Cleantec Innovation ENVIRODRI GEN4 User manual

CLEANTEC INNOVATION LIMITED

E00-4-2050 READ INSTRUCTIONS CAREFULLY BEFORE OPERATING THE MACHINE

E

CARPET CLEANING MACHINE

INSTRUCTION MANUAL

Model: GEN4

TABLE OF CONTENTS

INTRODUCTION

SAFETY

OPERATIONS

MAINTENANCE

WARRANTY

SPARE PARTS LIST............................................................... 1-7

How to use this Manual .............................................. 2.0

Machine Data Log/Overview....................................... 2-1

Important Safety Instructions.......................................3-0

Hazard Intensity Level ................................................3-1

Earthing and Grounding Instructions ........................... 3-2

Product Technical Specifications .................................4-0

How the Machine Works.............................................. 4-1

Machine Operation .....................................................4-2

Pre-run Inspection...............................................4-2

Starting Machine.................................................4-2

Machine Shut-down and Storage.......................... 4-2

Brush Cleaning and Maintenance................................. 5-0

Machine Maintenance .................................................5-0

Daily Maintenance .............................................. 5-0

Periodic Maintenance.......................................... 5-0

Annual Maintenance ............................................5-0

Machine Troubleshooting.............................................5-1

Electrical Diagram.......................................................5-2

Cleantec Innovation Ltd Warranty Policy ...................... 6-0

Warranty Card............................................................ 6-1

Machine Warranty Request Form................................. 6-2

-1.1-

INTRODUCTION

This manual contains the following sections:

- HOW TO USE THIS MANUAL

- SAFETY

- OPERATIONS

- MAINTENANCE

the HOW TO USE THIS MANUAL section

will tell you how to find important information

for ordering correct spare parts.

Parts may be ordered from authorized

envirodri dealers. When placing an order for

parts, the machine model, and machine serial

number are important, Refer to the MACHINE

DATA box which is filled out during the

installation of your machine. The MACHINE

DATA box is located on the inside of the front

cover of this manual.

The model and serial number of your

machine is on the operator’s left hand side

panel of base.

The SAFETY section is to familiarize

the operator with the operation and function

of the machine.

The MAINTENANCE section contains

preventive maintenance to keep the machine

and its components in good working condition.

MODEL

DATE OF PURCHASE

SERIAL NUMBER

SALES REPRESENTATIVE #

DEALER NAME

OPERATIONS GUIDE NUMBER

-2-

MODEL

DATE OF PURCHASE

SERIAL NUMBER

SALES REPRESENTATIVE #

DEALER NAME

OPERATIONS GUIDE NUMBER

Name:

Address:

Phone Number:

