Clayton Power 1600FF Setup guide

851846D-1908E

Model: 1600EF

Wood or Coal External Furnace

United States Stove Company • 227 Industrial Park Road, P.O. Box 151 • South Pittsburg, TN 37380 • www.usstove.com

SAFETY NOTICE:

If this furnace is not properly installed, a house re may result! For your safety, follow these installation instructions. Contact

local building or re ocials about restrictions and installation requirements in your area. is furnace must be installed by a

qualied technician. Keep these instructions for future reference.

Installation/Operator’s Manual

Safety Tested to UL 391

Tested & Listed

By:

Report #

215-S-13b-2

Portland

Oregon USA

U.S. Environmental Protection Agency

Certified to comply with 2015 particulate emissions standards.

2

INTRODUCTION

ank You for your purchase of a U.S. Stove Wood/Coal Burning

External Furnace. Your decision to buy our Clayton Furnace was

undoubtedly reached aer much careful thought and consider-

ation. We are very proud you chose this furnace and trust you

will receive the comfort and economy that others realize when

heating with a U.S. Stove product.

Your dealer is important in your experience with the furnace

not only with the purchase, but for recommendations for pro-

fessional installation for your home. e qualied professional

installer has been expertly trained in solid-fuel furnace installa-

tion to assure the safety and comfort for your family while saving

you money. Trust your experienced installer. ey are specialist

in this eld.

IMPORTANT

Before installing and using your furnace, please read the follow-

ing pages thoroughly and carefully. If you follow the instructions,

your furnace will give you safe and more dependable service for

years to come.

• Check your local codes. is installation must comply with

their rulings.

• is is an outdoor hot air furnace and must NOT be installed

inside the home or a building.

• is furnace must be connected to a 110 volt Ground Fault

Circuit Interrupter (GFCI) outlet suitable for outdoor use.

• A back-up generator, 2,000 watts minimum, is recommend-

ed in case of a power failure.

• Always have a properly functioning smoke or ionization de-

tector and a CO detector installed in your home.

• To prevent injury or damage, do not allow anyone who is

unfamiliar with the furnace to operate it.

• Spend adequate time with your furnace to become well ac-

quainted with the dierent settings and how each will aect

its burning patterns. It is impossible to state just how each

setting will aect your furnace because of the variations in

each installation.

DISCLAIMER NOTICE

e BTU ranges and heating capacity specications are provided

as a guide and in no way guarantee the output or capacity of

this unit. e actual BTU output depends on the type of fuel be-

ing burned and its conditions, the thermostat setting, the dra

adjustment and the chimney to which the unit is attached. e

actual area that this unit will heat depends on factors such as

the conditions of the building, heat loss, type of construction,

amount of insulation, type of air movement, the location of the

unit and more importantly the duct work and return air facility.

Warning:

Do not alter this appliance in any way other than specied in

these instructions. Doing so may void your warranty.

GENERAL INFORMATION

Your 1600EF furnace comes ready for installation. No assem-

bly required. Unpack your furnace and insure that there is no

shipping damage. If damage exist, please contact your dealer im-

mediately. Review the items included with your furnace located

inside the rebox.

1 - 10” Starter Collar

1 - 12” Starter Collar for Cold Air Return

8 - #10 x 3/4 Screws w/ Sealing Washer

1 - Literature Package

is furnace may be installed as a Stand-Alone Central Furnace

or as a Supplementary Furnace in the US only. For Canadian in-

stallations, it may be installed as a Stand-Alone Central Furnace

Only.

If installed as a Central Furnace, this unit will have it’s own cen-

tral ducting system and will essentially be your primary heat

source. If installed as a Supplementary Furnace, the 1600EF will

assist an Electric, Gas or Oil Fired Furnace in heating your home

by utilizing the existing furnace’s duct work system. e 1600EF

must not be wired in conjunction with the existing furnace. e

outdoor furnace may be operated with the supplied wall thermo-

stat or a 24 volt thermostat that you supply yourself.

e furnace should be placed outdoors on a level noncombus-

tible base, preferably a 4’ x 8’ concrete pad, as close to the home

as clearances to combustibles will allow. If locating the furnace

more than 10 feet away from the home, a minimum of 6 feet of

Class “A” HT 2100 All Fuel 6 inch chimney pipe is required - Do

not place the furnace more than 40 feet away from the home.

Maintain all clearances stated in this manual.

Class “A” HT 2100 All Fuel 6” Chimney Pipe is recommended

for optimum performance and can be purchased from your local

dealer. A Chimney Base Plate should be installed over the ue

outlet and sealed to maintain weather resistance. A 2” clearance

to combustibles must be maintained from the pipe. We suggest

using either Simpson Dura-Vent or Metal Fab chimney products

for your installation.

If you choose to use single wall stainless, the ue temperatures

will be reduced which promotes the formation of creosote, pos-

sibly creating a re hazard. If you use single wall stainless pipe,

the minimum clearance to combustibles is 20”.

Attach the appropriate chimney pipe lengths to the chosen chim-

ney base plate and nish with a rain cap. Secure the chimney

with guy wires to each of the four anchors point on the furnace.

Your furnace requires it’s own chimney system and can not share

a ue with another appliance.

Once you have selected a location for the furnace and connect-

ed your furnace to a chimney and a 110 volt GFCI outlet, you

will need to commence an initial ring. DO NOT connect the

furnace to your duct work at this time. Your new furnace has a

protective coating of oil and paint on the surface which could

produce smoke or odors during the initial ring and will burn

o. Build a small re - DO NOT ll the rebox to it’s full capac-

ity for the initial burn. is initial ring allows the metals and

castings to cure.

Aer completing the ring and allowing it to cool, you are ready

to nish the installation. Refer to the remainder of this manual

for detailed instructions.

CUT HERE CUT HERE

WARRANTY INFORMATION CARD

Name__________________________________________ Telephone #: (_____)_____________

City____________________________________________ State_______ Zip_________________

Email Address __________________________________________________________________

Model # of Unit________________________________ Serial #___________________________

Fuel Type: Wood Coal Pellet Gas Other _________________________

Place of Purchase (Retailer)______________________________________________________

City____________________________________________ State_______ Zip_________________

If internet purchase, please list website address___________________________________

Date of Purchase _______________________________________________________________

Reason for Purchase: Alternative Heat Main Heat Source

Decoration Cost Other _________________________

What was the determining factor for purchasing your new USSC appliance?_______

I have read the owner’s manual that accompanies this unit and fully understand the:

Installation

Operation

and Maintenance

of my new USSC appliance.

Print Name Signature Date

Please attach a copy of your purchase receipt.

Warranty not valid without a Proof of Purchase.

Warranty information must be received within 30 days of original purchase.

Detach this page from this manual, fold in half with this page to the inside and tape together. Apply a

stamp and mail to the address provided. You may use an envelope if you choose.

You may register online by going to www.usstove.com

All information submitted will be kept strictly condential. Information provided will not be sold for advertising purposes.

Contact information will be used solely for the purpose of product notications.

