ClimateWorx M52 User manual

Advanced M52 Micro processor

User’s Guide for Color Display

ClimateWorx International Inc.

ADVANCED M52UMCT2019 COLOR 14 Chelsea Lane, Brampton, Ontario, Canada L6T 3Y4

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR

2

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR 3

Table of Contents

Sequence of Operation ...................................................................................................................................................... 6

Phase Loss (OPTION):..................................................................................................6

Analogue and digital outputs for functions....................................................................6

DX Demand (Cooling) ...................................................................................................6

Chilled Water.................................................................................................................7

DX Demand (Dehumidification): ..................................................................................7

Rapid Dehumidification Feature (Series 6 units only) ..................................................7

Dual Cooling Units: ......................................................................................................8

Free Cooling Units:.......................................................................................................8

Reheat:...........................................................................................................................9

Humidifier:....................................................................................................................9

PID ..............................................................................................................................10

Internal Safety Controls...............................................................................................10

External Optional Safety Controls...............................................................................10

On/Off Control.............................................................................................................10

Back up Capability ......................................................................................................10

Note: On/Off mode:.....................................................................................................11

Powering Up / Powering Down ...................................................................................................................................... 12

The Control Panel ........................................................................................................................................................... 13

Active tab display area.................................................................................................13

Tab bar.........................................................................................................................13

Operating Status ............................................................................................................................................................. 14

Main Air Temperature & Humidity Readout................................................................14

Process Status Display.................................................................................................14

Network Address ..........................................................................................................14

Unit fan On/Off Icon ....................................................................................................15

Alarm Icon....................................................................................................................15

On/Off Mode Icon ........................................................................................................15

Co-Work™ Address Icon.............................................................................................15

Security ............................................................................................................................................................................ 18

Log-in Security.............................................................................................................18

Log-out Security...........................................................................................................19

Alarms .............................................................................................................................................................................. 20

Active Alarm Queue.....................................................................................................20

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR

4

Clear Alarm Message ..................................................................................................20

Alarm Configuration....................................................................................................21

High Temperature Alarm note:....................................................................................22

Historical Event Log ....................................................................................................................................................... 25

Timer On/Off Schedule ................................................................................................................................................... 26

Review Timer On/Off Schedule....................................................................................26

Programming the Timer On/Off Schedule...................................................................27

Set Clock......................................................................................................................27

Temperature and Humidity Log Graph ........................................................................................................................ 28

Settings ............................................................................................................................................................................. 29

Programming Settings.................................................................................................29

Settings Summary.........................................................................................................30

Settings Summary Glossary.........................................................................................33

Test Mode ......................................................................................................................................................................... 37

Microprocessor Board Diagnostic ..............................................................................37

Digital Board Diagnostic.............................................................................................39

Test Mode Unit on/off..................................................................................................39

Data Re-initialization ..................................................................................................40

Component Configuration ...........................................................................................41

Co-Work™ ....................................................................................................................................................................... 48

Settings Menu, Sensor mode:.......................................................................................49

Alarm Settings, Responses chart: ................................................................................50

Fault Finding ................................................................................................................................................................... 54

High Temperature Alarm.............................................................................................54

Low Temperature Alarm..............................................................................................54

High Humidity Alarm ..................................................................................................55

Low Humidity Alarm....................................................................................................55

High Voltage Alarm.....................................................................................................56

Low Voltage Alarm......................................................................................................56

Low Airflow Alarm ......................................................................................................57

Filter Dirty Alarm........................................................................................................57

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR 5

Fan Overload Alarm....................................................................................................58

Heater Overheat Alarm...............................................................................................58

Boiler Dirty Alarm.......................................................................................................59

High Pressure Alarm...................................................................................................60

Low Pressure or Short Cycling Alarm.........................................................................61

Appendix A: Electrical Schematic Diagrams ................................................................................................................ 62

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR

6

Sequence of Operation

The following is an outline of the operation of the unit. Not all units have all options.