MACHINE DATA LOG/OVERIEW

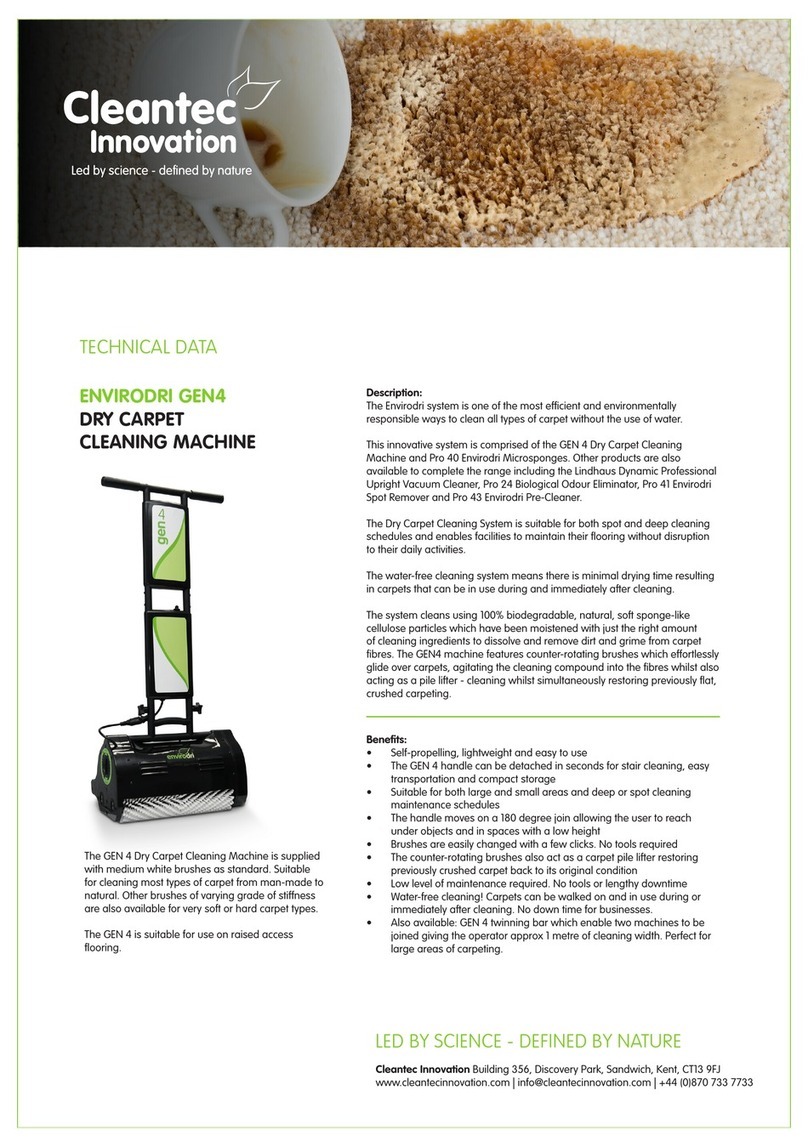

The GEN4 Carpet Cleaning Machine is designed to maintain your carpet using the envirodri

MicroSponges, dry carpet cleaning system. The machine has two counter rotating brushes that enable

the envirodri Microsponges to be brushed into the carpet. The envirodri Microsponges encapsulate the

dirt when being brushed into the carpet. The MicroSponges can then be vacuumed up leaving the

carpet dry. The brushes also help to raise the pile of the carpet, giving it a lush groomed appearance.

YOUR DEALER

OVERVIEW

-2.1-

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

WARNING

This machine is for commercial use.

To reduce the risk of fire, electric shock, or injury:

Connect to a properly grounded/earthed outlet. See Grounding and Earthing Instructions.

Do not leave the machine unattended. Unplug machine from power outlet when not in use and

always before maintenance or service.

Do not allow machine to be used as a toy. Close attention is necessary when used by or near

children.

Use only as described in this manual. Use only manufacturer’s recommended components and

attachments.

Do not use damaged electrical cord or plug. Follow all instructions in this manual concerning

grounding/earthing the machine. If the machine is not working properly, has been dropped.

damaged, left outdoors, or dropped into water, return it to an authorized service centre.

Do not pull or carry machine by electrical cord, use as a handle, close a door on cord, or pull cord

around sharp edges or corners.

Do not run machine over cord or allow the rotating brushes to come in contact with the cord. Keep

cord away from heated surfaces.

Do not unplug machine by pulling on cord. To unplug, grasp the electrical plug, not the electrical cord.

Always use cable restraint provided and wind the cable around the cable holder on the handle. For

quick release of the electrical cable rotate the cable holder 180 degrees.

Do not handle the electrical plug or machine with wet hands.

Do not operate the machine with any openings blocked. keep openings free of debris that may

reduce airflow.

Machine is designed for indoor use only and must not be operated or stored outdoors in wet

conditions.

Turn off all controls before unplugging.

Machine can cause a fire when operating near flammable vapours or materials. Do not operate this

machine near flammable fluids, dust or vapours.

Only the brushes provided with the machine or those specified by the manufacturer can be used.

The intended use of the brushes is specifically for the cleaning of carpeting and should not be used

in any other way.

This machine is suitable for commercial use, for example in hotels, schools, hospitals,

factories, shops and offices.

Maintenance and repairs must be done by qualified personnel.

-3-

SAVE THESE INSTRUCTIONS

WARNING

CAUTION

The following symbols are used throughout this guide as indicated in their descriptions:

There are three levels of hazard intensity identified by signal words -WARNING and

CAUTION and FOR SAFETY. The level of hazard intensity is determined by the following

definitions:

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or

product or property damage

CAUTION - Hazards or unsafe practices which could result in minor personal injury or

product or property damage.

FOR SAFETY: To identify actions which must be followed for safe operation of equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not

in proper operating condition. Following is information that signals some potentially

dangerous

conditions to the operator or the equipment. Read this information carefully. Know when

these

conditions can exist. Locate all safety devices on the machine. Please take the necessary

steps

to train the machine operating personnel

FOR SAFETY:

NO NOT OPERATE MACHINE:

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working

on the machine. Use envirodri approved replacement parts.

HAZARD INTENSITY LEVEL

HAZARD INTENSITY LEVEL

• Unless Trained and Authorized.

• Unless Operation Guide is Read and understood.

• In Flammable or Explosive areas.

• In areas with possible falling objects.

• In wet or outdoor areas.

-3.1-

THIS PRODUCT IS FOR COMMERCIAL

USE ONLY.

