Cobra Pro CP2040 Quick start guide

“WARNING - READ THIS OPERATION MANUAL

CAREFULLY BEFORE USING THIS PRODUCT. FAILURE TO

UNDERSTAND AND FOLLOW THE CONTENTS OF THIS

MANUAL MAY RESULT IN ELECTRICAL SHOCK, FIRE,

AND/OR SERIOUS PERSONAL INJURY OR DEATH. KEEP

THESE INSTRUCTIONS IN A SAFE PLACE FOR FUTURE

USE OR WHEN LOANING OR SELLING THE PRODUCT.”

Cable Drum Machine

Operational Manual CP2040

Used For: Sinks, Showers and Tub Drains

(Not for roots)

42FM

TOOLS FOR THE PROFESSIONAL PLUMBER

TOOLS FOR THE PROFESSIONAL PLUMBER

www.cobratools.com

Acquaint yourself with the functions and controls prior to

using this machine. Should you have any questions or

uncertainties about the operation of this machine, please

call Customer Service (toll free) at 800-835-2200. If you

have any uncertainty about how to use this machine,

contact a drain cleaning specialist. Failure to follow the

instructions and warnings may result in electric shock, re,

serious injury or even death.

Make Sure This is The Right Tool

For Your Job

• This cable drum machine is intended for use in

sinks, tubs, oor drains and roof stacks with 3/4

inch to 3 inch diameter lines.

• This machine is NOT designed to clear tree roots

from pipes – attempting to clear tree roots can result

in injury and will damage the machine/cable, in turn

voiding the warranty. For clearing root disturbances,

utilize a larger drain cleaning machine such as the

Cobra 650 series.

• Do not modify this product or use it for anything

other than its intended purpose. Only use equipment

suggested by the manufacturer. Alterations or other

improper use could result in personal injury or damage

to the product also nullifying the product warranty.

Personal Protection Equipment

• Wear snug tting leather gloves when operating this

machine. Never grasp the rotating cable with anything

else, including a rag or non-leather gloves.

• Exercise cleanliness. Use hot soapy water to clean

hands and other body parts that may have been

exposed to drain cleaning contents. Do not eat or smoke

while cleaning drains.

Personal safety

• Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under the

inuence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

• Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

• Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

Read all safety warnings and instructions.

In this Operation Manual and on the product, safety

symbols and signal words are used to communicate

important safety information. This section is provided to

improve understanding of these signal words and symbols.

• This is the safety alert

symbol. It is used to alert you

to potential physical injury

hazards. Obey all safety

messages that follow this

symbol to avoid possible

injury or death.

• This symbol signies the

importance of the user to

read the operator’s manual

carefully prior to using

the machine. The manual

encompasses essential

information regarding the

safe and proper operation of

the equipment.

• This symbol denotes the

signicance to always

wear safety glasses with

side shields or goggles

when handling or using this

equipment to reduce the risk

of eye injury.

• This symbol denotes the risk

of ngers getting trapped in a

belt and/or pulley

• WARNING indicates a

hazardous situation that, if

not avoided, could result in

death or serious injury.

• This symbol indicates the

risk of hands, ngers or other

body parts being trapped,

wrapped or crushed in the

drain cleaning cable.

• This symbol designates the

risk of electrical shock. This

could result in death if the

machine is plugged into an

improperly wired outlet.

?

?

?

SAFETY SYMBOLS &

SIGNAL WORD CABLE DRUM MACHINE

SAFETY

www.cobratools.com

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery operated

(cordless) power tool.

Work area safety

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• Do not operate power tools in explosive

atmospheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose control.

Electrical safety

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power tools.

Unmodied plugs and matching outlets will reduce risk

of electric shock.

• Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risks of

electric shock.

• If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces the

risk of electric shock.

Power tool use and care

• Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

• Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your nger on the

switch or energizing power tools that have the switch

on invites accidents.

• Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

• Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

• When lifting heavy objects, always lift with your

knees, never with your back. Consider using two-

people when lift is heavy and/or awkward.

