Dekker Maxima-K 1 Series User manual

DEKKER Vacuum Technologies, Inc./Maxima-K/June2007 1

Installation

Operation

and

Maintenance

Manual

Large capacity

liquid ring vacuum pumps

series-1

series-2

series-3

SERIAL NO.:___________________________ June 2007/1

Model Numbers Subject to Change

DEKKER Vacuum Technologies, Inc./Maxima-K/June2007 2

INTRODUCTION

The Maxima-K (series 1, 2 and 3) liquid ring vacuum pump guarantees you improved reliability and reduced

maintenance costs. Compared with other vacuum pumps the Maxima-K water-sealed liquid ring vacuum pump

system offers the advantages of no metal-to-metal contact between the impeller and casing. Grease lubricated

bearings are mounted external to the pumping chamber, isolated by packed gland or mechanical shaft seals.

This means that the pump requires no internal lubrication.

DEKKER pumps and systems have been designed to provide safe and reliable service with low maintenance.

Because a vacuum pump is a rotating piece of equipment, the operator must exercise good judgment and

follow proper safety procedures to avoid damage to the equipment or personal injury. Please review and follow

all instructions in this manual before attempting to install, start or operate equipment.

Safety

All products offered by DEKKER have been designed and manufactured for safe operation. However, the

responsibility for safe operation rests with those who use and maintain these products. Your safety department

should establish a safety program based on OSHA, federal, state and local codes. It is important that due

consideration be given to hazards which arise from the presence of electrical power, hot liquids, toxic gases and

rotating equipment. Proper installation and care of protective devices is essential to safe system operation.

These safety procedures are to be used in conjunction with the instructions contained in this manual.

STORAGE

Keep the pump in a cool dry environment and close the seal fluid isolation valve. Plug all open ports to keep

out dirt and foreign objects. Every 2 - 3 months add a small amount of rust inhibitor into the inlet of the liquid

ring pump and rotate the impeller by rotating the shaft by hand.

If the pump has been idle for more than 2 years, replace the bearing grease before starting up. Use #3 lithium

grease.

After a long idle period, empty the pump completely and remove any scale deposit by using the specially

formulated DEKKER descaling compound Scale-Ex. When the descaling process is complete, add a small

amount of rust inhibitor and rotate the impeller by rotating the shaft by hand. If you cannot rotate the shaft

because the impeller is locked up, contact the factory.

INSTALLATION

The design of the piping system, foundation layout and plant location are the responsibility of the purchaser.

DEKKER Vacuum Technologies, Inc. and its representatives may offer advice but cannot assume responsibility

for operation and installation design.

Please consult an authorized dealer or a specialist skilled in the design of plant layout, system piping design

and foundation design. The installer should carefully read this manual before installing the equipment.

DEKKER or your local dealer can provide start up assistance in most instances at reasonable cost.

Unpacking

Upon receipt of pump or system, immediately inspect for signs of damage. Carefully remove the packing

or crating from around the pump or system. Be sure to keep equipment in the upright position. DEKKER

products are shipped F.O.B. factory, which means that any damage is the responsibility of the carrier and

should be reported to them.

Lifting

Lift the equipment carefully and with weight evenly distributed. DEKKER is not responsible for equipment that

has been damaged through mishandling or dropping.

Location

Install the unit in a well ventilated and dust free area. The pump or system should be a minimum distance of 3

feet from surrounding walls to allow for checking fluid level, temperatures, pressures and general servicing.

Mounting

The pump or system must be installed on a level surface in a horizontal position. The foundation must be

designed to support the total unit weight, without any settlement or crushing, be rigid and substantial enough

to absorb any equipment vibration, maintain true alignment with any drive mechanism, and must permanently

support the baseplate at all points.

DEKKER Vacuum Technologies, Inc./Maxima-K/June2007 3

The vacuum pump system must be leveled and secured with foundation bolts. Foundation bolts must be of

adequate size to withstand the mechanical stresses exerted on it.

All systems should also be grouted into position. The foundation should be constructed to allow for ¾ to 1-½

inch of grout. The baseplate is set on shims and the grout is poured between the foundation and the

baseplate. To have the required body to support the baseplate, grout should be at least ¾ inch thick.

The number and location of shims will be determined by the design of the baseplate. Firm support should be

provided at points where weight will be concentrated at the anchor bolt locations. Use enough, and large

enough shims to provide rigid support. Baseplates are usually designed with openings to allow pouring grout.

When the baseplate has been shimmed and leveled and the anchor bolts have been snugly tightened, a dam

is constructed around the foundation to contain the grout. The dam level should be at least ½ inch above the

top surface of the shims. Grout should be poured inside and around the outside of the baseplate and leveled.

Allow the grout to dry for a minimum of 48 hours before tightening the anchor bolts.

Please note that the pump/motor coupling and V-belt units will need to be realigned prior to start-up,

except with monoblock units.

WORKING PRINCIPLE AND CONSTRUCTION

Working Principle

Liquid ring

Inlet port

Discharge port

Casing

Rotor

The rotor is mounted off-center in a cylindrical pump casing. As the impeller revolves in the direction of the

arrow , the seal liquid forms a liquid ring by centrifugal force. As a result, a half moon shape is developed

between the rings inner face and the rotor hub. When the impeller goes from point A to point B, the pocket

between the two adjacent blades will increase with gas drawn in. When the rotor turns from point C to point A,

the corresponding pocket will reduce from large to small with the previously-drawn gas compressed. When

the pressure is equal to or slightly larger than ambient pressure , the compressed gas will be expelled

through the discharge port.