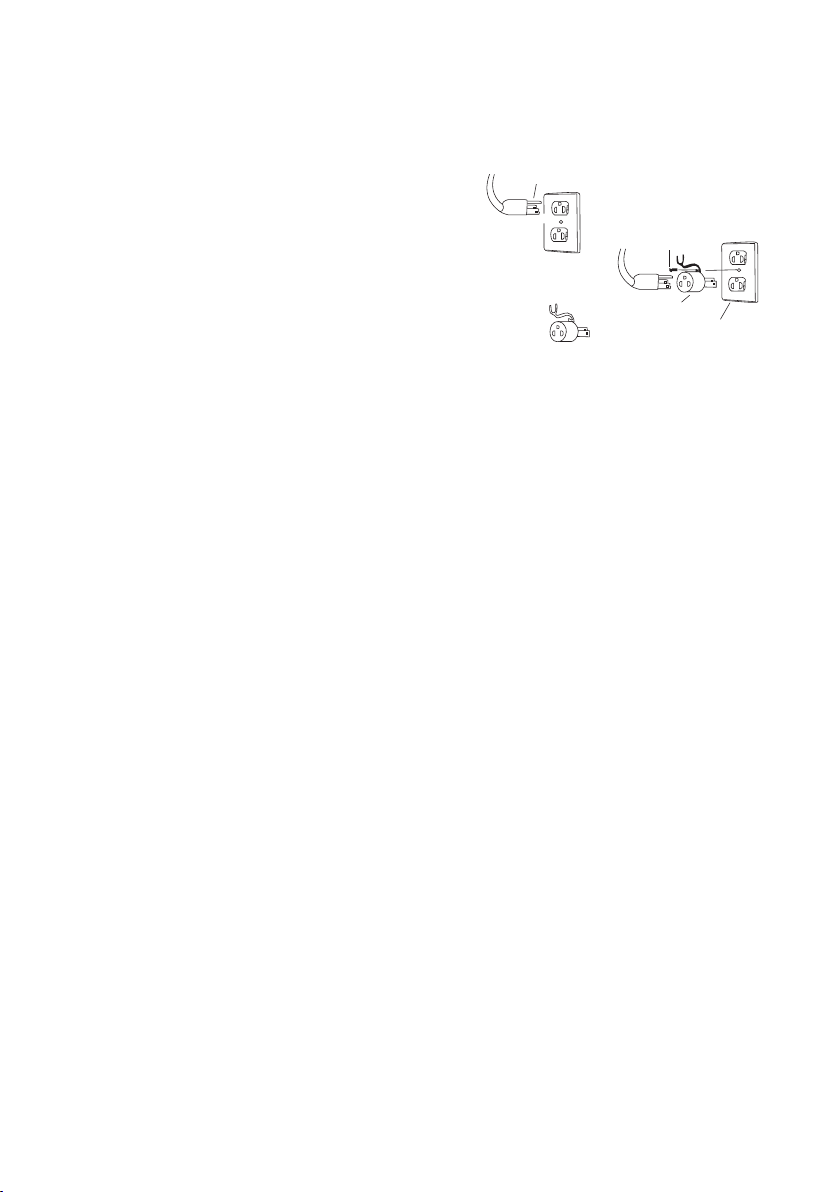

ELECTRICAL - USA:

In the USA this machine operates on a

standard 15 amp 115V, 60 Hz, A.C. power

circuit. The amp, hertz, and voltage are listed

on the data label found on each machine.

Using voltages above or below those

indicated on the data label will cause serious

damage to the motors:

EXTENSION CORDS:

If an extension cord is used, the wire size

must be at least one size larger than the

power cord on the machine, and must be

limited to 50 feet (15.5m) in length.

GROUNDING INSTRUCTIONS:

This appliance must be grounded. If it should

malfunction or break down, grounding

provides a path of least resistance for electric

current to reduce the risk of electric shock.

This appliance is equipped with a cord having

and equipment-grounding conductor and

grounding plug. The plug must be inserted

into an appropriate outlet that is properly

installed and grounded in accordance with all

local codes and ordinances.

This appliance is intended for use on a

nominal 120-volt circuit, and has a grounded

plug that looks like the plug in “Fig.A.”A

temporary adaptor that looks like the adaptor

in “Fig.C” may be used to connect this plug

to a 2-pole receptacle as shown in “Fig.B,” if

a properly grounded outlet is not available.

The temporary adaptor should be used only

until a properly grounded outlet (Fig. A)can

be installed by a qualified electrician. The

green colored rigid ear, lug, or wire extending

from the adaptor must be connected to a

permanent ground such as a properly

grounded outlet box cover. Be sure to fasten

the grounding tab with a metal faceplate

screw, whenever the adaptor is used

Improper connection of the equipment

grounding conductor can result in a risk

of electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the outlet is properly

grounded. Do not modify the plug

provided with the appliance - if it will not

fit the outlet; have a proper outlet installed

by a qualified electrician.