Proper Machine Operation

• Cleaning chemicals can be present in clogged

drains. If you have previously used chemicals or are

unsure, take care to avoid contact with the cable or

debris found in the drain.

• Machine is designed to be used by one person only.

The operator must control both the cable and the foot

switch. Should the cutter stop rotating, the operator

must be able to quickly stop the motor. This helps to

prevent kinking and breaking of the cable which could

cause crushing or striking injuries.

• Do not allow the cable to twist, kink or build up

tension. Do not let the cable endure overstressed

situations. This could potentially result in crushing and/

or striking injuries and unpredicted cable reactions. If

the cable starts to become overstressed, immediately

turn the machine off by taking your foot off the switch

and rotate the cable in the opposite direction until the

twist or buckle has been removed.

• Do not operate machine with motor in reverse.

Reverse is only used when the cable is stuck or

overstressed. Running the machine in reverse could result

in possible kinked or stressed cable and personal injury.

• Never retract the cable from the inlet while drum

is spinning. The cable could whip around and cause

serious personal injury or death.

WARNING indicates a hazardous

situation that, if not avoided, could result in death or

serious injury.

www.cobratools.com

• Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

• Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool

or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

• Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed. Use of the power tool for operations

different than those intended could result in a

hazardous situation.

Service

• Have your power tool serviced by a qualied repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

