CleanMaster 100-610-400 Operating instructions

1

O

O

O

2-3-09

100-610-400100-610-400

100-610-400100-610-400

100-610-400

MAXX-400MAXX-400

MAXX-400MAXX-400

MAXX-400

EXTRACTOREXTRACTOR

EXTRACTOREXTRACTOR

EXTRACTOR

120V120V

120V120V

120V

INFORMATION

&

OPERATING

INSTRUCTIONS

11-56380572REVB

CAUTION: DO NOT OPERATE MACHINE UNTIL YOU HAVE READ

ALL SECTIONS OF THIS INSTRUCTION MANUAL

IMPROPER USE OF THE MACHINE WILL VOID THE WARRANTY

1. Always use a defoamer when foaming occurs to prevent vacuum motor damage.

2. Connect the machine to a properly grounded outlet.

3. Keep machine from rain, snow, and extremes in temperatures. Store the machine in a

heated location. Use the machine indoors. Do not use outdoors.

4. Use approved chemicals only. NO SOLVENTS.

5. Wear gloves or use rags when removing quick disconnects to prevent burns.

6. Never use water above 130º F/54º C in the solution tank.

2

IMPORTANT SAFETY INSTRUCTIONS

The Maxx 400 is only suitable for commercial use, for example in hotels, schools, hospitals, factories, shops, and

offices. The Maxx 400 is not intended for normal residential housekeeping purposes.

NOTE: Read all instructions before using this machine.

When using any electrical appliance, basic precautions should always be followed, including the following warnings:

WARNING!

To reduce the risk of fire, electric shock, or injury:

•Do not leave the machine unattended when it is plugged in. Unplug the unit from the outlet when not in use

and before servicing.

•To avoid electric shock, do not expose to rain or snow. Use and store indoors.

•Do not allow to be used as a toy. Close attention is necessary when used near children.

•Use only as described in this manual. Use only the manufacturer’s recommended attachments.

•Never add water over 130º F/54º C to the solution tank.

•Do not use with damaged cord or plug. If the machine is not working as it should, has been dropped,

damaged, left outdoors or dropped into water, return it to a service center.

•Do not pull by the cord, use the cord as a handle, close a door on the cord, or pull the cord around sharp

edges or corners. Do not run the machine over the cord. Keep the cord away from heated surfaces. To

unplug, grasp the plug, not the cord.

•Do not handle the plug, the cord, or the machine with wet hands.

•Extension cords must be 12/3 and no longer than 50 feet. Replace the cord or unplug immediately if the

ground prong becomes damaged.

•Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair, and

anything that may reduce air flow.

•Keep loose clothing, hair, fingers, and all parts of body away from openings and moving parts.

•Do not pick up anything that is burning or smoking, such as cigarettes, matches, hot ashes, or any health

endangering dusts. Do not use to pick up flammable or combustible liquids such as gasoline or use in areas

where these liquids may be present.

•Turn off all controls before unplugging.

•Use extra care when cleaning on stairs.

•Connect to a properly grounded outlet only.

•Liquid ejected at the spray nozzle could be dangerous as a result of its temperature, pressure, or chemical

content.

3

INSPECTION:

Carefully unpack and inspect your MAXX-400 for shipping damage. Each machine is tested and inspected before

shipping. Any shipping damage incurred is the responsibility of the carrier. You should notify the carrier immediately

if you notice damage to the box or to the machine or parts.

CLEANING SOLUTIONS:

We recommend liquid cleaning chemicals. Powder chemicals may be used, but unless mixed very thoroughly they

could cause a build-up in the pump, lines, heat exchanger and/or quick disconnects. Any problem caused by a

chemical build-up is not covered by warranty. Use a neutral cleaner with a pH between 5 and 10 to avoid premature

wear of the pump, seals, and/or other components.

MAINTENANCE:

For optimum performance flush the machine with clear water at the end of each working day. Once a month,

minimum, run a flushing compound through the machine to break up any mineral or chemical build-up that may

have formed. The vacuum motor and the pump do not require any scheduled maintenance; however, the motor

may require replacement brushes after 1000 - 1500 hours. Clean the body with an all-purpose detergent, and

protect it with an automobile interior polish. Lubricate the wheels, castors, and quick disconnects with an all

purpose silicone spray.