EARTHING AND GROUNDING INSTRUCTIONS

Grounding Pin

Grounded

Outlet

GROUNDING CONNECTION

USING AN ADAPTOR

Metal Screw

Adaptor

Grounded Outlet Box

Fig. B

Fig. A

Tab for Grounding

Screw

ADAPTOR

Fig. C

Note: Adaptors are not allowed in Canada.

-3.2-

EARTHING AND GROUNDING INSTRUCTIONS

ELECTRICAL - UK:

In the UK this machine operates on a

standard 240 V, 50 Hz, A.C. power circuit.

The amp, herz, and voltage are listed on the

data label found on each machine. Using

voltages above or below those indicated on

the data label will cause serious damage to

the motors.

GROUNDING INSTRUCTIONS:

The UK machine is intended for use on a

nominal 240 V, and it has a grounded plug

with three rectangular prongs that form a

triangle, whick looks like the plug in “Fig D.”

This plug has been designed to be plugged

into Power Outlets similar to the one shown

in “Fig E.” It complies with the BS 1363

British Standard. The molded plug

incorporates a 10 Amps cartridge Fuse.

The Wire colour coding for the UK is as

follows:

> Neutral: Blue Wire

> Live: Brown Wire

> Earth: Green & Yellow

Do not use the UK ‘G’type plug in

conjunction with any type of adators

Only operate the GEN4 envirodri machine

with a Cord-set sertified and provided by

the manufacturer

WARNING

Neutral

(Blue)

Earth

(Green&Yellow)

Live

(Brown)

Fig.D

Fig.E

-3.2-

ELECTRICAL - EUROPE:

In Europe this machine operates on a

standard 230 V,50 Hz, A.C. power circuit.

The amp, herz, and voltage are listed on the

data label found on each machine. Using

voltages above or below those indicated on

the data label will cause serious damage to

the motors.

GROUNDING INSTRUCTIONS:

The European machine is intended for use on

a nominal 230 V, and it has a type‘F’ plug

with two round prongs and two grounding

clips on the side of the plug (Fig F). The

machine is intended to be plugged into outlets

that look like the one shown in “Fig. G.”

The Wire colour coding for Europe is as

follows:

> Neutral: Blue Wire

> Live: Brown Wire

> Earth: Green & Yellow

Do not use type ‘F’ plug in conjunction with any type of adaptors.

Only operate the GEN4 envirodri machine with a Cord-set certified

and provided by the manufacturer.

WARNING

EARTHING AND GROUNDING INSTRUCTIONS

Live

(Brown)

Earth

(Green&Yellow)

Neutral

(Blue)

Fig.F Fig.G

-3.2-

PRODUCT TECHNICAL SPECIFICATIONS

1.SPECIFICATION OF US MACHINES

2. SPECIFICATION OF UK AND EUROPEAN MACHINES

ITEM

ITEM

DIMENSION/CAPACITY

DIMENSION/CAPACITY

Electrical

Electrical

Nominal Power

Nominal Power

Rated Amperage

Rated Amperage

650W

550W (Nikoda motor: 3/4 HP)

7.5 Amps

3.5Amps

16 inches (40 cm)

16 inches (40 cm)

550 RPM

500 RPM

2 inches (5 cm) non-marking black

2 inches (5 cm) non-marking black

46 lbs. (21 kg)

46 lbs. (21 kg)

44 inches(112 cm)

44 inches(112 cm)

12 inches (30 cm)

Dimensions - Depth 12 inches (30 cm)

33 feet (10 m)

33 feet (10 m)

120V

230V

Power Cord

Power Cord

Dimensions - Depth

Dimensions - Depth

Dimensions - Height with handle

Dimensions - Height with handle

Dimensions - Weight

Dimensions - Weight

Wheels

Wheels

Brush RPM

Brush RPM

Brush Width

Brush Width

-4-

Congratulations!

You are nowthe proud owner of the GEN4 Dry

Carpet Cleaning Machine.

This machine is designed to maintain your carpet

using the envirodri Dry Carpet Cleaning System.

By using the envirodri MicroSponges you can

perform regular light cleaning and grooming of

your carpet very quickly, and have the carpet dry

and ready for use immediately.

The GEN4 handle detaches for easy

transportation and compact storage. The handle

has a 180 degree movement for maximum

flexibility and allows the machine to clean under

low furniture. There are foot operated On/Off

Switches and a handle lock keeping the handle in

an upright position when placed in the tray.

The tray is for machine storage when not in use

This will protect the brush bristles from being

crushed.