1. Unit powered

2. ClimateWorx Banner appears, controller counts down and beeps ten times.

3. Microprocessor initializes Co-Work and runs self check.

4. Random start timer activates

5. Restart delay counts down

Phase Loss (OPTION):

On loss or cross of a phase of supply power the unit will shut down or display Phase Loss

alarm. You must acknowledge the alarm and correct the phase before the unit will restart.

6. Blower starts (Blower runs continuously) when unit is in the ON position and when

Restart mode is set to Auto.

7. Warm-up period begins to allow time for steady signal from sensors. Temp/Hum readings

flash on screen during warm-up.

8. DX systems, crankcase heaters are energized when compressor is OFF through auxiliary

N/C contact on compressor contactor.

9. Air cooled DX units with flooded condenser Low Ambient Control (LAC) N/C auxiliary

contact on compressor contactor energizes receiver heaters.

Analogue and digital outputs for functions

Cooling 0-10 vdc and 1 or 2 relay outputs

Heating 0-10 vdc and 1, 2 and/or 3 relay outputs

Humidifying 0-10 vdc and 1 relay outputs

Dehumidifying 0-10 vdc and 1 or 2 relay outputs

DX Demand (Cooling)

Cycles on compressors in stages 1 to 32 depending on number of units connected together with Co-

Work as demand for cooling increases from 0 to 100%.

Demand for compressor:

Compressor contactor receives signal from microprocessor. Positive Start timer (Pos. start

delay) starts and bypasses LP switch for cold start-up. When HP switch is closed the start

circuit is complete and the compressor starts.

N/C auxiliary contact on compressor contactor opens and de-energizes receiver heaters.

(Flooded Condenser LAC)

N/C auxiliary contact on compressor contactor opens and de-energizes crankcase heater.

N/O auxiliary contact on compressor contactor enables fans on remote condenser. (Air-cooled

units only)

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR 7

Low-pressure switch remains closed after Pos. start time expires and compressor remains on.

Compressor stops when:

Loss of demand

Compressor contactor opens

Low pressure condition

Compressor stops when LP SW. opens. (Automatic reset) compressor contactor opens.

Short cycling alarm (Low Pressure)

After three consecutive low-pressure alarms in 60 mins, compressor contactor opens. Alarm must

be acknowledged and cleared before Compressor will start.

High pressure condition

Compressor stops when HP Switch opens. (Manual reset)

Compressor contactor opens. Compressor will not start until HP Switch is manually reset and

Alarm is acknowledged and cleared.

Thermal protection opens (automatic reset)

Line voltage cut-outs on all compressors except Specter compressor where the compressor module

causes a Compressor Overload alarm and stops the compressor through the microprocessor.

Compressor module resets after 30 minutes.

Note: Anytime the contactor opens the comp. elapse timer keeps compressor off for 3 minutes

(adjustable)

Chilled Water

On demand for cooling or dehumidification chilled water valve opens as demand signal ramps up

from 0 to 100%. Valve operates on 0-10 Vdc.

Valve closes when:

Loss of demand, signal diminishes to 0 Vdc

DX Demand (Dehumidification):

Cycles on compressors in stages 1 to 32 depending on Series and number of units connected together

with Co-Work as demand for dehumidification increases from 0 to 100%.

Variable speed fans (if available) will nominally slow down to accelerate this process. See settings

tab.

Demand for compressor:

Compressor contactor receives signal from microprocessor. Positive Start timer (Pos. start delay)

starts and bypasses LP switch for cold winter start-up. When HP switch is closed the start circuit

is complete and the compressor starts.

N/C auxiliary contact on compressor contactor opens and de-energizes receiver heaters. (Flooded

Condenser LAC)

N/C auxiliary contact on compressor contactor opens and de-energizes crankcase heater.

N/O auxiliary contact on compressor contactor enables fans on remote condenser. (Air-cooled

units only)

Low-pressure switch remains closed after Pos. start time expires and compressor remains on.

Rapid Dehumidification Feature (Series 6 units only)

If there is less than 20 percent demand for cooling and a demand for dehumidification the Dehum.

Solenoid valve (DSV) closes.

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR

8

The Dehum. Solenoid (DSV) closes off refrigerant flow to part of the evaporator coil. This

causes a drop in suction pressure and a lower coil surface temperature over a portion of the coil.

