Page 4

TYPE D LOW BOY ASSEMBLY

FOR CISSELL STEAM-ELECTRIC IRON

WITH ELECTRIC THUMB SWITCH

LB148 Solenoid Lowboy Valve

120V. 50-60 Cy. consists of Ref. No. 1-21

LB149 Solenoid Lowboy Valve

250V. 50-60 Cy. consists of Ref. No. 1-21

Support Rod and Hose Assembly - LB105

Consists of Ref. Nos. 22-27

For Lowboy & Condenser Ass'y Electric Box Assembly

Consists of Ref. Nos. 40-56

LB225 - 120V/50/60

LB226 - 240V/50/60

Ref. No. Part No. Description

1 SV80 ............. 1/4-20 Hex Hd. Scw.

2 LB901........... Nameplate (120/50-60)

LB902........... Nameplate (240/50-60)

3 LB82 ............. Top Cover

4 SV19 ............. Leaf Spring

5 SV137 ........... Flux Washer

6

7 SV54 ............. Tube

8

9 LB231........... Solenoid Coil (120/50-60)

LB232........... Solenoid Coil (240/50-60)

10 LB116 ........... Shield

11 LB83 ............. Bottom Cover

12 SV22 ............. Plunger Casing Assy.

13 SV11 ............. Metal Gasket

14 SVA50 ........... Plunger Assy.

15 SV51 ............. Teflon Seat

16 LB2 ............... Valve Body

17 LB5 ............... Hose Connection

18 V73 ............... Valve Stem Assy.

19 V30 ............... Small Pack Ring

20 V18 ............... Gasket

21 LB118 ........... Cable Assy.

22 LB7 ............... Support Rod

2 3 S 5 .................. 5 Ft. Steam Hose

24 GSB145........ Hose Clamp

25 GSB145........ Hose Clamp

26 J 1 .................. Spring Clip

2 7 J 1 7 ................ S Hook

28 F876 ............. 90° Connector

29 C170 ............. Cable Bushing

30 LB117 ........... Flexible Cable

31 LB56 ............. Spring Support Plate

32 LB48 ............. 1/4 - 20 x 1/2 Set Screw

33 FB188........... 5/16 x 2 Hex Hd. Screw

34 V56 ............... 5/16 - 24 Hex Nut

35 LB13 ............. Chamber Shield

36 LB55 ............. No. 14 x 1 Pan Hd. Screw

37 LB129........... Rating Nameplate

38 LB20 ............. 1/2 x 3 Pipe Nipple

39 SG45 ............. 1/2 Pipe Tee

40 LB30 ............. Switch Cover Plate

41 LB53 ............. Double Pole Switch

42 M102 ............ Amber Light 110V

M454 ............ Amber Light 220V

43 LB221........... Box Welded Asm.

44 LB227........... Terminal Mounting Plate

45 LB222........... Terminal Block

46 LB59 ............. Blank Face Plate

47 LB166........... 6-32 x 1/2 O. H. Screw

48 TU3478 ........ #8-32 x 1/2 S. T. Screw

49 TU3400 ........ #6-32 Hex Nut

50 LB291........... #6-32 x 3/8 Screw

51 M270 ............ #6 I. T. Lockwasher

52 M271 ............ #8 I. T. Lockwasher

53 LB211 ........... Power Conn. Label

54 TU10193 ...... Heyco Bushing

55 TU7414 ........ Cup Washer

56 TU8563 ........ Green Ground Screw

57 TU2714 ........ 1/2 Close Nipple

58 SGC2 ............ Condenser Assy.

59 SGV1 ............ Valve Assy.

60 LB1 ............... Chamber

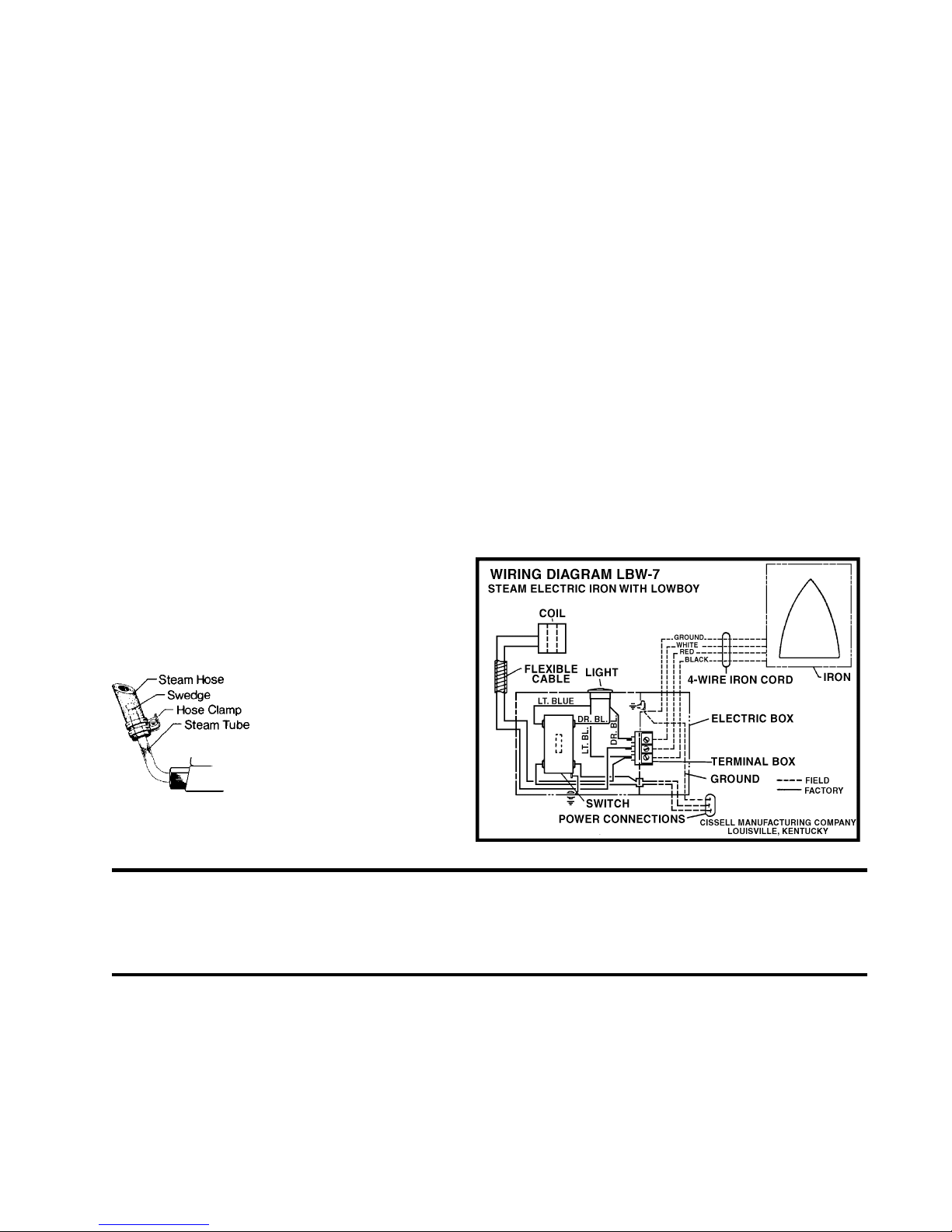

LB224 .......... Wiring (120, 240 V. 50/60 Cy.)

Not Illustrated