Seal Liquid

The seal liquid should be fresh, clean water of ambient temperature of neutral pH (soften if necessary). The

seal liquid not only forms a liquid ring, but also dissipates the heat developed by compression and seals the

clearances between the impeller and the port plates.

During operation, the pump has to be continually supplied with fresh water, as part of the seal liquid supplied

is discharged together with the compressed gas.

Use the seal liquid as cool as possible. The seal liquid must not contain solid materials, e.g. sand, otherwise

the casing will be subject to heavy wear or the impeller will jam.

DEKKER Vacuum Technologies, Inc./Maxima-K/June2007 4

Ultimate Suction Pressure (Maxima-K 2 and 3 series only)

For the Maxima-K 2 and 3 series the minimum suction pressure depends on the temperature of the seal

liquid used.

The ultimate suction pressure is down 1”Hg Absolute with the seal liquid and gas at the temperature 60oF and

70oF respectively. Without cavitation protection the suction pressure must not fall below 2.5”Hg Absolute

(ultimate pressure) for continuous operation. If the seal liquid has a higher temperature (higher vapor

pressure), minimum suction pressure is correspondingly higher.

WARNING

Operation of the pump below the minimum permissible suction pressure for a prolonged period of

time can result in the pump being damaged by the cavitation. For high vacuum operation use

cavitation protection.

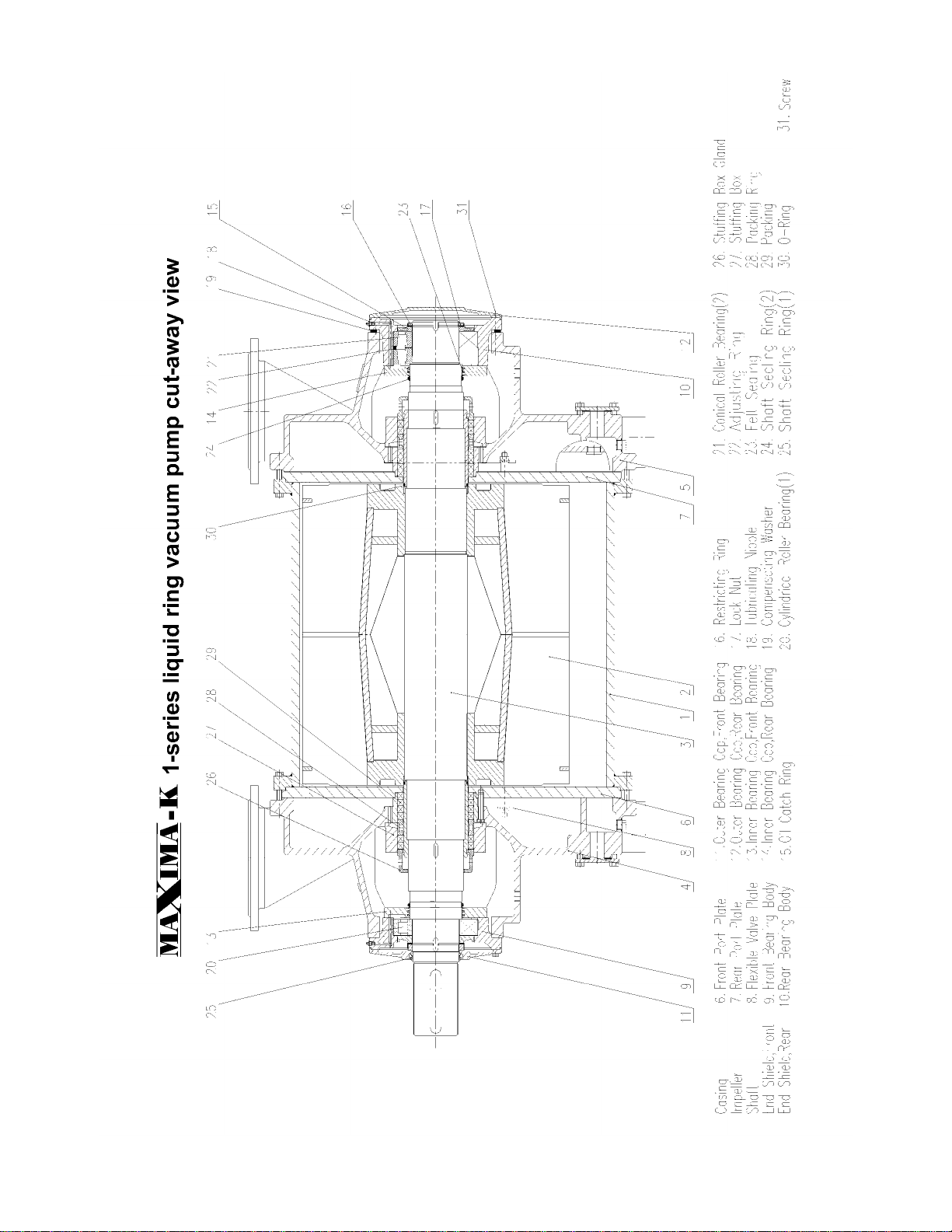

Construction Description

All Maxima-K series pumps consist of the following ten principle components:

(1) Casing

(2) Rotor: of which the impeller and shaft are combined through shrinking process. The shaft is equipped

with shaft sleeves.

(3) Port Plates: the front and rear port plates are bolted to the end housings.

(4) Valve Plate Combination: consisting of a steel plate and a flexible Teflon valve, mounted on the

discharge port of each port plate, allows for the pump to operate at maximum efficiency over the full

vacuum range.. The flexible Teflon valve is a wearing part.