The coil begins to remove more moisture as a result. The air is partially reheated, as the air

through the inactive part of the evaporator is unconditioned. This creates an overall drop in the

sensible heat ratio (Rapid Dehumidification)

During dehumidification demand, some sensible cooling takes place. Under very low load

conditions, the sensible cooling affect maybe greater than the combined offsetting effect of the

heat load plus the available reheat capacity, which may cause a drop in room temperature. If

temp continues to drop and is less than (set point MINUS (temp dead band DIVIDED by 2)

MINUS heating proportional band) the compressors will stop overriding the demand for

Dehum. The temperature must return to set point before another cycle of dehumidification

starts.

ie: Low limit cutout =Set point – (temp deadband 2) – heating propband

Compressor stops when:

Loss of demand

Compressor contactor opens

Low pressure condition

Compressor stops when LP SW. opens. (Automatic reset) compressor contactor opens.

Short cycling alarm (Low Pressure)

After three consecutive low-pressure alarms in 60 minutes, compressor contactor opens.

Alarm must be acknowledged and cleared before Compressor will start or cycle power.

High pressure condition

Compressor stops when HP Switch opens. (Manual reset)

Compressor contactor opens. Compressor will not start until HP Switch is manually reset

and Alarm is acknowledged and cleared.

Thermal protection opens (automatic reset)

Line voltage cut-outs on all compressors except Specter compressor where the compressor

module causes a Compressor Overload alarm and stops the compressor through the

microprocessor. Compressor module resets after 30 minutes.

Low limit temperature

If return air temperature continues to drop and is less than (setpoint MINUS (temp dead

band DIVIDED by 2) MINUS heating proportional band) the compressors will stop

overriding the demand for Dehum.

Note: Anytime the compressor contactor opens the comp. elapse timer keeps compressor off

for 3 minutes (adjustable). There is also a compressor minimum runtime of 3 minutes

(adjustable) which will prevent the compressor from being turned off by the control. The

compressor can stop during this time through high or low pressure or by cycling the power.

Dual Cooling Units:

Dual cooled units operate on DX as described above in DX Cooling Demand and DX

Dehumidification Demand. In DX mode the chilled water valve is closed. When a remote

signal contact input closes on Compressor Disable Terminal 31 and 32 the compressors will

stop and the unit will operate as described in Chilled Water above.

Free Cooling Units:

Free cooling units operate on DX as described above in DX Cooling Demand and DX

Dehumidification Demand when the glycol loop or outside air temperature is above 7.2C, (45F

adjustable). The modulating glycol valve or output signal for outside air dampers begins to open when

the difference between the return air temperature (Temp Return Air) and the entering glycol

temperature or outside air temperature (Temp EGT/ Ambient) is greater than 3C, (6F adjustable).

The unit will operate in Free Cooling as long as the cooling demand remains in the 0-50% range.

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR 9

Once the cooling demand reaches 51-99% range the unit will operate with one circuit in Free Cooling

and the opposite circuit in DX Cooling. If the cooling demand reaches 100% then the unit will switch

to DX cooling only.

When the glycol or outside air temperature drops below 7.2C (45F adjustable) the compressors will

stop automatically. The unit will operate in Free Cooling mode only at this time. The glycol or outside

air temperature is monitored by the unit using Temp EGT/ Ambient input. Temp Return Air and Temp

EGT/ Ambient can be viewed in the Settings Tab on page one. If the Glycol or Outside Air

Temperature drops below 0C, (32F) the unit will switch to DX cooling only as this too low of a

Glycol fluid or outside air temperature would cause any condensation on the evaporator coil to freeze.

Note: The Status screen on the controller indicates full free cooling is on when it displays 2/2 and will

display 1/1 in combination with DX cooling. Free cooling is off when it displays 0/2 or 0/1 under the

percentage demand next to the Free Cooling icon. The percentage of free cooling in 2/2 will show

double what the main cooling bar is showing. This percentage is reflective of the % that each valve is

open.

Reheat:

On demand for reheat the demand signal ramps up and heater contactor closes at 33% demand. SCR

or Hot Water/ Steam Reheat Valve modulates from 33% to 100% output to match the demand signal.

