CK WORLDWIDE TURBO-SHARP X User manual

1

OPERATING INSTRUCTIONS

TECHNICAL DATA

TURBO-SHARP®X

DECLARATION OF CONFORMITY

We declare that we are solely responsible for this product meeting the

following standards and directives: EN 50144:1998, EN 50144-1/A1:2002,

EN 50144-2-3:1998 EN 55014:1993, EN 61000-3-2:1995, 61000-3-3:1995 in

accordance with directive 89/392/EWG, 73/23/EWG and 89/336/EWG1998

Power Consumption 710 W

Voltage 120 V

Amps 6.4 A

No Load Speed 34000 RPM

Grinder Weight 4.1 lb (1860g)

Shipping Weight 10.1 lb (4581g)

Form 6000

December, 2016

CK Worldwide, Inc.

P.O. Box 1636 Auburn, WA 98071 USA

Ph: (253) 854-5820

Fax: (253) 939-1746

Angle Iron

CK Worldwide, Inc.

2

• Make adjustments for the angle of the point (in degrees)

and the electrode diameter;

- Loosen the central screw on the head

- Set the degree and the electrode

diameter by turning the grinder head

- Tighten the central screw

The number of degrees equals the angle

of the point on the sharpened electrode

• Turn on the TURBO-SHARP®X

• Guide the tungsten electrode through the opening that

coincides with its diameter

• Carefully press the tungsten electrode onto the revolving

disc, while at the same time rotating it with light pressure

(the harder the tungsten is pressed against the disc, the

shorter the lifespan of the disc is)

• Continue to rotate the electrode as it is removed from the

disc until there is no longer any contact

• Inspect the results and, if necessary, repeat the process

• The multi-functional cover with integrated opening slide

makes it possible to surface grind electrodes that have

welding deposits due to the welding process. In addition,

ground electrodes can be given a truncated cone.

6. Optional Grinding Head :

• A second head (colored red) is available for the

TURBO-SHARP®X for electrodes with diameters of

.040“(1.0mm) - 5/32“(4.0mm) - 3/16“(4.8mm) - 1/4“(6.4mm)

ORDER NUMBER: TS3-HR

7. How to Use :

4. Vacuum Removal of Dust :

We recommend this procedure as a safety measure to

minimize contact with tungsten dust that results from

the grinding process.

Multi-functional Cover

Opening Slide

Scale to adjust the grinding angle

Tungsten Electrode

Central screw to adjust electrode diameter and angle

2. Motor unit :

Changes :

Text, illustrations and data correspond with the state of

technology at the time of printing. We reserve the right

to make changes that will further the development of our

product.

3. Power On/Off :

Power off: Press the back

of the on/off switch. The

switch will automatically

return in the off position.

Power on : Push the on/off

switch back. Press the front

of the switch to lock it in

position.

5. Angle Iron :

• The angle iron can be mounted so that the machine

- can be fastened in a vice

- can be fastened by means

of a screw clamp

x

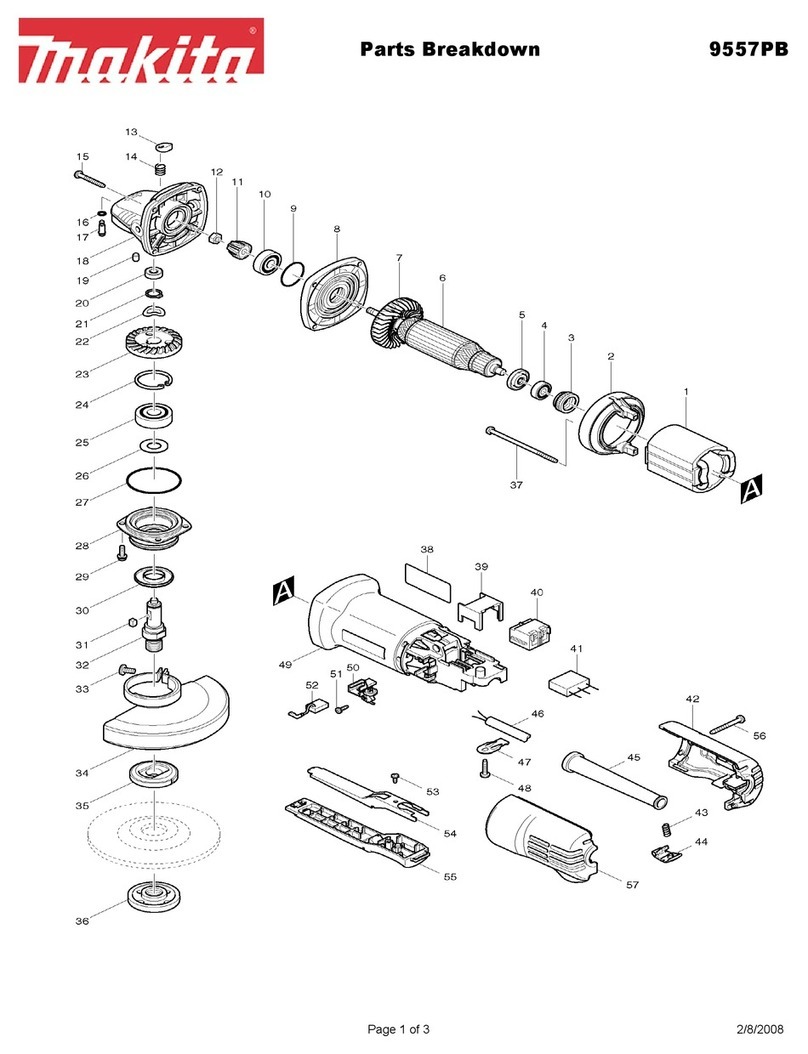

1. Grinder Housing :

Warning ! Do not sharpen bent or burnt electrodes.