CUT HERE CUT HERE

Fold Here Fold Here

United States Stove Company

P.O. Box 151

South Pittsburg, TN 37380

Fold Here

PLACE

STAMP

HERE

5

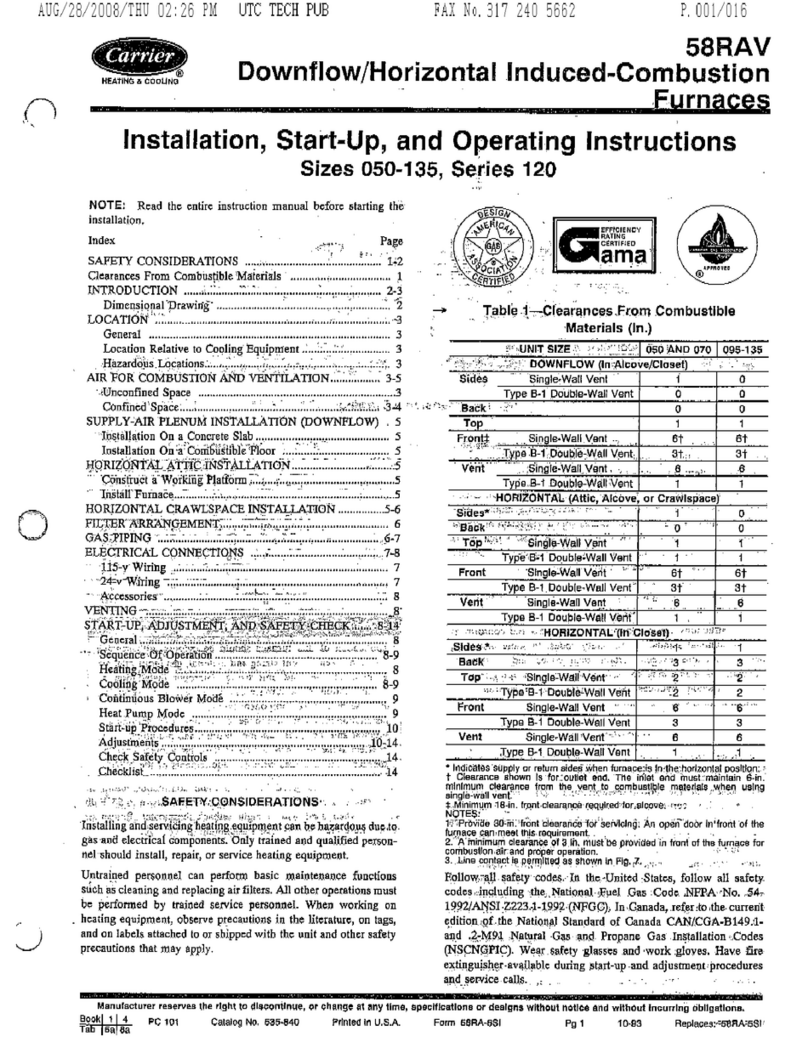

UNIT DIMENSIONS

LIMIT SWITCH

ACCESS

A

6.00

31-5/8"

12" COLD AIR

RETURN

14-1/4"

43-7/16"

29-3/16"

10" HOT AIR OUTLET

HOT WATER COIL ACCESS

(OPTIONAL)

BLOWER SPEED

SELECTOR SWITCH

B

D-RINGS FOR GUY WIRE

ATTACHMENT

17-5/16"

55-5/8"

5-3/16"

45-3/4"

65-1/2"

2-9/16"

29-1/2"

24-1/4"

6" FLUE GAS OUTLET

6

22”

12”

20” 15”

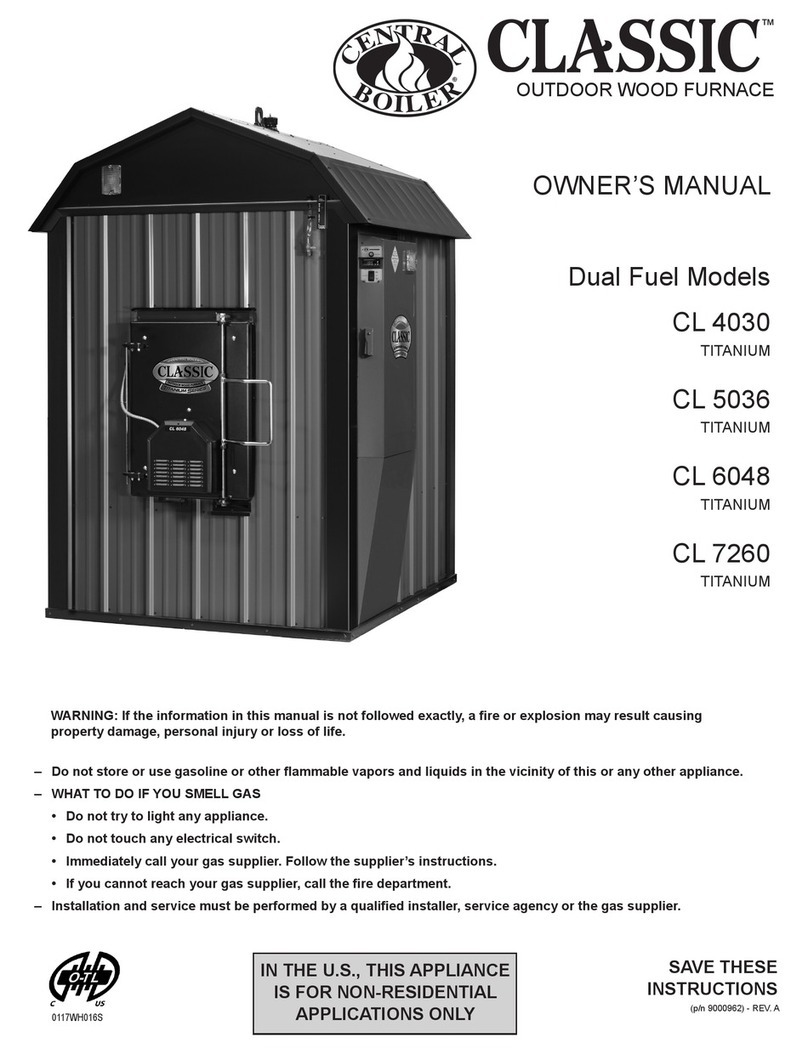

COMBUSTIBLE WALL

COMBUSTIBLE WALL

FLUE

(TOP VIEW)

MINIMUM CLEARANCES

TO A COMBUSTIBLE

WALL

CAUTION:

DO NOT store

combustible or

flammable materials or

liquids near the

furnace.

WOOD SUPPLY

Some important rules for preparing good rewood are: Cut, split

and stack the wood in the early spring and let it stand in the sun

and wind all summer.Whether you purchase your wood or cut it

yourself, spring is the best time to buy or cut your wood to insure

it is good and dry come winter. If you live in a damper climate, it

will take longer for the wood to season. By far the most important

characteristic of any rewood is its moisture content. Firewood

with a moisture content higher than twenty percent will burn,

but it will be hard to light and keep burning, will make a lot of

smoke and will produce less ecient res with lower sustained

BTU output. Plus much of its energy content will be wasted right

up the chimney. Firewood should be between 15 and 25 percent

moisture to burn properly and to get that dry it must be split and

stacked in the open for at least a full summer.All wood burns, but

wood that’s cut green (between 50 and more than 100 percent

moisture content) burns with more diculty, because the water

in the wood must be boiled o before the actual wood ber can

burn. Air-dried (“seasoned”) wood is generally between 20-30

percent.Kiln-driedrewoodgenerallycontainslessthan20percent

moisture.Green wood can produce more creosote--a black sooty

liquid which deposits and hardens on the inside of your chimney

and can ignite, causing a chimney re.When you stack your wood,

you should stack it in an open location where the summer sun can

warm it and breezes can help remove moisture. Be sure to cover

the top of the wood pile to keep the rain out. It is important that

you do not stack unseasoned wood in an unventilated area for it

will not dry properly. You shouldn’t allow your rewood to lay on

the ground for more than a couple days before stacking , or it will

start to mold and rot quickly.Once your wood is seasoned, store

it in a dry location before burning.

CLEARANCES

Sides of furnace, 12”; Rear of furnace, 15” (allow approximately

20” for the return box); Front of furnace, 36”; Heat Duct, 2” for

the rst 9 feet then 1” thereaer.

FLUE PIPE INSTALLATION

Clearances to combustible materials will vary with the type of ue

connection used. Be sure to maintain the specied clearances for

your type of installation.

