Cleveland

™

Project ________________________________

Item __________________________________

Quantity_______________________________

FCSI Section ____________________________

Approval _______________________________

Date __________________________________

1333 East 179 St.,

Cleveland, Ohio,U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site:www.ClevelandRange.com

Email: Steam@ClevelandRange.com

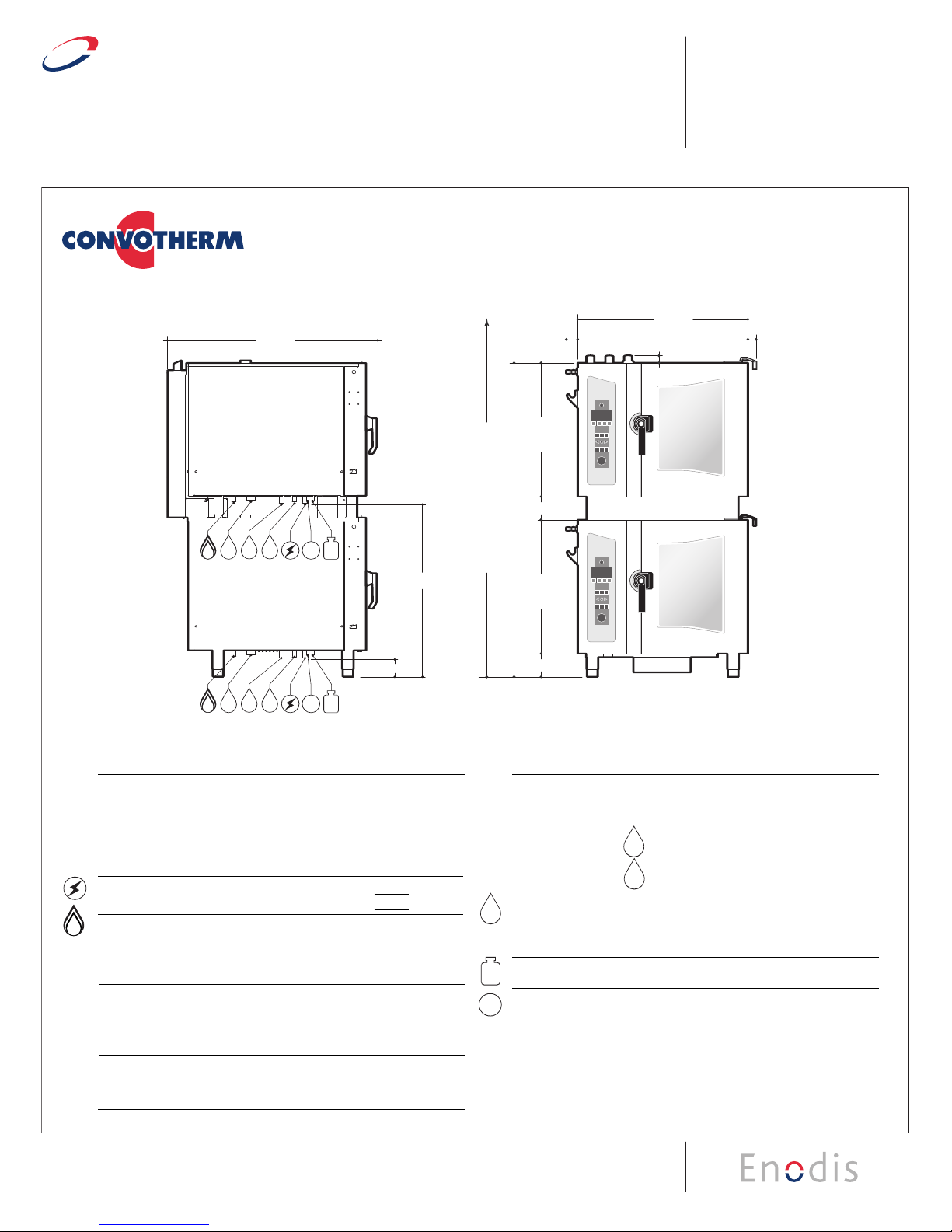

COMBI OVEN-STEAMER

Stacking Kits for Electric Table Type Models

(OEB 6.20 on OEB 10.20 or OES 6.20 on OES 10.20)

SECT. IIB PAGE 5H

0707

Model # Description

CSTK-1020 for mounting one 6.20 model on top of one 10.20 model

CSTK-1020CA for mounting one 6.20 model on top of one 10.20 model (with casters)

UNIT A

UNIT B

& CSTK-6.1CA*

36.70"

1.58"

28.43

5.00"

1.82"

67.8 5 "

71.24"

80.09"

78.41"

28.43

6.00"

6.10

6.10

2.52"

36.70"

2.52" 1.58" 1.82"

28.43

5.00"

38.98"

6.00"

6.10

10.10

47.92"

2.52" 1.58" 1.82"

CSTK-10.10 & CSTK-10.10CA*

30.12"

5.00"

38.98"

6.00"

NOTE: Overall height of unit does not change for units with casters.