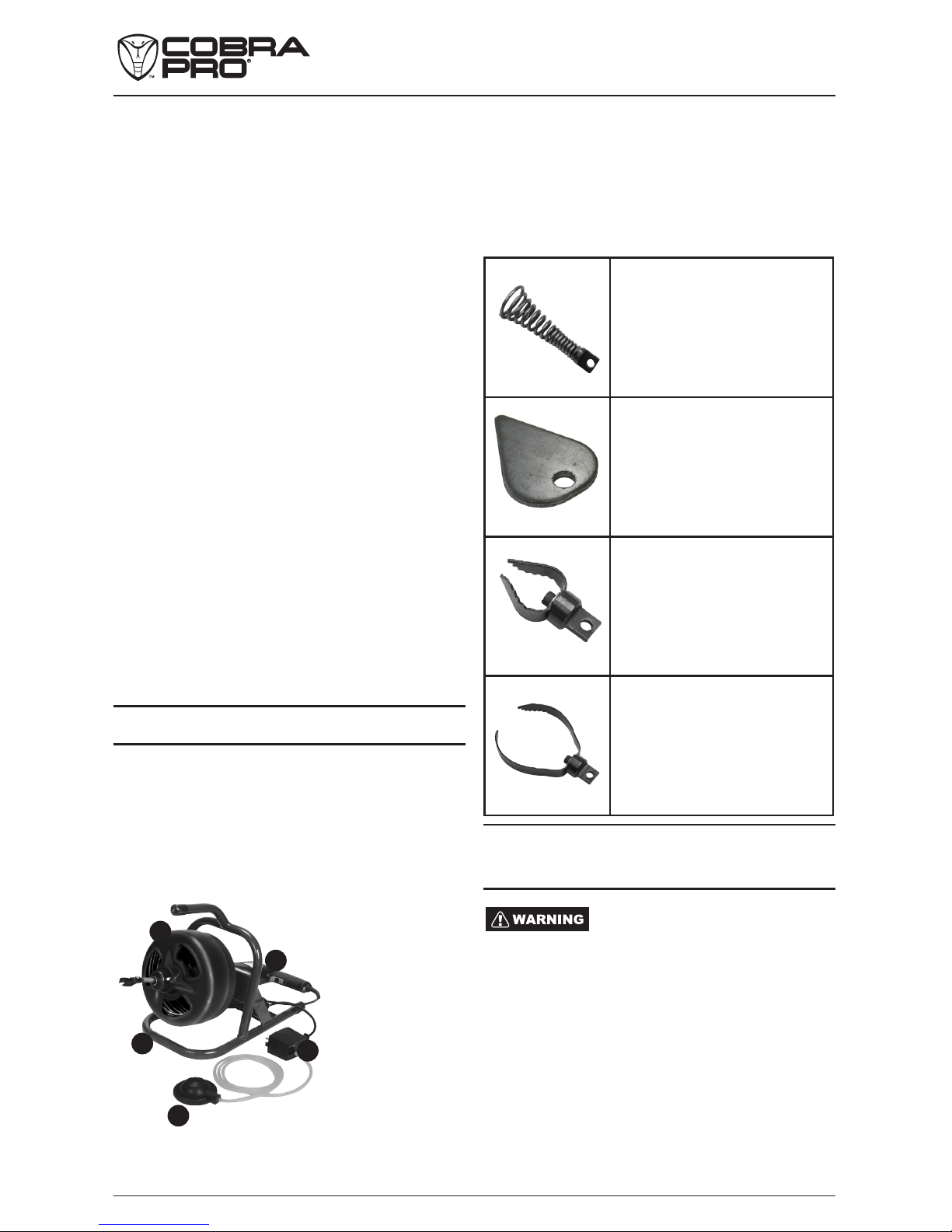

Tool description

Your cable drum machine has four benecial

tool attachments to cope with a wide variety of

obstructions. As a general guideline, it is wise to use a

tool that is at least 1"smaller than the line to be cleared.

The nature of the job and the operator’s judgment should

determine the type of tool.

• 992021

• 3/4" x 5"

Straight Boring Head

for initial exploration of clog

• 99204

• 1-1/2" x 2"

Slotted Spear Head

for piercing clogs

• 99205

• 1-1/4" x 2"

Grease Cutter

for grease blockages

• 99206

• 2" x 4"

Side Cutter

for nishing pipe cleaning

MACHINE DESCRIPTION

Do not operate a machine that has the belt guard

removed, any absent or broken parts, or that is

incorrectly assembled. If your machine does not meet all

of the conditions in this section, do not operate until the

machine is properly repaired (See Repairing Your Drum

Machine). Failure to properly prepare for operation may

result in shock, re, and/or serious personal injury or death.

Check your Personal Protective Equipment

Be sure your personal protective equipment (See

Personal Protection Equipment Section) is in good

condition. Before use, ensure gloves are not damaged.

PREPARATION

FOR OPERATION

This machine has manual cable feed. The cable must be

fed by hand and does not automatically extend or retract

into the machine.

This machine should not be operated in reverse under

normal operating conditions. Reverse should be used

only for a few seconds at a time to free a stuck cutting tool.

1. Frame

2. Drum

3. Drill

4. Air Actuated

Press Box

5. Foot Switch

Actuator

1

2

3

4

5

www.cobratools.com

been modied or is missing any components, do not use

the machine. It will need to be repaired by a qualied

person prior to use.

• Ensure the foot switch is attached to the air press

box properly. Do not operate the machine without the

foot switch.

• Before use, clean any grease, dirt or oil off the

equipment controls and handles. This will reduce the

risk of the machine or controls slipping from your grip.

• Conrm that the machine is accurately assembled.

Look for any parts that are not in a condition which

would prevent safe and normal operation. Rotate the

drum and make sure that it smoothly rotates. If any

problems are found, or if you are unsure, do not use the

machine until it has been properly repaired.

• Make sure the warning label on the motor is intact

and readable. Do not operate the machine without the

warning label.

• Clean any debris from the tools and cable while

inspecting the cable for any wear and damage.

Check for ats on the outside of the cable, if any

portion looks as though it is not round, the cable should

be replaced. Inspect the cable for any kinks, space

between the coils or excessive corrosion. These can

weaken the cable during use.

• Inspect the cutting tools for any damage or wear. If

damage or wear is found, the tools need to be replaced.

• Using dry hands, plug the cord into a correctly

grounded outlet. To test the GFCI provided, push the

test button in, the indicator light should go off. Restart

by pushing the reset button in. If the indicator light goes

on, the GFCI is functioning properly. If it is not working

properly, unplug the cord and do not use the machine

untill it has been correctly xed.

• Move the FOR/OFF/REV switch to the FOR position.