TYPE OF FLUE REQUIRED

CONNECTION

CLEARANCE

Class A 103HT All-Fuel or Equivalent .2”

Double Wall, Stainless Steel or................6”

Double Wall, Black Pipe w/

Stainless Steel Inner wall

24 Gauge or Heavier ................................20”

Single Wall Stainless Steel or Black Pipe

e above clearances to combustibles must be maintained.

CHIMNEY REQUIREMENTS

A Class “A” HT 2100 All Fuel 6” Chimney Pipe and Base Plate

should be used for the installation. See Illustration. Place the Base

Plate over the ue outlet of the furnace and drill eight(8) pilot

holes into the Cabinet Top. Apply a generous amount of high

temperature sealant to the bottom of the base plate, and around

the ue outlet. Position the base plate over the ue and secure with

the eight(8) screws provided. en attach the ue pipe sections.

A minimum chimney height of 6 feet is required not including the

rain cap. In order to determine proper chimney height above the

roof, measure from the side of the chimney horizontally. As you

move up the chimney, the length increases. Once this measure-

ment reaches 10 feet, this is the base height of the chimney. e

chimney must be 2 feet taller than the base height. If the chimney

is closer than 10 feet from the peak of the roof, the chimney must

be 2 feet taller than the peak of the roof. e 2 feet measurement

does not include the rain cap.

Oncecorrectchimney heightisachieved,checkthe chimneydra.

It should not exceed 0.06 inches of water column. en secure

with three screws at each joint and attach guy wires down to the

rings located around the top of the furnace cabinet.

See illustration.

IMPORTANCE OF PROPER DRAFT

Dra is the force which moves air from the appliance up through

the chimney. e amount of dra in your chimney depends on the

length of the chimney, local geography, nearby obstructions and

other factors. Too much dra may cause excessive temperatures

in the appliance. Inadequate dra may cause backpung into the

room and ‘plugging’ of the chimney.

“Inadequate dra will cause the appliance to leak smoke into the

room through appliance and chimney connector joints.”

“An uncontrollable burn or excessive temperature indicates ex-

cessive dra.”

Take into account the chimney’s location to insure it is not too

close to neighbors or in a valley which may cause unhealthy or

nuisance conditions.

7

CONNECTING HOT AIR DUCT

TO FURNACE

We strongly recommend that the hot air duct work be installed by

a home heating specialist. If doing the installation yourself, before

you decide which installation will best suit your needs, consult a

qualied heating technician and follow his recommendations as

to the safest and most ecient method of installation.

e warm-air supply-duct system shall be constructed of metal

in accordance with NFPA 90B, 2-1.1. e plenums installed to

the furnace be constructed of metal in accordance with NFPA

90B, 2-1.3.

Outside the house you must use 10 inch galvanized pipe, wrapped

with weather proof, UV resistant insulation. e 12 inch return

may be galvanized pipe and attached to the home so as to not

pressurize the home.

NEVERreducethe10”hotair or the12”returnairas thiswill result

in restricted air ow and cause the furnace to not operate properly.

NEVER draw cold outside air into the blower housing. By doing

so, the furnace’s heat chamber will not reach the necessary tem-

perature to heat the home.

e duct work should be designed so the external static pressure

does not exceed 0.2 inches water column while developing air ve-

locities of 600 to 1,000 feet per minute in the main trunk duct and

400 to 600 feet per minute at the registers. e heat outlet should

never be less than ten inches (10”) round or 79 square inches.

is furnace must be installed with a cold air return system. e

system must be a minimum of twelve inches (12”) to readily

transfer the cold air from the home back to the furnace. If desired,

a cold air lter box may be constructed with a minimum opening

of 225 square inches.

e warm-air supply outlet of the outdoor furnace must not be

connected to the cold-air-return inlet of an existing central fur-

nace because the possibility exist of components of the existing

furnace overheating and may cause the central furnace to operate

other than intended.

TYPES OF INSTALLATION

NO DUCT WORK INSTALLATION

Cold air return must be installed in all installations, even those without an air duct system. If you do not, the furnace will not be able

to heat the home. A lter should be installed in the cold air return. Furnace lters should be checked and cleaned/replaced regularly.

When there is no duct system to connect the furnace to, keep the following in mind:

1. You must separate the hot air duct from the cold air return.

Ideally, locate each at opposite ends of the home. is method

will work well in homes that are built on concrete slabs and

should create a good air ow. If you do not, air will not ow

evenly through the home.

2. In homes with a basement, you may run the hot air duct to

the basement and pull the cold air return from the main oor.

is will create the perfect air ow since hot air rises.

8

INSTALLATION #1

With this installation, a back dra damper (optional) is inserted

into the heat run before the plenum of the existing furnace to pre-

vent air from the existing furnace to blow back into the furnace

when it is not in use. When a back damper is employed, it should

be located as close to the existing furnace plenum as practical.

CENTRAL DUCT CONNECTION

When connecting to a central duct system, avoid 90 degree el-

bows as this will reduce air ow delivery. A duct run in excess

of 40 feet is NOT RECOMMENDED. e air ow and heat

output will be greatly decreased.

Run 10” insulated hot air duct from the outdoor furnace

through a wall or window of the structure. en attach a ex-

ible hot air duct to the existing duct work. Connect the duct

with a 45 degree elbow or at an angle so the hot air from the

outdoor furnace is delivered downstream. is will insure

proper air ow into the system.

Avoid delivering hot air through an air conditioning coil as this

will cause an obstruction reducing heat output.

e following illustrations may be used as examples for your

installation.

INSTALLATION EXAMPLES

TYPES OF INSTALLATION

INSTALLATION #2

e bae on this system should be made the full width of the

furnace plenum in order to properly direct the air into the dis-

tribution ducts.

INSTALLATION #3

Extending the hot air duct from the furnace into the existing

plenum will help direct the ow of air from the furnace as well

as the ow in the existing furnace. Ducting entering the exist-

ing plenum at an angle (approximately 45 degrees) will facilitate

air ow from the furnace while diverting air from the existing

furnace.

9

Read and follow these instructions in the event you have to re-

place or re-assemble components of your furnace.

DOOR HANDLES

Insert door handle into door. From rear side of door, place a

1/2” washer over the threaded part of the handle, then attach

the lock nut. Tighten the nut, then back o 1/4 turn to allow

free operation of the handle.

Follow these same directions for the ash door handle assembly.

(2) Door Handle

(2) 1/2” Washer

(2) 1/2” Lock Nut

ASH DOOR SPIN DRAFT

Screw the spin dra onto the 3/8” x 2-1/2” carriage bolt. en

screw the spin dra and bolt into the ash door allowing ap-

proximately 1/2” of the bolt to stick through the back side of

the ash door. Secure the bolt in place with the 3/8”-16 lock nut.

(1) Spin Dra

(1) 3/8-16 Carriage Bolt

(1) 3/8-16 Lock Nut

FUEL & ASH DOOR LATCH

With two 1/4-20 x 3/4 hex bolts each, attach the door latches

to the door latch mounting brackets on the le side of the door

frames as illustrated. e slots in the brackets and latches are

for door seal adjustment. Make the proper adjustments, then

tighten the nuts. e door’s gasket should be snug against the

door frame on the furnace.

Feed Door

Illustration

Ash Door

Illustration

(1) Feed Door Latch

(1) Ash Door Latch

(4) 1/4-20 x 3/4 Hex Bolt

(4) 1/4-20 Kep Nut

BRACKET

SHAKER GRATE HANDLE

Insert the Shaker Rod into the hole on the ash door frame as

shown. en attach the Shaker Bracket to the front of the fur-

nace using two 1/4-20 x 3/4” Hex Bolts and two 1/4-20 Lock

Nuts. Next, insert the shaker Rod into the bracket and attach

to the shaker grate bar using the 1/4-20 x 1” Hex Bolt and a

1/4-20 Lock Nut. e bolt and nut retaining the shaker bar and

rod should be le loose to allow free movement of the grates.