78.00”(MIN. HOOD REQUIREMENT)

80.00”(MIN. HOOD REQUIREMENT)

78.00”(MIN. HOOD REQUIREMENT)

81.00”(MIN. HOOD REQUIREMENT)

RC CS

W1 W2

D

G

RC CS

W1 W2

D

RC CS

W1 W2

D

RC CS

W1 W2

D

G

4.38"

39.50"

4.38"

48.32"

47.72"

46.34"

NOTE: Overall height of unit does not change for units with casters.

UNIT A UNIT A

UNIT B

UNIT B

UNIT A UNIT A

UNIT B UNIT B

LEFT SIDE VIEW

FRONT VIEW

LEFT SIDE VIEW

FRONT VIEW

71.20"

47.92"

2.52" 1.58" 1.82"

30.12"

5.00"

30.12"

6.00"

78.00”(MIN. HOOD REQUIREMENT)

RC CS

W1 W2

D

RCCS

W1 W2

D

4.38"

39.50"

46.34"

NOTE: Overall height of unit does not change for units with casters.

UNIT A UNIT A

UNIT B UNIT B

LEFT SIDE VIEW

FRONT VIEW

6.20

on 6.20

GAS

6.20

on 6.20

ELEC

6.20

on 10.20

GAS

6.20

on 10.20

ELEC

80.09"

47.92"

2.52" 1.58" 1.82"

30.12"

5.00"

38.98"

6.00"

81.00”(MIN. HOOD REQUIREMENT)

RC CS

W1 W2

D

G

RC CS

W1 W2

D

G

4.38"

48.32"

47.72"

NOTE: Overall height of unit does not change for units with casters.

UNIT A UNIT A

UNIT B UNIT B

LEFT SIDE VIEW

FRONT VIEW

NOTE: Overall height of unit does not change for units with casters.

RC CS

W1 W2

D

G

RC CS

W1 W2

D

G

4.38"

38.08"

39.21"