(5) Shaft Seal Assembly: Large-sized pumps usually use packing seals. Mechanical shaft seals are

available as an option. There are two shaft sealing methods for lubrication: internal water supply and

external water supply. The stuffing box is mounted in a direction depending on the shaft sealing method

used. Details as per the following figures.

Internal water supply method for External water supply method for

All Maxima-K series All Maxima-K series

Internal water supply method is indicated External water supply method is indicated

with number 4 cast above the axis with number 4 cast under the axis

Details of specifications of packing as per table below

The pumps are supplied with external water supply as standard.

Maxima-K 1-series

DV4501K-K

DV6000K-K

DV8001K-K

DV9001K-K

DV100001K-K

DV13001K-K

DV18001K-K

(Packing Cross

Section)x circumference

(19X19)X710 mm

(19X19)X820

mm

(19X19)X890

mm

(19X19)X980

mm

Maxima-K

2-series, 3-series

DV2303K-K

DV3503K-K

DV4002K-K

DV4003K-K

DV5002K-K

DV6503K-K

DV7002K-K

DV9003K-K

DV11002K-K

DV13003K-K

DV15002K-K

(Packing Cross

Section)x circumference

(13X13)X530 mm

(16X16)X633

mm

(19X19)X710

mm

(19X19)X820

mm

(19X19)X890

mm

(19X19)X980

mm

DEKKER Vacuum Technologies, Inc./Maxima-K/June2007 5

Note: external water supply is employed with clean water of ambient temperature supplied to shaft

sealing water feed pipe when toxic gases are handled and no seal liquid is allowed to leak from the

shaft seal.

(6) End Shield

(7) Bearings: ball bearings are used for axial shaft loading while the cylindrical roller bearings bear the radial

loads.

(8) Water feed pipes: through which working water is supplied to the pump.

(9) Shaft Sealing Water Feed Pipes: through which cooling and sealing water is supplied to the stuffing box

when external water supply is employed.

(10)Automatic Drain Valve: used to control the water level in the pump at start-up.

For cut-away view of the Maxima-K 1-series, see page 13 at the end of this manual.

For cut-away view of the Maxima-K 2- and 3-series, see page 14 at the end of this manual.

INSTALLATION OF PUMP, MOTOR AND DRIVE

Note: the pumps are subject to strict tests and inspections at the factory before being shipped.

Installation of pump, motor and drives must be carried out by experienced technicians.

The drive variations for all 3 Maxima-K series are either direct, via belt drives or gear reducer.

The mounting methods are:

Direct Drive

Check drive coupling alignment. Angular alignment should be within .035”- .175”. Parallel alignment should

be within .010” - .025”. Consult the factory for specific system size alignment. Mono-block units do not

require any field adjustment (motors are C-face mounted).

Note: Misalignment may occur during the lifting and handling processes. Re-align the unit if

necessary.

V-Belt Drive

For units utilizing V-belt drives, make sure the sheaves are properly installed and aligned before attempting to

tension the drive. The V-belts should be placed over the sheaves and in the grooves without forcing them

over the sides of the grooves. The tensioning steps 1, 2, 3 and 4 can be used for all types of V-belts, all cross

sections and number of belts and all types of construction.

Avoid excessive heat (140oF and higher); belt life will be shortened. Never switch or mix belts from one

groove to another on the sheaves. Do not use belt dressing. Sheaves should remain free of oil and grease.

When replacing belts install an identical set.

For more specific V-belt tensioning guidelines consult factory.

1. With all belts in their grooves, adjust centers to take up the slack until they are fairly taut. Use standard V-

belt tensioning guidelines.

DEKKER Vacuum Technologies, Inc./Maxima-K/June2007 6

2. Start the drive and continue to adjust until the belts have only a slight bow on the slack side while

operating with load conditions.

3. After several days of operation, the belts will seat themselves in the sheave grooves. Further tensioning

may be necessary to the point that the drive shows a slight bow in the slack side. Insufficient tension is

often evidenced by slipping (squealing) at start-up.

4. If the unit is idle for an extended period of time, the tension on the belts should be removed.

Note: To guarantee safety operation, set on belt guards.

Gear Reducer Drive

If a gear reducer drive is supplied follow manufacturer’s instructions.

ARRANGEMENT AND INSTALLATION OF PIPING

Before installing piping, especially the suction pipe, clear out welding slag, rust and other foreign matter.

When dealing with new pipes, mount a mesh filter screen (20/30 mesh) between pipe and pump flange.

The screen should have a certain amount of extension beyond the circumference of pipe to prevent it from

being sucked into the pump. Clean the screen whenever it is clogged by foreign matter, which will restrict

the gas flow. In general stop the pump to clean the filter once a week until the system inside is clean

enough. After a period of time, it may be removed after making sure that there is no foreign matter

remaining inside.

Note: Use straight piping as much as possible at site. Use piping not smaller in diameter than the

pump connections to prevent higher suction and discharge resistance.

Mount the pressure gauge on the water feed pipe and vacuum gauge on the suction pipe respectively.

Based on the different handling duties, the piping are to be arranged with reference to Figures 5,6,7 on the

next page.