The brush guard protects the machine

brushes by preventing loose threads or wires

(telephone or electrical)getting caught-up in the

brushes.

This appliance conforms with the following

international and national safety directives:

›ANSY/UL 561 STD;

›CAN/CSA STD C22.2 NO 10-1965, R 2004;

›BS EN 60335 - 1:2002;

›BS EN 60335 - 2 - 10:2003.

The GEN4 Machine comes with a one year

warranty on all parts except for cords, switches,

gears, capacitors and brushes.

See envirodri New Machine Warranty Policy.

EARTHING AND GROUNDING INSTRUCTIONS

-4.1-

MACHINE OPERATION

PRE-RUN MACHINE INSPECTION

Perform a pre-run inspection to find possible

problems that could cause poor performance or

lost time from breakdown. Check the rating plate

to confirm voltage and frequency is the same as

the power supply. NOTE: A 10% variation in

voltage is acceptable.

STARTING MACHINE

NOTE: Perform pre-run machine check before

operating machine.

FOR SAFETY: Before stating machine, make

sure that all covers are in place and secured

properly.

After manually applying the envirodri

MicroSponges onto the carpet commence

cleaning following the steps below:

1. Take the machine out of the tray. Do this by

Leaning the machine back and applying

pressure on the end of the tray with your

foot. NOTE: Place the tray out of the way

when machine in use.

2. Connect the machine to a power supply.

3. Release the handle lock.

4. Depress the ‘ON’ foot switch to engage

machine as shown in the drawing provided.

5. Push and pull the machine slowing over the

carpet.

NB: Best results are obtained by moving the

machine in multiple directions and overlapping

strokes.

Flammable materials can cause an explosion or

fire. Do not use near flammable or

combustible substances or hot ashes or burning

objects of any kind.

Always ensure that the handle lock is released prior

to switching on the machine.

MACHINE SHUT-DOWN AND STORAGE

1. Depress the ‘OFF’ foot switch to power off

machine as shown in the drawing provided.

2. Lock handle in the upright position.

3. Disconnect the power cord from the power

supply. Wind the power cord around the

cable holder on the handle.

4. Remove the brushes for cleaning. See Brush

Cleaning and Maintenance section.

5. Once daily maintenance has been

Performed, place the machine back into the

tray.

The machine is now ready for storage until the

next use. Make sure to store your equipment in

a dry place to prolong the life of your machine.

Storage outdoors or if left unprotected could

cause damage to your machine or its internal

parts, therefore voiding your warranty.

When not in use or during interrupted cleaning,

the machine must always be placed in the tray

provided to prevent deformation of the brush

bristles. Deformation of brush bristles can

result in unbalanced running and excessive

vibrating or instability of the appliance.

WARNING

CAUTION

CAUTION

‘ON’ Foot

Switch

‘OFF’Foot

Switch

-4.2-

MACHINE OPERATION

MACHINE SAFETY DEVICE:

The GEM4 machine incorporates a Safety

device which prevents its operation when the

handle falls below 0˚ and/or 180˚

Should the handle fall bellow these points, the

machine power will be cut off. The power will

not be reset simply by tilting the handle to the

upright position.

In order to restart the machine after the power

has been cut off, tilt the handle back to the 90˚

position and turn the machine on by pressing the

‘ON’ switch.

HANDLE LOCKING POSITION

The handle must be locked for transport and

storage.

Lock the handle in an upright position(90˚)

following the steps below:

1. After having completed the cleaning

process, tilt the handle back to the 90˚

position.

2. Turn the machine Locking Button

(clockwise until the green dot aligns with

the Locked arrow).

HANDLE UNLOCKING POSITION

Follow the steps below in order to unlock the

handle:

1. Turn the machine Locking Buttong

clockwise until the green dot aligns with

the Unlocked arrow

Do not use the GEN4 wheels to transport it

over uneven surfaces. Only wheel the

machine on even surface. The machine

wheels have been for internal transportation

‘only’ on carpeted areas. Do not transport the

machine downstairs.