Once demand has been satisfied the SCR or Hot Water/ Steam Reheat Valve modulates down to 0%

and the heater contactor opens. On Multi-stage heaters each stage will be energized at equal intervals

as the demand increases from 0 to 100%. Stage 1 activates at 33%, Stage 2 activates at 66%, Stage 3

activates at 99%. When demand is met stages deactivate at Stage 3 deactivates at 66%, Stage 2

deactivates at 33% and Stage 1 deactivates at 0% heating demand.

Hot gas reheat only operates on demand for reheat during a dehumidification cycle as the demand

signal ramps up the Hot Gas reheat solenoid valve is activated at 33% reheat demand and remains

open until reheat demand decreases to 0%.

Heater stops when:

Loss of demand

Loss of air flow

Heater high temp cut out

Humidifier:

When the “On/Off/Drain “ switch is in the “On” position, a demand for humidification causes the

humidifier contactor(s) to close in stages 1 to 16, (depending on the number of units connected

together with Co-Work), as demand for humidification increases from 0 to 100%.

After a short time delay, approximately 1 to 3 minutes, the fill valve will energize allowing water to

fill the boiler bottle. The fill valve closes when the humidifier reaches its FLA current or when the

water level reaches the high water level sensor. Water begins to boil after a few minutes. The

humidifier will continue to boil and fill to maintain the humidity set point. Periodically the humidifier

will initiate a flush cycle to maintain constant steam output and to flush some of the mineral content

from the boiler bottle.

When the boiler bottle reaches the end of its useful life it will activate a Boiler Dirty Alarm and will

shut off the humidifier. It is common for the Boiler Dirty Alarm to sound on an initial start-up as the

humidifier begins the process of concentrating the mineral content of the contained water.

To drain the humidifier you must cause a humidification demand and then switch the “On/Off/ Drain”

switch to Drain. You must set the switch back to “Off “when the bottle has completely drained.

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR

10

Humidifier stops when:

“On/Off/Drain” switch is switched "Off" or “Drain”

Loss of demand

Loss of air flow

Humidifier Service Alarm intervention.

PID

The M52 microprocessor uses PID control logic to maintain the set point conditions. The following

parameters are adjustable so the controller can be fine-tuned to specific site conditions.

Dead band, temp. humid. dead band

Cool prop. band

Heating prop. band

Humidifying prop. band

Dehum. prop. band

Integral time temp

Integral time hum.

Internal Safety Controls

Fuses (60 Hz), circuit breakers (50 Hz) on all components

Fan overload relay (Vertical floor mount, VFM systems only)

Air proving switch (Vertical floor mount, VFM systems only)

Dirty filter switch (Vertical floor mount, VFM systems only)

High pressure refrigerant (manual reset)

Low pressure refrigerant

Internal thermal protection compressor

High temp cut out for heater

High water level sensor/ current transducer

Compressor elapse timer

Crank case heaters

External Optional Safety Controls

Fire stat or Smoke detector terminals 19 and 20

EPO terminals 19 and 20

On/Off Control

Local Mode:

When the controller is set to Local Mode, On/Off control of the unit is controlled by the keypad

When the controller is set to Remote Mode, On/Off control can also be controlled by a remote signal

through terminals 15 and 16. When this is active, On/Off control of the unit cannot be controlled by

the keypad

Timer Mode:

When the controller is set to Timer, On/Off control follows the time schedule programmed on the

controller. Unit can be set to be On, Off or Relax. Relax mode cause the microprocessor to control

using the RELAX deadbands which are programmable. In this mode the fan continues to operate.

Back up Capability

Standby Enable:

Each unit sends an output to start a back up unit in the event of an alarm condition as configured in the

Alarm Response menu. Terminals 11 and 12

Standby Start:

Each unit accepts an input signal to start regardless of its On/Off mode state at terminals 17 and 18

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR 11

Note: On/Off mode:

When operating in a Co-Work network all On/Off mode options are synchronized. Therefore,

turning off a unit, either by the touch screen when in Local, by the remote on/off at terminals 15

and 16 when in Remote, or through the schedule when in Timer mode will turn off all units in

that network.