DEKKER Vacuum Technologies, Inc./Maxima-K/June2007 7

1. Pump

6 Compound Gauge

11 Vacuum Gauge

16 Level Indicator

2. discharge Pipe

7 Feed Valve for

Working Water

12 Suction Pipe

17 Check Valve

3. Flush and Drain Gate

Valve

8 Shaft Sealing Water

Feed Pipe

13 Gas and Water

Separator

18 Suction Valve

4. Automatic Drain Valve

9 Shaft Sealing Water

Valve

14 Cylindrical Separator

19 Stuffing Box Drip

5. Working Water Feed

Pipe

10 Pressure Gauge

15 Heat Exchanger

20 Flush and Drain

Connection

Pump Set Arrangement

DEKKER Vacuum Technologies, Inc./Maxima-K/June2007 8

Description of Figure 5

Shows a no recovery, or once-through seal liquid system. This arrangement is preferred when large quantities of seal

liquid are available and no financial advantages are foreseen for re-utilization of the same.

Description of Figure 6

Shows a full-recovery liquid ring vacuum pump systems offering total re-circulation of the seal liquid. In this arrangement

the seal liquid is re-circulated in a closed loop system through a heat exchanger, which removes the heat of compression.

This arrangement is used when corrosive or toxic gases are conveyed.

Description of Figure 7

Shows a liquid ring vacuum pump systems configuration with partial recovery or partial re-circulation of the seal liquid.

This arrangement allows for up to 50% savings of seal liquid. Variations in application and pump models will affect the

amount of seal liquid savings.

Description of Figure 8

Shows a pump installation with floor discharge. The discharge trench should have sufficient flow cross

section, for the seal liquid to discharge by gravity. Mount a check valve on the suction line to prevent back

flow of gas and liquids.

Note: If no circulation of seal liquid is required drain in accordance with the environmental

regulations.

START AND STOP

Preparations before starting

(1) When the pump has been out of operation for a prolonged period of time ( more than two years) , renew

the grease for the bearings of the pump before starting. The grease recommended to use is 3# lithium

grease. Clean the bearings thoroughly with solvent before regreasing.

(2) Flush the pump through the water feed pipes. Turn the rotor by hand to drain the dirty water out through

the discharge line. Before re-starting, two days or more of normal operation, flush the whole piping

system with water to flush out scale and rust.

(4) Check the electrical connections for safety and correctness.

(5) Check the pump for rotation direction, see arrow on pump.

(6) Check the coupling or V-belt alignment.

Start-up

See Figure 5

(1) Open the water feed valve 7 to supply water to the pump (if the pump employs shaft sealing water supply,

open the shaft sealing water valve 9 at the same time). When there is water coming out of the automatic

drain valve 4, shut down water feed valve 7.

(2) Open the suction valve 18.

(3) Start the motor with no water coming from the automatic drain valve 4. When the pump starts running,

open the water feed valve 7 to a point where compound gauge 6 shows pressure. At higher vacuum the

gauge should show between 0 –5” Hg.

(4) In case of external shaft sealing water supply, adjust the shaft sealing water valve 9 to a point where the

water sealing supply pressure gauge 10 shows a reading between 3 –5 psig.

Shut-down

(1) Check if all the corresponding equipment of the pump set has been put into stop mode before stopping

the unit.

(2) Shut down the water feed valve 7 and shaft seal water supply valve 9 (if applicable) and at the same time

shut down the motor.

(3) Open the drain valve 3 to drain water from pump if pump is to be stopped for an extended period of time.

DEKKER Vacuum Technologies, Inc./Maxima-K/June2007 9

OPERATION, SUPERVISION AND MAINTENANCE

During the operation, check the following :

(1) The voltage and the shaft power (current).

(2) The temperature rise of the bearings of the pump. The temperature rise should not exceed 100oF, i.e. the

real working temperature should not be more than 180oF.

(3) Water flow rate of the pump and shaft sealing external water supply if any.

(4) If fitted with V-belt drive check belt tension. New belts are easy to stretch and deform. Stop the unit to

check and adjust 20 minutes after first start-up.

(5) Renew the grease of the bearings every 2500 hour-operation period. The amount of the grease accounts

for 2/3 of the free space of the bearing

(6) If fitted with packed gland stuffing box tighten the packing slightly. Adjust it through the packing gland and

the bolts. There are normally some water drops leaking from the shaft seal. When the packing has been

used too long to be adjusted further, renew it. When renewing, remove the old one, clean the traces of

stuffing box. When mounting the packing, stagger the packing with its cuts at 90°.

(7) Use soft water if possible when water is required as sealing water. If not possible, take away the lime

deposits from the working liquid at appropriate intervals. If the impeller jams after a prolonged standstill

period because of lime deposits, flush with DEKKER descaling compound Scale-Ex and then flush with

clean water. In case of heavy deposits, clean by disassembling the pump

.

ASSEMBLY AND DISASSEMBLY

Disassembly of Maxima-K pumps

For construction, refer to cut-away views on pages 13 and 14 at back of manual.

Separate the pipes and take out the coupling. If belt drive, remove the pulleys.