(1) Shaker Rod

(1) Shaker Bracket

(1) 1/4-20 x 1” Hex Bolt

(2) 1/4-20 x 3/4” Hex Bolt

(3) 1/4-20 Lock Nut

FRONT

SMOKE CURTAIN

SMOKE CURTAIN

CLIP

NUT

BOLT

1/4-20 NUT

SMOKE CURTAIN

CLIP

1/4-20 x 1-1/4

CARRIAGE BOLT

SMOKE CURTAIN

SMOKE CURTAIN

Using two 1/4-20 x 1-1/4” Carriage bolts, the smoke curtain

clips and two nuts, attach the smoke curtain in place above the

Fuel Feed Door as shown below. Aer installation, the smoke

curtain should swing freely back into the furnace.

(1) Smoke Curtain (2) Smoke Curtain Clips

(2) 1/4-20 x 1-1/4 Carriage Bolt (2) 1/4-20 Kep Nut

FURNACE ASSEMBLY INSTRUCTIONS

10

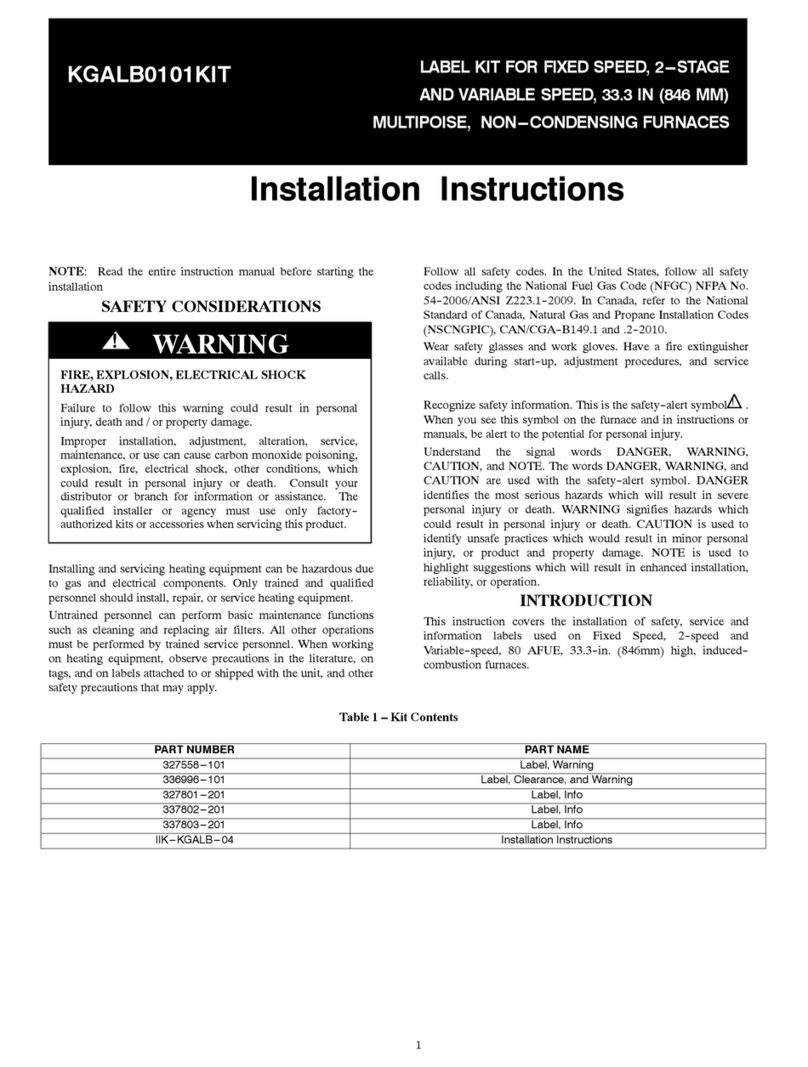

All electrical connections should be done by a qualied elec-

trician.

1. To replace the Honeywell Limit Control (A): Unplug from

power supply

e control may be removable thru the access panel on item

“B”. However it may be easier to remove item “B” entirely for

better access. Remove item “B” by means of the eight(8) screws.

If siliconed, use a utility knife to score the silicone along the

edges of the part. Take o the cover of the control (A), remove

the three wires, and continue to remove the control by means of

the two screws retaining it. Use the wiring diagram in the rear

of this manual to re-connect the new control. Reattach item

“B” and re-silicone all the seams with weather resistant silicone.

2. To remove the return air box (D): Unplug from power sup-

ply.

If siliconed, use a utility knife to score the silicone along the

edges of the part. Remove item “B” as described above. en

remove the four(4) screws down each side and the four(4)

across the top of the return air box. Pull the box back away

from the unit enough that you can reach in to remove the snap-

in plug (C) from the top of the box. e power supply cord

will need to be feed back thru the plug in the bottom of the air

box for complete removal. When re-attaching, make sure that

the three plugs in the top of the Fan Center (G) are properly

plugged in. Do not forget to put the snap-in plug (C) back in

place. Re-silicone all the seams with weather resistant silicone.

3. To remove the Distribution Blower (E): Unplug from pow-

er supply.

Remove items”B” and “D” as described above. Unplug the

blower from the top of the Fan Center (G). Remove the four(4)

screws retaining the blower.

4. To remove the Blower Motor: Unplug from power supply.

Perform number 3 above. Before removing the motor from the

housing, measure two things:

1.) e distance from the edge of the motor to the edge of the

motor bracket. Record (d1) _________________

2.) e distance of the sha remaining outside the coupling on

the blower wheel. Record (d2) __________________

ese two measurements dictate the position of the blower in-

side the housing and is critical in determining motor longev-

ity. Repositioning of the blower motor, bracket, and wheel in

respect to one another should keep as close to the factory posi-

tion as possible.

Remove the three(3) screws (I) from the blower housing. en

loosen the bolt (J) on the motor sha. Next, loosen or remove

the bolt (K) in the motor bracket to remove the motor.

5.

To remove the Blower Capacitor (F): Unplug from power sup-

ply.

is may be accomplished by working thru the 12 inch diam-

eter return duct hole in the Return Box. Otherwise, you must

remove items”B” and “D” as described above. Unplug the blow-

er from the top of the Fan Center (G). Using pliers with rubber

coated handles, unplug the two connections on the capacitor.

Remove the two screws and cap bracket.

DISTRIBUTION BLOWER & ACC.

A

C

B

D

C

F

E

HG

J

I

d1

d2

K

11

FIREBOX BRICK REPLACEMENT

is furnace comes from the factory with the rebrick in-

stalled. However, if brick replacement is necessary, follow these

instructions. Before furnace operation, remove the brick re-

taining strip. is piece is used during shipping to reduce brick

damage.

ere are 6 full brick and 1 half brick per side. Install the half

brick rst by putting the bottom of the brick in rst and let it

rest against the rebox side and re grates. en slide it to the

rear. Aer that, install the #2, #3, #4, #5 & #6 brick, sliding the

6th brick forward to allow for the 7th brick. Repeat for opposite

side.

NOTE: Prior to operation, be sure to remove the brick re-

taining strips.

1. Make certain the unit has been unplugged from the power

source. Remove the cover from the motor and remove the

two wire nuts and grounding screw. With a pair of pliers,

remove the strain relief and cord assembly from the motor.

If motor comes with the cord, the above step is not required.

However, you will have to remove the panel on the inner

cabinet side to rewire the motor. Do so by removing the riv-

ets with a 3/16” drill bit. Screws may be used to replace the

rivets.