Remove any drops on the point

of the electrode before it is

sharpened. Use the electrode holder for short electrodes.

Rotation-direction indicator

Sleeve

Spindle

Collet Nut

Grinding Disc

Nut and Pin

to hold Wheel On/off Switch

with Lock

Cover

Screws

• Loosen and then completely remove the three hexagonal

countersunk screws with a 4mm hexagonal key

• Remove the cover

• Use the supplied

rotating socket and connect

to the vacuum system.

Electrical Connection :

Connect only to single-phase alternating current and only to the

voltage stated on the specication label. The TURBO-SHARP®X

is insulated according to DIN 57 740/ VDE 0740 (EEC 20) and

can be connected to ungrounded electrical sockets. Radio

interference complies with European Norm EN 55014.

Grinder Head

8. Grinding Disc Adjustment :

• To obtain a different grinding area on the disc, loosen

the 3 set screws on the base of the head-cover and

rotate the collar to 1,2 or 3. This will allow 3 different

grinding locations on the disc for one particular angle.

3

6. Optional Grinding Head :

• A second head (colored red) is available for the

TURBO-SHARP®X for electrodes with diameters of

.040“(1.0mm) - 5/32“(4.0mm) - 3/16“(4.8mm) - 1/4“(6.4mm)

ORDER NUMBER: TS3-HR

CK Worldwide, Inc.

Wheel Retaining Nut

(LEFT-HAND THREADS)

CHANGING THE GRINDING WHEEL

Follow the same

procedure to change

the collet, except

collet nut must be completely

unscrewed in order for the collet to be changed.

These procedures must be followed exactly as they are explained

and illustrated.

CHANGING THE TAKE-OFF SHAFT & COLLET

Very important !!!

Ensure that the wheel is properly

mounted and not crooked.

Spindle

Collet

Collet Nut

Wheel take-off Shaft

Grinding Wheel

Washer

Remove the plug from the electrical socket before doing any mainte-

nance on this machine !

Remove the plug from the electrical socket before doing any mainte-

nance on this machine !

• Position wrench #15 on the spindle

• Position wrench #17 on the collet nut

• Loosen the nut

• Replace the wheel take-off shaft

• Tighten the nut

• Locate and remove the three small set screws in grinder housing

• Remove grinder housing exposing wheel and shaft assembly

• Place wrench #17 on the collet nut

• Place wrench #10 on the wheel retaining nut

• Remove wheel retaining nut - NUT HAS LEFT-HAND THREADS

• Remove washer and grinding wheel

• Install new grinding wheel

• Replace washer and wheel retaining nut

• Tighten wheel retaining nut

• Make sure wheel is level

• Replace grinder housing (Don‘t force, gently slide housing on

to ensure an easy installation)

• To obtain a different grinding area on the disc, loosen

the 3 set screws on the base of the head-cover and

rotate the collar to 1,2 or 3. This will allow 3 different

grinding locations on the disc for one particular angle.

4

CK Worldwide, Inc.

• Observe the safety guidelines in this manual! Do not drill

through the safety cover of the machine, as it will then no

longer be insulated.

• Remove the plug from the electrical socket before doing any

work on the machine.

• Insert the plug into an electrical socket only if the machine is

turned off.

• Keep the cord away from the area where you are working. Run

the cord away from the back of the machine.

• Check the equipment, cord, extension lead and electrical plug

for damage and signs of wear before each use. Damaged parts

should be replaced by an expert.

• Follow the accident-prevention regulations of your professional

association.

• Do not reach into the danger zone of machinery that is turned

on.

• Always wear safety goggles.

• Only use tools with an rpm at least as high as the highest idle

rpm of the machine.

• Inspect the grinding wheel before use. The wheel must be per-

fectly mounted in order to turn freely. Test the wheel for at least

30 seconds before use. Do not use wheels that are damaged,

asymmetrical, or that vibrate.

• Tighten the wheel retaining nut before each use of the machine.

• Noise level values: Typically around GS 400=79db (A). Noise

levels can be higher than 85 dB (A) when in use. Wear

hearing protection.

• Vibration values: the effective speed is typically around GS 400

= 9m/s2

WARRANTY

In addition to the dealer’s sales contract warranty, the customer will receive a warranty

according to the following conditions:

1. The warranty covers 24 months, dating form delivery of the product. Delivery

must be substantiated by an invoice or other documentation.

2. CK Worldwide, Inc. warrants the TURBO-SHARP®X to be free of defects in

materials and workmanship. CK limits this warranty to replacement of the product

or parts thereof, and excludes liability for injury, property damage, or economic

loss attributable to product use or misuse. Warranty claims must be made within

the specied products valid warranty period.

3. In situations covered by the warranty, we ask that the product be returned,

together with the appropriate warranty documentation to the vendor. Please

provide a brief description of the problem.

4. Repairs that are covered by the warranty will not be charged to the customer.

The warranty will not be extended or affected by the repairs. Parts that have

been replaced become the property of CK.

The best results will be obtained by applying light pressure to the

electrode while at the same time rotating it on the disc. Remove

the electrode before turning off the grinder.

Using too much pressure while grinding will damage the grinder

and require more grinding discs; performance will suffer.

Warning :

Always keep the air-intake vents clean.

Accessories :

Only use CK accessories and spare parts.

Spare parts :

Grinding wheel TS3-W

Standard Head TS3-HB

Optional Head TS3-HR

USEFUL TIPS

SAFETY INSTRUCTIONS

Table of contents