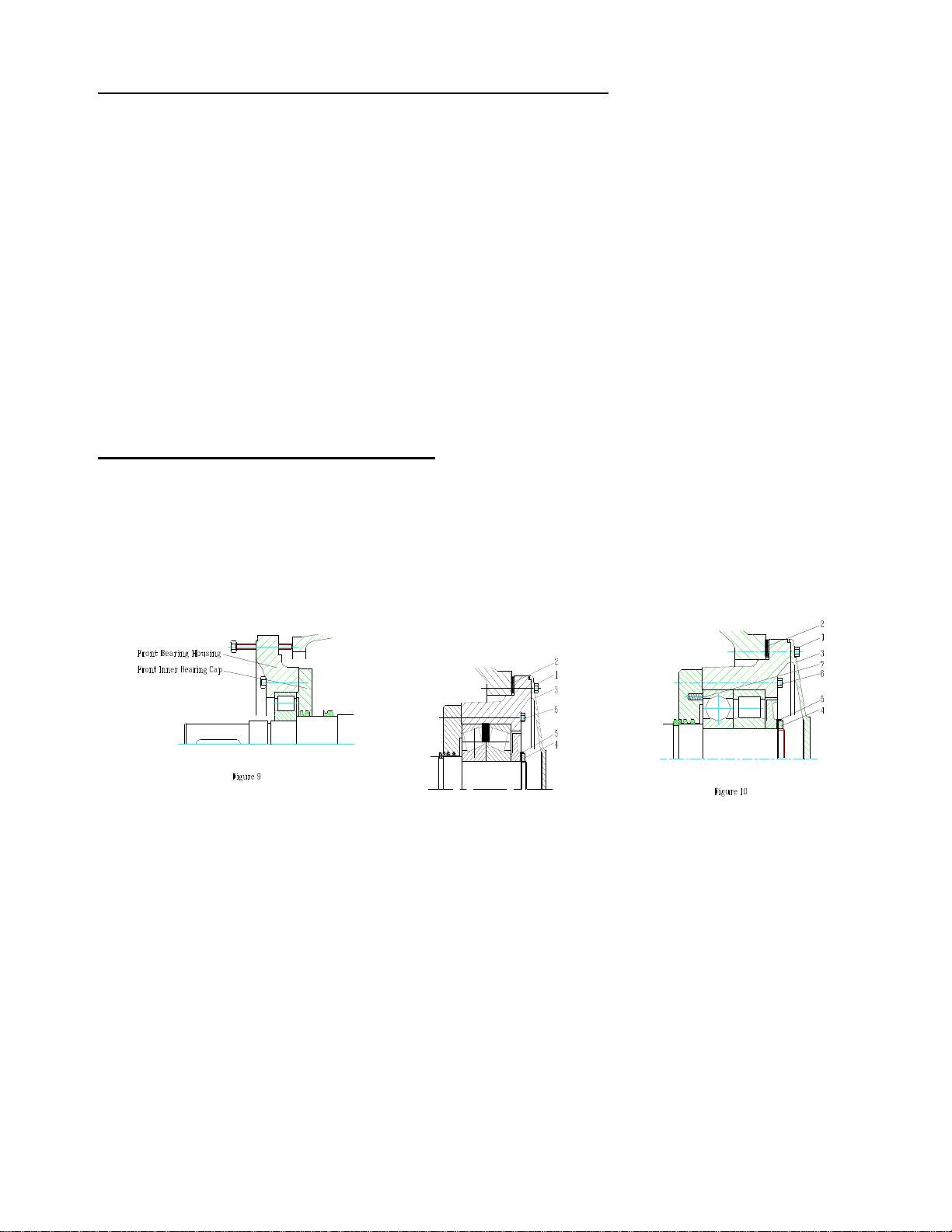

1. Dismantling the Front Bearing

a) dismantle the inner bearing cap 11 and then loosen the lock nuts, stop washer and oil catch ring.

b) Referring to the Figure 9, screw the four M12 screws uniformly to the M12 threaded holes in the front

bearing housing until the front bearing housing and the inner bearing cap are ejected.

Front bearing all series back bearing, 1-series back bearing 2 –and 3-series

2. Dismantling of Back Bearing

Referring to Figure 10

a) Unscrew the screw 1 one by one. Take out carefully each compensating washers set 2 on the screws

with a small thin steel plate. Place different washers on floor with reference to the corresponding

screws and then remove the outer bearing cap 3.

Note: The pumps are supplied with axial clearance set correctly between the impeller and port

plates.

The compensation washers act as adjusting the axial clearance between the impeller and both the

front and rear port plates. When dismantling, care should be taken to distinguish among the

washer sets. Store them separately. Make sure that they shall be re-mounted in their original

places respectively. Otherwise, the front and back axial clearances may be distributed unevenly,

affecting the pump performances or causing the impeller to jam.

b) Remove the lock nut 4 and the stop washer 5.

c) Unscrew the screws 6 tightened evenly and take out the springs 7 distributed uniformly in the inner

bearing cap.

d) Put on the stripping ring (see figure 11) , and then re-screw the screws 6 uniformly.

DEKKER Vacuum Technologies, Inc./Maxima-K/June2007 10

Stripping ring 1-series Stripping ring 2- and 3-series

The Rear Bearing disassembly, such as dismantling bearing housing, inner bearing cap and etc. , is

performed in the same manner of that of the Front Bearing. The ball bearing inner race can not bear the

force without using the stripping ring when disassembly of the bearing. In this case, the bearing will be

damaged. The unit is supplied together with the stripping ring. Customers’ requirements for it are

accepted.

3. Get the pump to stand up vertically across the two blacks with its drive end upward ( see Figure 12).

Dismantle it into pieces part by part . when the present condition limits, the pump may be disassembled

with the whole unit placed horizontally. As a matter of fact, there are some ways to perform the

disassembly. We are ready to provide the corresponding diagrams when the customers request.

4. Because of the bearings of Maxima-K pumps have large magnitude of interference, they may difficult to

remove in the manner stated in Figure 10 and 11. It is recommended that both the front and rear bearing

are to be dismantled to the extent as shown in the figure 13 and 14 and then the bearing inner face will

act as bearing point to enable the bearings to be pressed out. Refer to the reference books for the

methods of disassembly of bearings.