LEFT SIDE VIEW

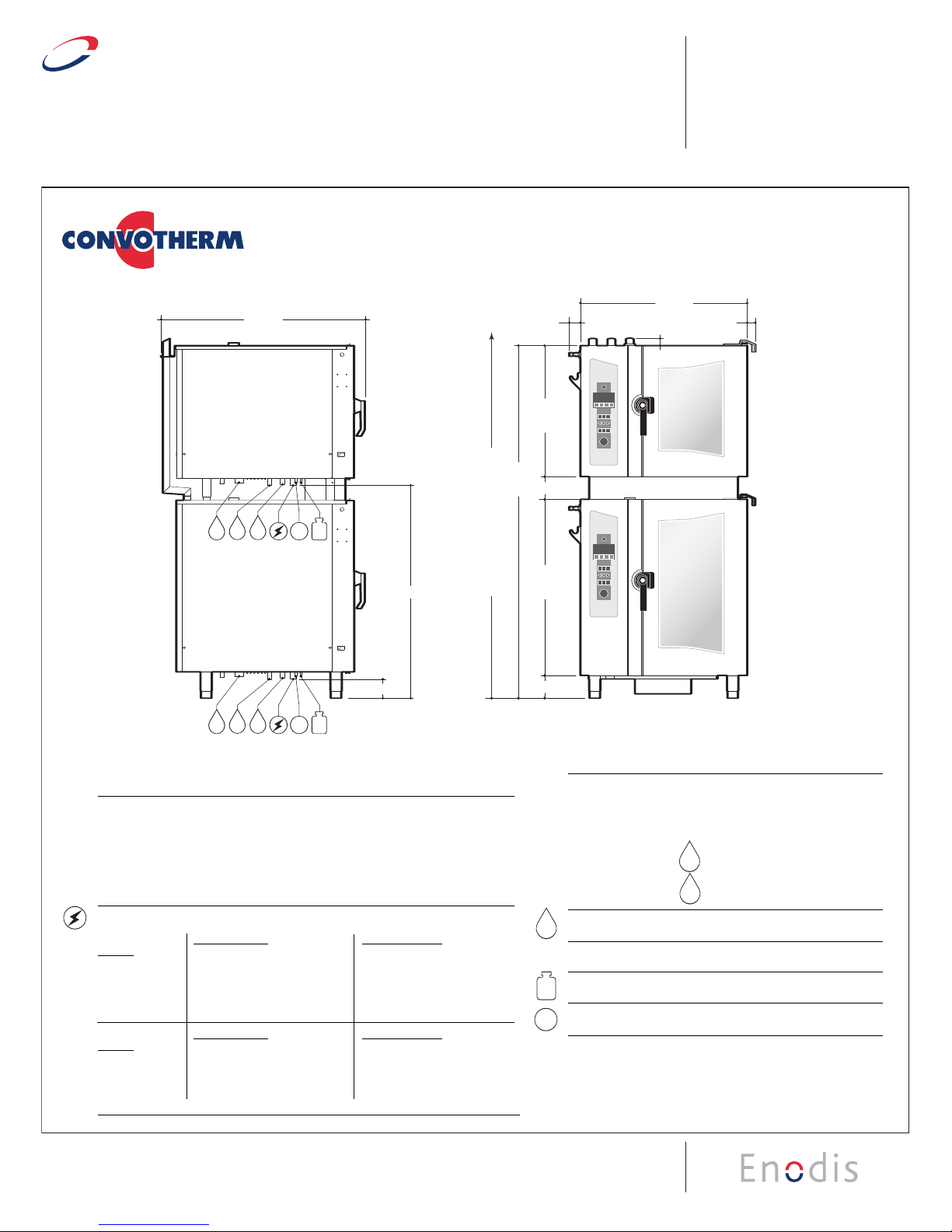

6.10

on 6.10

GAS

6.10

on 10.10

GAS

RC CS

W1 W2

D

G

RC CS

W1 W2

D

G

4.38"

48.54”

39.21"

NOTE: Overall height of unit does not change for units with casters.

UNIT A

UNIT B

LEFT SIDE VIEW

UNIT A

UNIT B

37.83"

LEFT SIDE VIEW

36.70"

1.58" 1.82"

2.52"

RC CS

W1 W2

D

RC CS

W1 W2

D

NOTE: Overall height of unit does not change for units with casters.

4.38"

38.08"

28.43

5.00"

67.8 5 "

28.43

6.00"

78.00”(MIN. HOOD REQUIREMENT)

UNIT A

UNIT B

UNIT A

UNIT B

RC CS

W1 W2

D

RC CS

W1 W2

D

37.83"

NOTE: Overall height of unit does not change for units with casters.

LEFT SIDE VIEW

UNIT A

UNIT B

4.38"

48.54"

6.10

on 6.10

ELEC

6.10

on 10.10

ELEC

36.70"

1.58"

28.43

5.00"

1.82"

67.8 5 "

28.43

6.00"

78.00”(MIN. HOOD REQUIREMENT)

2.52"

78.41"

36.70"

1.58" 1.82"

28.43

5.00"

38.98"

6.00"

80.00”(MIN. HOOD REQUIREMENT)

2.52"

78.41"

36.70"

1.58" 1.82"

28.43

5.00"

38.98"

6.00"

80.00”(MIN. HOOD REQUIREMENT)

2.52"

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

Rear - 2", Left Side - 4", Right Side - 2 1/2"

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located next to

the unit.

• Allow for sufficient clearance on left side for service access (contact the factory

service department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

Do not connect to a G.F.I. outlet.

BOILER UNIT A -OEB-6.20 UNIT B -OEB-10.20

MODELS

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

Total Connected Load: 16.4 KW 21.6 KW 18.5 KW 22 KW 26.3 KW 34.9 KW 29.4 KW 34.9 KW

Hot Air: 14.7 KW 19.6 KW 16.5 KW 19.6 KW 25.8 KW 34.3 KW 28.8 KW 34.3 KW

Steam Generator: 12.8 KW 17.1 KW 14.3 KW 17.1 KW 20.5 KW 27.3 KW 22.9 KW 27.3 KW

Amps per Phase: 45.5 51.8 24.2 26.4 77.8 88.8 41.4 44.9

BOILERLESS UNIT A -OES-6.20 UNIT B -OES-10.20

MODELS

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

Total Connected Load: 16.4 KW 21.6 KW 18.5 KW 22 KW 26.3 KW 34.9 KW 29.4 KW 34.9 KW

Hot Air: 14.7 KW 19.6 KW 16.5 KW 19.6 KW 25.8 KW 34.3 KW 28.8 KW 34.3 KW

Amps per Phase: 45.5 51.8 24.2 26.4 77.8 88.8 41.4 44.9

Water Connections: Cold Water (drinking water quality)

Flow Pressure: 30 - 60 PSI

Water Inlets: 3/4" GHT-F (Female Garden Hose

Connection)

Treated Water for Steam Generator

Untreated Water for Condenser

Drain Connection: 2" Tube

Venting: Exhaust Hood required

*Connection for Cleaning Solution

*Connection for Rinse Cycle

*Available as an option

Note: For additional connection details,

see spec sheet for each individual

combi model to be stacked.