CNC FACTORY V300 Series User manual

[USER GUIDE]

V300 SERIES VACUUM PUMP

User Guide © CNC Factory | Rev04222021

2

V300 SERIES VACUUM PUMP

LEFT SIDE

Grease Gun

MPa Gauge

& Valve

Filter

Filter

In-line Filter

In-line Filter

RIGHT SIDE

TOP VIEW

User Guide © CNC Factory | Rev04222021

3

V300 SERIES VACUUM PUMP

Please follow all the guidelines under this manual pertaining to the installation,

operation and maintenance of your V300 Series Vacuum Pump (“V300 Pump” or

“pump”).

To move the V300 pump, only use the lifting bolts on top of the pump. Verify the tightness of the rigging

before moving. The V300 pump always requires dry storage.

Install the V300 pump in a position for

easy maintenance access. However,

it should be 12” away from any wall or

obstacle to ensure that airflow and

cooling is not impeded. The ambient

temperature should not exceed 110

degrees.

The V300 Pump produces hot temperatures on the pump and the air exiting the pump.

To avoid contact with its hot surfaces:

• Install the pump in the proper, upright position on a stable surface. Allot a

minimum 12” clearance on all sides of the pump.

• Install warning signs around and/or block accidental access to the pump

via enclosures or barriers

• The V300 pump can be used to generate a vacuum (KVE).

• The V300 pump is a dry vane pump and does not require oil. It cannot be used with toxic or flammable

materials.

• Its inlet takes in dry, clean air free of dust and debris. Air with dust and debris will lead to internal vane

and structural damage and degrade the pump’s performance.

GENERAL

TRANSPORT AND STORAGE

INSTALLATION

READ BEFORE INSTALLATION

User Guide © CNC Factory | Rev04222021

4

V300 SERIES VACUUM PUMP

The in-line vacuum filter should always be used to help capture

any dust or debris. Having an in-line filter between the pump

and machine ensures proper operation of your pump. During

the initial installation, check the filter chamber and blow off/

remove any debris. For many new installations, there is usually

some leftover debris from the machine hose or vacuum table.

Make sure to check the in-line filter at least once a month.

IN-LINE FILTER

The in-line vacuum filter should always be used to help capture

any dust or debris. Having an in-line filter between the pump

and machine ensures proper operation of your pump. During

the initial installation, check the filter chamber and blow off/

remove any debris. For many new installations, there is usually

some leftover debris from the machine hose or vacuum table.

Make sure to check the in-line filter at least once a month.

IN-LINE FILTER

The V300 pump comes with fittings for 3”. The vacuum hose

should not exceed a 20’ distance between the machine

manifold and the air in-line filter.

VACUUM HOSE DIAMETER

Before installing the machine, consider the availability and proximity of the required power supply circuit.

If an existing circuit does not meet the requirements of this machine, a new circuit must be installed. To

minimize the risk of fire or equipment damage, electrical work must be done by a licensed electrician or

qualified service personnel in accordance with all applicable codes and standards.

ELECTRICAL CONNECTION

The full-load current rating is the amperage the V300 pump draws at 100% of the rated output power. On

machines with multiple vacuum motors, this is the amperage drawn by the sum of all vacuum motors and

any electrical device that might operate at the same time.

FULL-LOAD CURRENT RATING

User Guide © CNC Factory | Rev04222021

5

V300 SERIES VACUUM PUMP

220 Volt Configuration 380 Volt Configuration

• The number of switches (turning the machine on

and off) per hour should not exceed 6 times

• Once power is installed, turn on the machine to

allow the motor to slightly turn. Then, check is the

rotation is correct (it should match the directional

arrows on the vacuum pump case). If the rotation

is incorrect, switch a wire leg at the terminal.

