ClimateMaster Tranquility Series Guide

Air Handler for

Tranquility®Split Series

Installation, Operation &

Maintenance Instructions

97B0048N07

Rev.: 2/11/13

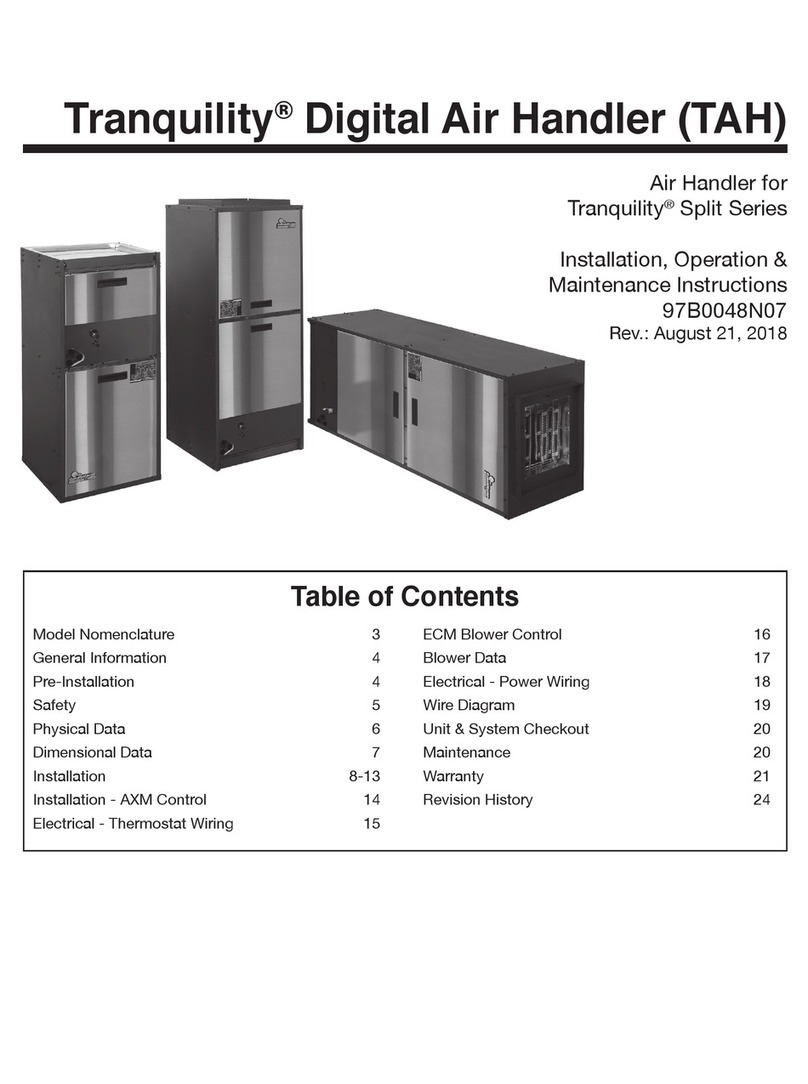

Tranquility®Digital Air Handler (TAH)

Table of Contents

Model Nomenclature 3

General Information 4

Pre-Installation 4

Safety 5

Physical Data 6

Dimensional Data 7

Installation 8-13

Installation - AXM Control 14

Electrical - Thermostat Wiring 15

ECM Blower Control 16

Blower Data 17

Electrical - Power Wiring 18

Electric Heat Installation 19

Electric Heat Wiring 20-21

Electric Heat Staging Options 21

Wire Diagram 22

Unit & System Checkout 23

Maintenance 23

Warranty 24

Revision History 26

T

ran

q

Insta

l

M

a

i

nt

e

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

2Geothermal Heat Pump Systems

This page was intentionally left blank.

3

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

Model Nomenclature

AHT02 6

2 31 4 5 6

T = TRANQUILITY

MODEL TYPE

AH =AIR HANDLER

CONFIGURATION

026

NOMINAL CAPACITY

038

049

REVISION

064

CABINET SIZE

S

12

FUTURE USE

SIZE 026 ONLY; 18.5 WIDTH

SIZES 026, 038, 049 ONLY; 22.5 WIDTH

SIZES 038, 049, 064 ; 25.5 WIDTH

B

7

B= CURRENT REVISION

WITH AXM CONTROL

G

8

VOLTAGE

G = 208-230/60/1

M

10

CABINET OPTIONS

M = MULTI-POSITION

A

11

A

B

C

(WIDTH, INCHES)

S

9

CONTROLS

S = STANDARD

S = STANDARD

( NOTE; FIELD CONVERTIBLE TO 115v )

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

4Geothermal Heat Pump Systems

WARNING!

WARNING! These instructions are intended as an aid to

qualified licensed service personnel for proper installation,

adjustment and operation of this unit. Read these

instructions thoroughly before attempting installation

or operation. Failure to follow these instructions may

result in improper installation, adjustment, service or

maintenance possibly resulting in property damage,

personal injury or death.

General Information

CAUTION!

CAUTION!

Air Handler Description

ClimateMaster Tranquility®Digital Air Handlers are designed

for use with ClimateMaster indoor/outdoor split units and are

available for vertical upflow or downflow, and horizontal left

or horizontal right airflow.

•New AXM board allows 4-wire connection with

communicating split (TEP/TES) and communicating

thermostat (ATC). Airflow and accessories can be

configured on the thermostat in plain English.

•Air coils are constructed of aluminum fins bonded to

internally grooved copper tubing.

• Air coils are tested at the factory with an extensive

refrigerant leak check.

• Air coils have sweat refrigerant connections.

•Ideally suited for new installations or add on air

conditioning.

•Feature two sets of 3/4” [14.1 mm] F.P.T. Condensate

drain connections for ease of connection.

