8

Preventive Maintenance and Troubleshooting Guide

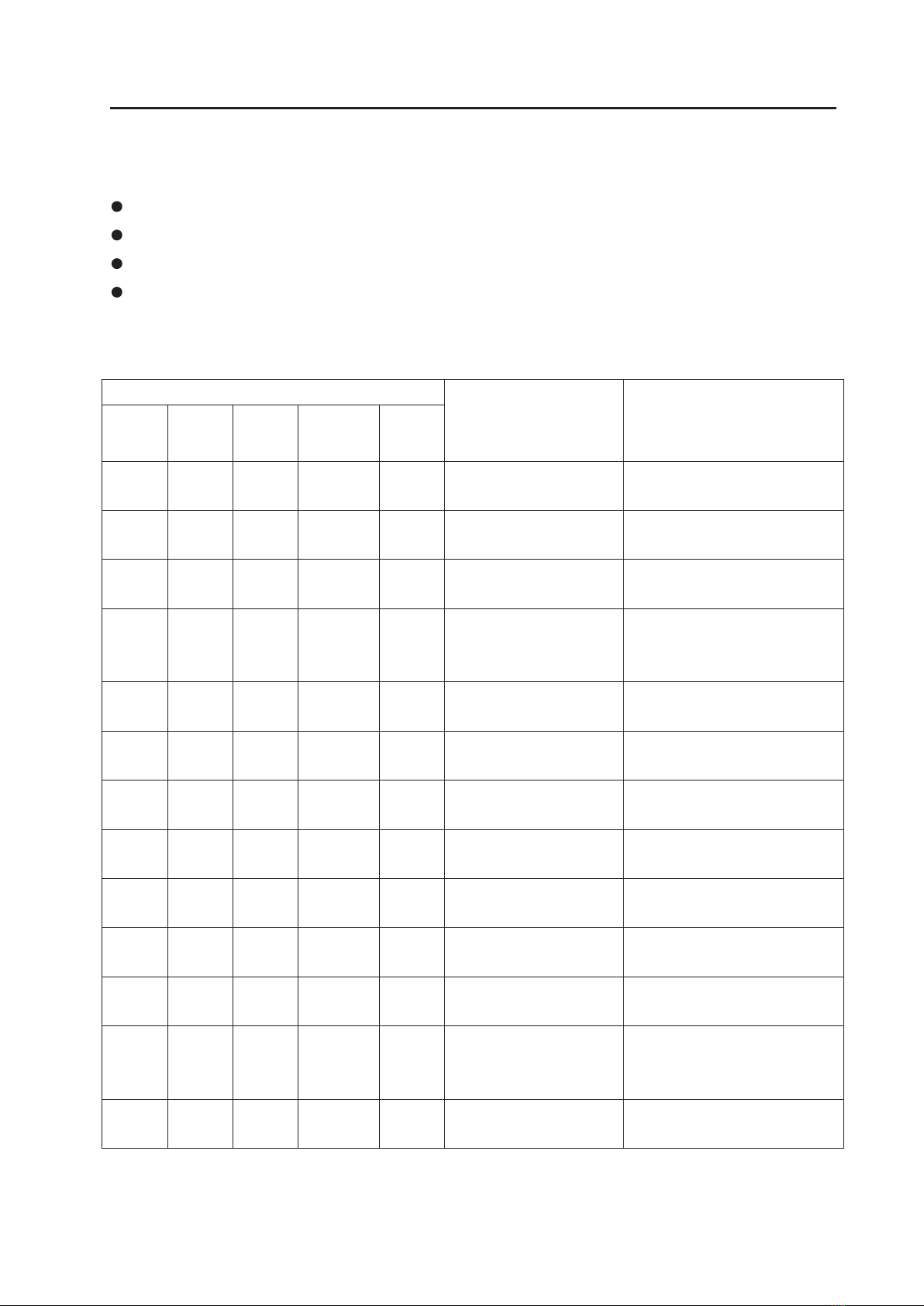

GSE®recommends that you perform the following service to minimize unexpected downtime for your

compressor:

Replace the connecting rods or piston cups and sleeves

Replace the flapper valves

Replace the head O-ring Head gasket.

Replace the valve plate O-rings

If you are having a problem with your compressor, use this table to help determine the cause(s):

Problem

Low

Flow Low

Pressure Unit Will

Not Start Motor ①

Overheats Loud

Unit

Possible Cause Corrective Action

×High voltage at compressor Reduce voltage

× × × × Low voltage at compressor Increase voltage

× × × Damaged valves Replace flapper valves

× × × Debris in valves Remove debris and check for valve

damage

× × × Damaged gaskets Replace gaskets

× × × Worn Cup Replace connecting rod

× × × Loose head screws Tighten head screws

×Broken fan Replace fan

× × × Bent motor shaft Replace entire unit

× × Damaged capacitor Replace capacitor

×Loose fittings Tighten fittings

× × Insufficient ventilation in

enclosure

Increase air circulation to enclosure

× × Worn bearings Replace Eccentric Bearing assembly

①Thermal protector in motor will interrupt current when motor overheats.