Slowly press the foot switch and note the direction of

rotation of the drum. If the foot switch does not rotate

the drum, do not use this machine until it is properly

inspected. The drum should rotate counter clockwise

when viewing from the front of the machine.

• Move the switch to the REV position to ensure

that the drum is rotating clockwise, repeating

the previous steps to ensure that the machine is

working properly. If the rotation is not correct, do not

operate this machine.

Prepare the Work Area

• Make sure the work area has satisfactory lighting.

• Do not work in areas that have combustible liquids,

dust or vapors that may ignite. The drain machine is

not explosion resistant and can create sparks.

• Do not work in any area until all the amable

sources have been identied and corrected.

• Never place the machine in water. If necessary,

remove the water from the work area prior to use.

• Be sure the electrical outlet is properly grounded. If

unsure, have the outlet inspected by a licensed electrician.

• Make sure the path for the power machine

transportation and power cord are clear of

obstructions. Any potential sources of damage to the

power cord or machine should be relocated prior to use.

• Keep bystanders and children away from the work area.

• Drain cleaning can be messy. If necessary, use

protective covers.

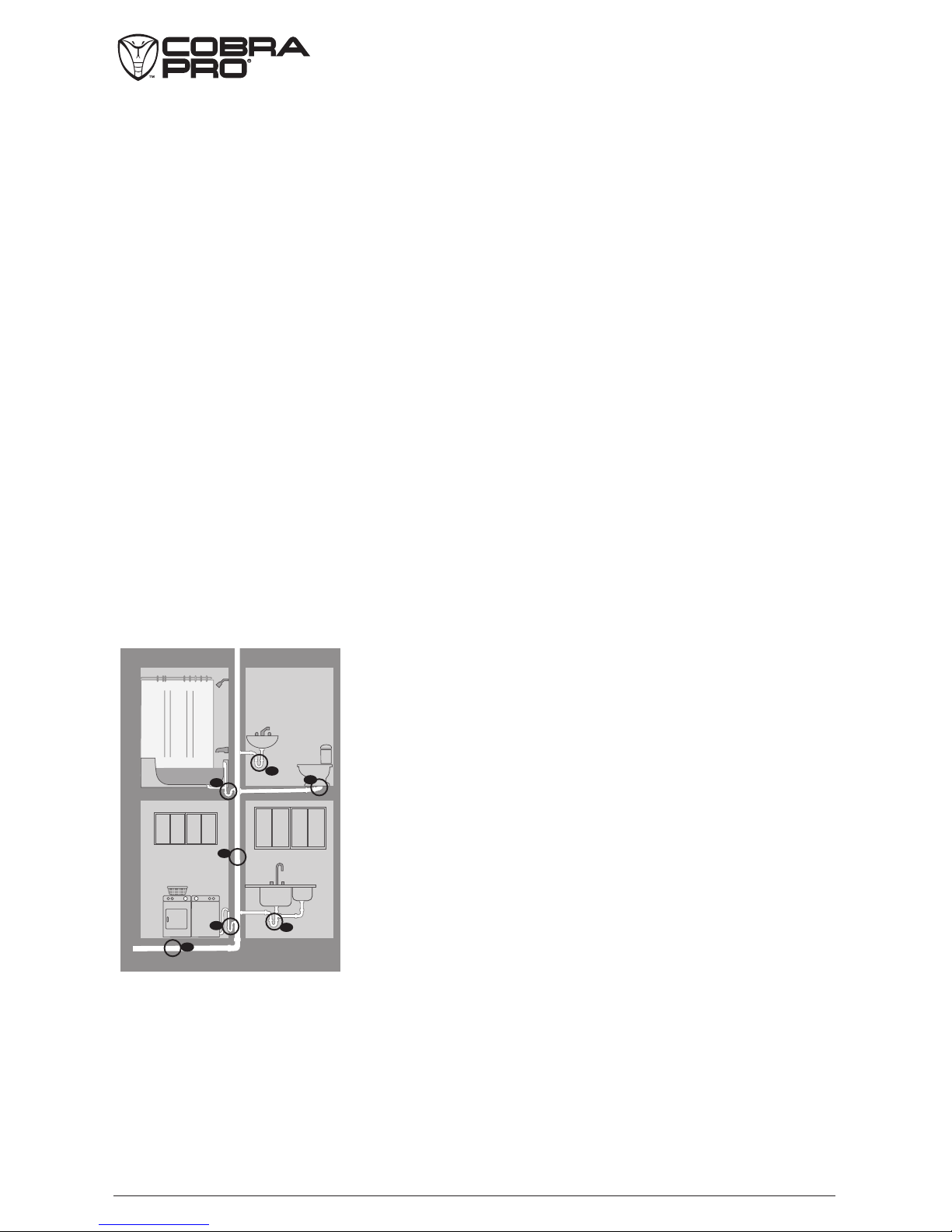

Inspect and Prepare the Drain

• Determine if cleaning chemicals have been used

in the drain. If chemicals are present, contact the

chemical manufacturer to understand the safety

measures that are necessary to work around those

substances.

• Properly

inspect the drain.

Determine the best

access point to

the drain and the

size of the drain. If

possible, determine

the distance to

the blockage or

the nature of the

clog. If necessary,

remove the xture

(water closet,

sink, etc.) to allow

access to the drain.

Inspect and Prepare the Machine

• Verify machine and components are in place.

• Inspect your drain cleaning gloves to ensure they

are in good condition with no holes, tears or loose

sections. It is critical to have the proper gloves to

protect your hands from the rotating cable.

• Make sure the drain cleaning machine is unplugged

and inspect the Ground Fault Circuit Interrupter,

plug and power cord for any damage. If the plug has

1

2

1

1

4

3

1

www.cobratools.com

If your machine is not properly operating, do not use it

until the machine is properly repaired.

Do not allow the cable to twist, kink, buckle, become