BAFFLE/BRICK REPLACEMENT

If bae replacement is necessary, slide the bae out until you

can access the nuts thru the ue outlet. Once the nuts have

been removed, slide the bae o the rod and thru the opening

in the rebrick. You may have to remove one of the rebrick to

make bae removal easier.

ere are 4 full brick and 1 half brick in the top of the furnace.

Install the brick by inserting one end of the brick angled up-

ward and then allowing the opposite end to rest on the rebox

lip. Lay the brick between the spacer and rebox back. Slide the

bae to the rear and let it rest on that half brick. Aer install-

ing brick #2 in the front, install #3 and slide it under the bae.

Finally install bricks #4 and #5.

MOTORIZED NATURAL DRAFT REPLACEMENT

FIREBRICK AND BAFFLE REPLACEMENT

2. Remove the dra assembly from the furnace by loosening

the two bolts retaining draw band.

3. To remove the motor from the tubing assembly, simply loos-

en the set screw in the collar on the motor and slide it o the

tube.

4. If replacing the Flipper, remove the two #8 screws retaining

the plate to the tube.

Reverse the above steps for re-assembly

(1) Dra Actuator

(1) Spin Dra

(1) 3/8-16 Carriage Bolt

(1) 3/8-16 Lock Nut

(1) Flipper Tube

(1) Flipper

(2) #8 Screw

12

GENERAL FURNACE OPERATION

Aer installation of the furnace is complete, it is ready for opera-

tion. e Honeywell Limit Control, in conjunction with a wall

thermostat, operates the distribution blowers and the motorized

dra on the front of the furnace. e limit control is located on

the rear of the furnace in the upper le corner and is accessible

by removing the two screws in the cover plate. DO NOT operate

your furnace with this plate removed! e control can be ad-

justed to your desired blower On/O times. e factory settings

are 100/150/200.

e wall thermostat setting operates the ON time of the motor-

ized dra. If the temperature is below the setting on the wall

thermostat, the motorized dra will come open. (Recommended

setting at 5 to 10 degrees higher than other heating thermostats.)

e rst two set points on the limit control operates the distri-

bution blower. When the furnace plenum reaches the second

set point on the limit control, the distribution blower will come

on. If the temperature falls to the rst set point, the distribu-

tion blower will shut-o. e distribution blower is a three speed

blower and can be manually adjusted by means of the three posi-

tion switch located behind the sliding access panel on the cold

air return box.

When the furnace reaches the third set point on the limit control,

the dra blower will shut-o. e dra blower will come back on

if the temperature falls below the setting on the wall thermostat.

TESTING

1. Check the motorized dra by turning the room thermostat up

high enough so that the motorized dra opens. en lower the

thermostat setting to ensure it closes o.

2. Use a sheet of newspaper to test your dra by placing it inside

the furnace and lighting it.

With completion of the tests above, you are ready to light the

furnace. Follow the operating steps.

STARTING A WOOD FIRE USING MOTORIZED

NATURAL DRAFT

e top down method of re building is recommended for this

appliance. Aer making sure that the stove air intake controls

are fully open (completely pull-out towards you), Place the larg-

est pieces of wood on the bottom, laid in parallel and close to-

gether. Smaller pieces are placed in a second layer, crossways to

the rst. A third layer of still smaller pieces is laid crossways to

the second, this time with some spaces between. en a fourth

layer of loose, small kindling and twisted newspaper sheets tops

o the pile.

Higher eciencies and lower emissions generally result when

burning air dried seasoned hardwoods, as compared to so-

woods or to green or freshly cut hardwoods.

DO NOT BURN:

1. Garbage;

2. Lawn clippings or yard waste;

3. Materials containing rubber, including tires;

4. Materials containing plastic;

5. Waste petroleum products, paints or paint thinners, or as-

phalt products;

6. Materials containing asbestos;

7. Construction or demolition debris;

8. Railroad ties or pressure-treated wood;

9. Manure or animal remains;

10. Salt water driwood or other previously salt water saturated

materials;

11. Unseasoned wood; or

12. Paper products, cardboard, plywood, or particleboard. e

prohibition against burning these materials does not pro-

hibit the use of re starters made from paper, cardboard,

saw dust, wax and similar substances for the purpose of

starting a re in an aected wood heater.

Burning these materials may result in release of toxic fumes or

render the heater ineective and cause smoke.

Dead wood lying on the forest oor should be considered wet,

and requires full seasoning time. Standing dead wood can usual-

ly be considered to be about 2/3 seasoned. Splitting and stacking

wood before it is stored accelerates drying time. Storing wood on

an elevated surface from the ground and under a cover or cov-

ered area from rain or snow also accelerates drying time. A good

indicator if wood is ready to burn is to check the piece ends. If

there are cracks radiating in all directions from the center then

the wood should be dry enough to burn. If your wood sizzles in

the re, even though the surface is dry, it may not be fully cured,

and should be seasoned longer

CAUTION: Never use gasoline, gasoline-type lantern fuel, kero-

sene, charcoal lighter uid, or similar liquids to start or “freshen

up” a re in the furnace. Keep all such liquids well away from the

furnace while it is in use.

1. Open spin dra cap on ash door.

2. Pull the slide bae rod to the front position.

3. Open the fuel load door and light re using kindling and several

sheets of newspaper, then close the furnace door. e furnace

door should remain closed for 5 to 10 minutes in order to

establish the re. If the re has established, you are ready to

load the furnace.

CAUTION: To prevent ame and smoke spillage, the slide bae

must be pulled out and the fuel door must be cracked for ten

seconds before being fully opened.

Do not over reyourfurnace! Aeryouhavebecomefamiliarwith

its operating, you should know how much wood to use.

4. Load the furnace, close the load door and push the slide Bae

rod to rear.

5. Close the spin dra cap on ash door, leaving it cracked about

the diameter of a dime.

6. e motorized dra cycles (opened & closed) on demand from

the wall thermostat. Setting the U.S. Stove thermostat four de-

grees higher than your existing thermostat is recommended.

In operation, the power dra will remain open until the U.S.

Stove thermostat temperature setting is reached. en it will

close to reduce combustion air. If the furnace looses power, the

TESTING AND OPERATING PROCEDURES

13

dra will automatically close.

CAUTION: To avoid excessive temperatures, do not operate

with fuel door or ash pan open.

STARTING A COAL FIRE

Shut o FAD when fuel door is open

• Open all dra controls on your furnace. Pull the slide bae

forward.

• Place about 10-15 lb. of coal in on the shaker grates. It should

come up to about half of the rst rebrick level.

• Place crumpled paper over the coal and crisscross a couple

handfulsofdry kindlingwood3/4”inthicknessontopofpaper.

• Ignitethe paper andclose loadingdoor. Waitabout30minutes

until coal re is established before adding more coal. NOTE:

NEVER load coal over the level of rebrick.

• Close by-pass damper and set all dra controls to your own

needs. It may take 3 to 4 coal res to determine how your

local coal and the Clayton Furnace reacts together. Adjusts

dras accordingly.

• When loading with a good bed of coals in the morning - Open

by-pass damper.

1. In normal shaking, only rock the grates a small amount to

si ash through. Do not agitate the re bed too oen. is

practice will waste coal. If glowing coal is visible in the ash

pan, you have shaken to much.

2. Remove all ashes every day from ash pit.

CAUTION: Ashes should be placed in a metal container with a

tight tting lid. e closed container of ashes should be placed

on a non-combustible oor or on the ground well away from

all combustible materials pending nal disposal. If the ashes are

disposed of by burial in soil or otherwise locally dispersed, they

should be retained in the closed container until all coals have

thoroughly cooled.

3. With your poker, push hot burning embers to the rear of the

unit and add green coal in front. NEVER load over height

of rebrick. is can result in damage to your furnace and

home.