When the back bearing is drawn out with its outer ring bearing force, it will be damaged.

5. It is an important task to examine and clean all the components after the disassembly. According to the

concrete conditions. Carry out the repair, replacement on them or decide whether they are capable of

continuing to work or not.

2 - 3

series

d

D

S

30

125

165

10

35

148

191

10

40

168

223

10

1

series

d

D

S

40

168

223

10

DEKKER Vacuum Technologies, Inc./Maxima-K/June2007 11

Bearings- Check for smooth running. According to the fault and corrosive state, renew them if necessary.

The Front and Rear Port Plates- they are subject to finish turning process when there are some deep

scratch on the faces, which will affect the pump performances.

Shaft Bushing- Renew it based on the wear state.

Impeller- Its face is subject to finish turning process when it has been so worn out to affect the pump

performances. As the difference between the impeller and the pump body in length is the axial clearance,

the two should reduced the same in length through finish turning process.

Assembly of Maxima-K pumps

The assembly of the pump is performed in the reverse manner of the disassembly. In addition to that, attention

should be drawn to the facts that:

1. When the pumps was assembled on a uneven floor, the four pump feet would not remain horizontal like a

plane surface and the clearance between the impeller and the port plates would be reduced with the

impeller jamming after completing the assembly. The correct method is: the pump body is placed on its

bed plate or on a even floor with its end shields mounted on it and then loosen the screws, tighten them

after making sure that the four pump feet are in good touch with the plane surface.

2. Tighten the screws after replacing the compensating washers to their original places, which act as

dominating the distribution of the axial clearance.

3. Adjust the axial clearance again where the rotor is renewed or the finish turning is performed on the

impeller and the port plates.

Adjustment of Axial Clearance

a) Loosen the screws one by one ( See Figure 2).

b) Put a shaft clip on AS end of the shaft.

c) Put a dial meter on the AS end of the shaft.

d) Prize the rotor toward AS with a steel stick to make it be in touch

with the front port plate.

e) Set the meter at zero, prize the rotor toward BS to enable it to be

in touch with the front port plate.

f) The reading shown in the meter is the total axial clearance value ó

of the pump.

g) Replace the compensating washers in their original places. The

washers, made of steel, take three sizes of 0.1mm, 0.2mm and

0.5mm in thickness. All the washers sets are the same in thickness.

h) Secure the screws tightly. At the moment, the meter reads ó/2.

It is likely that he clearance on AS is slightly larger than that on BS.

The minimum clearance on BS should be in conformity with the

requirements specified. Otherwise, paper washers will be added to

both ends of the pump body.

DEKKER Vacuum Technologies, Inc./Maxima-K/June2007 12

Troubleshooting

Symbols

Causes

Points to check and actions

1.

Difficult in starting,

Motor circuit –breaker trips

or over-heat

1.Water level too high inside

when starting;

2.Packing gland too tight;

3.Belt too tight;

4.Wear developing in pump;

5.Discharge pressure too high;

6.Failure to adjust the current

protection of the electric

cabinet.

1.Start with the water level specified;

2.Loosen the gland adequately;

3.Loosen the belt adequately;

4.Turn the rotor with force and flush with water;

5.Check if the pipes and valves are too small in

diameters;

6.Adjust the thermal relay to the rated current

setting.

2

Jamming during trial or

normal operation

1.Welding slag or other foreign

matters have been drawn in

from new pipes with coming

gas.

2.Heavy lime deposit

1. Loosen both the front and back shrouds, turn

the rotor and flush it with water until it rotate

freely and then secure them. In case of failure,

open it for checking.

2. Dismantle for cleaning or acid washing.

3

Pump capacity low.

Vacuum degree low.

1.Speed low due the belt

slippage;

2.Insufficient water feed or water

too hot;

3.Leakage occurring in the

system;

4.Excessive clearance in the

pump due to excessive

corrosive allowance or

corrosive substance in the

medium;

5.Leaks from packing seal;

6.Heavy lime deposits in pump;

7.Corrosion in pump;

8.Axial clearance not in

conformity with the

requirements after repair;

9.Damage to the flexible valve

plate.

1. Tighten the belt;

2. Adjust the water flow. Check the feed pipes

for clogging;

3. Check the joints for sealing;

4. Clean the medium preventing solids from

entering. Replace the worn parts;

5. Tighten the packing gland;

6. Remove the lime deposits;

7. Replace the parts if necessary;

8. Calibrate the axial clearance.

9. Replace the valve plate.

4

a

Unexpected noise

All series

1.The belt too loose;

2.Gas blowing and ejecting;

3.Suction and discharge pipes’

walls too thin;

1. Tighten the belt;

2. Move the discharge opening to outdoor;

3. Use the pipes with thicker walls;

4

b

Unexpected Noise

2- and 3-series

4.Cavitation occurring when the

pump running under vacuum

4. Use cooler working water or replenish gas in

the suction side; use gas ejector.

5

Excessive vibration

1.The bed plate connected with

foundation badly, the anchor

bolts loose;

2.Misalignment

1.Pour mortar around and under the base plate.

tighten the bolts;

2.Make re-alignment and lock.

6

Bearings overheat

1.Belt too tight ;

2.Misalignment of pump with

motor;

3.Inadequate lubricating, the

grease too dry or too much;

4.Bearings inadequately

mounted;

5.Wear, rust and damage

developing.

1.Loosen the belt adequately;

2.Make re-alignment;

3.Improve the lubricating conditions;

4.Re-mount the bearings.

