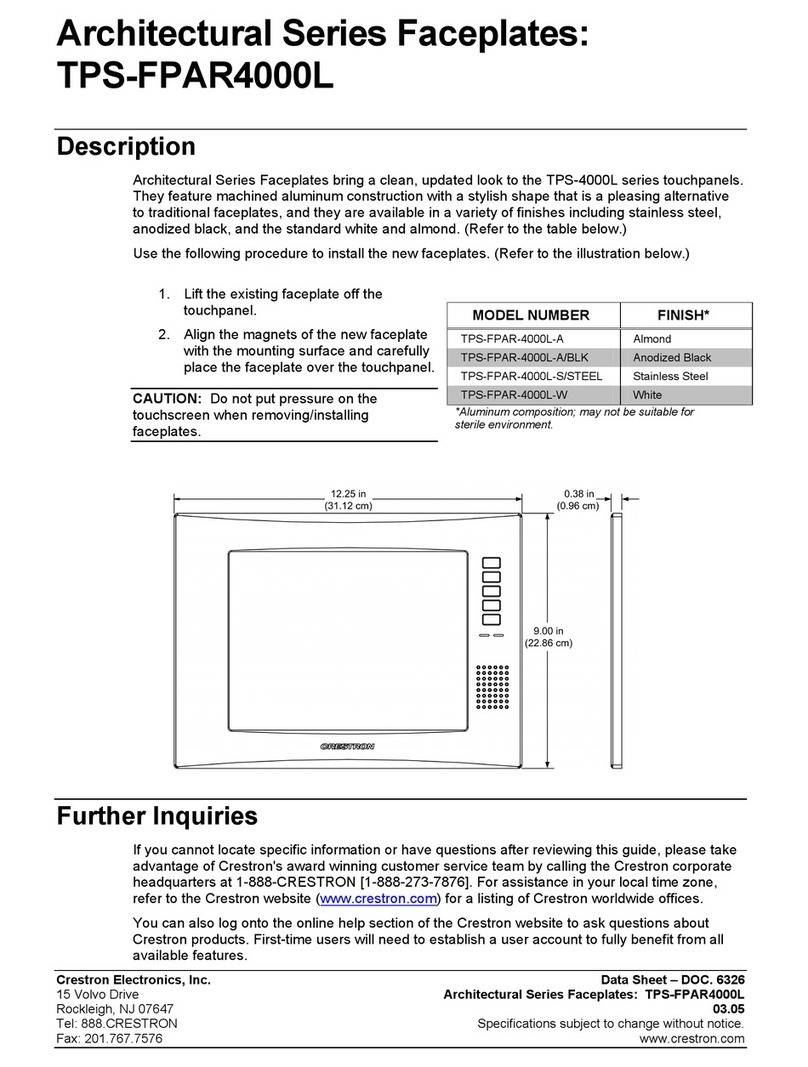

1. Dimensions

Unit: mm

T12FS

P12FS

Unit: mm

T15FS

P15FS

Unit: mm

T15FP

P15FP

Unit: mm

T19FP

P19FP

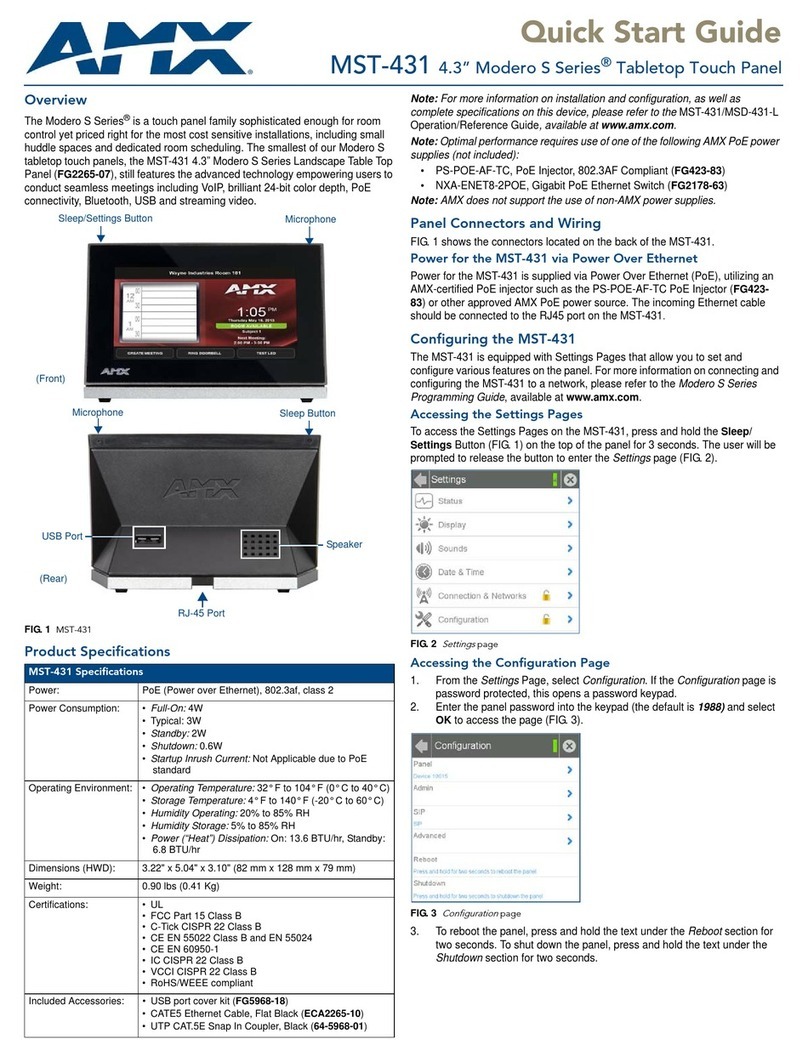

2. Interfaces

Outline

COM1: RS-232C

This interface is used to connect the TOUCH/PPC to the host (PLC), via an RS-

232C cable. When you use COM1 RS-232C ort, you must not use COM1 RS-

485/422 ort.

Connector Pin No

Name Descri tion

1 DCD Data Carrier Detect

2 RD Receive Data

3 TD Transmit Data

4 DTR Data Terminal Ready

5 SG Signal Ground

6 DSR Data Set Ready

7 RTS Request To Send

8 CTS Clear To Send

9 RI Ring Indicator

COM1: RS-422/485

This interface is used to connect the TOUCH/PPC to the host (PLC), via an RS-

422/485 cable. When you use COM1 RS-422/485 ort, you must not use COM1

RS-232C ort.

Connector Pin No

Name Descri tion

1 TXD+ Transmit Data +

2 TXD- Transmit Data -

3 GND Ground

4 RXD+ Receive Data +

5 RXD- Receive Data -

Select RS-232C/422/485

Ty e Switch

RS-232

(Default)

RS-485

RS-422

If you connect the TOUCH/PPC to the host via an RS-485 cable

(2wire), you must connect TXD+ and TXD- lines.

The RS-485 of the TOUCH/PPC runs under auto toggle mode.

To reduce the risk of damaging the RS-422 circuit, be sure to

connect the SG terminal.

COM2~COM4: RS-232C

XT10A and XT12A series units have this interface.

This interface is used to connect the TOUCH/PPC to the host (PLC), via an RS-

232C cable. You can use in 2, 3, 5 of this interface.

Connector Pin No

Name Descri tion

1 DCD Data Carrier Detect

2 RD Receive Data

3 TD Transmit Data

4 DTR Data Terminal Ready

5 SG Signal Ground

6 DSR Data Set Ready

7 RTS Request To Send

8 CTS Clear To Send

9 RI Ring Indicator

The serial ort of the TOUCH/PPC is not isolated. When the

host(PLC) unit is also not isolated

Inside the TOUCH/PPC unit, the SG (Signal Ground) and FG

(Frame Ground) terminals are connected to each other.

When connecting an external device to the TOUCH/PPC with the

SG terminal, ensure that no short-circuit loo is created when you

setu the system.

Ethernet

This interface com lies with the IEEE802.3 for Ethernet (10BaseT/100BaseTX).