•Air Handlers are A.H.R.I. certified for system application

with ClimateMaster indoor and outdoor split units.

•Condensate drain pan is constructed of high grade, heat

resistant, corrosion free thermal-set material.

•Bi-Directional airflow eliminates the need to switch any

internal components from horizontal left to right.

•Unique drain pan design maximizes application flexibility

and condensate removal.

Inspection

Upon receipt of the equipment, carefully check the shipment

against the bill of lading. Make sure all units have been

received. Inspect the packaging of each unit, and inspect each

unit for damage. Insure that the carrier makes proper notation

of any shortages or damage on all copies of the freight bill and

completes a common carrier inspection report. Concealed

damage not discovered during unloading must be reported

to the carrier within 15 days of receipt of shipment. If not filed

within 15 days, the freight company can deny the claim without

recourse. Note: It is the responsibility of the purchaser to file

all necessary claims with the carrier. Notify your equipment

supplier of all damage within fifteen (15) days of shipment.

Storage

Equipment should be stored in its original packaging in a

clean, dry area. Store units in an upright position at all times.

Stack units a maximum of 3 units high.

Unit Protection

Cover units on the job site with either the original packaging

or an equivalent protective covering. Cap the open ends of

pipes stored on the job site. In areas where painting, plastering,

and/or spraying has not been completed, all due precautions

must be taken to avoid physical damage to the units and

contamination by foreign material. Physical damage and

contamination may prevent proper start-up and may result in

costly equipment clean-up.

Examine all pipes, fittings, and valves before installing any of

the system components. Remove any dirt or debris found in

or on these components.

Pre-Installation

Installation, Operation, and Maintenance instructions

are provided with each unit. Horizontal equipment is

designed for installation above false ceiling or in a ceiling

plenum. Other unit configurations are typically installed

in a mechanical room. The installation site chosen should

include adequate service clearance around the unit. Before

unit start-up, read all manuals and become familiar with the

unit and its operation. Thoroughly check the system before

operation.

Prepare units for installation as follows:

1. Compare the electrical data on the unit nameplate with

ordering and shipping information to verify that the

correct unit has been shipped.

2. Keep the cabinet covered with the original packaging

until installation is complete and all plastering, painting,

etc. is finished.

3. Verify refrigerant tubing is free of kinks or dents and that

it does not touch other unit components.

4. Inspect all electrical connections. Connections must be

clean and tight at the terminals.

CAUTION! DO NOT store or install units in corrosive

environments or in locations subject to temperature

or humidity extremes. Corrosive conditions and high

temperature or humidity can significantly reduce

performance, reliability, and service life.

CAUTION! CUT HAZARD - Failure to follow this caution

may result in personal injury. Sheet metal parts may have

sharp edges or burrs. Use care and wear appropriate

protective clothing, safety glasses and gloves when

handling parts and servicing.

5

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

Safety

CAUTION!

CAUTION! It is recommended that an auxiliary

secondary drain pan be installed under units containing

evaporator coils that are located in any area of a structure

where damage to the building or building contents may

occur as a result of an overflow of the coil drain pan or a

stoppage in the primary condensate drain piping.

The installation of water source heat pump units and all

associated components, parts and accessories which make

up the installation shall be in accordance with the regulations

of ALL authorities having jurisdiction and MUST conform to

all applicable codes. It is the responsibility of the installing

contractor to determine and comply with ALL applicable

codes and regulations.

Replacement Parts

Any replacement part must be the same as or an approved

alternate to the original part supplied. The manufacturer will

not be responsible for replacement parts not designed to

physically fit or operate within the design parameters the

original parts were selected for. When ordering replacement

parts, it is necessary to order by part number and include

the complete model number and serial number from the coil

rating plate. (See parts list for unit component part numbers.

Parts are available through the local distributor.)

WARNING!

WARNING!

WARNING!

CAUTION!

Safety

Warnings, cautions and notices appear throughout this

manual. Read these items carefully before attempting any

installation, service, or troubleshooting of the equipment.

DANGER: Indicates an immediate hazardous situation, which

if not avoided will result in death or serious injury. DANGER

labels on unit access panels must be observed.

WARNING: Indicates a potentially hazardous situation, which

if not avoided could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation or an

unsafe practice, which if not avoided could result in minor or

moderate injury or product or property damage.

NOTICE: Notification of installation, operation or maintenance

information, which is important, but which is not hazard-

related.

WARNING! All refrigerant discharged from this unit must

be recovered WITHOUT EXCEPTION. Technicians must

follow industry accepted guidelines and all local, state, and

federal statutes for the recovery and disposal of refrigerants.

To avoid leakage of compressor oil, refrigerant lines of the

compressor must be sealed after it is removed.

CAUTION! To avoid equipment damage, DO NOT use

these units as a source of heating or cooling during the

construction process. The mechanical components and

filters will quickly become clogged with construction dirt

and debris, which may cause system damage.

WARNING! The EarthPure® Application and Service

Manual should be read and understood before

attempting to service refrigerant circuits with HFC-410A.

WARNING! To avoid the release of refrigerant into the

atmosphere, the refrigerant circuit of this unit must be

serviced only by technicians who meet local, state, and

federal proficiency requirements.