PARTS AND SERVICE:

Repairs, when required, should be performed by your authorized distributor who maintains an inventory of

original replacement parts and accessories. Call the distributor from whom you purchased this machine if you

need parts and service. Be sure to specify the machine model. Have your serial number handy.

Contact Info: CleanMaster Corporation

11015 47th Ave. West

Mukilteo, WA 98275

Toll free: 1-800-426-8972

Phone: 425-775-7272

Fax: 425-771-7156

Serial Number: __________________

Model: MAXX-400

Purchase Date:_____________

Write the name and phone number of your

distributor:

_____________________________________

_____________________________________

4

III

MODEL

O

O

O

PUMP SWITCH (3):

The pump switch will illuminate when it is activated, and it will turn on the pump.

HEAT SWITCH (4):

The heat switch will illuminate when it is activated and will turn on the heater. NOTE: if the green, two-circuit

indicator light is not turned on, you may have both power cords on the same circuit and this can trip the circuit

breaker in the wall.

GREEN, TWO CIRCUIT INDICATOR (5):

This light will automatically turn on when you have plugged the two power cords into separate circuits. If this light

does not turn on, try other outlets with one of the cords until the light does turn on. NOTE: all systems in the

machine will operate if this light does not turn on, but you may trip a circuit breaker in the wall.

SWITCH PLATE

Switches

12” Wheel

Castor

RecoveryTank

Lid

VacuumHose

Connection

Recovery

Tank

Drain

SolutionTank

Access

Solution

Output

1

234

YOUR MACHINE

5

MODEL (1):

This identifies the model

of your MAXX machine.

VACUUM SWITCH (2):

This push-button switch

turns on the vacuum. The

switch will illuminate when

it is on.

O

O

O

5

SET-UP & OPERATION:

1. Inspect the machine, hoses, and cleaning tools for cleanliness and completeness.

CAUTION: Always make sure the float cage is clean and the ball can travel freely before

turning on the machine.

2. Screw the lid on the recovery tank. Close the drain gate.

3. Fill the holding tank with clear water.

NOTE: Although this machine is designed to supply instant hot water, the addition of warm water to the

solution tank would increase heater efficiency. Never use water above 130º F/54º C in the solution tank.

4. Turn off all the switches. Plug the power cords into properly grounded outlets. Do not connect both cords to the

same outlet. The green, circuit locator light (5) on the switch plate should light up. If the locator light does not

come on, try different outlets until it does.

5. Connect the priming hose to the machine, and position the open end of the hose over the solution tank. Turn the

pump ON (3) to prime the air out of the pump. When the water is clear (no air in it) turn the pump off, and remove

the priming hose. NOTE: If priming is difficult, place the open end of the priming hose into the vacuum inlet hose

barb, and turn the vacuum on. Use your hand to block the open area in the hose barb. This will allow the pump and

the vacuum to work together to get the water moving. Priming may take 20 - 60 seconds, and the solution tank

should be full.

Once the pump has been primed, turn off the motor(s) off. Remove the priming hose.

6. Turn on the Heat switch (4), and wait two minutes for the heat exchanger to reach temperature.

7. Pre-spray with the detergent of your choice. If you choose to add a detergent to the solution tank, be sure to

mix well, and always follow the use & dilution instructions on the chemical label. Use a chemical with a pH

between 5 and 10.

8. Attach the spray hose to the solution quick disconnect and the vacuum hose to the hose barb on the

recovery tank.Attach the other ends of the hoses to the cleaning tool.

9. Turn on the vacuum (2).

10. Turn the pump ON and begin cleaning.

11. Use defoamer any time foaming occurs to prevent damage to the motor or other components. NOTE: Foam will

not lift the ball float.

12. Monitor the water level in the solution tank. Do not let the pump run dry.

13. When the solution tank gets low, turn off the pump and the vacuum, fill the solution tank, empty

and clean the recovery tank.

14. When finished with the job, remove any unused solution from the solution tank, and run a few gallons of

clean water through the system. Drain the recovery tank by opening the drain gate over a drain or a bucket.