CAUTION

HandleLocked HandleUnlocked

-4.2-

0180

90

MAINTENANCE

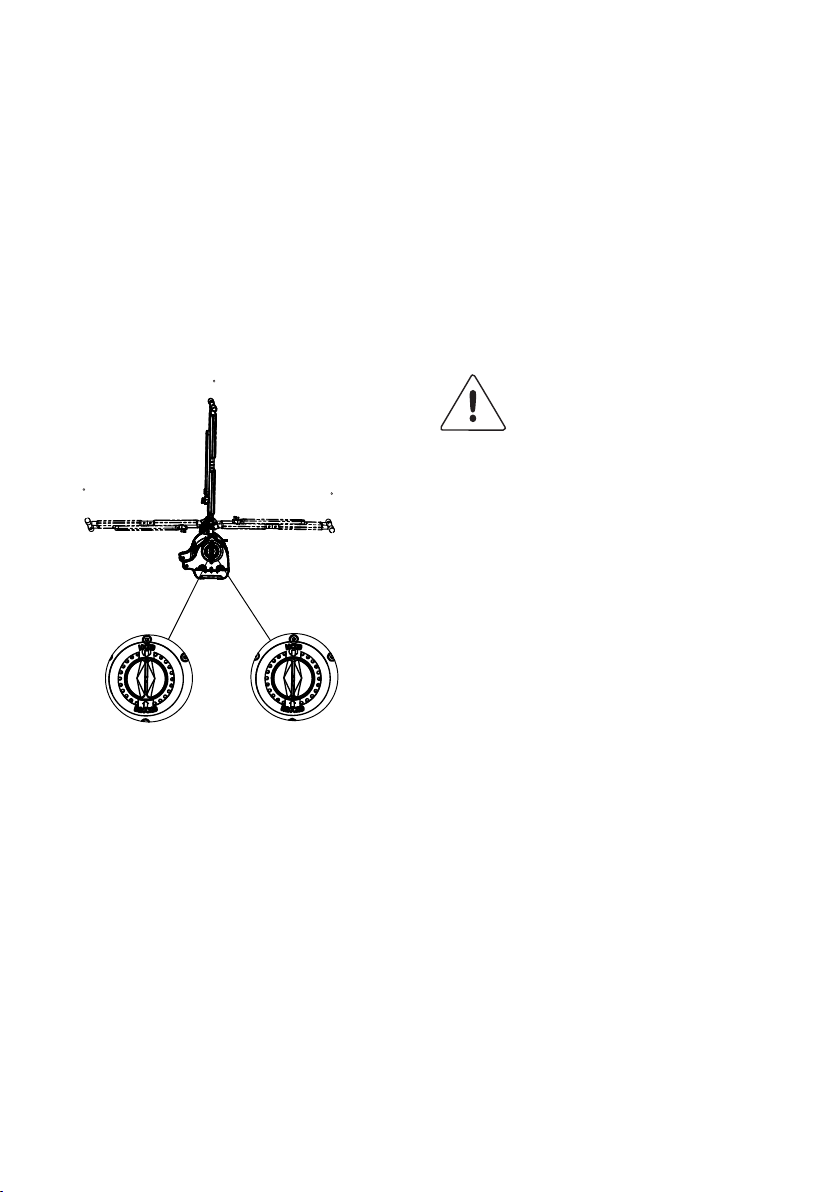

BRUSH CLEANING AND MAINTENANCE

After each session of carpet cleaning. the brushes and the brush housing should be

cleaned. Before

cleaning or changing the brushes, always unplug the machine from the power supply.

Brushes are removed without tools. Tilt and rest the machine on the handle. Push the brush shafts

through with your finger. Alternatively, use a screw driver. Once unlocked. pull the brush shafts through

the brushes and machine housings.

The brushes may be soaked in warm or hot water using mild detergent, and then rinsed with warm

water.

NOTE: Brushes with crushed bristles can often be restored to original condition by soaking in hot water.

Brushes should only be reassembled to the machine base when fully dry. Keep brushes clean and free

from debris. Rotate brushes regularly as this will increase the life span of the brushes and ensure even

wear.

Before reinstalling brushes, clean out machine brush housing by wiping with a clean damp cloth.

BRUSH ASSEMBLY

1- Push Components 4A and 4B towards component 2, until the ‘Internal Hex Profiles’ of both ends of

components 4A and 4B are aligned with the hex profiles of the ‘Top Brush Shaft

Housing’ and the Bottom Brush Shaft Housing’ of components 1 and 3. Assemble

components 4A and 4B following the illustration in image 1, which shows the position of the

bristles of components 4 A and 4B in relation to machine

2- Align components 5A and 5B with the ‘Top Brush Housing’

3- In order to complete the assembly of components 4A, 4B, 5A and 5B follow the steps below: Hold the

‘Brush Top’ with one hand and component 5A with the other.

Slowly push component %A through the ‘Top Brush Shaft Housing’ of component 1 until the ‘Locking

End’ of component 5A reaches the ‘Top Surface’ of component 4A.

Align component 5A with the ‘Top Internal Hex Profile’ of component 4A following the steps below:

> Slowly push component 5A into the ‘Top Internal Hex Profile’ of component 4A

-5-

MAINTENANCE

> As component 5 is being pushed into the ‘Top Internal Hex Profile’, move the ‘Brush Top’

away from and towards component 2 and simultaneously turn the ‘Brush Top’ clock and

anticlockwise. This will help to align and guide component 5A through the ‘Top Internal Hex

Profile’ of component 4A;

► Continue pushing component 5A through until it reaches the ‘Bottom Internal Hex Profile’ of

component 4A.

