Page 10 of 15

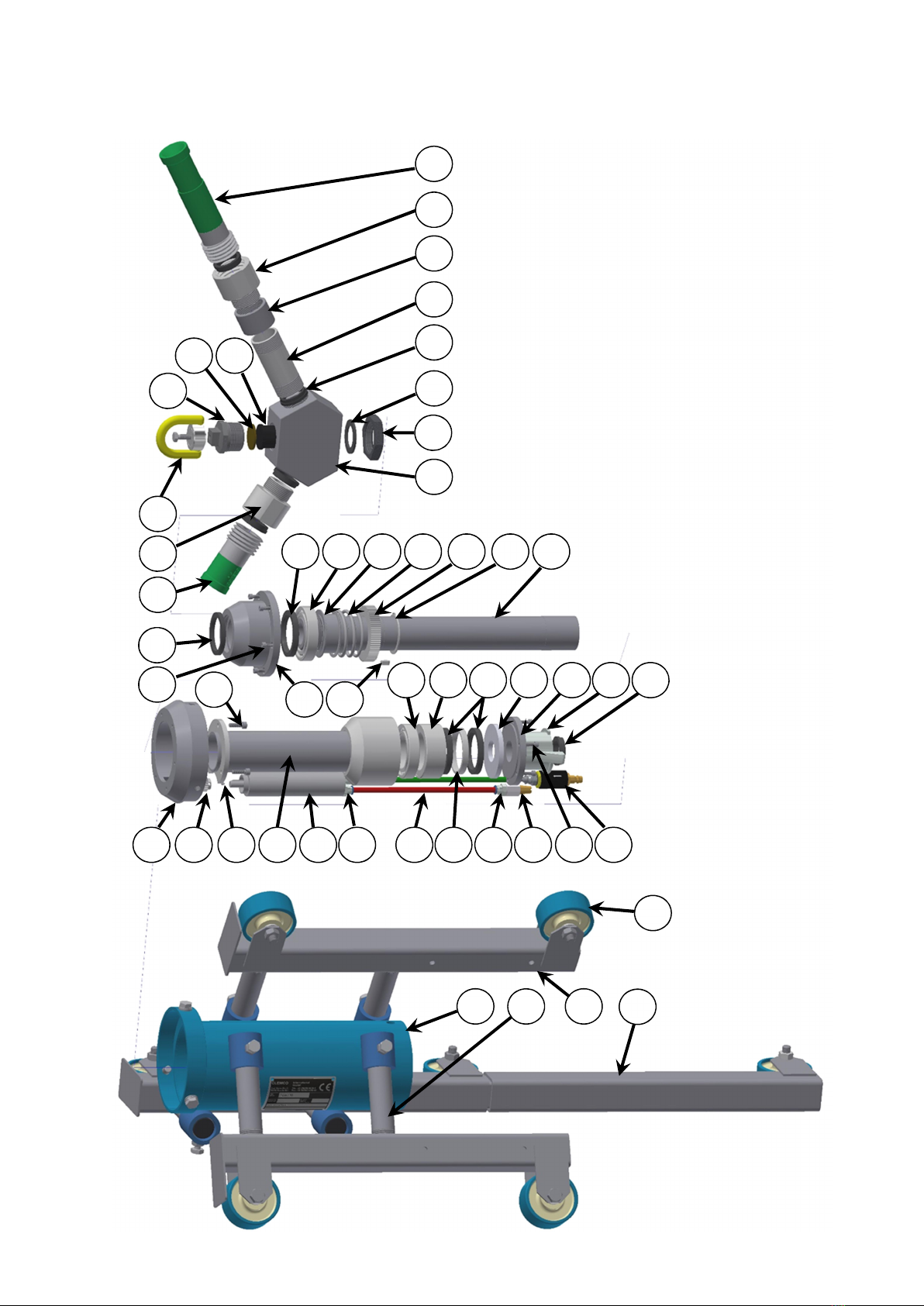

24407D Basis Rohrinnenstrahlgerät Spin XL mit

pneumatisch angetriebenem Strahlkopf,

inkl. Spin XL Fahrgestell 400-580 (Art.

24443D), Filterregler und 10m Luft-

schlauch.