Configure the wiring and disconnect according to the electric motor configuration and model:

Model V300: Full-Load Current Rating at 220V…..40 Amps

Model V300: Full-Load Current Rating at 380V…..32 Amps

Model V340: Full-Load Current Rating at 480V…..25 Amps

Model V340: Full-Load Current Rating at 720V…..12.5 Amps

Directional Arrows

User Guide © CNC Factory | Rev04222021

6

V300 SERIES VACUUM PUMP

GENERAL PUMP DESCRIPTION

KL: Cylinder Air Duct

SD: Rear Inner Vane Cover

BC: Vacuum Air Intake

SA: Vacuum Access Port

GD: Side Filter Cover

SV: Vacuum Air Safety Valve

AS: Vacuum Silencer

SN: Grease Inlet

LH: Rear Pump Cover

GD

SA

SV AS

LH

BC

SN

KL

SD

GD

FILTER

User Guide © CNC Factory | Rev04222021

7

V300 SERIES VACUUM PUMP

Hose or

PVC Pipe

Air

Filter

Single

Direction Valve

Bypass

Port

Power

Box

Exhaust

Port

FILTER ASSEMBLY

Assemble the pump as shown below. The blue arrow indicates the air flow direction. The air filter and

single direction valve both have directional arrows marking the correct direction. Make sure they match

with the blue arrow.

Remove all plastic protection covers on both ports before powering on the pump. Use Teflon tape on all

pipe thread; be careful not to over thread the pipe.

User Guide © CNC Factory | Rev04222021

8

V300 SERIES VACUUM PUMP

Regular maintenance of the V300 pump allows it to maintain optimum operating conditions. Each

maintenance cycle depends on how much the pump is used as well as its work environment (i.e. degree

of dust generated and hours used). Minimum maintenance should be performed monthly until a regular

maintenance schedule can be established based on your usage and environment.

Before performing maintenance or servicing your V300 pump, disengage the electrical

power to the pump to ensure there is no chance for an accidental start.

The filter cartridge is installed behind the side

cover (GD location) and is cleaned to remove

dust and debris accumulation. When cleaning,

use compressed air to clean the filter inside out.

Adjust your maintenance schedule based on dust

and debris accumulation here. A clean side filter

is crucial to proper operation and warranty

coverage!

The filter cartridge is installed inside the vacuum

intake housing (GD location) and is cleaned to

remove dust and debris accumulation. When

cleaning, use compressed air to clean the filter

inside out. Adjust your maintenance schedule

based on dust and debris accumulation here. A

clean vacuum intake filter is crucial to proper

operation and warranty coverage!

MAINTENANCE

Standard Scheduled Maintenance:

Cleaning the Intake Filter

Cleaning the Vacuum Intake Filter

User Guide © CNC Factory | Rev04222021

9

V300 SERIES VACUUM PUMP

Blow compressed air into the cylinder air duct (KL

location) to remove any build up.

Cleaning the Cylinder Air Duct

Lubrication

The V300 pump requires lubrication every 300

hours of use to ensure enough grease to lubricate

its bearings. Install grease at both SN locations until

the grease starts to back out from the input plug. For

new installations, lubricate after the first 3 months of

use. Your vacuum includes a grease gun. Refills can

be purchased from CNC Factory or at most hardware

stores. Regular lubrication is crucial to proper

operation and warranty coverage!

Use Klüber PETAMO GY 193

lubrication. Apply 5 grams to

each grease port.

Use

lubrication. Apply 5 grams to

each grease port.