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

6Geothermal Heat Pump Systems

Unit Physical Data

Model 026-A 026-B 038-B 038-C 049-B 049-C 064-C

Emerson ECM Fan Motor & Blower in. [cm]

Liquid I.D. 3/8 [0.95] 3/8 [0.95] 3/8 [0.95] 3/8 [0.95] 3/8 [0.95] 3/8 [0.95] 3/8 [0.95]

Suction I.D. 3/4 [1.9] 3/4 [1.9] 7/8 [2.22] 7/8 [2.22] 7/8 [2.22] 7/8 [2.22] 7/8 [2.22]

Fan Motor Type/Speeds ECM Variable

Fan Motor (hp) 1/2 1

Blower Wheel Size (Dia x W)

in. [mm] 9 x 7 [229 x 178] 12 x 10 [305 x 254]

Air Coil Dimensions (H x W)

in. [mm] 3 - 2 Row 14 x 17 [356 x 432] 3 - 2 Row 24 x 17 [610 x 432] 3 - 3 Row 24x17

[610 x 432]

Filter Standard - 1” [25mm]

Throwaway 16 x 20 [406 x 508] 20 x 20 [508 x 508] 20 x 24

[508 x 610] 20 x 20

[508 x 508] 20 x 24 [508 x 610]

Weight - Operating lbs. [kg] 80 [36] 163 [74] 173 [78] 181 [82] 180 [82] 188 [85] 198 [90]

Weight - Packaged lbs. [kg] 96 [44] 179 [81] 198 [90] 206 [93] 218 [99] 226 [103] 236 [107]

7

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

Unit Dimensional Data

0.0 1.6

[4.0]

3.6

[9.1] 5.8

[14.7]

5.9

[15.0]

0.0

3.7 [9.4]

4.5 [11.4]

5.6 [14.2]

6.7 [17.0]

8.5 [21.6]

Detail A

Scale 5/32

[0.4]

C

5.5

[14.0]

See Detail A

A

FD

G

H

E

J

R.A. Opening 0.625

[1.6]

0.625

[1.6] R.A. Opening 0.875

[2.2]

0.75

[1.9]

8.5

[21.6]

3.6

[9.4]

Detail A

A = Primary Drain - Vertical,

Horizontal and Downflow

Configuration

B = Secondary Drain - Vertical

and Downflow Configuration

C = Secondary Drain - Horizontal

Configuration

AB

C

Cabinet

Size

Overall Cabinet 1 2 3 4 5 6

A

Width B

Height C

Depth D E F G H J

A - Cabinet in. 18.5 44.0 22.0 14.0 14.0 2.3 2.3 4.1 4.1

cm. 47.0 111.8 55.9 35.6 35.5 5.8 5.8 10.3 10.3

B - Cabinet in. 22.0 55.0 22.0 18.0 18.0 2.1 2.1 2.1 2.1

cm. 55.9 139.7 55.9 45.7 45.7 5.2 5.2 5.2 5.2

C - Cabinet in. 25.5 59.0 22.0 18.0 18.0 3.8 3.8 2.1 2.1

cm. 64.8 149.9 55.9 45.7 45.7 9.9 9.9 5.2 5.2

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

8Geothermal Heat Pump Systems

Installation

The Tranquility Air Handlers are designed for upflow, horizon-

tal, and downflow applications. The coils have a dry nitrogen

holding charge and are equipped with brazing stub refriger-

ant connections for easy installation. Both models come

equipped with a factory installed TXV.

The installer should read the installation manual supplied

with the compressor section for refrigerant line set sizing,

connection procedure, and other important information per-

taining to the system installation.

The installer should:

1. Where precise forming of refrigerant lines is required, a

copper tubing bender is recommended for small diameter

tubing. One should avoid sharp bends and contact of the

refrigerant lines with metal surfaces.

2. Refrigerant lines should be protected where they pass

through the raw edges of holes.

3. Air Handler must be level for proper condensate drainage.

4. Seal the openings into the cabinet to reduce risk of con-

densate blow off from the coil.

Air Handler Installation

WARNING!

WARNING! Electric furnaces may be connected to

more than one supply circuit.

Charging the System

TAH Air Handlers are designed to match TEP/TES split

units. For correct charging, please refer to the Compressor

Section IOM.

Upflow Installation

1. Position unit on plenum box or other suitable foundation.

Provide a minimum height for proper unrestricted airflow

based on CFM requirement for each unit size.

2. If a return air duct is connected to the air handler, it must

be the same dimensions as shown in the outline drawing in

Figure 2.

3. Plenum box and unit should be isolated from the foundation

using a suitable isolating material.

4. Openings where field wiring enters the cabinet must be

completely sealed. Location of power entry is shown on the

outline drawing.

5. After ductwork connections are made, seal airtight and per

local codes.

Downflow Installation

1. Position unit on plenum box or other suitable foundation.

Provide a minimum height for proper unrestricted airflow

based on CFM requirement for each unit size.

2. If a return air duct is connected to the air handler, it must

be the same dimensions as shown in the outline drawing in

Figure 2.

3. Plenum box and unit should be isolated from the foundation

using a suitable isolating material.

4. Openings where field wiring enters the cabinet must be

completely sealed. Location of power entry is shown on the

outline drawing.

5. After ductwork connections are made, seal airtight and per

local codes.

6. The unit is then placed with the blower side down and the

coil is replaced on the coil channel supports with the drain

connections at the bottom. The unit is now in downflow

position with front access.

Position the ECM wire harness connection at the 4 to 8

o’clock position to prevent condensation from entering

motor controller.

7. If a return duct is connected to the air handler, it must be the

same dimensions as the return opening.

8. After ductwork connections are made, seal airtight and per

local codes.

Horizontal Right Installation

For maximum efficiency and customer ease of filter

maintenance, it is recommended that a properly sized

remote filter grille be installed for horizontal applications.

Airflow should not exceed the face velocity of the filter being

used. The factory installed filter should then be removed

from the unit.

1. To convert the unit to horizontal right, front access, slide the

coil out on the coil channel supports and rotate the complete

coil 180 degrees.

2. The coil is then inserted back into the cabinet on the

opposite side coil channel supports. The unit is now

horizontal right with front access.

Position the ECM wire harness connection at the 4 to 8

o’clock position to prevent condensation from entering

motor controller.