Disconnect the hoses from the cleaning tool.

NOTE: If the green, circuit locator light does not illuminate when the cords are plugged in, then both cords are on

the same circuit. Try other outlets with one of the cords until you get the locator light to come on. NOTE: If the

heat switch is turned on when both cords are on the same circuit, the breaker in the wall may trip.

AUTO VACUUM SHUT OFF:

When the recovery tank is full, the ball float will shut-off the suction to prevent the machine from overflowing.

NOTE: The float may not work if there is foam in the tank. Always use defoamer to prevent overflow.

7

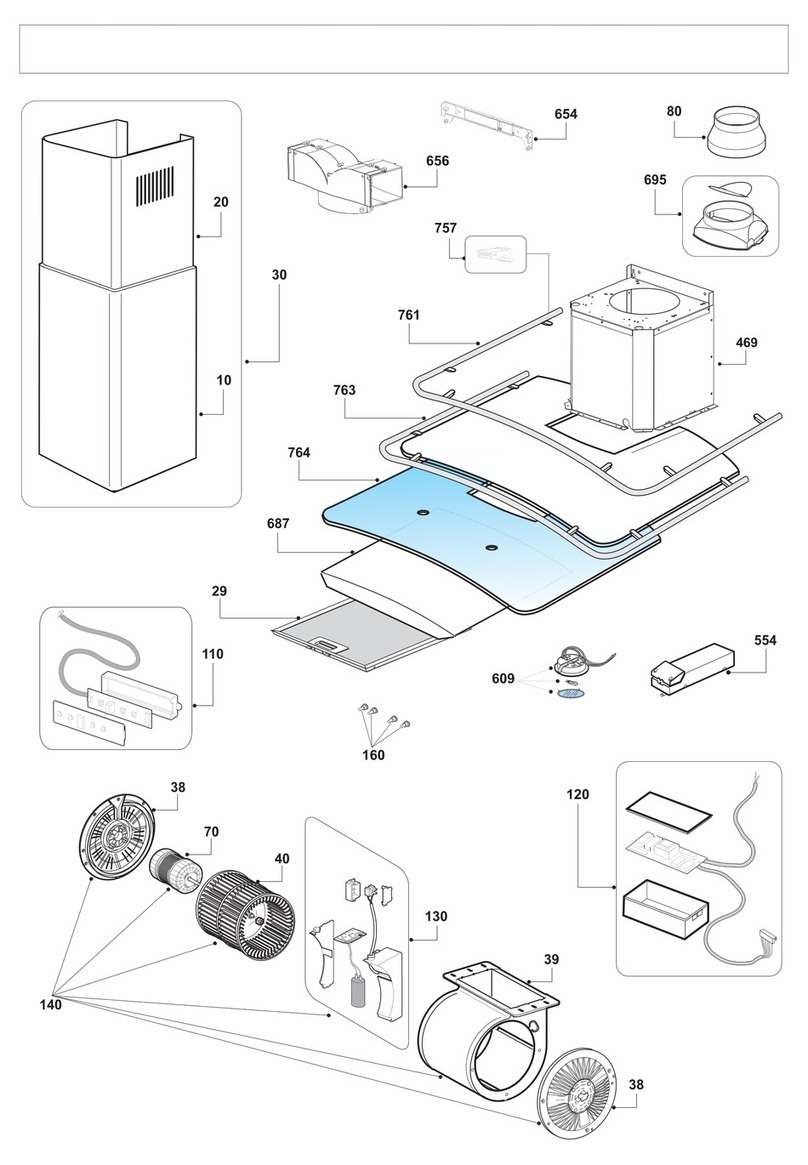

MAXX-400

PART LIST

ITEM PARTNo DESCRIPTION

120V

2-3-2009

ITEM PARTNo DESCRIPTION

Miscellaneous parts

1 903 Drain Gate

2 187B Gasket

3 187 O-ring

4 185 Nut, 1-1/2”

6 907 Hose Barb, vacuum inlet

7 1074 Gasket

8 2086 Lid with Ring, 6”

10 929B Ball Float, vac shut-off

10A 1140 Elbow, 90º, ABS

11 921 Elbow, PVC, MPT

11A 922 Elbow, PVC, FPT

12 156 Hose Clamp

13 430 Hose, vacuum, 2”ID X 27”