overstressed or stuck. If the cable begins to get stuck

or buckle/ twist, immediately remove your foot from

the foot switch while rmly holding the cable with

both hands. Allow the machine to come to a complete

stop and the tension to release from the cable. Turn the

machine off and immediately manually rotate the cable

in the opposite direction until the twist or buckle has

been removed.

If the cutter is stuck in the clog, turn the machine into

the OFF position, then to REV and slowly press the foot

switch. Let the machine run slowly in reverse, stopping

the motor often to check if the cutter has become

released by manually retrieving the cable into the

drum. ONLY run the motor in REV if the cutter has

become caught. If the cable begins to get stuck or

buckle/kink/ twist, immediately remove your foot from

the foot switch while rmly holding the cable with

both hands. Allow the machine to come to a complete

stop and the tension to release from the cable. Turn the

machine off and immediately manually rotate the cable

in the opposite direction until the twist or buckle has

been removed.

Fingers or other body parts can be caught in rotating

parts and crush. Do not wear loose clothing, neck ties,

unbuttoned jackets, rings, watches or jewelry and always

tie back long hair. This will help reduce the risk of

entanglement with moving parts.

This machine has manual cable feed and it does NOT

automatically extend or retract the cable into the machine.

Cable MUST be fed by hand. You will use the machine

to clear obstructions, return to hand feeding the cable in

between clogs or joints.

1. Plug the machine into a properly grounded outlet.

Leave the motor in the OFF position.

2. Loosen thumbscrew and pull sufcient cable out of

the drum and place the end of the cable as far into the

inlet as possible. The machine should be NO MORE

THAN 2 FEET from the drain opening, with around 4

feet of uncovered cable between the drain opening and

drum opening. The cable should form a slight arch.

NEVER FORCE cable down the line. When the cable

will not feed further into the drain pipe, the cable is

probably stuck against an elbow or joint in the pipe or

may have reached the clog.

Do not continue to force cable into the

drain pipe. This can cause the cable

to twist, buckle, kink or break.

3. Tighten thumbscrew.

4. Place the motor in the forward (FOR) position and

slowly depress the footswitch to start the machine.

The drum will begin to turn as will the cable.