3. If the unit is suspended, it must be supported from the

bottom near both ends as well as the middle to prevent

sagging. The service access must remain unobstructed. If

the unit is supported along the length of the front and back

with rails, the air handler only needs to be suspended at

both ends. See Figure 1.

If the unit is not suspended it must be supported as

mentioned above and isolated carefully to prevent sound

transmission. Vibration isolators (purchased locally) must be

placed under the unit.

4. It is always recommended that an auxiliary drain pan be

installed under a horizontal air handler (See Condensate

Piping) to prevent possible damage to ceilings.

5. Isolate the auxiliary drain pan from the unit or from the

structure.

6. Connect the auxiliary drain line to a separate drain line

(no trap is needed in this line) and terminate according to

national and local codes.

7. If a return duct is connected to the air handler, it must be the

same dimensions as the return opening shown in the outline

drawing on Figure 2.

8. Openings where field wiring enters the cabinet must be

completely sealed.

9. After ductwork connections are made, seal airtight and per

local codes.

9

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

Horizontal Left Installation

1. For maximum efficiency and customer ease of filter

maintenance, it is recommended that a properly sized

remote filter grille be installed for horizontal applications.

Airflow should not exceed the face velocity of the filter being

used. The factory installed filter should then be removed

from the unit.

2. Unit is shipped from the factory in the upflow or horizontal

left configuration. Unit conversion is not required.

Conversion is required: Rotate motor to ensure connection

at the 4 to 8 o’clock position.

3. If the unit is suspended, it must be supported from the

bottom near both ends as well as the middle to prevent

sagging. The service access must remain unobstructed. If

the unit is supported along the length of the front and back,

the air handler only needs to be suspended at both ends.

See Figure 1.

4. If the unit is not suspended it must be supported as

mentioned above and isolated carefully to prevent sound

transmission. Vibration isolators (purchased locally) must

be placed under the unit.

5. It is always recommended that an auxiliary drain pan be

installed under a horizontal air handler (See Condensate

Drain Piping) to prevent possible damage to ceilings.

6. Isolate the auxiliary drain pan from the unit or from the

structure.

7. Connect the auxiliary drain line to a separate drain line

(no trap is needed in this line) and terminate according to

national and local codes.

8. If a return duct is connected to the air handler, it must be

the same dimensions as the return opening shown in the

outline drawing on Figure 2.

9. Openings where field wiring enters the cabinet must be

completely sealed. Location of power entry is shown on

the outline drawing.

10. After ductwork connections are made, seal airtight and per

local codes.

Duct Connections

The supply and return air ducts should be connected to the

unit with flame retardant duct connectors.

NOTE: No sheetmetal screws may be used to

attach return ductwork on the side.

NOTE: Any duct board return connection can be

made to the sides of the unit using tape or mastic.

Installation

Rail

Auxiliary

Drain Pan

Tranquility

EarthPure

®

27

Tranquility

EarthPure

®

27

Tranquility

EarthPure

®

27

Figure 1: Mounting Installation Options

Figure 2: Flange Attachment

Tranquility

EarthPure

®

27

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

10 Geothermal Heat Pump Systems

Applications

Tranquility Air Handlers can be applied in upflow, downflow,

horizontal right and horizontal left applications without

modifications. For horizontal applications, installation of an

auxiliary/secondary drain pan is required.

CAUTION!

CAUTION! For horizontal applications, the horizontal drain

pan must be located under the indoor coil. Failure to place

the pan under the coil can result in property damage.

Installation

5HWXUQ

'LVFKDUJH

TOP

DISCHARGE

5HWXUQ

'LVFKDUJH

TAH 1” to 2” Filter Rack Conversion

The unit is shipped with1” filter rack from the factory. The

conversion process is assumed that the unit is in upflow

configuration.

1. Place unit on a flat surface. Remove 2 knurled thumb knobs

that secure the filter rack door at the bottom of the unit.

2. Remove 3 screws that secure the lower filter tracks on each

side of the unit.

3. Lift and rotate the filter tracks upside down and reinstall filter

tracks and screws back.

4. Replace the filter rack door and the 2 knurled thumb knobs.

LEFT

DISCHARGE

5HWXUQ

'L

'LVFKDUJH

RIGHT

DISCHARGE

BOTTOM

DISCHARGE

5

'LV

5HWXUQ

'LVFKDUJH

11

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

CAUTION!

CAUTION! Installation of a factory supplied liquid line

bi-directional filter drier is required. Never install a suction

line filter in the liquid line.

CAUTION!

See compressor section IOM for refrigerant charge

information.

Line Set Installation

Figure 5 illustrates a typical installations of an air handler or

cased coil matched to an indoor compressor section. Table

A shows typical line-set diameters at various lengths. Lineset

lengths should be kept to a minimum and should always be

installed with care to avoid kinking. Line sets over 60 feet [18

meters] long are not recommended due to potential oil transport

problems and excessive pressure drop. If the line set is kinked

or distorted, and it cannot be formed back into its original

shape, the damaged portion of the line should be replaced. A

restricted line set will effect the performance of the system.

All brazing should be performed using nitrogen circulating

at 2-3 psi [13.8-20.7 kPa] to prevent oxidation inside the

tubing. All linesets should be insulated with a minimum

of 1/2” [13mm] thick closed cell insulation. All insulation

tubing should be sealed using a UV resistant paint or

covering to prevent deterioration from sunlight.

When passing refrigerant lines through a wall, seal

opening with silicon-based caulk. Avoid direct contact

with water pipes, duct work, floor joists, wall studs,

floors or other structural components that could transmit

compressor vibration. Do not suspend refrigerant tubing

from joists with rigid straps. Do not attach line set to the

wall. When necessary, use hanger straps with isolation

sleeves to minimize transmission of line set vibration to

the structure.