5.Replace the bearings.

DEKKER Vacuum Technologies, Inc./Maxima-K/June2007 13

DEKKER Vacuum Technologies, Inc./Maxima-K/June2007 14

WARRANTY, REPLACEMENT & RETURN POLICIES (Page 1)

DKR_KNOW_GEN_09_rev2

Warranty policy for DEKKER vacuum pumps, systems and/or compressors (hereafter referred to as the

Product)

DEKKER Vacuum Technologies, Inc. (hereafter referred to as DEKKER) warrants that the products hereunder

shall be free of defects in material and workmanship and conform to the specifications given in connection with the

sale of the product.

DEKKER warranty is from date of shipment, provided the DEKKER Products have been operated exclusively with

DEKKER seal fluid (where noted) and have been operated during the full warranty period as per the instructions

given in the Installation, Operation, and Maintenance (IOM) Manual. If purchaser elects to use a non-DEKKER seal

fluid, which has been approved by DEKKER, product warranty may be reduced (as noted below). If purchaser

elects to use a non-DEKKER seal fluid, which has NOT been approved by DEKKER, product warranty may be

void.

3-Year Warranty

Vmax systems: 3-year warranty with DEKKER Vmaxol seal fluid; 2-year warranty with non-DEKKER seal

fluid

HullVac pumps and systems: 3-year warranty with DEKKER HullVac seal fluid; 2-year warranty with non-

DEKKER

seal fluid

2-Year Warranty

DuraVane pumps, systems and compressors: 2-year warranty with DEKKER Duratex seal fluid;

18-month warranty with non-DEKKER seal fluid

TiTan liquid ring vacuum pumps and compressors: 2-year warranty

Maxima-C and Maxima-K liquid ring vacuum pumps: 2-year warranty

AquaSeal systems: 2-year warranty

ChemSeal systems: 2-year warranty

1-Year Warranty

VmaxMTH systems: 1-year warranty with DEKKER Vmaxol seal fluid; 1-year warranty with non-DEKKER seal

fluid

All other systems not specified above: 1-year warranty

All custom-engineered systems: 1-year warranty

6-Month Warranty

Rebuilt pumps and systems: 6-month warranty

Ninety (90) Days

Mechanical shaft seals: Ninety (90) day warranty

All 3rd party components are subject to Manufacturers’ Warranty.

15

WARRANTY, REPLACEMENT & RETURN POLICIES (Page 2)

DKR_KNOW_GEN_09_rev2

The replacement of maintenance items including, but not limited to oil, seals, bearings, filters, vanes in rotary

vane pumps, etc., made in connection with normal maintenance service are not covered under this warranty.

No warranty shall apply to products that have been misused or neglected, which includes operation in excessive

ambient temperatures, dirty environments or the pumping of corrosive, erosive or explosive liquids or gasses or

for problems caused by a build-up of material on the internal parts of the product.

Under this warranty the purchaser is entitled to the repair or replacement (whichever DEKKER elects) of any part

or parts of the product which do not conform to specifications. This warranty shall be void unless said

nonconformance is discovered before the expiration of this warranty. For repairs, DEKKER must be notified in

writing, a Return Merchandise Authorization (RMA) must be obtained and the nonconforming part(s) need to be

returned to DEKKER, transport charges prepaid, within thirty (30) days of discovery. Repairs shall be made at

DEKKER’s facility without charge, except for return transport charges. Replacement parts provided under the

terms of this warranty are warranted for the remainder of the

warranty period applicable to the product in which they are installed, as if such parts were original components of

that product.

No allowance will be granted for repairs or alterations made by the purchaser without the DEKKER’s written

consent.

In lieu of the foregoing remedy, DEKKER may (if DEKKER so elects), redesign and/or replace the product or

refund the full purchase price thereof.

If purchaser disassembles the product for any reason without the written consent of DEKKER, this warranty shall

be void.

Limitation of liability for DEKKER vacuum pumps, systems and compressors:

DEKKER’s obligations are limited to repair, redesign, replacement or refund of the purchase price, at DEKKER’s

option. In no event shall the purchaser be entitled to recover incidental, special or consequential damages arising

out of any defect, failure or malfunction of the product.

This warranty and DEKKER’s obligation there under is expressly in lieu of all other warranties, including but not

limited to the implied warranties of merchantability and fitness for a particular purpose. All warranties which

exceed the aforementioned obligations are hereby disclaimed by DEKKER and excluded from this warranty. No

other person is authorized to give any other warranty or to assume any other liability on DEKKER’s behalf without

written authorization.

Replacement Policy (Product Failure) for DEKKER vacuum pumps, systems and/or compressors

(hereafter referred to as the Product)

DEKKER Product failures must be reported directly to DEKKER immediately. Product must be returned to

DEKKER factory for warranty consideration, unless field service is Pre-Authorized by DEKKER. The product

will be evaluated for defects in workmanship and materials. Under no circumstance will product be considered

for immediate, no-charge replacement without substantial evidence of material defect or assembly error.

User error, incorrect supply voltage, or damage incurred as a result of mishandling will not be honored.

16

WARRANTY, REPLACEMENT & RETURN POLICIES (Page 3)

DKR_KNOW_GEN_09_rev2

Product failures will require a purchase order (in the original dollar amount of damaged/failed product) from the

distributor or direct customer to release the replacement pump or product. A Return Merchandise Authorization

(RMA) number will be generated by a DEKKER After Sales Associate and issued to the distributor or customer to

return the original product. The product will undergo a thorough evaluation upon receipt and credit will be issued

in full if the failure is determined to be warrantable. If failure is determined not to be warrantable, the purchase

order will be charged for the replacement product.