4. Close by-pass damper.

• Too much dra air will cause clinkering of coal and will waste

heat up the chimney. Shut dra down to as low a point as you

can and still heat your home.

1. NOTE: Never stand in front of loading door when opening

it. Stand to the side.

2. NEVER completely cover the live re with fresh coal. Always

leave a generous area of glowing coal at the top of the re

and at the rear.

3. Always keep the ash pit clean.

• If the re goes out or does not hold overnight, look for:

1. Poor dra.

2. Incorrect damper settings.

3. Improper ring methods for coal being used.

4. More combustion air needed.

5. Coal not sized to the furnace. We recommend 1” to 3”

diameter pieces of coal.

6. Ashes, if allowed to accumulate in the ash pit, will not allow

the passage of required air for combustion. Keep ash pit

clean.

7. is furnace is not to be used with an automatic stoker un-

less so certied.

• ere are ONLY two types of coal allowed for use in this

furnace: Bituminous Coal (so coal) and Anthracite Coal

(hard coal). NEVER USE Cannel (or Channel) coal or Brown

(Lignite) Coal.

• See our Bulletin RC454 at the rear of this manual for the best

information available on burning coal.

• DANGER: Risk of Fire or Explosion - Do not burn garbage,

plastics,gasoline,drainoilorotherammableliquids.Plastics,

whenburned,form hydrouoricandhydrochloricacidswhich

will damage and destroy your furnace pipe and chimney. e

burning of trash or oil can result in an extremely hot re and is

sometimes a cause of chimney res. NEVER BURN GREEN

WOOD OR TIRES.

• WARNING: Risk of Fire - Do not operate with ue dra

exceeding .06 inches of water column and must be set with a

dra gauge to maintain a steady dra. (Barometric Damper

recommended.)

OPERATING NOTES

is wood heater has a manufacturer-set minimum low burn

rate that must not be altered. It is against federal regulations to

alter this setting or otherwise operate this wood heater in a man-

ner inconsistent with operating instructions in this manual.

VISIBLE SMOKE

e amount of visible smoke being produced can be an eective

method of determining how eciently the combustion process

is taking place at the given settings. Visible smoke consist of un-

burned fuel and moisture leaving your stove. Learn to adjust the

air settings of your specic unit to produce the smallest amount

of visible smoke. Wood that has not been seasoned properly and

has a high wood moisture content will produce excess visible

smoke and burn poorly.

EFFICIENCY

Eciencies can be based on either the lower heating value (LHV)

or the higher heating value (HHV) of the fuel. e lower heating

value is when water leaves the combustion process as a vapor, in

the case of woodstoves the moisture in the wood being burned

leaves the stove as a vapor. e higher heating value is when

water leaves the combustion process completely condensed. In

the case of woodstoves this would assume the exhaust gases are

room temperature when leaving the system, and therefore cal-

culations using this heating value consider the heat going up the

chimney as lost energy. erefore, eciency calculated using

the lower heating value of wood will be higher than eciency

calculated using the higher heating value. In the United States

all woodstove eciencies should be calculated using the higher

heating value.

e best way to achieve optimum eciencies is to learn the burn

characteristic of you appliance and burn well-seasoned wood.

Higher burn rates are not always the best heating burn rates; af-

ter a good re is established a lower burn rate may be a better

option for ecient heating. A lower burn rate slows the ow of

usable heat out of the home through the chimney, and it also

consumes less wood.

• Donotoperate with thefuelloadingorashremovaldoorsopen.

• Do not store fuel or other combustible material within

marked installation clearances.

• Inspect and clean your ues and chimney regularly.

14

• CAUTION: Hot Surfaces - Keep children away. Do not touch

during operation. Maximum dra marked on nameplate.

• Equip your home with re extinguishers and smoke detectors

appropriately located.

• Wood should be placed directly onto the cast iron shaker

grate of the Clayton furnace. Do not use additional grates

and/or irons.

• Do not allow ashes to build up higher than 2” above grates.

• Never allow the ashes in the ash pan to touch the grate sec-

tion. REMOVE ASHES FREQUENTLY!

• Be extremely careful when removing furnace ash pan; it can

get very hot.

• With new steel, there is a small amount of oil or dirt on the

metal. You may smell an odor. is is normal during the rst

operation. You may want to build a small re in the furnace

to “burn o” this dirt and oil before installing the duct work.

• e furnace is designed to burn air dried wood and coal at a

predetermined ring rate. Over ring could result in damage

to the heat exchanger and cause dangerous operation. Over

ring occurs when the ash door is le open during operation

or a highly volatile fuel, i.e. large amounts of small kindling,

is used. If any portion of the connector pipe glows orange or

red, you are in an over-ring situation. Close all dampers.

• When tending the rebox always pull the bae slide rod out

prior to opening load door. Open load door slowly to avoid

a “ash back”. Aer closing load door, push the bae slide

rod to the rear.

• In event of chimney re, shut all dra controls and call your

re department immediately. Alert everyone in the house.

If the re is still burning vigorously, throw baking soda into

rebox or discharge a re extinguisher into the rebox. Aer

chimney re is over, completely inspect system for damage

before further use.

• NEVER throw water on the re or at the furnace, as rapidly

expanding steam could result in a severe scalding.

• Slowres:It isnotrecommendedburningtheClayton furnace

any more than necessary early in the fall and late spring, as

you cannot keep the rebox hot enough (without overheat-

ing your home) to burn gases. Slow res can cause excessive

creosote build-up in smoke pipe, chimney and rebox.

• Inspect air lters regularly. e air lter should be changed

at least every 30 days.

• Oil motors every 90 days with a few drops of 30 wt. oil.

• Check the t on the load door. It must t tightly. If it does

not, check for deterioration or wear of the ceramic rope seal.

Replace defective seals.

• In the event of a power failure, the furnace will not distribute

heat to the home. We recommend the use of a back-up gen-

erator, 2,000 watts minimum, for continued use until regular

power is restored

• INSPECT FLUE PIPES, FLUE PIPE JOINTS AND FLUE

PIPE SEALS REGULARLY TO ENSURE THAT SMOKE

AND FLUE GASES ARE NOT DRAWN INTO, AND CIR

CULATED BY, THE AIRCIRCULATION SYSTEM.

• CAUTION: CLEANOUT OF THE HEAT EXCHANGER,

FLUEPIPE, CHIMNEY,ANDDRAGTINDUCERIF USED,

ISESPECIALYIMPORTANTATTHE ENDOFTHEHEAT

ING SEASON TO MINIMIZE CORROSION DURING

THESUMMERMONTHS,CAUSEDBY ACCUMULATED

ASH.

NOTE: For further information on using your furnace safely,

obtain a copy of the National Fire Protection Association pub-

lication “Using Coal and Wood Stoves Safely.” NFPA NO. NW-

8-1974. e address of the NFPA is 470 Atlantic Ave., Boston,

Massachusetts 02210.

THIS IS A WOOD AND COAL BURNING

FURNACE AND SHOULD NOT BE AL-

TERED IN ANY WAY! DOING SO WILL

VOID YOUR WARRANTY!

THIS IS A WOOD AND COAL BURNING

FURNACE AND SHOULD NOT BE AL-

TERED IN ANY WAY! DOING SO WILL

VOID YOUR WARRANTY!

When wood is burned slowly, it produces tar and other organic

vapors, which combine with expelled moisture to form creosote.

e creosote vapors condense in the relatively cool chimney ue

of a slow-burning re. As a result, creosote residue accumulates

on the ue lining. When ignited, this creosote makes an extremely

hot re. e chimney should be inspected at least twice monthly

during the heating season to determine if a creosote build-up has

occurred. If creosote has accumulated, it should be removed to

reduce the risk of a chimney re.