Installing the Indoor Coil and Lineset

Figure 3 shows the installation of the lineset and TXV to

a typical indoor coil. Braze the copper line set to the coil.

Nitrogen should be circulated through the system at 2-3 psi

[13.8-20.7 kPa] to prevent oxidation inside the refrigerant

tubing. Use a low silver phos-copper braze alloy on all brazed

connections.

Installation

Figure 3: Air Coil Connection

NOTICE! The air coil should be thoroughly washed with a

filming agent, (dishwasher detergent like Cascade) to help

condensate drainage. Apply a 20 to 1 solution of detergent

and water. Spray both sides of coil, repeat and rinse

thoroughly with water. Care should be taken not to overflow

drain pan. Wash after connecting condensate line.

Sensing Bulb

IMPORTANT: DO NOT perform any brazing with the TXV

bulb attached to any line. After brazing operations have been

completed, clamp the TXV bulb securely on the suction line

at the 10 or 2 o’clock position with the strap provided in the

parts bag. Insulate the TXV sensing bulb and suction line

with the provided pressure sensitive insulation (size 4” x 7”).

IMPORTANT: TXV sensing bulb should be located on a

horizontal section of suction line, just outside of coil box.

IMPORTANT: Always protect TXV from heat when brazing.

IMPORTANT: TXV sensing bulb is shipped unattached.

Installer must attach bulb to suction line after brazing and

cooling line for proper unit operation.

CAUTION! HFC-410A systems operate at higher

pressures than R-22 systems. Be certain that service

equipment (gauges, tools, etc.) is rated for HFC-410A.

Some R-22 service equipment may not be acceptable.

TXV (‘IN’ toward

compressor section)

Suction Line

Liquid Line

Bulb (Must be

Installed and

Insulated) Equalizer

Line

TXV has internal

check valve

LT2

Sensor

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

12 Geothermal Heat Pump Systems

Evacuation and Charging the Unit

LEAK TESTING -

The refrigeration line set must be pressurized

and checked for leaks before evacuating and charging the unit.

To pressurize the line set, attach refrigerant gauges to the service

ports and add an inert gas (nitrogen or dry carbon dioxide) until

pressure reaches 60-90 psig [413-620 kPa]. Never use oxygen

or acetylene to pressure test. Use a good quality bubble solution

to detect leaks on all connections made in the field. Check the

service valve ports and stem for leaks. If a leak is found, repair it

and repeat the above steps. For safety reasons do not pressurize

system above 150 psig [1034 kPa]. System is now ready for

evacuation and charging.

Condensate Drain Tubing

Consult local codes or ordinances for specific requirements.

IMPORTANT: When making drain fitting connections to the

drain pan, use a thin layer of Teflon paste, silicone or Teflon

tape and install hand tight.

IMPORTANT: When making drain fitting connections to drain

pan, do not overtighten. Overtightening fittings can split pipe

connections on the drain pan.

•Install drain lines so they do not block service access

to front of the unit. Minimum clearance of 24 inches is

required for filter, coil or blower removal and service

access.

• Make sure unit is level or pitched slightly toward primary

drain connection so that water will drain completely from

the pan (See Figure 4).

• Do not reduce drain line size less than connection size

provided on condensate drain pan.

• All drain lines must be pitched downward away from the

unit a minimum of 1/8” per foot of line to ensure proper

drainage.

• Do not connect condensate drain line to a closed or

open sewer pipe. Run condensate to an open drain or

outdoors.

• The drain line should be insulated where necessary to

prevent sweating and damage due to condensate forming

on the outside surface of the line.

• Make provisions for disconnecting and cleaning of the

primary drain line should it become necessary. Install

a 3 in. trap in the primary drain line as close to the unit

as possible. Make sure that the top of the trap is below

connection to the drain pan to allow complete drainage of

pan (See Figure 4).

• Auxiliary drain line should be run to a place where it will

be noticeable if it becomes operational. Occupant should

be warned that a problem exists if water should begin

running from the auxiliary drain line.

• Plug the unused drain connection with the plugs provided

in the parts bag, using a thin layer of Teflon paste, silicone

or Teflon tape to form a water tight seal.

• Test condensate drain pan and drain line after installation

is complete. Pour water into drain pan, enough to fill

drain trap and line. Check to make sure drain pan is

draining completely, no leaks are found in drain line

fittings, and water is draining from the termination of the

primary drain line.

'2 127 23(5$7( 81,7 :,7+287

&21'(16$7( '5$,1 75$3

81,7 0867 %( 6/,*+7/< ,1&/,1('

72:$5' '5$,1 &211(&7,21

'2 127 29(57,*+7(1 '5$,1 ),77,1*

81,7

Installation

It is always recommended that an auxiliary drain pan be

installed under a horizontally installed air handler.

Connect the auxiliary drain line to a separate drain line (no

trap is needed in this line) and terminate according to local

codes.

NOTE: DO NOT use a torch or flame near the

plastic drain pan coupling.

NOTE: DO NOT tighten the drain pipe excessively.

Support the condensate piping and traps outside

the unit to prevent strain on the drain connection.

Figure 4: Condensate Drain Trap

13

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

Installation

Figure 5: Typical Split/Air Handler Installation

Compressor Section

Low Voltage

Insulated

Linesets

Air pad or Extruded

polystryene

PVC Condensate

with vented trap

Power

Disconnects

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

14 Geothermal Heat Pump Systems

AXM Control

The Tranquility®Digital Air handler (TAH Revision B) is

equipped with a communicating AXM board to allow

communication with the communicating compressor section

(TES/TEP) and communicating thermostat (ATC).

The AXM control allows either 4-wire connection with

Communicating DXM2 board and Communicating

ATC Thermostat. It can also be connected to a non-

communicating thermostat and compressor section using

up to 9-wires (plus additional if functionality requires). Please

see Thermostat section for more details.