SN

User Guide © CNC Factory | Rev04222021

10

V300 SERIES VACUUM PUMP

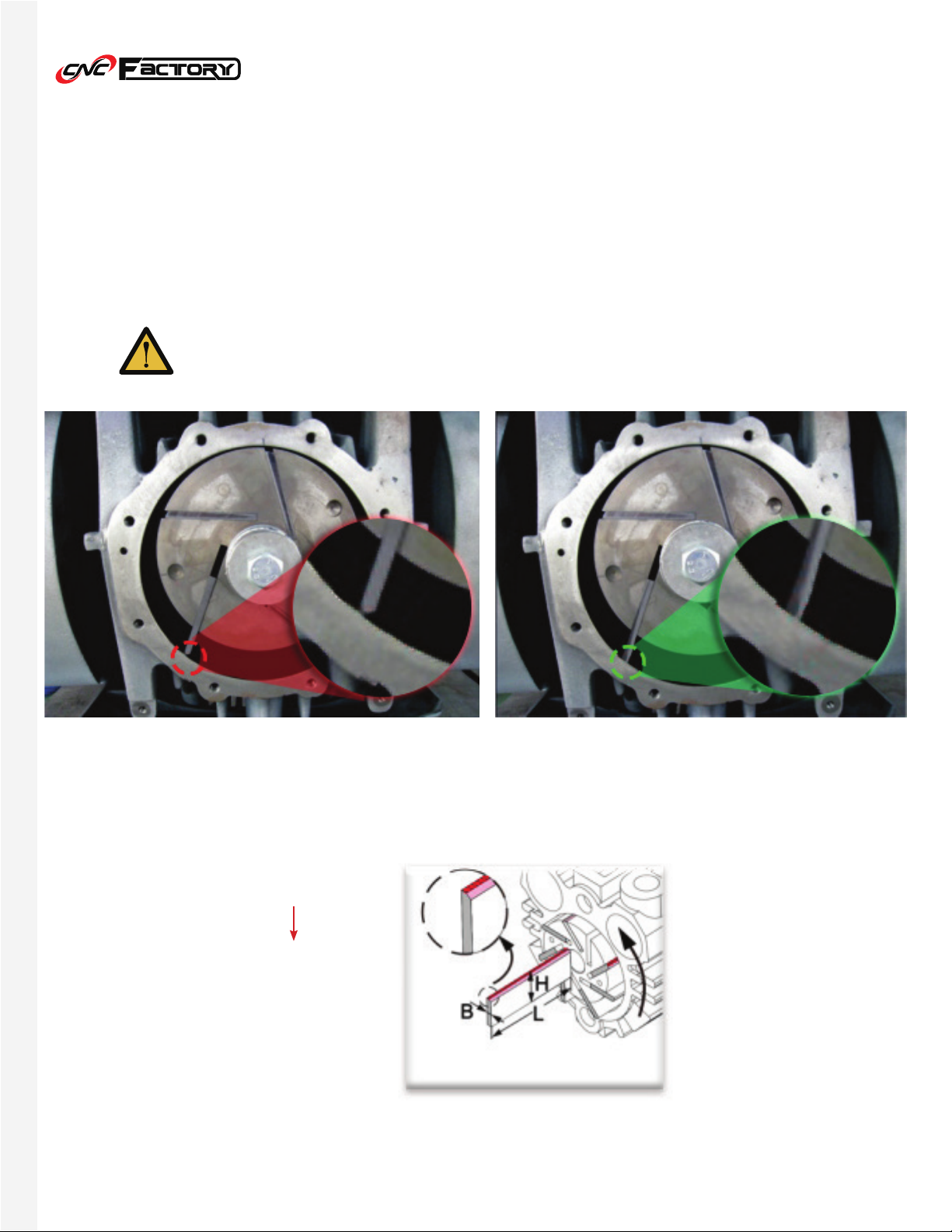

Carbon vanes are installed INCORRECTLY Carbon vanes are installed CORRECTLY

L = 355mm

H = 65mm

B = 5mm

H = 65mm

41mm

The V300 pump uses Rotary Vane Technology to perform robust vacuum pressure. The vanes

should be checked after 3,000 hours of use or at least once a year. Check the width of the blades

(see table for minimum width) to see if they need replacement. Blades will eventually wear out due

to the friction the rotary vanes have with the inner wall.

Annual Cleaning or Vane Replacement

Wear a mask, gloves and safety glasses when cleaning or replacing vanes

User Guide © CNC Factory | Rev04222021

11

V300 SERIES VACUUM PUMP

1. To access the inside, slide open both the rear case

cover (LH) and side case cover (SD). You will need to

remove 8 bolts.

2. Carefully open the belt by unscrewing the next 2

bolts and slowly remove the blades from the rotor.

3. Do not use external force on the rotor while touching

the blade.

4. Make sure it is clean and free from dust and debris.

5. When assembling the blades back, note that the

blade should be 1-2mm from the end of the rotor.

6. Check the oil seal.

7. Clean the grease on the rotor shaft and carefully put

back the cover of the rotor.

8. If the screws do not immediately fit, slightly raise the

cover so the screw hits precisely the center of the

hole. Tighten when it’s locked in.

9. Check if the rotor turns easily.

Table of contents

Popular Water Pump manuals by other brands

Dekker

Dekker Maxima-K 1 Series Installation, operation and maintenance manual

Hydra-Cell

Hydra-Cell T100 Series Installation operation & maintenance

Stryker

Stryker TP600 Service manual

Pentair

Pentair Myers SRM4 Series Installation and operation manual

BUSCH

BUSCH COBRA NC 0630 instruction manual

Champion Pump

Champion Pump CPSE manual