OVER FIRING

Attempts to achieve heat output rates that exceed heater design

specications can result in permanent damage to the heater.

Whenever ashes get 3 to 4 inches deep in your rebox or ash pan,

and when the re has burned down and cooled, remove excess

ashes. Leave an ash bed approximately 1 inch deep on the rebox

bottom to help maintain a hot charcoal bed.

ASH REMOVAL AND DISPOSAL

Ashes should be placed in a metal container with a tight-tting lid.

e closed container of ashes should be placed on a noncombus-

tible oor or on the ground, away from all combustible materials,

pending nal disposal. e ashes should be retained in the closed

container until all cinders have thoroughly cooled.

SMOKE AND CO MONITORS

Burningwoodnaturallyproducessmokeandcarbonmonoxide(CO)

emissions. CO is a poisonous gas when exposed to elevated con-

centrations for extended periods of time. While the modern

combustion systems in heaters drastically reduce the amount of

CO emitted out the chimney, exposure to the gases in closed or

conned areas can be dangerous. Make sure your stove gaskets

and chimney joints are in good working order and sealing prop-

erly to ensure unintended exposure. It is recommended that you

use both smoke and CO monitors in areas having the potential

to generate CO.

GASKETS

It is recommended that you change the door gasket (which makes

your stove door air tight) once a year, in order to insure good con-

trol over the combustion, maximum e ciency and security. To

change thedoorgasket,simplyremovethe damagedone.Carefully

cleantheavailablegasketgroove,apply ahigh temperaturesilicone

sold for this purpose, and install the new gasket. You may light up

your stove again approximately 24 hours aer having completed

ATTENTION:

This wood heater needs periodic inspection and repair for proper operation. It is against federal regulations to operate this

wood heater in a manner inconsistent with operating instructions in this manual.

15

1. Problem:

Smoke pus from furnace

Solution:

A. Check chimney dra. Check for blocked chimney or ue pipe.

Use mirror to check chimney clearance.

B. Check ash pit — if it is too full, empty.

C. Make sure all of chimney mortar connections are airtight.

D. Check ash drawer. Make sure it’s airtight.

E. Check chimney for possible down-dra caused by taller sur-

rounding trees or objects. Correct with proper chimney vent cap.

F. Check the possibility of a cold chimney forcing cool gases

backward. Remedied by properly insulating chimney with non-

combustible liner — non-combustible insulation.

G. Fuel may be too green.

H. Make sure no other fuel burning devices are connected to the

chimney impairing the dra.

I. Check chimney dra, it should be .06 inches of water column.

is service is provided by a certied chimney sweep.

2. Problem:

Inadequate heat being delivered to your home

Solution:

A. Check home insulation — is it adequate?

B. Check hook-up to furnace — is it installed correctly?

C. Cool air inlet may be inadequate.

D. Your wood fuel may be too low grade. Hardwoods are recom-

mended.

E. Make sure your hot air duct (and other duct work) is airtight.

F. Is air to the blower available?

3. Problem:

Excess smoke or ames coming out door when refueling

Solution:

A. Wait 15 seconds and open door SLOWLY — then refuel.

B. Check length of ue pipe to chimney.

C. Make sure chimney cap is not too close to the top of the chimney.

D. Check chimney dra — make sure chimney ue pipe is clean

and chimney is of adequate height.

E. Make sure you’re not suocating the re with excessive amounts

of unburned wood.

F. Slide bae should be pulled out prior to load door opening.

4. Problem:

Distribution blower vibrating

Solution:

A. Tighten blower wheel to motor sha.

B. Check for bad fan bearings.

5. Problem:

Distribution blower continues to run or will not run

Solution:

A.Check fan limit or heat sensor and cable.

B. Check to see that blower is properly wired.

(See Wiring and Assembly Instructions).

C. Check fuse box or power source.

D. Check power supply.

6. Problem:

Motorized dra stays open or will not close

Solution:

A. Check wiring.

B. Check thermostat or thermostat wire for short.

C. Make sure temperature is calling for heat.

7. Problem:

Odor from rst re

Solution:

A. e odor from new steel should disappear in a few hours.

B. If the odor remains, call you dealer immediately. A bad weld can

cause a fume leak.

8. Problem:

Excessive Creosote

Solution:

A. Check the grade of wood you are burning.

B. Make sure your unit is serviced by its own proper chimney.

C. Check length of ue pipe and its connections.

D. Make sure you are burning the smallest, hottest re to adequately

heat your home.

E. Also see Solutions to Problem number 1.

9. Problem:

If the re goes out or does not hold over night

Solution:

A. Poor Dra.

B. Incorrect damper settings.

C. Improper ring methods if burning coal.

D. More combustion air needed.

E. Coal not sized to the furnace. We recommend 1” to 3” diameter

pieces of coal.

F. Ashes, if allowed to accumulate in the ash pit, will not allow

passage of the required air for combustion. Keep ash pit clean.

G.is furnace is not to be used with an automatic stoker unless so

certied.

this operation. is unit’s doors use a 3/8” diameter rope gasket.

OPERATIONAL TIPS

• Operational Tips for Good, Ecient, and Clean Combustion

• • Get the appliance hot and establish a good coal bed before

adjusting to a low burn rate (this may take 30 minutes or

more depending on your wood)

• • Use smaller pieces of wood during start-up and a high burn

rate to increase the stove temperature

• • Be considerate of the environment and only burn dry wood

• • Burn small, intense res instead of large, slow burning res

when possible

• • Learn your appliance’s operating characteristics to obtain

optimum performance

• • Burning unseasoned wet wood only hurts your stoves ef-

ciency and leads to accelerated creosote buildup in your

chimney.