Low Air Temperature Sensor Installation

Tranquility

®

Digital Air Handlers are shipped with LT2 (Low

Air Temperature) sensor installed in the Air Handler (Figure

3) and connected to the AXM control. No additional action

required (do not clip the VIO wires).

Installation

Test Button

The test button puts the AXM into test mode, which

bypasses the soft start ramping profile and the blower

immediately ramps up to the nominal target speed.

FIELD SELECTABLE INPUTS

DIP SWITCHES

Note: In the following field configuration options, DIP

switches should only be moved when power is removed

from the DXM2 Control to ensure proper operation.

DIP #2: Dehumidification Mode - Provides selection of normal

or Dehumidification Fan Mode. In Dehumidification Mode, the

fan speed will be adjusted for Cooling. In Normal Mode, the

fan speed will be normal during Cooling.

On = Normal Fan Mode. Off = Dehumidification Mode

Rest of the DIP switches are not used.

ACCESSORY CONNECTION / CONFIGURATION

2 Accessory outputs on AXM board only track blower

operation.

Other accessories are connected to the DXM2 board. Please

refer to DXM2 AOM for more details.

Fan Connections

Electric Heat

Connections

9-wire connection to non-

communicating thermostat/

compressor section

4-wire connection to

communicating thermostat

4-wire

connection

to DXM2

Accessory

outputs

that track

blower

operation

LT2

Sensor Condensate

Sensor

Figure 5:

AXM Connections

15

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

Electrical -ThermostatWiring

Thermostat Installation

The thermostat should be located on an interior wall in a

larger room, away from supply duct drafts. DO NOT locate

the thermostat in areas subject to sunlight, drafts or on

external walls. The wire access hole behind the thermostat

may in certain cases need to be sealed to prevent erroneous

temperature measurement. Position the thermostat back

plate against the wall so that it appears level and so the

thermostat wires protrude through the middle of the back

plate. Mark the position of the back plate mounting holes

and drill holes with a 3/16” (5mm) bit. Install supplied

anchors and secure plate to the wall. Thermostat wire must

be 18 AWG wire. Wire the appropriate thermostat as shown

in Figures 6 and 7 to the low voltage terminal strip on the

ECM control board. Practically any heat pump thermostat

will work with these units, provided it has the correct number

of heating and cooling stages.

4-Wire Connection ATC communicating thermostat and

DXM2 Communicating control in Tranquility®Digital Splits

AXM control in Tranquility®Digital Air Handler allows

4-wire connection with Communicating DXM2 board and

Communicating ATC Thermostat.

Thermostat Connections

C 24V Common for Control Circuit

R 24V Supply for Control Circuit

A+ Communications (Positive)

B – Communications (Negative)

iGate™Thermostat

ATC32**

DXM2 in

Compressor

Section

Communicating

TAH with

AXM Control

R

A+

A+ B-

B-

C

R

C

24V

A+

B-

C

24V

A+

B-

C

Figure 6: 4-Wire

Connection to ATC communicating

thermostat, AXM Communicating control

and Tranquility®Digital Splits

Connection to Non-Communicating thermostat, AXM

communicating control in Tranquility®Digital Air Handler

and Tranquility® Digital Splits

Figure 7:

Connection to Non-Communicating

thermostat and AXM communicating control

in Tranquility®Digital Air Handler

Non-Communicating

2 Cool / 3 Heat Thermostat

Compressor

Compressor Stage 2

Communicating

TAH AXM Control

Y1

Y2

O

R

G

C

DH

AL1

Y1

Y2

DXM2 In

Compressor

Section

Fault LED L

Reversing Valve O

24Vac Hot R

Fan G

24Vac Common C

DH

Dehumidification

(ATP32U04 Only)

C

A+

B-

24V

C

A+

B-

24V

Thermostat Connections

C 24V Common for Control Circuit

R 24V Supply for Control Circuit

A+ Communications (Positive)

B – Communications (Negative)

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

16 Geothermal Heat Pump Systems

ECM Blower Control

The ECM fan is controlled directly by the DXM2/AXM

control board that converts thermostat inputs and CFM

settings to signals used by the ECM motor controller. To

take full advantage of the ECM motor features, an iGate™

communicating multi-stage thermostat should be used

(ATC32U**).

The AXM control maintains a selectable operating airflow

[CFM] for each heat pump operating mode. For each

operating mode there are maximum and minimum airflow

limits. See the ECM Blower Performance tables for the

maximum, minimum, and default operating airflows.

Airflow levels are selected using the configuration menus of

a communicating thermostat (ATC32U**) or diagnostic tool

(ACDU**). The configuration menus allow the installer to

independently select and adjust the operating airflow for each

of the operating modes. Air flow can be selected in 25 CFM

increments within the minimum and maximum limits shown in

Table 8. The blower operating modes include:

• First Stage Cooling (Y1 & O)

• Second Stage Cooling (Y1, Y2, & O)

• First Stage Cooling in Dehumidification Mode

(Y1, O, & Dehumid)

• Second Stage Cooling in Dehumidification Mode

(Y1, Y2, O, & Dehumid)

• First Stage Heating (Y1)

• Second Stage Heating (Y1 & Y2)

• Third Stage (Auxiliary) Heating (Y1, Y2, & W)

• Emergency Heating (W with no Y1 or Y2)

• Fan (G with no Y1, Y2, or W)

The ECM motor includes “soft start” and “ramp down”

features. The soft start feature is a gentle increase of motor

rpm at blower start up. This creates a much quieter blower

start cycle.

The ramp down feature allows the blower to slowly decrease

rpm to a full stop at the end of each blower cycle. This

creates a much quieter end to each blower cycle and adds

overall unit efficiency.