► Align component 5A with the ‘Bottom Internal Hex Profile’ of component 4A by following the

steps below:

►

> Slowly push component 5A towards th ‘Bottom Internal Hex Profile’ of component 4A.

> As component 5A is being pushed into the ‘Bottom Internal Hex Profile’, move the ‘Brush

Bottom’ away from and towards component 2 and simultaneously turn the ‘Brush Bottom’

clock and anticlockwise.

► Push component 5A through the ‘Bottom Internal Hex Profile’ once it has been properly aligned.

component 5A will reach the ‘Bottom Brush Shaft Housing’ as it goes through the ‘Bottom

Internal

Hex Profile’.

► Align component 5A(which has already been pushed through the ‘Top Brush Shaft Housing’,

the

‘Top Internal Hex Profile’ and the ‘Bottom Internal Hex Profile’) with the ‘Bottom Brush Shaft

Housing’ by following the steps below:

> Slowly push component 5A towards the ‘Bottom Brush Shaft Housing’ of component 4A

> As component 5A is being pushed into the ‘Bottom Brush Shaft Housing’, move the ‘Brush

Bottom’ away from and towards component 2 and simultaneously turn the ‘Brush Bottom’

clock and anticlockwise.

> Once component 5A is engaged with the ‘Bottom Brush Shaft Housing’, push it through the

Housing until the ‘Stop End’ of component 5A touches to surface of the ‘Top Brush shaft

Housing’.

► Repeat the previous steps for components 4B and 5B.

► Ensure the brushes are properly assembled by turning both brushes towards the direction of the

arrows shown in drawing 5.

Drawing 1 Drawing 2 Drawing 3 Drawing 4 Drawing 5

-5-

MAINTENANCE

MACHINE MAINTENANCE

The GEN4 machine requires very little

maintenance. Wipe down the machine periodically

with a clean cloth and ensure motor air vents are

not obstructed. DO NOT spray water directly over

the top of machine.

During interruptions of the cleaning process,

always place the machine into the tray or lay it on

its side (gear housing) to prevent deformation of

the brush bristles.

Deformation of the brush bristles can result in

unbalanced running and excessive vibrating

or instability of the appliance.

The machine motor is fitted with a thermal cut out

In the unlikely event of overloading, the motor cut

out will automatically trip. It can be reset after

approximately 30 seconds (or when the machine

cools down) by pushing the ON switch.

DAILY MAINTENANCE

1. Clean and inspect brushes.

2. Clean and inspect brush housing and

machine.

3. Inspect power cord for wear or damage.

To prevent electrical shock replace cords

that are frayed or have cracked insulation

immediately.

PERIODIC MAINTENANCE

1. Check all handles, switches, knobs,

electrical cables and connections on your

machine for damage. Repair or replace

immediately.

2. Inspect and/or replace brushes

3. Inspect and clean (if necessary) brush

guard of any outside debris

ANNUAL MAINTENANCE

1. Check all bearings for noise and wear.

2. Check motor for operation.

3. Check overall machine for operation.

CAUTION

-5-

MAINTENANCE

PROBLEM SOLUTION

CAUSE

No power to machine Dead electrical circuit breaker

in fuse box

Check building circuit breaker

Replace power cord

Replace power switch

Replace circuit breaker

Faulty power cord

Power switch failure

Faulty circuit breaker

Equipment not grounding Follow earthing and

grounding instructions

Have an electrician inspect

the building’s wiring

Receptacle not grounded

Faulty circuit breaker Replace circuit breaker

Test circuit breaker for

continuity. Higher amp draw

may indicate faulty parts. Find

parts not moving freely and

repair or replace

Mechanical problem

Faulty motor Replace motor

Replace gears not functioning

Replace brushes

Replace worn bearing

Gears worn

Brushes worn

Bearing squealing or grinding

in brush housing

Electrical Shock

Nuisance tripping of circuit

breaker

Brush not turning or scrubbing

Worn bearings

-5.1-

ExternalWiring

POWER CABLE

BLACK (12)

BLACK (13) Push Button Stop

(Normally Closed) Micro Switch

Push Button Start

(Normally Opened)

BLACK (11)

BLACK (10)

BLACK (14)

BLACK (15)

Internal Wiring

WHITE

BLUE

YELLOW

ORANGE

10m Cord-Set

BUTT SPLICE

GREEN

RED

BLACK

BROWN

BROWN

RUNNING

CAPACITOR

16uF

START

CAPACITOR

60uF

MOTOR

220~240V 50Hz

220~240V,

PCB

10 11 12 13 14 15 L2 143

(Nikoda Motor)