To turn off an individual unit either as a stand-alone or in a Co-Work network see the Test Mode

section or simply open the disconnect switch.

Local/Remote RemoteON/OFF RemoteDem.Off StandbyStart UnitOperation

Local OFF OFF OFF STOP

Local ON OFF OFF RUN

Local OFF ON OFF Stop

Local OFF OFF ON RUN

Local ON ON OFF STOP

Local ON ON ON RUN

Local OFF ON ON RUN

Local OFF OFF OFF RUN

Local ON OFF OFF RUN

Local OFF ON OFF STOP

Local OFF OFF ON RUN

Local ON ON OFF STOP

Local ON ON ON RUN

Local OFF ON ON RUN

Remote OFF OFF OFF STOP

Remote ON OFF OFF RUN

Remote OFF ON OFF STOP

Remote OFF OFF ON RUN

Remote ON ON OFF STOP

Remote ON ON ON RUN

Remote OFF ON ON RUN

Remote OFF OFF OFF RUN

Remote ON OFF OFF RUN

Remote OFF ON OFF STOP

Remote OFF OFF ON RUN

Remote On ON OFF STOP

Remote On ON ON RUN

Remote OFF ON ON RUN

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR

12

Powering Up / Powering Down

The first powering up must be performed by CLIMATEWORX authorized

personnel only. Failure to do so may damage the unit and void the warranty.

The main power switch (rotary disconnect) is located on the front of the unit. Series 6, 8, 9 and

P only. For Series 7 and 11 it is located inside electrical panel

Immediately after turning on the main power switch, the control system will perform the

following power up sequence:

1. The control system will generate three short “beep” sound to alert power has been

applied and the unit is about to start.

2. The control system will then perform a self-test and verify all stored setting and data are

within valid range.

3. After the self-test, the control system will count down the programmed “Restart delay”

time and then put the system into normal operation.

To power down unit:

For units in Local Mode log into appropriate security level (refer to Log-in Security). An

On/Off toggle switch will appear on the bottom left corner of the display. Press “O” to power

down unit. Once fan stops, open disconnect.

For units in Timer or Remote Modes, log into security level three, change On/Off mode to

“Local” (Settings tab, page 4). Follow above procedure to power down unit.

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR 13

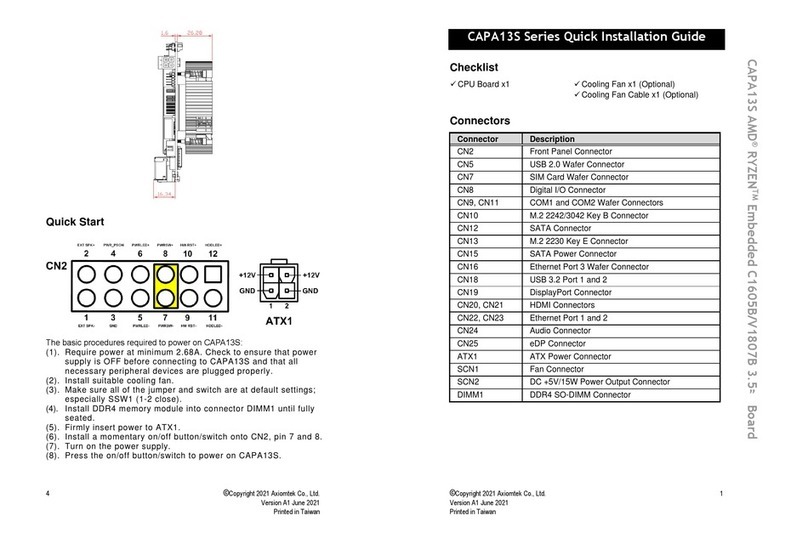

The Control Panel

The control panel is formed by a graphic LCD display and an overlay touch screen keypad. The

layout of the screen consists of three distinctive regions - the Banner line, the Active tab display

area and the Tab bar. The tabs are set-up like the tabs in a 3-ring binder. Each section contains

different information.