The ramp down feature is eliminated during an ESD

(Emergency Shut Down) situation. When the DXM2 ESD

input is activated, the blower and all other control outputs are

immediately de-activated.

The duration of the “ramp down” periods are adjustable from

0 seconds to 255 seconds. This adjustment is available

in the Aiflow Selection screen using the communicating

thermostat or configuration/diagnostics tool, see Figure 27.

Special Note for AHRI Testing: To achieve rated airflow for

AHRI testing purposes, it is necessary to change the CFM

settings to rated airflow.

AIRFLOW SELECTION

CFM

HEAT STAGE 1 600

HEAT STAGE 2 750

AUXILIARY HEAT 850

EMERGENCY HEAT 850

COOL STAGE 1 525

COOL STAGE 2 700

COOL DEHUMID 1 425

COOL DEHUMID 2 550

CONTINUOUS FAN 350

HEAT OFF DELAY 60

COOL OFF DELAY 30

PREVIOUS NEXT

Figure 27: Airflow Configuration Screen on

Communicating Thermostat

17

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

Blower Performance Data

Table 8:TAH Digital Standard Unit

Airflow in CFM with wet coil and clean air filter

Model Max

ESP

(in. wg)

Fan

Motor

(hp) Range Cooling Mode Dehumid Mode Heating

Mode Fan

Only

Mode

Aux/

Emerg

Mode

Stg 2 Stg 1 Stg 2 Stg 1 Stg 2 Stg 1

TAH

026 1.0 1/2

Default 700 525 550 425 750 600 350 850

Maximum 1000 800 800 600 1000 850 1000 1000

Minimum 600 450 550 400 600 450 300 700

TAH

038 0.9 1/2

Default 1050 800 850 650 1100 850 550 1350

Maximum 1500 1100 1200 900 1500 1100 1500 1500

Minimum 900 600 825 550 900 600 450 1350

TAH

049 1.0 1

Default 1400 1050 1100 850 1500 1150 700 1500

Maximum 2000 1500 1600 1200 2000 1500 2000 2000

Minimum 1200 900 1100 825 1200 900 600 1350

TAH

064 0.7 1

Default 1750 1300 1400 1050 1875 1450 875 1875

Maximum 2300 1900 2000 1500 2300 1900 2300 2300

Minimum 1500 1100 1375 1000 1500 1100 750 1500

TAH

072 0.7 1

Default 1900 1450 1650 1250 2000 1650 950 2000

Maximum 2300 2200 2000 1800 2300 2200 2300 2300

Minimum 1800 1350 1650 1250 1800 1350 900 1800

Airflow is controlled within 5% up to the Max ESP shown with wet coil

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

18 Geothermal Heat Pump Systems

1. These Air Handlers are shipped from the factory wired

for 230 volts. The units may be wired for 208 or 115

volts. Follow instructions on unit wiring diagram located

on blower housing and in the Service Facts document

included with the unit.

2. The selection of wire and fuse sizes should be made

according to the Minimum Branch Circuit Ampacity and the

Maximum Overcurrent Device listed on the unit nameplate.

3. Field wiring diagrams for electric heaters and unit

accessories are shipped with the accessory.

4. Wiring must conform to National and Local codes.

5. Ground unit per local codes with good safety procedures.

NOTE: If air handler is used with or without a

heater, the electrical entry hole as well as any other

cabinet penetrations must be sealed air-tight.

Wiring Instructions for 115v Conversion from 230 volt

1. Disconnect all power to the unit.

2. Disconnect Transformer primary orange wire from power

block T2 and insulate open end of wire. Connect the

white lead from transformer primary wire to power block

terminal T2. Note: (L2 will be used as Netural)

3. Remove plug in ECM power wiring harness (Fig. 9) and

Install 2 pin jumper plug provided in control box (Fig. 10).

NOTE: When supplementary heaters are installed,

inspect to insure that all packaging material has

been removed.

Electrical - PowerWiring

WARNING! Figure 9: Remove Harness Plug

Note: For 115v power only. Damage will occur to motor

with 230v power supply if 115v jumper is used.

Table 4: Electric Table (115) 208/230

WARNING! Electrical shock hazard - Lock unit disconnect

switch in open position before servicing unit. Failure

to follow this warning could result in property damage,

personal injury, or death.

Figure 10: Install Two Pin Jumper Plug

Model Fan

Motor

FLA

Fan

Motor

HP

Max

Fan

ESP

Min Circ

Amp

(120)

208/230

Total

Unit

FLA

Max Fuse/

HACR

(120)

208/230

026 (7.7) 4.3 1/2 0.5 (7.8) 4.9 (7.7) 4.3 (15) 15

038 (7.7) 4.3 1/2 0.5 (7.8) 4.9 (7.7) 4.3 (15) 15

049 (12.8) 7 1 1 (14.4) 8.6 (12.8) 7 (25) 15

064 (12.8) 7 1 1 (14.4) 8.6 (12.8) 7 (25) 15

Dual Rated Voltate: (115) 208/230

Min/Max Voltage: 115: 114/132

Min/Max Voltage: 208/230: 197/254

19

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

Overview

The AG Series Auxiliary Electric Heat mounts internally in

upflow (Figure 11) or downflow units and horizontal units.

Horizontal units are rated for zero clearance at the unit

and 1" clearance for first three feet of duct, vertical units

rated for zero clearance for both unit and duct. Downflow

units can not be located directly over a discharge register.

The discharge plenum must be constructed from non

combustible material. The AG electric heat contains a four

stage relay control board which activates the elements

directly via an internally wired low voltage harness. Low

voltage signals (W1 and W2) are staged from the AXM

control.

