7

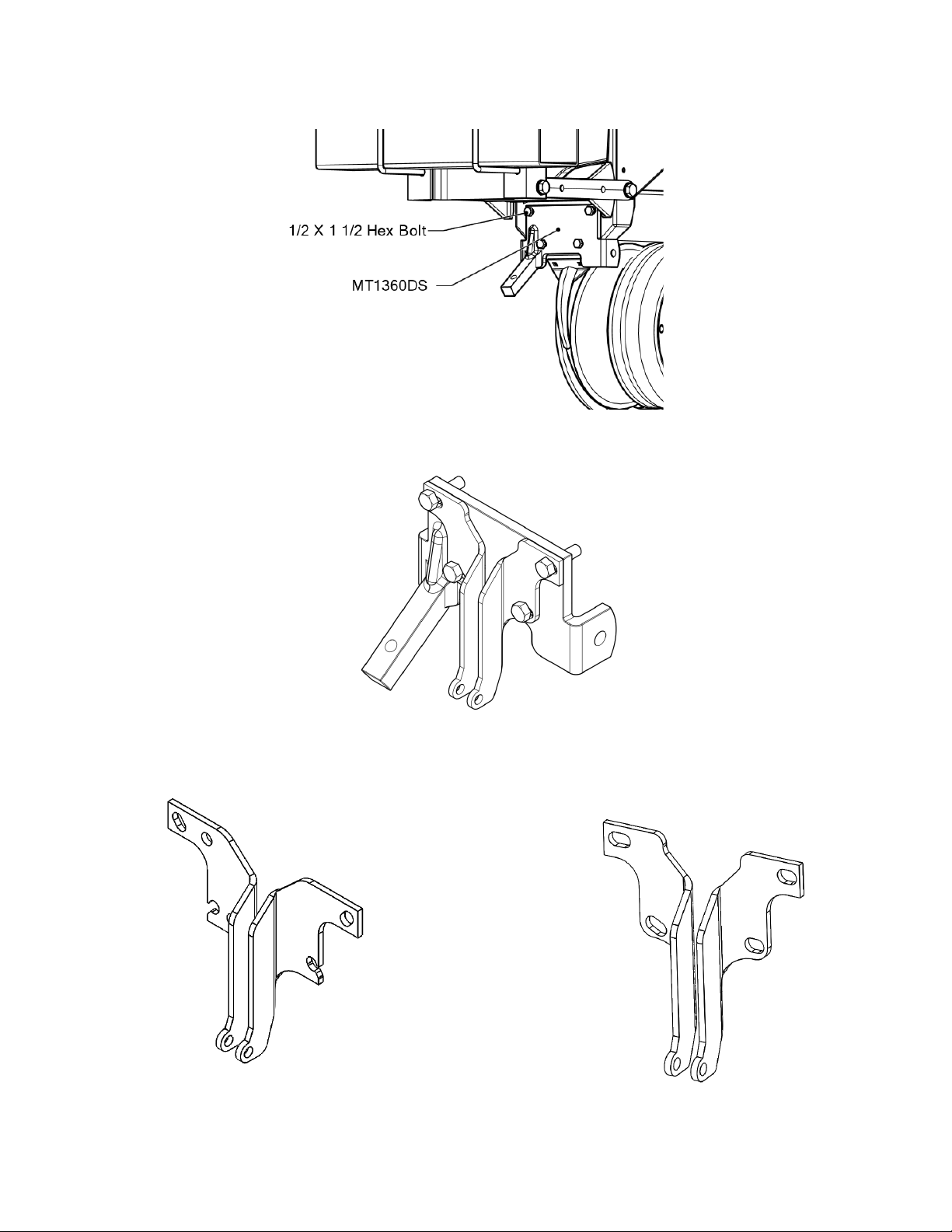

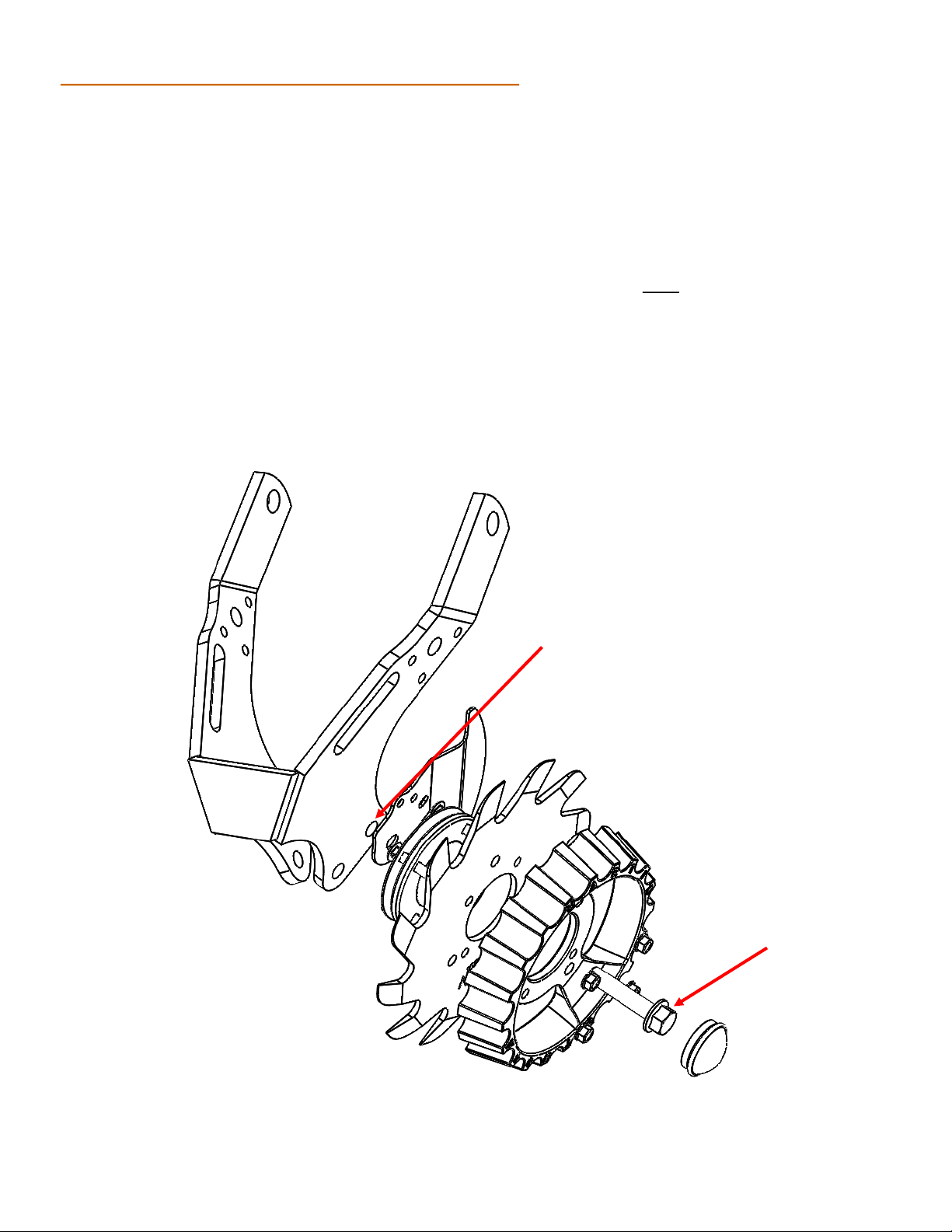

STEP 7: INSTALL OPTIONAL DEFLECTOR (SCRAPER)

NOTE: The Deflector (Scraper) is recommended when operating in wetter conditions, or damp

stringy residue, to reduce wrapping.

NOTE: The Deflector (Scraper) comes in pair of left and right for left and right wheels.