WHITE

BLACK

WHITE

BLACK

-5.2-

ELECTRICAL DIAGRAM

CLEANTEC INNOVATION LTD WARRANTY POLICY

CLEANTEC INNOVATION LTD -Limited Warranty

Cleantec Innovation Ltd warrants to the original purchaser only (ʺBuyerʺ) that each new envirodri Machine

shall be free from defect in material and workmanship upon delivery. Cleantec Innovation Ltd’ liability is

limited to repair or replacement of parts at the discretion of Cleantec Innovation Limited and/or the factory

authorised service centre.

A warranty registration card is to be completed and returned within 14 days of purchase to register the

purchases of your machine. Failure could result in any warranty claims not being undertaken.

Items not covered by warranty include, but are not limited to:

► Damage resulting from accidents abuse, misuse or acts of God(lightning/flood etc,)

► Damage in transit

► Rental units

► Failure due to lack of proper maintenance or care

► Relatively minor adjustments such as tightening of screws or bolts, etc. not connected with the

placement of parts.

► Repairs or alterations by a person or organisation other than the factory or authorised repair

centre.

► Normal wear items, handles, wheels, brushes**, gears**, power cords.

Cleantec Innovation Ltd equipment used in commercial applications has limited warranty of one year with

exception of electric motors with carbon brushes, being subject to wear, their durability depends on the

number of hours of use. It does not depend on the years of life of the machine. Example: In commercial

application, The eventual substitution of the motor under warranty will therefore be effected only in case

of tatal wear. If, after inspection of the returned machine or any part or parts, Cleantec Innovation Ltd in

connection with the replacement or repair or any parts there of shall be at the buyer’s responsibility.

Any parts returned to Cleantec Innovation Ltd for replacement shall become the property of Cleantec

Innovation Ltd. In no Event shall cleantec Innovation Ltd be liable for any indirect, special, incidental,

consequential or other damages including but not limited to damage or loss of property or equipment,

lost revenues or profits, claims of customers, or harm to goodwill or business reputation directly or

indirectly arsing from the safe, handling or use of the envirodri Machine, or from any other costs

relating thereto and Cleantec Innovation Ltd liability hereunder. Cleantec Innovation Ltd shall not be

liable to the buyer for any claims, damages, injuries, actions or causes of action whatsoever based on

negligence or strict liability. Cleantec Innovation Ltd Limited makes no warranty that its envirodri

Machines shall be merchantable or that such machine shall be fit for any particular purpose. Moreover,

Cleantec Innovation Ltd makes no expressed or implied warranties except for the limited warranty set

forth herein. In addition no representation or warranty, expressed or implied, made by any dealer, sales

representative, or field agent or Cleantec Innovation Ltd which is not specifically set forth herein shall

be binding on Cleantec Innovation Ltd.

Genuine envirodri replacement parts shall be free from defects in material and workmanship for a period of 90

days after ″installation″ and shall be subject in all respects to the limitations and exclusions of this limited

warranty.

Making a Claim

With each new machine sold a warranty card and Warranty Request Form will be supplied with the instruction

manual of the new machine, this is standard practice.

PLEASE RETURN YOUR CARD AS FAILURE TO DO SO COULD INVALIDATE YOUR WARRANTY.

Upon finding a fault with your machine which you believe to still have warranty the″envirodri Machine Warranty

Request Form(1)″ should be completed in full and faxed to 08707 337734.

Once we have received your form a representative from Cleantec Innovation Ltd will call you within 24 hours

to discuss the problem and arrange for collection of your machine if required. Bookings for collections are

normally made for the same day but you will be advised when to expect a courier.

-6-

SPARE PARTS LIST

MODEL GEN4

CONFIGURATIONS:

E00-4-9001-US Model

E00-4-9002-UK Model

E00-4-9003-Europe Model

E00-4-9004-China Model

NB:

▪ The Bearing Pack(Item 29) is composed of 5 of 35x17x10(6003) Bearings and 2 of

32x12x10 (6201) Bearings.

▪ The Machine Base Label Set (Item 43) is composed of the “ON” and “OFF” labels,

the LOCKED/UNLOCKED label and the CAUTION label.

▪ Item 47 refers to the Wiring Harness that connects the “ON” and “OFF” Switches to the

PCB.

▪ The Micro-Switch (Item 6) is cold with its Wiring Harness.

SHEET 1 OF 7

Other manuals for ENVIRODRI GEN4

1

Table of contents

Other Cleantec Innovation Vacuum Cleaner manuals