2FCE/FCRU IO&M B51150-003

1. Remove the top cap which covers the motor assembly

by unbolting the lid.

2. For internal wiring, run the electrical wire and conduit

through the opening drilled in the damper shelf (refer

to Damper Installation), then through the wiring con-

duit in the ventilator base to the motor compartment.

For external wiring, run the wires through the horizon-

tal conduit on upblast units, or under top cap in down-

blast units.

3. Pull the wires through and complete the wiring. For

further information. Refer to Wiring Diagrams on page

3.

Final Installation Steps

1. Ensure fasteners and set screws, particularly fan

mounting and bearing fasteners are tightened accord-

ing to the recommended torque shown on the table

below.

2. Inspect for correct amperage with an ammeter and

correct voltage with a voltmeter.

3. Ensure that all accessories are installed.

4. Test the fan to be sure the rotation is the same as indi-

cated by the arrow marked “Rotation.”

NOTICE! Do not allow the fan to run in the wrong

direction. This will overheat the motor and cause

serious damage. For 3-phase motors, if the fan is

running in the wrong direction, check the control

switch. It is possible to interchange two leads at

this location so that the fan is operating in the cor-

rect direction.

5. Inspect wheel-to-inlet clearance. Wheels may shift in

shipment. To realign wheel-to-inlet, shift upper bearing

so there is an equal radial clearance between the wheel

and inlet. Refer to Wheel to Inlet Clearance, page 6.

Recommended Torque for Setscrews/Bolts on Metal (IN-LB)

Setscrews Hold Down Bolts

Size

Key Hex

Across

Flats

Recommended

Torque Size Recommended

Torque

Min. Max.

#8 5/64” 15 21 3/8”-16 324

#10 3/32” 27 33 1/2”-13 780

1/4 1/8” 70 80 5/8 ”-11 1440

5/16 5/32” 140 160 3/4”-10 2400

3/8 3/16” 250 290 7/8”-9 1920

7/16 7/32” 355 405 1”-8 2700

1/2 1/4” 560 640 1-1/8”-7 4200

5/8 5/16” 1120 1280 1-1/4”-7 6000

3/4 3/8” 1680 1920 - -

7/8 1/2” 4200 4800 - -

19/16” 5600 6400 - -

Recommended Torque for Setscrews/Bolts on FRP (FT-LB)

Size (inches) 18-8 SST Hardware Torque

No. 10 7

1/4” 12

5/16” 20

3/8” 30

7/16” 41

1/2” 54

5/8” 86

3/4” 128

To maintain good working condition of the fan when it is

stored outdoors, follow the additional instructions below.

• Coat the shaft with grease or a rust preventative

compound.

• Wrap bearings for weather protection. Cover the inlet

and outlet to prevent the accumulation of dirt and mois-

ture in the housing.

• Periodically rotate the wheel and operate dampers (if

supplied). Periodically inspect the unit to prevent dam-

aging conditions.

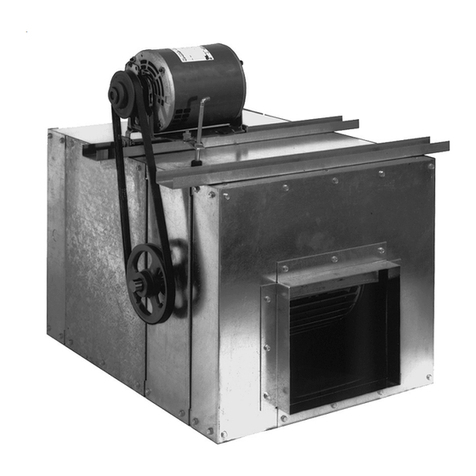

Installation

If the fan was delivered with the motor unmounted, see

the maintenance section for belt and pulley installation.

Damper Installation

If your fan is supplied with dampers, follow the directions

below. If your fan does not include dampers, proceed to

Belt and Pulley Installation.

1. Place the damper inside the curb or inside the duct

work. Ensure the damper will open freely for the cor-

rect direction of the airow.

2. Secure to curb at the damper shelf.

3. Drill hole in the curb shelf for conduit needed for mo-

tor wiring.

4. Operate the dampers manually to ensure the blades

move freely.

5. Install fan over curb while aligning the conduit location

with the conduit hole in the curb.

Wiring Installation

NOTICE! All wiring should be in accordance with

local ordinances and the National Electrical Code,

NFPA 70. Ensure the power supply (voltage, fre-

quency, and current carrying capacity of wires) is

in accordance with the motor nameplate (see page

3 for diagram). Fan must be grounded to prevent

electrical discharge.

For Units Without A Junction Box:

An approved metal eld wiring compartment must be

secured to the unit with two screws in order that the box

does not rotate. All wires must be protected from abrasion

where they enter and exit the wiring compartment.

The green ground wire from the motor must be secured

under the green ground screws inside the eld wiring

compartment using a closed loop connector. Complete

connections in accordance with the wiring diagram on the

motor.

For Units With A Junction Box:

Pull wires through the appropriate conduit. Protect wires

from abrasion where they enter the eld wiring compart-

ment and complete connections in accordance with the

diagram on the motor.

Leave enough slack in the wiring to allow for motor

movement when adjusting belt tension. Some fractional

motors have to be removed in order to make the connec-

tion with the terminal box at the end of the motor.

NOTICE! Follow the wiring diagram in the discon-

nect switch and the wiring diagram provided with

the motor. Correctly label the circuit on the main

power box and always identify a closed switch to

promote safety (i.e., red tape over a closed switch).