TROUBLE SHOOTING AND PROBLEM SOLVING

16

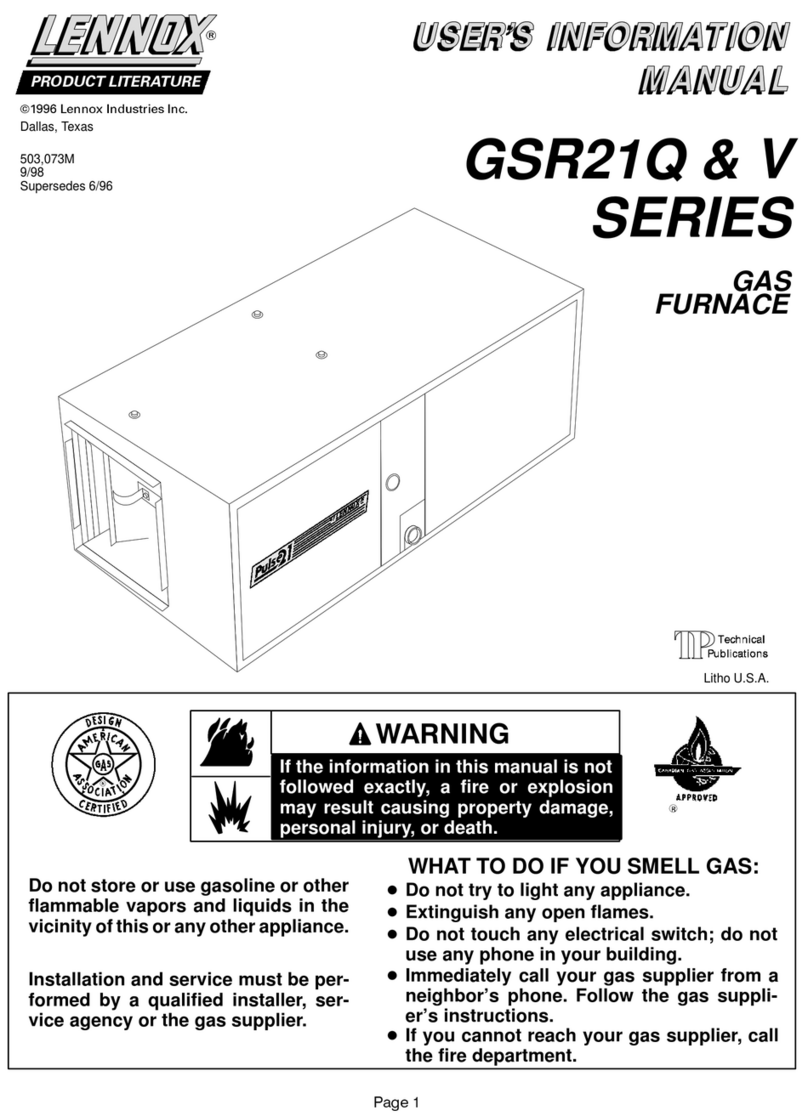

WIRING DIAGRAM

SERVO MOTOR

17

PARTS DIAGRAM

18

PARTS DIAGRAM AND LIST

Key Description Part # Qty

1 Grate Retainer 40312 2

2 Shaker Bar 891341 1

3 Shaker Grate Section 40314 5

4 Front Liner 40344 1

5 Back Liner 40313 1

6 Full Firebrick (4-1/2 wide x 9 tall x 1-1/4 thick) 89066 16

7 Half Firebrick (2-1/4 wide x 9 tall x 1-1/4 thick) 891414 3

8 Slide Bae 24231 1

9Bae Rod 86662 1

10 Inside Cover Plate 24220 1

11 Gasket, Water Coil Cover C97999 1

12 #12 x 3/4: Tek Screw C23799 3

13 Carriage Bolt, 1/4-20 x 1-1/4 Long 83445 2

14 Smoke Door Clip 23787 2

15 Kep Nut, 1/4-20 83250 2

16 Smoke Curtain 23800 1

17a Door Handle (Feed Door with Roll Pin) 69655 1

17b Door Handle (Ash Door) 24179 1

N/S Lock Nut, 1/2-13 83444 2

N/S Washer 83835 2

18 Feed Door Latch 23786 1

19 Feed Door Assy. (w/Rope Gasket) 69653 1

20 Shaker Handle 69005 1

21 Bracket, Shaker Handle 24204 1

22 Ash Door Latch 23823 1

23 Ash Pan 68882 1

24 Carry Handle 24233 1

25 Ash Door Assy. (w/Rope Gasket) 68880 1

26 Dra Cap 23859 2

27 Outer Side Wall, Le (25715) 891889 1

28 Panel-L, Inner Cabinet, Painted 25746B 1

29 Clip, Outer Wall (25718) 891912 2

30 Bracket, Alignment (25719) 891913 2

31 Cabinet Door Stop (25720) 891891 1

32 Insulation, Cabinet Side 88149 4

33 Outer Side Wall, Right (25716) 891890 1

34 Panel-R, Inner Cabinet, Painted 25717B 1

35 Harness, 2 Circuit Plug 80587 1

36 Filler, Top (25721) 891892 1

37 Hood, Front (25744) 891907 1

38 Assembly, Cabinet Back 69647 1

39 Insulation, Back 88153 1

40 Insulation Holder 83884 16

41 Inner Top, Painted 25726B 1

Key Description Part # Qty

42 Insulation, Top-Front 88150 1

43 Insulation, Top-Middle 88151 1

44 Insulation, Top-Rear 88152 1

45 Mount, Flue Outlet (25727) 891916 1

46 Weldment, Cabinet Top (69648) 891910 1

47 D-Ring Clip 83912 4

48 Bottom Intake, Painted 25722B 1

49 Assembly, Cabinet Door 69649 1

50 Latch, Cabinet Door 891865 1

51 1800 CFM Blower Assembly 80590 1

N/S 1/4-20 x 3/4 Self Tapping Screw 83236 4

N/S Washer 83045 4

52 Blower Motor 80588 1

53 Fan Center Assembly 69651 1

54 Honeywell Limit Control 80145 1

55 Harness, 3 Circuit Plug 80586 1

56 7/8” Snap Bushing-Heyco (BLK) 83909 3

57 Cable Chase (25732) 891897 1

58 Gasket, Access Panel 88155 1

59 Probe Access Panel (25733) 891898 1

60 Cover, Water Coil (25725) 891894 1

61 Bottom, Blower Box (25734) 891899 1

62 1-1/4” Bushing, Heyco 83910 1

63 Right Side, Blower Box (25737) 891902 1

64 Le Side Assy., Blower Box 69650 1

65 Back, Blower Box (25736) 891901 1

66 Top, Blower Box (25735) 891900 1

67 MTG. Bracket, Blower Box (25741) 891906 2

68 Motorized Natural Dra (MND) Assembly 69654 1

N/S MND Motor 80592 1

69 3” Draw Band 23888 1

70 1/4-20 x 1” Hex Bolt 83379 2

71 1/4-20 Lock Nut 83261 2

72 Plate, Electrical Connection, Painted 25745B 1

73 Strain Relief Bushing 80154 1

74 Hook, Handle (25748) 891919 1

75 Handle, Separable 891884 1

N/S Spring Handle 891135 1

76 12” Stub Collar 89799 1

77 10” Stub Collar 891868 1

N/S #10 x 3/4 Tek Screw w/ Bonded Neoprene Washer 83572 96

N/S = Not Shown

IN ORDER TO MAINTAIN WARRANTY, COMPONENTS MUST BE REPLACED USING ORIGINAL

MANUFACTURERS PARTS PURCHASED THROUGH YOUR DEALER OR DIRECTLY FROM THE

APPLIANCE MANUFACTURER.

USE OF THIRD PARTY COMPONENTS WILL VOID THE WARRANTY.

19

Key Description Part # Qty

1 Weldment, Dra Tube 68872 1

2 Spin Dra 40379 1

3 3/8-16 x 2-1/2 Carriage Bolt 83503 1

4 Lock Nut, 3/8-16 83274 1

5 Actuator, Motorized Dra 80592 1

6 Tube, Flipper 23899 1

7 Flipper 23898 1

8 #8 x 1/2 Tek Screw, Hex Head 83455 2

9 Strain Relief 80154 1

10 Power Supply Cord 80593 17 in.

11 Male, Tyco Terminal 80382 2

PARTS DIAGRAMS AND LISTS - MOTORIZED DRAFT KIT

4

20

PARTS DIAGRAMS AND LISTS - FAN CENTER CONTROL

Key Description Part # Qty

1 Electrical Box Cover 25742 1

2 Electrical Box Body 25743 1

3 Switch, 3-Position 80692 1

4 Harness, 6 Circuit Receptacle 80583 1

5 Harness, 3 Circuit Receptacle 80584 1

6 Harness, 2 Circuit Receptacle 80585 1

7 Transformer, Fan Center 80130 1

8 Strain Relief 80154 1

9 Power Supply Cord 80232 1

10 #10 x 1/2 Sheet Metal Screw 83172Z 13

11 Washer, Internal tooth, #10 83240 1

Table of contents

Popular Furnace manuals by other brands

Lennox

Lennox SL280V installation instructions

McQuay

McQuay IM 685 Installation & maintenance manual

PSG

PSG PSG-3000 Installation and operating instructions

Crown

Crown CSHB60-90ABP Installation, operation and service manual

Daikin

Daikin DM96SE manual

Lennox

Lennox Allied Air Enterprises A95DF2V installation instructions

Braemar

Braemar WF2000 owner's manual

Carrier

Carrier 58MSA Series instruction manual

ICP

ICP F8MXN installation instructions

VERDER

VERDER CARBOLITE GERO E Series Installation, operation and maintenance instructions

Rheem

Rheem GF801U UPFLOW Series installation instructions

ICP

ICP N9MP1 Installation insrtuctions