Installation Manual PA Pro III online –2018-03-16 Page 3 of 30

Table of Contents

Safety Precautions............................................................................................................... 2

1Introduction .................................................................................................................. 5

2Handling and safety ....................................................................................................... 6

3Required documents and equipment ................................................................................ 7

4Connection of power measurement .................................................................................. 8

4.1 Motor configurations ................................................................................................. 8

4.1.1 Part Winding ..................................................................................................... 8

4.1.2 Y/D (Star/Delta) ................................................................................................ 8

4.2 Systems with inverter ............................................................................................... 9

4.3 Differential protection ............................................................................................... 9

5Connection of sensors ...................................................................................................10

5.1 Mounting of pressure transmitters/transducers ...........................................................10

5.2 Mounting temperature sensors ..................................................................................10

5.2.1 Required insulation ...........................................................................................10

5.2.2 Compensating for changes in temperature sensor cable length ...............................11

5.3 1-wire temperature sensors......................................................................................11

6ClimaCheck PA Pro III Hardware.....................................................................................13

6.1 LED indicators.........................................................................................................13

6.2 Display...................................................................................................................14

6.3 Start......................................................................................................................15

6.4 Menus....................................................................................................................16

6.5 Monitor ..................................................................................................................16

6.5.1 View all values .................................................................................................17

6.5.2 Send interval / Intense send ..............................................................................17

6.5.3 Signal level ......................................................................................................17

6.6 Setup.....................................................................................................................17

6.6.1 Reload configuration .........................................................................................17

6.6.2 Reboot ............................................................................................................18

7Configuration of 1-wire sensors ......................................................................................19

7.1 Connecting sensors..................................................................................................19

7.2 Replace a 1-wire senor.............................................................................................19

7.3 Clear all 1-wire sensors ............................................................................................19

8Configuration of PA Pro III .............................................................................................21

8.1 Change analog input mode (mA/V) ............................................................................21

8.2 Change communication mode ...................................................................................21

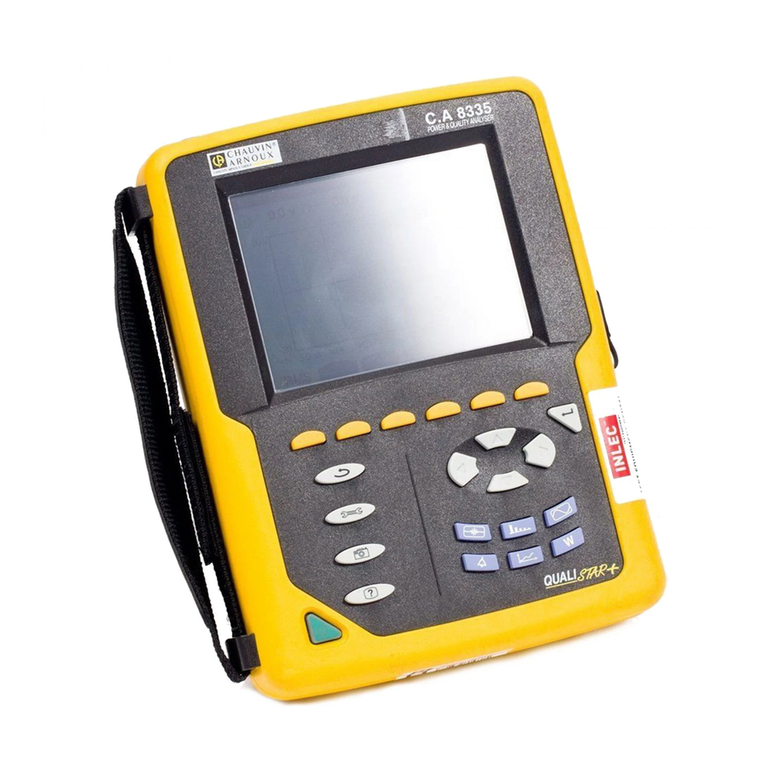

9Configuration of Power Meter EM24.................................................................................23

9.1 Change CT-ratio configuration...................................................................................23

9.2 Change Modbus address...........................................................................................23

10 Configuration of Power Meter EM210 ...............................................................................24

10.1 Change CT type configuration ...................................................................................24

10.2 Change Modbus address...........................................................................................24

11 Configuration of IO module R560 ....................................................................................25

11.1 Change Modbus address...........................................................................................25

11.2 Change Analog input mode .......................................................................................25

12 Troubleshooting............................................................................................................26