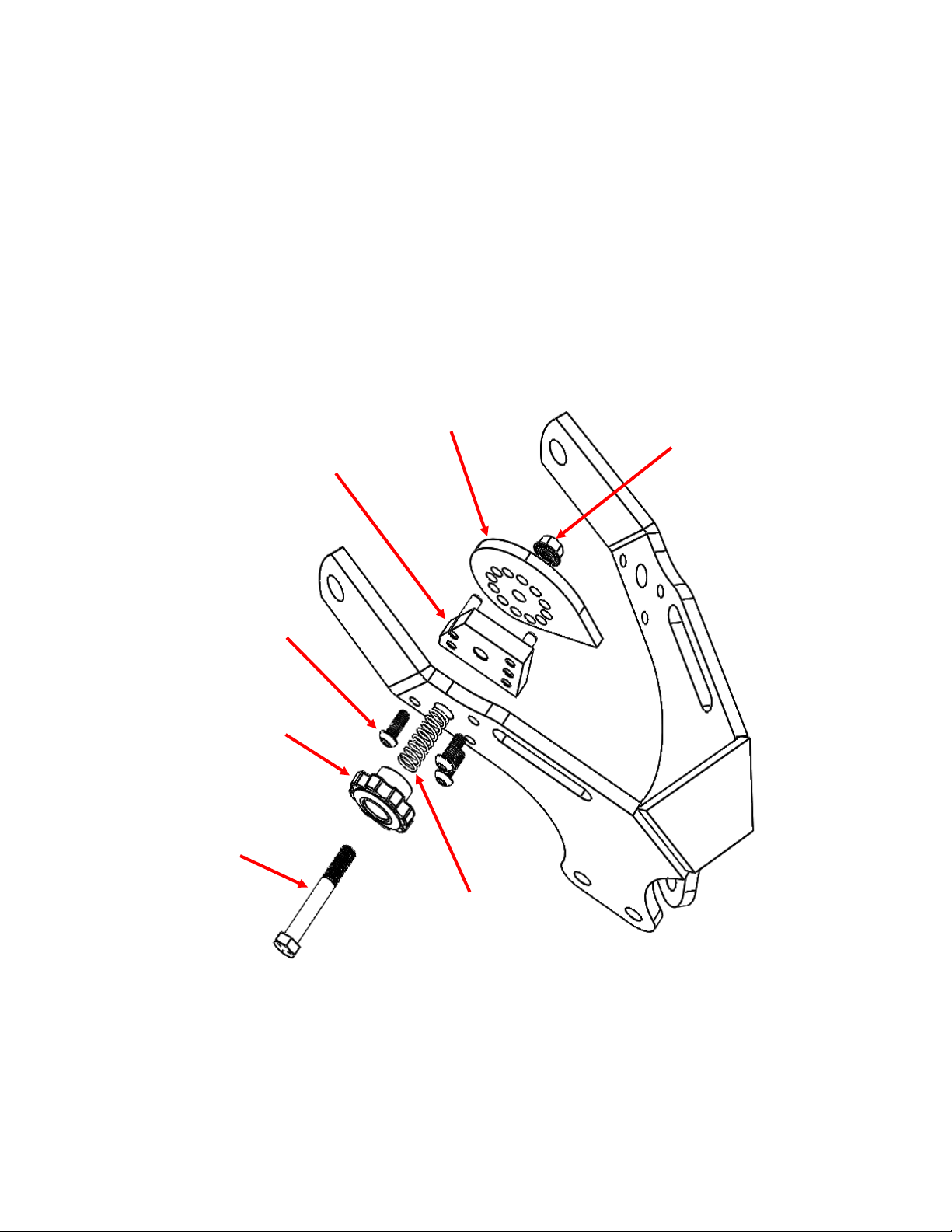

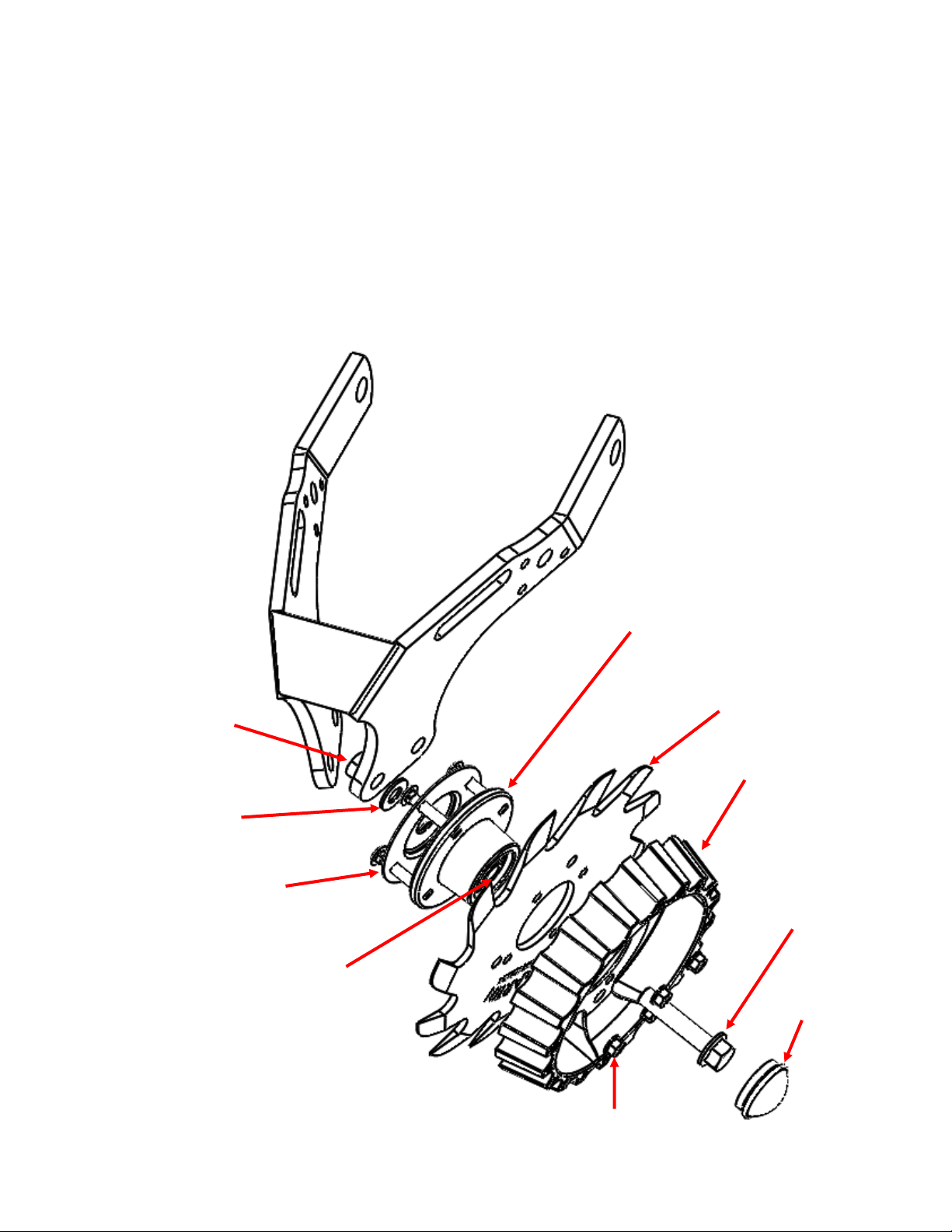

Intersected Configuration ( Wheel in front hole)

1) Place the deflector (Scraper) on the back of the assembled wheel unit (previously assembled in

step 6) as shown here and pass the flange bolt (BFS0156) through the wheel assembly and the

deflector and attach the flange nut (NFSL007) hand tighten and locate the deflector as shown

and torque the flange bolt (BFS0156) to 116 ft-lbs being careful not to allow the deflector to ro-

tate during bolt tightening.

2) The wheel marked TW3813-L4 (Or RTW1412.5-L4 for the Razor wheel) is for use on the left side

of the frame (as viewed from behind the machine). Repeat for opposite side.

NOTE: When the deflector (scraper) is to be installed the washer (WSN0064) is NOT used

FLANGE NUT

(NFSL007)

FLANGE BOLT

(BFS0156)

DEFLECTOR

(SCRAPER)

(ITD STW L)

(SHOWN IN CORRECT

POSITION)