14 430A Hose, vacuum, 2”ID X 14.5”

14A 4404C Bar, vacuum hose hold-down

15 2167+2167-2C Switch plate, Advantage 400

16 1623R Switch, push-botton, ON/OFF

17 227 Green light

18 116A Bushing, fiber, heat resistant

19 92A Nipple, 1/4 mpt, S/S

20 115 Washer, fiber, heat resistant

21 31 Washer, brass

22 FP610 Heat exchanger, complete

22A FP256 Heat Repair kit

23 1284 Hose, pulsation dampening

23A 1581A Hose, pump to heater

24 945D Pressure regulator valve, unloader

25 1554 Mount, pressure reg.

25A 1555 Clamp, press. reg to mount

26 FP____ Pump, complete, 400 psi

26A 2158 Motor, pump drive, sealed bearings

27 1506 Hose assembly, 21”

28 166 Hose clamp

29 207A Filter, pump inlet

29A 92B Nipple

32 2175 Lid, Solution tank

32A 805 Chain, 8”

33 TKC-6 Solution tank

34 946 Hose, pump inlet, 1/2” ID X 15”

35 925 Hose, pump bypass, 3/8” ID X 15”

36 408G Vacuum, 3-stage

37 2013 Gasket, vacuum

38 MA-6 Manifold, vacuum

39 230 Retainer, cord pigtail

40 2154 Pigtail, power cord

40A 2155 Power cord, 25 ft

41 801 Hinge pin

42 910-18.50 Axle rod, 18.5”

43 2092 Wheel, 12 inch

44 27A Axle cap

45 BKC-1 Base

46 905 Castor

47 908 Latch

48 909A Catch, for latch

49 459 Louver, 2-1/2”

50 45 Quick disconnect

51 SYP1 Priming hose

52 VT-29 Recovery tank

53 2165 Pressure gauge

53A 219 Quick disconnect

54 2050 Gasket, around top of base, 78.5”

55 1603 Strap, cord wrap

FP Pump and motor, complete

950CP Pump rebuild kit, valves & o-rings

250 Pump rebuild kit, plunger and seals

8

SPECIFICATIONS:

Rotomolded Body:

Vacuum:

VAC Shutoff:

Waterlift:

Pump:

Heat:

Heater:

Wand:

Weight:

Dimensions:

Lifetime Warranty

One, 3-stage

Ball Float

137”

400 PSI, positive displacement, adjustable

212º F, Maximum

2000 Watts

Stainless steel, single bend, two tip

100 lbs.

18W x 38L x 34.5H (inches)

TROUBLE SHOOTING:

IF THIS OCCURS CHECK THIS

NO SPRAY

PUMP DOES NOT RUN

Solution tank is empty, or filter is plugged.

Clogged spray tip.

Pump not running.

Valve on wand not operating.

Solution hose not completely connected to hose or to machine.

LOW SUCTION

NO SUCTION

LOW HEAT

NO HEAT

This pump motor runs on AC voltage, so it should start running as soon as you

turn on the switch. If the pump motor does not start running, check the wiring

to the switch and to the motor. Check the switch to see if it is ‘open.’

Debris is plugging cleaning tool or vacuum hose.

Drain gate is not completely closed, or seals are damaged.

Vacuum lid is not closed completely or is damaged.

Ball in the float is blocking air flow. Turn off the vacuum so the ball will drop down.

No power to motor. Does the switch light up? If not, the switch may be bad or

there may be no power getting to the switch. Check wiring connections.

Test the switch.

Test the vacuum motor.

Spraying for too long will significantly drop the heat. Try spraying for 8 - 10 seconds,

or about three strokes.

Heat exchanger needs to be flushed.

Wrong tool being used. Too much water passing through. Longer hose or larger

diameter hose, than standard.

Heat is not turned on.

No power in the wall outlet - check to see if the breaker has tripped.

No power to the heat switch - check wiring for ‘opens’.

No power out of heat switch. Replace switch.

Call your distributor for additional help.

MAXX- 400

This manual suits for next models

1

Table of contents