A

ctive Tab Display Area

T

ab Bar Banne r Line

The Banner line shows the current date and time. Date is in DD/MM/YYYY format and time in

24-hour HH:mm format.

Active tab display area

Data and information are grouped into tabs for ease of retrieval. The Active tab display area

shows information corresponding to the current selected tab.

Tab bar

Tab bar shows the available tabs and allows user to switch tab display by pressing the

corresponding tab icon. There are 7 tabs in the Tab bar:

Settings Tab

Testmode Tab

Alarm Tab

Timer On/ Off Schedule Tab

Historical Event Tab

Temperature and Humidity Graph Tab

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR

14

Operating Status

Main air humidity

Alarm description

Main air temperature

Co Work address icon

System Type

Alarm Icon

Unit fan on/off icon

On/Off Switch

Main Air Temperature & Humidity Readout

The main temperature & humidity readout shows the values of the sensor set to control the

system “Control Sensor”. Temperature readout can be displayed in either °C or °F depending

on the setting “Temp units”.

Process Status Display

This region shows the current operating status of the system by means of graphic icons and

analogue bar.

Cooling Heating

Dehumidifying Hum idifying

Free Cooling

shows when active)

Network Address

This shows the Network address set in setting “Network address”. Every unit in the network

must be set to a unique address. This address relates to the RS485 serial communication buss.

The terminal connection is P501 on main board with a native output protocol MODbus RTU.

Follow the field wiring diagram as shown on page 70.

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR 15

Unit fan On/Off Icon

The unit fan on/off icon appears when the unit fan is running except during fan purge delay the

icon does not appear while the fan continues to operate for this period of time.

Alarm Icon

The alarm icon shows up if there is any active alarm in the system. You can review the details

of the alarm in the {Alarm} tab.

On/Off Mode Icon

The On/Off mode icons keep you aware of the current On/Off mode selection. The On/Off

mode selection can be set in the “On/Off mode” setting under the {Setting} tab for local, remote

and timer modes. Remote on/off and Standby Start Icons will appear only when the function is

active.

Local on/off control via control panel

Remote on/off control via switch input

Programmed timer schedule auto on/off

Standby start back-up start mode

Co-Work™ Address Icon

This shows the Co-Work™ operation mode and Co-work network address.

Duty Unit (e.g. Address 1) Standby Unit (e.g. Address 1)

Co-work icon is always visible but will only be blue when unit is connected in a co work

network and the unit is in the standby mode.

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR

1

6

Every master unit in the Co-Work™ network must have a unique address which can be set

through the DIP switches on the main board. Jumpers must also be installed on 2 units in each

Co-work network at position JP401 shown below.

LED Flash Fast- Single Unit, Flash Slow- Master Unit, Solid ON- Slave Unit

Co work DIP Switches SW402

Co work Jumper JP401

Co work LED Y202

Fig 1.MainBoard DIP Switch

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR 17

This is CAN ID and is only used for co-work.

CANBUS ID

1

2

3

4

1 0 0 0 0

2

0

0

0

1

3

0

0

1

0

4

0

0

1

1

5

0

1

0

0

6

0

1

0

1

7

0

1

1

0

8

0

1

1

1

9

1

0

0

0

10 1 0 0 1

11 1 0 1 0

12 1 0 1 1

13 1 1 0 0

14 1 1 0 1

15 1 1 1 0

16 1 1 1 1

Each display must have the corresponding Co-work address selected to display in the upper

right hand corner. This is done by logging in with level 1 pass word and then touching the co work

icon in the upper right hand corner. Selected the appropriate number of icon to correspond with the

addressing of the main board done in the previous step.

Note: In the Co-work configuration the member with the lowest Co-work number will always be the

master unit.

Co Work network active Icon

Select unit Icon

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR 18

Security

To prevent unauthorized interference with the system operation and settings, the M52

Microprocessors have three levels of security that can be assigned to different personnel having

different responsibilities.

Settings can only be altered after entering the four-digit password for the corresponding security

level.