Spin XL basic with pneumatic driven blast

head, incl. Spin XL carriage 400-580 (part

24443D), filter regulator and 10m air

hose.

1 24439D Halterung Räder Fixture wheels

2 24440D Gestell Räder (ohne PU-Rollen) Frame wheels (without PU-wheels)

3 24445D Rohr 1" - 160mm (in "Fahrgestell 400-

580")

Rod 1" - 160mm (in carriage 400-580

incl.)

24449D Rohr 1" - 275mm (in "Fahrgestell 580-

800")

Rod 1" - 275mm (in carriage 580-800

incl.)

24452D Rohr 1" - 635mm (in "Fahrgestell 790-

1500")

Rod 1" - 635mm (in carriage 790-1500

incl.)

24446D Kappe Cap

4 24441D PU-Rolle D80 PU-wheel D80

5 24453D Gestellverlängerung (ohne Rad) empfoh-

len für Ø > 800mm (enthalten in Fahrge-

stell 790-1500)

Frame extension (without wheel) recom-

mended for Ø > 800mm (in carriage 790-

1500 incl.)

6 27192D DL-Motor, abwürgefest + ölfrei Air motor, stall-proof + oil free

7 24435D Stirnzahnrad Z20 Gear wheel Z20

8 90592D Madenschraube M4x6 Headless screw M4x6

9 24433D Elsa gerade 8-1/8 A Elsa straight 8-1/8 A

10 27224D PA-Schlauch 8/6 rot, pro Meter - 0,25m PA-hose 8/6 red, per meter - 0,25m

27225D PA-Schlauch 8/6 grün, pro Meter - 0,25m PA-hose 8/6 green, per meter - 0,25m

11 24434D Elsa gerade 8-1/4 A Elsa straight 8-1/4 A

12 27198D Schalldämpfer 1/4" Exhaust silencer 1/4"

13 24428D Deckel Antrieb Cap

14 24413D Mantelrohr Casing tube

15 90155D Zylinderkopfschraube M6x18 Hexagon bolt M6x18

16 24414D Kugellager Ball bearing

17 24415D Mantelrohr Einsatz Casing tube insert

18 24417D Wellendichtring 50x68x8 Shaft seal50x68x8

19 24416D Mantelrohr Distanzring Casing tube distance ring

20 24430D Dichtung Kunststoff Sealing plastic

21 24429D Anschlussflansch Connecting flange

22 24431D Zylinderkopfschraube M5x16 Hexagon bolt M5x16

23 24232D CFT-Kupplung 1 1/2" CFT-Coupling 1 1/2"

24 08416D Dichtung CQG 32 Sealing CQG 32

25 24426D Kopf Antrieb Head

26 24427D Filzdichtung 6x6-177 Felt seal 6x6-177

27 24424D Hülse Feder Bushing spring

28 24425D Druckfeder Spring

29 24421D Stirnzahnrad Z80 Gear wheel Z80

30 24420D Paßfeder 6x6x14 Flat key 6x6x14

31 24419D Sicherungsring 50x2 Snap ring 50x2

32 24418D Welle Axle

33 24412D Dichtung Kopf Eingang PU Sealing head entrance PU

34 24408D Strahlkopf Blast head

35 24409D HM-Einsatz Kopf Hardened insert head

36 24410D Dichtung Kopf PU Sealing head PU

37 24411D Blindstopfen 1 1/4" mit M8 Blank plug 1 1/4" with M8

38 100956 Anschlagpunkt Attachment point

39 91025D Düsendichtung NW32 Sealing blast nozzle NW32

91023D Düsendichtung NW25 Sealing blast nozzle NW32

40 24444D Düsenhalter 25 Nozzle holder 25

41 *) Kurzdüse mit NW25 Short nozzle with NW25

42 90437D Rohr 1 1/4" - 95 (in "Fahrgestell 790-

1500")

Tube 1 1/4" -95mm (in carriage 790-1500

incl.)

90435D Rohr 1 1/4" - 285 (in "Fahrgestell 790-

1500")

Tube 1 1/4" -285mm (in carriage 790-1500

incl.)

43 24451D Muffe 1 1/4" (in "Fahrgestell 790-1500") Pipe coupling 1 1/4" (in carriage 790-1500