C15R Compressor Instructions

ULVAC CRYOGENICS INCORPORATED I

Table of Contents

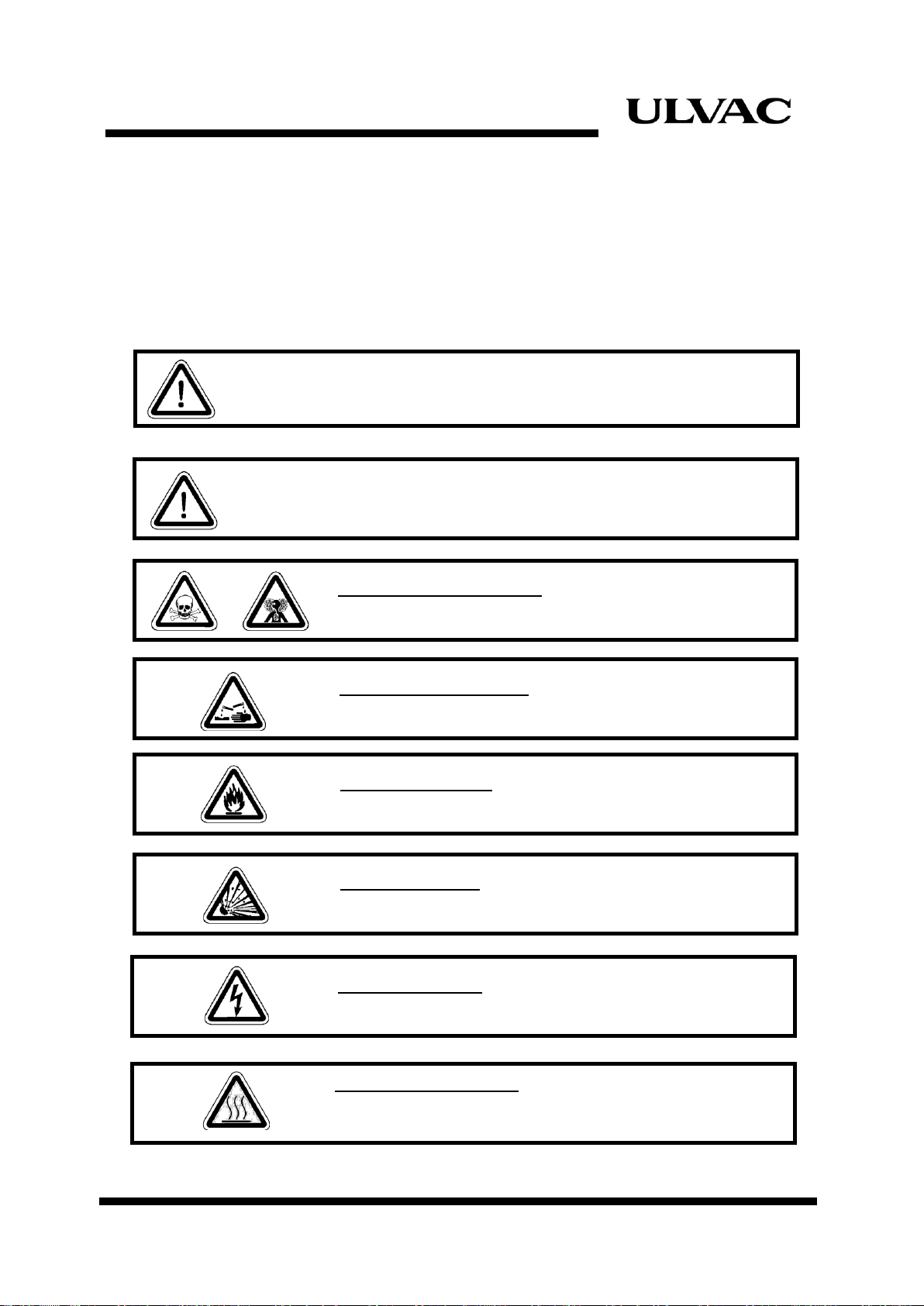

Safety Instructions························································································ S-1

Disposal Considerations ················································································IW-1

1. COMPRESSOR UNIT DESCRIPTION··························································1-1

1.1 General ···························································································1-1

1.2 Specifications ···················································································1-1

2. INSPECTION··························································································2-1

2.1 Shipping List·····················································································2-1

2.2 Inspect Compressor Unit·····································································2-1

2.3 Inspect Flexible Hoses········································································2-2

2.4 Inspect Cables··················································································2-2

3. INSTALLATION ·······················································································3-1

3.1 Installation························································································3-1

3.2 Connecting Cooling Water Piping··························································3-2

3.3 Cooling Water···················································································3-2

3.4 Connecting the Compressor Unit to the Cryopump····································3-5

3.5 Connecting Electrical Cables································································3-7

4. OPERATION···························································································4-1

4.1 Before Operation···············································································4-1

4.2 Normal Operation ··············································································4-1

5. DISCONNECTION AND STORAGE·····························································5-1

5.1 Disconnecting Flexible Hose ································································5-1

5-2 Storage ···························································································5-2

6. MAINTENANCE ······················································································6-1

6.1 Scheduled and Unscheduled Maintenance··············································6-1

6.2 Adsorber Replacement ·······································································6-1

6.3 Charging Helium Gas ·········································································6-5

Appendix A Trouble Shooting··········································································· A-1

Appendix B Circuit Diagram············································································· B-1

Appendix C Flexible Hose··············································································· C-1

Appendix D Flow Diagram··············································································· D-1

Service Network·························································································· CS-1