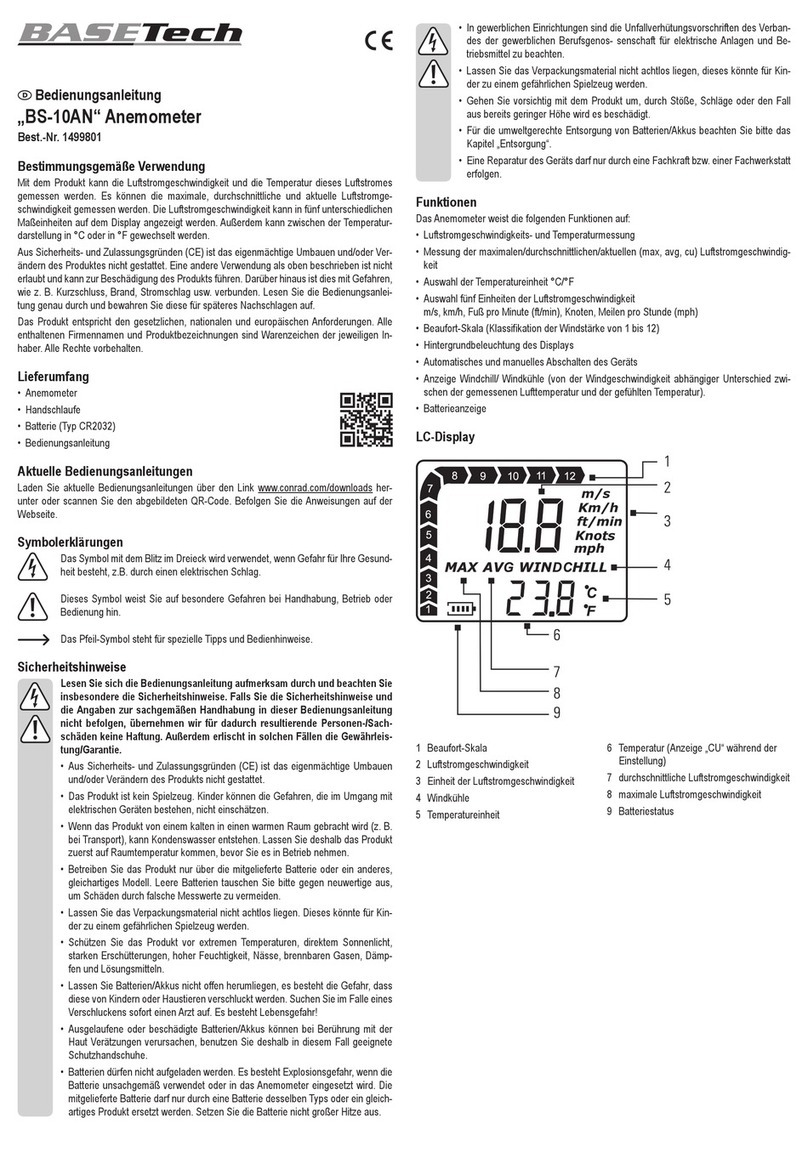

12.1 Pressure readings....................................................................................................26

12.1.1 Required tools and spare parts ...........................................................................26

12.1.2 Transmitter type...............................................................................................26

12.1.3 Supply voltage .................................................................................................26

12.1.4 Pressure signal .................................................................................................27

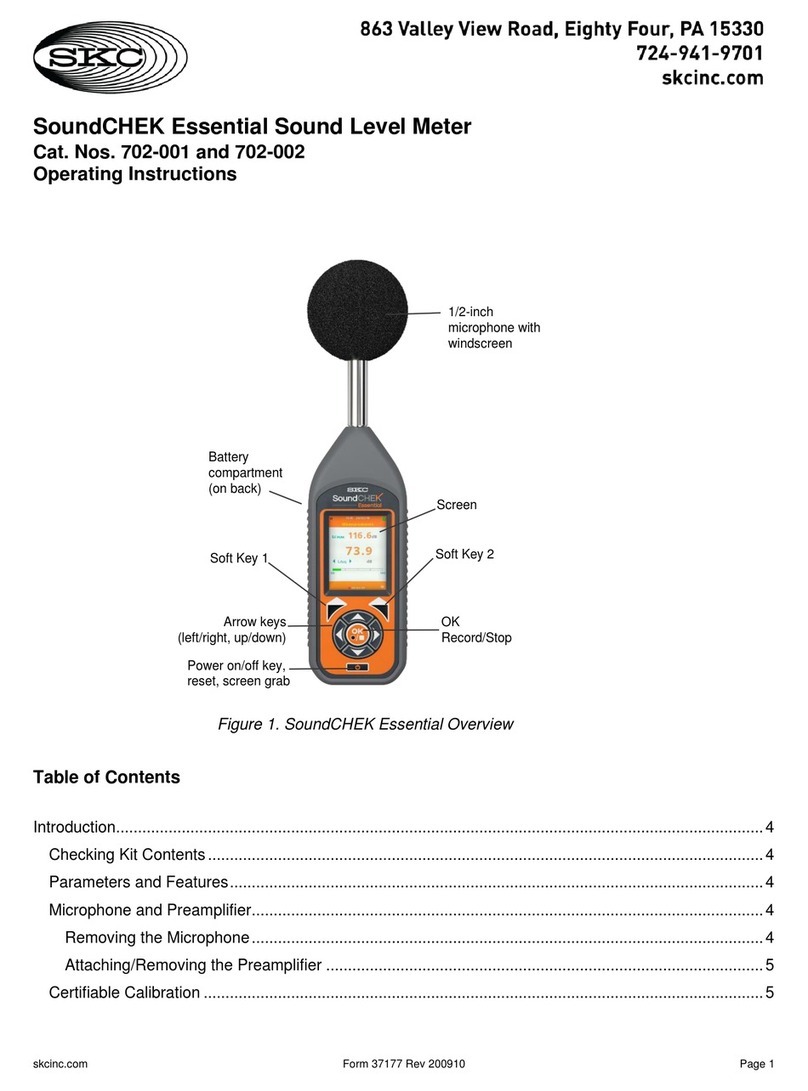

12.2 Temperature readings with PT1000 sensors ................................................................27

12.2.1 Required tools and spare parts ...........................................................................27

12.2.2 Common issues ................................................................................................28

12.2.3 Temperature-resistance table.............................................................................28