CMS Marine SonicShield I Micro User manual

This manual suits for next models

1

Table of contents

Popular Marine Equipment manuals by other brands

MIVARDI

MIVARDI MX33 user manual

Boss Audio Systems

Boss Audio Systems MR637U Manual de usuario

APPLIED ACOUSTICS SYSTEMS

APPLIED ACOUSTICS SYSTEMS Easytrak Nexus Lite 2695 Operation manual

Vetus

Vetus EC3 Operation manual and installation instructions

Marina

Marina BU3050 Installation, maintenance and operation manual

Simrad

Simrad EQ 50 Maintenance manual

Teledyne RD Instruments

Teledyne RD Instruments EXPLORER Integration guide

Power-Pole

Power-Pole Graphics Wrap installation instructions

Raymarine

Raymarine i60 wind Installation & operation instructions

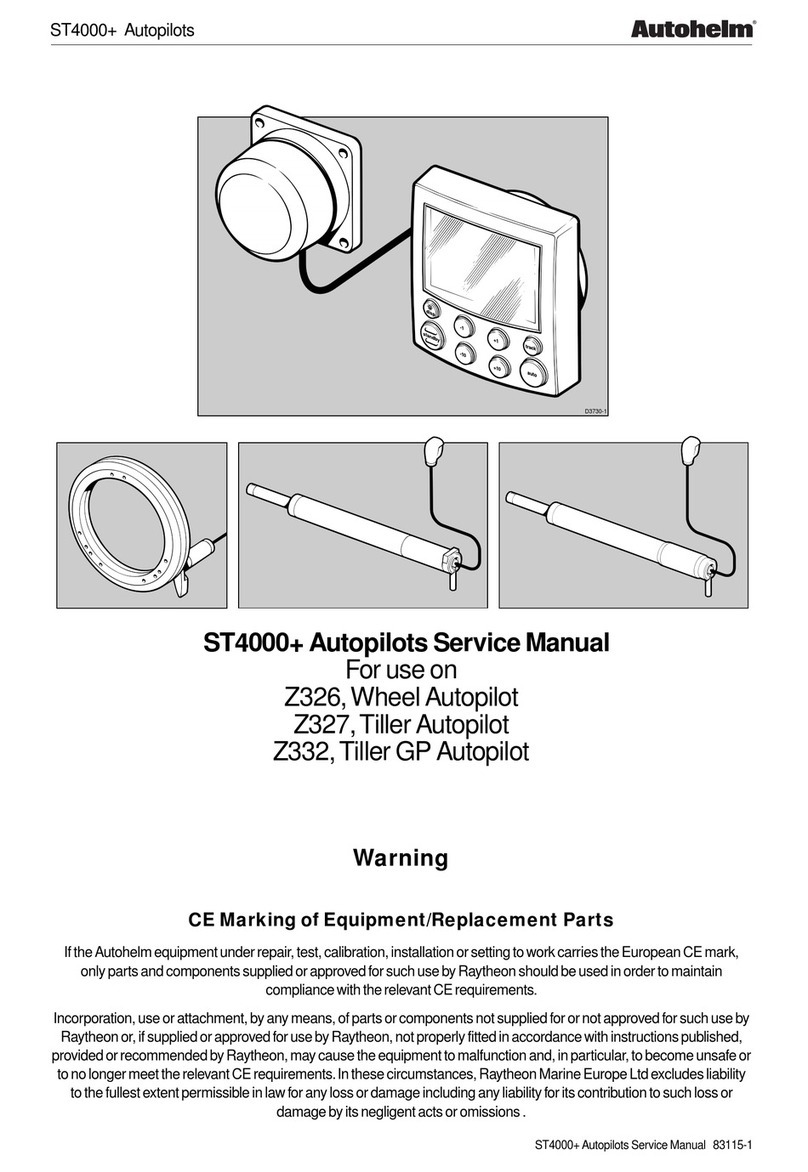

Raymarine

Raymarine autopilot ST4000+ Service manual

1st-Relief

1st-Relief VersaChock 1st23VCWHITE4PK manual

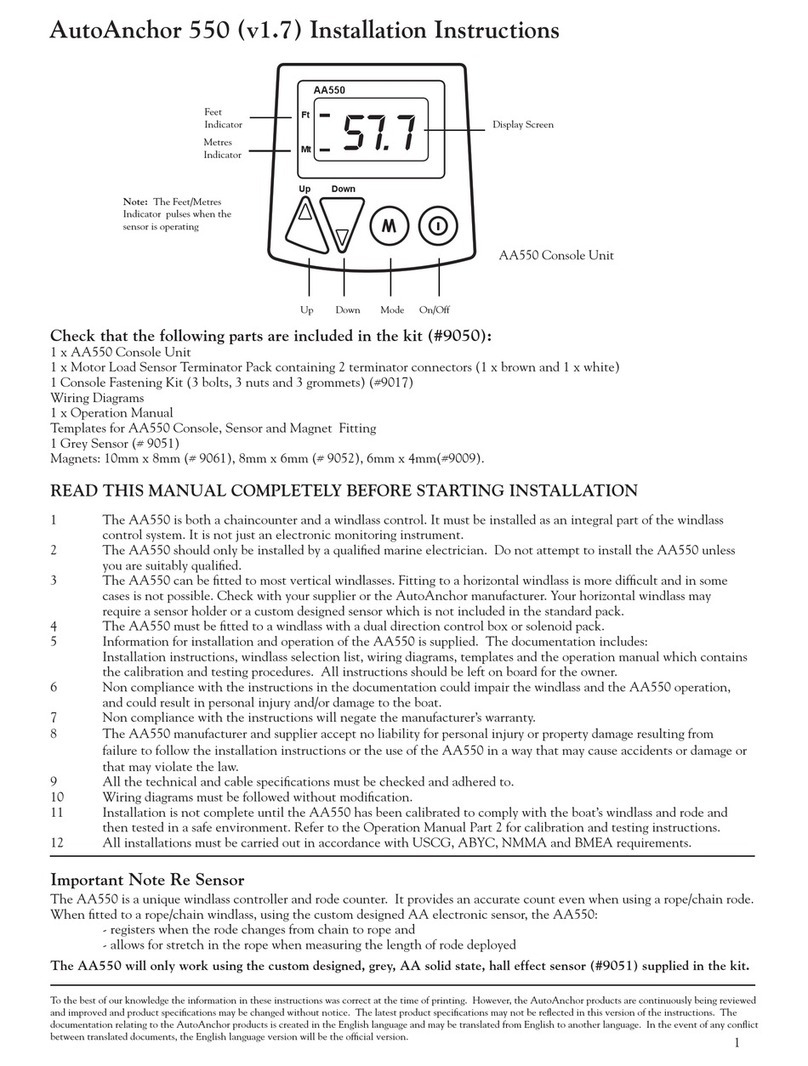

Lewmar

Lewmar AA550 installation instructions

auto maskin

auto maskin Marine Pro 400 Series Quick installation guide

NASA Marine

NASA Marine CLIPPER SPEED AND DISTANCE LOG manual

Furuno

Furuno Sc 50 Operator's guide

allpa

allpa TWIN DISC TECHNODRIVE MC 60 A Service manual

TRAC

TRAC Impeller Puller instructions

Simrad

Simrad NX40 Installation & operation manual