Vertical Upflow or Downflow and Horizontal Installation

1. Disconnect power to the unit

2. Remove blower access panels.

3. Clip wire-tie holding electric heat low voltage 3-wire

harness to discharge panel stiffener.

4. Remove blower mounting screws and then drop down

blower assembly as shown in Figure 12. Removal of

blower wires should not be necessary.

5. Install electric heat in discharge flange where blower

assembly has been removed using provided screws as

shown In Figure 13.

5.5 For downflow or horizontal right discharge units, the

air handler support bracket must be removed to re-

install the blower housing assembly. After re-installing

the blower housing, re-install the air handler support

bracket.

6. Re-install blower assembly, Figure 13, into electric heat

assembly using blower mounting screws. Check blower

wiring for proper wiring connections.

7. Route the low voltage harness through the provided

‘pie’ bushing and plug into electric heat control board

connector P2 as shown in Figure 18.

8. Install power conduit through unit corner post knockout

and attach conduit directly to the electric heat control

box.

9. Optional: AG**C kits only. Blower power may be supplied

from T3 & T4 CB5 breaker. Refer to wiring diagram

96B0143N01.

Electric Heat Installation

Locate electric heat assembly

on pins in discharge panel

and insert screws

Relocate blower in electric

heat assembly in same

manner

Figure 12: Blower removal

Figure 13: AG electric heat mounting and

blower re-installation

Figure 11: Typical air handler installation

Route condiut thru cabinet and

connect to electric heat control

box. Seal to eliminate air leaks on

cabinet exterior.

Low voltage control

harness is prewired

on all distributor class units.

Electric Heat

Assembly

Auxiliary electric heat

power supply knockout

opposite air coil

Disconnect (optional

refer to local code)

Air Coil

Tranquility®Digital Air Handler (TAH)

Rev.: 11 Feb., 2013

20 Geothermal Heat Pump Systems

Figure 14: Power Wiring, Dual Circuits, 15 and 20kw Figure 15: Power Wiring, Single Circuit, 15, 20kw

Wiring and Setup (all models)

1. Install power wiring and connect to power block or

circuit breakers. In 12, 15 or 20kW models two power

circuits may be used to reduce wiring and breaker

costs as in Figure 14. If a single circuit supply is

desired, install the optional single circuit accessory kit

(P/N 16B0002N02), as shown in Figure 15, that can be

obtained from your distributor.

2.

Ensure unit airflow setting is above minimum airflow rating

for the electric heat model from Table 1.

3. Check staging jumpers for the application. Typically

only 5 kW (factory setting on all models except 10kW on

20kW models) is needed for first stage electric (W1) to

minimize electric demand. This staging can be adjusted

by moving the staging jumpers as shown in Figure 17.

Whatever is jumped to P1 pin 1 will be energized on

1st stage of electric heat, and P1-2 will be energized as

stage 2 electric heat. See Table C for staging options.

4. Mark the appropriate box of the electric heat model

installed on the additional serial plate on the exterior of

the unit.

5. Turn on the power to the unit and the auxiliary

electric heat.

Auxiliary Electric Heat Start-up

Put thermostat in emergency heat mode in manual mode on

ATC/ACD (see figure #) and setpoint to high setting. Unit will

require 15-20 seconds before engaging emergency heat mode

stage 1 (W1) and then another 15-20 seconds to engage

stage 2 (W2) when in ‘Test mode’. Verify proper electric heat

operation. Exit manual mode for normal operation.

NO

Com ER1

NO

Com ER2

NO

Com ER3

NO

Com ER4

123

Tan

Ora

Factory Staging

(see Table 2)

Low Voltage Connector

(from Unit Control Board)

AG Electric Heat

Relay Board P1P2

24V

W1

W2

4

5kW (‘ER1’ 5kW & ‘ER4’ 0kW) and W2 (second stage)

will have 10kW (‘ER2 & 3’ 5kW each)

1234

Tan

Ora

P2

Side View as seen in Control Box

P1

Staging Example on a 15kW unit W1 (first stage) has

blank

Figure 17: Staging Jumpers

Figure 16: Power Wiring, 4, 5, 8, and 10kw

Electric Heat Wiring

21

2))

21

2))

3

,QDQGN:XQLWV

WZRSRZHUFLUFXLWVDUH

HPSOR\HGWRUHGXFHZLUHV

VL]HDQGFRVWRIEUHDNHUV

/

/

/

/

3

&RQGXLW

MANUAL OPERATING MODE

Y1 COMM OUTPUT OFF

Y2 COMM OUTPUT OFF

W COMM OUTPUT OFF

O COMM OUTPUT OFF

G COMM OUTPUT OFF

H COMM OUTPUT OFF

DH COMM OUTPUT OFF

ECM AIRFLOW 0

PUMP SPEED 0%

TEST MODE OFF

SELECT OPTION

PREVIOUS SELECT

Y1 COMM OUTPUT OFF

W COMM OUTPUT OFF

This manual suits for next models

8

Table of contents

Other ClimateMaster Air Handler manuals

Popular Air Handler manuals by other brands

RDZ

RDZ CHR 120-FC/S Technical installation manual

Bryant

Bryant fe4anf005 installation instructions

Trox Technik

Trox Technik X-CUBE X2 compact 2 Transport and installation manual

MrCool

MrCool PRODIRECT Series Installation & owner's manual

BLAUBERG

BLAUBERG Komfort EC S5B270 S14 installation guide

MrCool

MrCool Olympus Series Installation & owner's manual

Daikin

Daikin DAX Series installation instructions

VES

VES ecovent mini Operation & maintenance manual

Trane

Trane 4TGB3F18A Installer's guide

VTS CLIMA

VTS CLIMA CV-P/230V Operation and maintenance manual

Goodman

Goodman AVPTC42D14 series Installation & operating instructions

Dantherm

Dantherm DanX 2/4 Service manual