RJ45 Connector RJ45 Jack

Direct Cable: Host <-> HUB

Cable No

Color Color No

Cable

1 Orange/W Orange/W 1

2 Orange Orange 2

3 Green/W Green/W 3

4 Blue Blue 4

5 Blue/W Blue/W 5

6 Green Green 6

7 Brown/W Brown/W 7

8 Brown Brown 8

Crossover Cable: Host <-> Host

Cable No

Color Color No

Cable

1 Orange/W Green/W 1

2 Orange Green 2

3 Green/W Orange/W 3

4 Blue Blue 4

5 Blue/W Blue/W 5

6 Green Orange 6

7 Brown/W Brown/W 7

8 Brown Brown 8

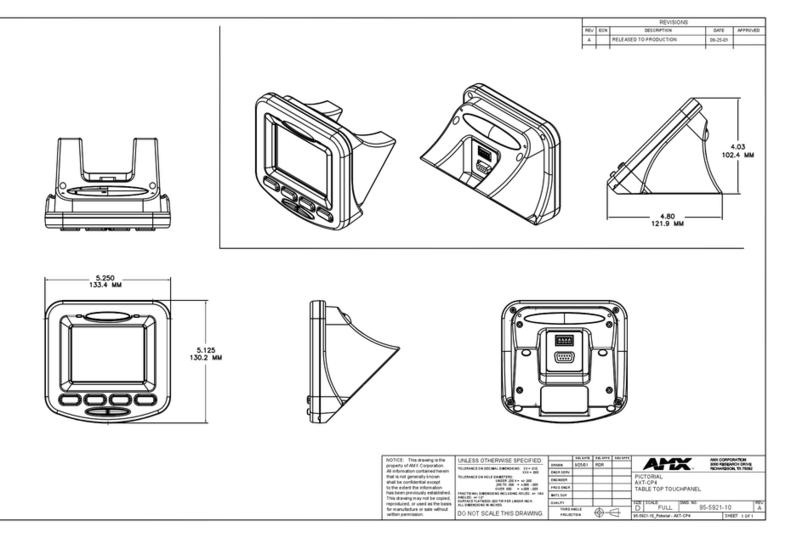

3. Installation

Create a Panel Cut and insert the TOUCH/PPC into the anel from the

front

Unit: mm

T12FS

P12FS

T15FS / T15FP

P15FS / P15FP

T19FP

P19FP

Attach the Installation Fasteners from inside the anel

Insert each the hook of faster into slot and tighten it with a screwdriver.

Tightening the screws with too much force can damage the case of

the TOUCH/PPC.

The necessary torque is 0.5 N•m.

De ending on the thickness of installation anel, the number of

installation fasteners used may need to be increased to rovide the

desired level of moisture resistance.

4. Wiring

WARNINGS

To avoid an electric shock, when connecting the TOUCH/PPC ower cord

terminals to the ower terminal block, confirm that the TOUCH/PPC ower

su ly is com letely turned OFF, via a breaker, or similar unit.

Since there is no ower switch on the TOUCH/PPC unit, be sure to attach a

breaker-ty e switch to its ower cord.

To avoid a short caused by loose ring terminals, be sure to use ring

terminals with an insulating sleeve.

When the FG terminal is connected, be sure the wire is grounded.

Not grounding the TOUCH/PPC unit will result in excess noise and

vibration.

Connecting the TOUCH/PPC Power Cord

When connecting the ower cord, be sure to follow the rocedures given below.

Confirm that the Power Cord is un lugged from the ower su ly.

Unscrew the screws from the middle three (3) terminals, align the Ring

Terminals and re-attach the screws.

Confirm that the ring terminal wires are connected correctly.

The torque required to tighten these screws is 0.5 to 0.6N•m.

5. Power Su ly Caution

Please ay s ecial attention to the following instructions when connecting the

ower cord terminals to the TOUCH/PPC unit.

If the ower su ly voltage exceeds the GP's s ecified range, connect a

voltage transformer.

Between the line and the ground, be sure to use a low noise ower su ly. If

there is still an excessive amount of noise, connect a noise reducing

transformer.

The ower su ly cord should not be bundled with or ke t close to main

circuit lines (high voltage, high current), or in ut/out ut signal lines.

Connect a surge absorber to handle ower surges.

To reduce noise, make the ower cord as short as ossible.

6. Grounding Caution

When grounding to the rear face FG terminal of the TOUCH/PPC, (on the

Power In ut Terminal Block), be sure to create an exclusive ground.

Inside the TOUCH/PPC unit, the SG (Signal Ground) and FG (Frame Ground)

terminals are connected to each other.

When connecting an external device to the TOUCH/PPC with the SG terminal,

ensure that no short-circuit loo is created when you setu the system.

7. S ecification

T12FS

P12FS

T15FS

P15FS

T15FP

P15FP

T19FP

P19FP

Touch Screen Analog 8-Wire Resistive

CPU Intel ATOM Processor N450 1.6GHz(FANLess)

RAM DDR2 SDRAM 1GB(Data transfer rate: 667 MT/s)

Storage SSD 64GB

Gra hic Chi Integrated Intel

®

Gra hics Media Accelerator 3150

Dis lay 12.1" TFT LCD 15" TFT LCD 19" TFT LCD

Video Out CRT Out ut(15P DSUB)

Serial RS 232C/422/485 (COM1), RS232C (COM2-4)

Ethernet Gigabit Ethernet 2 Port

Parallel 1 Port

PS/2 Keyboard & Mouse

USB USB 2.0 4 Port USB 2.0 6 Port

Audio Out 1 Port

CD-ROM None YES

PCI Slot None 1 Slot

OS Windows Embedded POSReady 2009(XP Base)

Utility Program EWF(Disk Image Safeguard ) / Rescue(Factory Default Recovering Tool)

Power AC200-240V

This manual suits for next models

1

Table of contents