The factory default password and access right for each security level is summarized in the

following table:

Function / Description Admin Factory User

Default password 1024 4321 1234

Local on/off control

Alarm clear

Alarm configuration

Time schedule / clock

Setting - configuration 1

Setting - configuration 2

Setting - control parameter

Test mode – Data Re-initialization

Test mode – Local net setting

Test mode – Server setting

To invoke security log-in or log-out, simply press the tab at log-in or log-out:

Press tab

not logged-

in

yet

already logged-in

Log-in Security

On the first power-up, you can log-in to security by using the factory preset password “1024”,

“4321” and “1234” for security level Admin, Factory and User respectively.

Advanced M52 Microprocessor User's Guide

ADVANCED M52UMCT2019 COLOR 19

Log-out Security

Exiting the security can be achieved by pressing the Log-out key in the log-out / change

password screen.

Password Entr

y

Ke

y

s

Securit

y

level selector

The system will also automatically re-lock security approximately 1 minute after the last key is

released.

Table of contents

Popular Computer Hardware manuals by other brands

NEC

NEC N8151-53 user guide

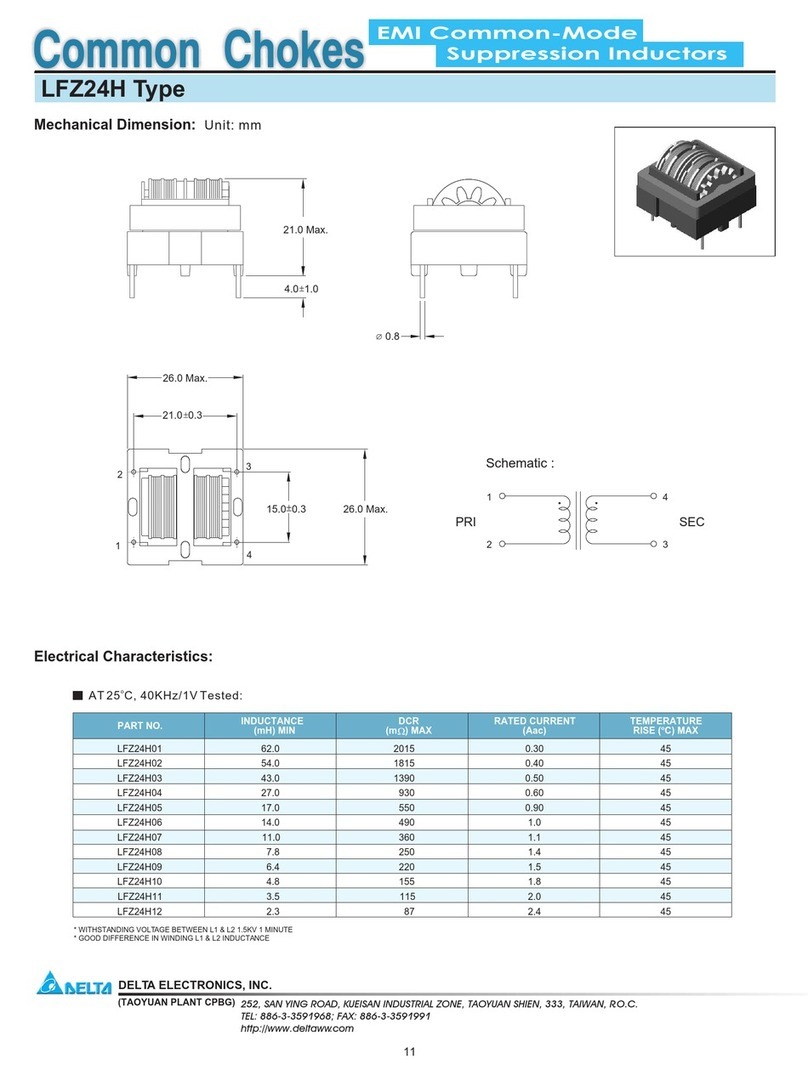

Delta Electronics

Delta Electronics Suppression Inductors LFZ24H Specification sheet

Nexo

Nexo Digital TDcontroller Series user manual

Siemens

Siemens SIMATIC NET CP 5613 A2 operating instructions

HighPoint

HighPoint Rocket 1120 Quick installation guide

Pico Macom

Pico Macom SC-3 Installation and operation manual