DEKKER does not cover expedited shipping in any circumstance.

Motor failures will be determined warrantable based on the evaluation of the motor manufacturer or their

authorized representative. Please contact DEKKER for assistance with finding your motor manufacturer’s local

authorized repair center.

Return Policy for DEKKER vacuum pumps, systems and/or compressors (hereafter referred to as the

Product)

Return for Credit (product not needed):

Distributor or direct customer will request an RMA number from DEKKER After Sales Associate and return

the product pre-paid. Collect freight or parcels will be refused unless prior approval is given by After Sales

Associate.

A minimum 15% restock fee applies. If product is damaged by customer, as a result of mishandling or poor

packaging for return shipment, this fee may be increased as determined by DEKKER.

Return for Replacement (incorrect part number received due to DEKKER shipping error):

New purchase order is required to release correct items. DEKKER After Sales Associate will issue RMA for

incorrect items. Upon receipt, if product is returned in good condition, the original order will be credited in

full.

Return for Replacement (customer ordered incorrect part):

New purchase order is required to release correct items. DEKKER After Sales Associate will issue RMA for

incorrect items. Upon receipt, original order will be credited less minimum 15% restock fee. If product is

damaged by customer, as a result of mishandling or poor packaging for return shipment, this fee may be

increased as determined by DEKKER.

Return for Replacement (damaged product received):

Photos should be taken immediately upon discovery of damage to assist in a claim with the shipping company.

A new purchase order is required to release replacement items. Once items are received at DEKKER, they

will be evaluated for repair/replacement and liability determined with shipping company. It is the discretion of

the receiver to refuse any shipment. If you have any questions or concerns, contact a DEKKER After Sales

Associate.

17

This manual suits for next models

20

Table of contents

Other Dekker Water Pump manuals

Popular Water Pump manuals by other brands

Aspen

Aspen mini orange manual

YAMADA

YAMADA DR-50B1SUS instructions

ITT

ITT Goulds Pumps 3175 Installation, operation and maintenance instructions

Hayward

Hayward TriStar SP3200 Series owner's guide

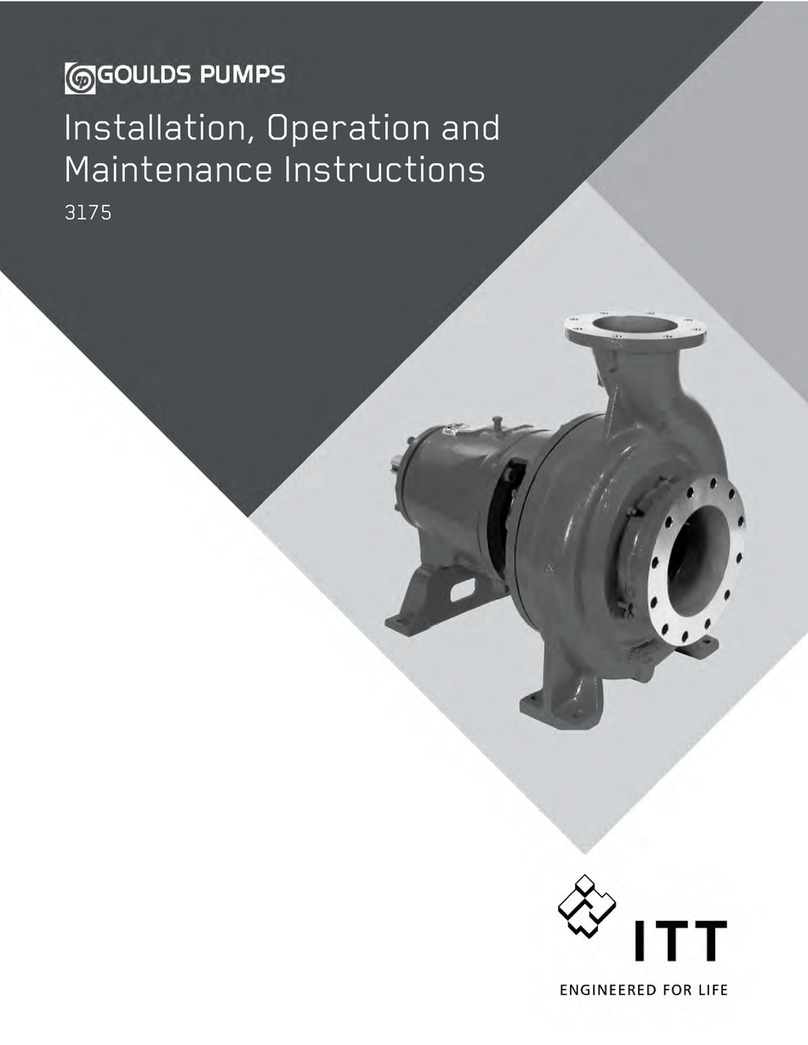

Ingersoll-Rand

Ingersoll-Rand ARO WLM2203A 2 Series Operator's manual

teel

teel 4RJ47 Operating instructions & parts manual

Nordic

Nordic AP-L0218 operating manual

Interpump Group

Interpump Group Pratissoli WK Series Repair manual

Raider

Raider RD-WP800S instruction manual

Nordson

Nordson BM 200 Operator card

WOERNER

WOERNER GMG-K Translation of the original operation manual

Grundfos

Grundfos DME series Installation and operating instructions