5. While depressing the foot switch, apply slight pressure

to the top of the arch of cable with both gloved hands.

If your cutter is at an elbow, this will help the cutter

“jump” the elbow, freeing it to continue through the

drain. If your cutter is at the clog, the cable will not

feed further.

6. Continue steps 2-5 until you have reached your clog.

7. Let the cutter do the work. Do not use too much force.

Do not continue to force cable into the drain pipe. This

can cause the cable to twist, buckle, kink or break.

Continue applying pressure to the arch of the cable until

the cutter has cleared past the clog.

Do not allow the cable to twist, kink, and buckle,

become overstressed or stuck. If the cable begins to

get stuck or buckle/twist, immediately remove your

foot from the foot switch while rmly holding the

cable with both hands. Allow the machine to come to

a complete stop and the tension to release from the

cable. Turn the machine off and immediately manually

rotate the cable in the opposite direction until the twist

or buckle has been removed. If the cutter is stuck

in the clog, turn the machine into the OFF position,

then to REV and slowly press the foot switch. Let the

machine run slowly in reverse, stopping the motor

often to check if the cutter has released by manually

retrieving the cable into the drum. ONLY run the motor

in REV if the cutter has become caught. If the cable

begins to get stuck or buckle/kink/twist, immediately

remove your foot from the foot switch while rmly

holding the cable with both hands. Allow the machine

to come to a complete stop and the tension to release

from the cable. Turn the machine off and immediately

manually rotate the cable in the opposite direction

until the twist or buckle has been removed.

If drum continues to rotate under power when the

cable/cutter is stuck, the cable can twist, buckle, kink

or break.

OPERATING INSTRUCTIONS

www.cobratools.com

Retrieving the cable

8. Move the motor switch to the OFF position. Do not

operate the motor in reverse.

9. Unplug the power cord.

10. Loosen the thumbscrew and hand feed all the cable

back into the drum, cleaning in cold water then oiling

the cable as you go. It is recommended that the cable

is continuously ushed through with clean water and

oiled as it is being retrieved from the pipe before

putting it away. This will prolong cable life and prevent

unpleasant odors as well as the damaging effects of

drain cleaning compounds.

11. Once all of the cable is fed back into the drum, tighten

the thumbscrew.

Post-operation maintenance

12. Drain water from drum. Your model is equipped with

a drain hole in the cable drum. Water, sediment and

debris can corrode cable – remove the drum from the

machine (see “To Remove Drum from Frame” below)

and place it face down to allow all the water to drip

out. This should be done after every use.

MACHINE MAINTENANCE

To reduce the risk of electric shock, re, serious injury

or death, the motor switch should be OFF and machine

unplugged prior to performing any maintenance,

adjusting, or when cleaning this product.

Cables

• The metal cable should be thoroughly cleaned with

water and lubricated to prolong cable life and prevent

unpleasant odors and the damaging effects of sediment

and drain cleaning compounds. Cleaning and lubricating

should occur prior to storing the machine.

• Regularly inspect cables for damage. Replace cables

that are worn or kinked.

Cleaning the drum machine

This machine is equipped with a drain hole in the cable

drum. It is recommended prior to storage that all water

residues should be removed from the drum. Remove the

drum from the machine (see “To Remove Drum from Frame”

below) and place it face down. This will allow all of the

water to drip out. Conrm the drum is dry prior to storing.

Lubrication

Typically, the drain cleaning machine will not require

lubrication. The bearings will need to be greased with a

general lubricant if the drum is removed or changed. The

cable will need to be lubricated after each use.

Storage

Make sure all water and residue is removed from the

drum prior to storage. Drum should be stored properly

mounted on the machine frame. Store machine in a dry,

safe, secured place, out of the reach of children and people

unfamiliar with this machine.

To Remove Drum from

Frame

1. Remove wing nuts on the belt

guard (pulley wheel cover) and

remove the belt guard.

2. Remove the drive belt from the

drum by pressing down rmly on

the spring motor housing and

release the drive belt.

3.

A release hook is situated immediately behind the drum.

Pull this hook upward and pull the drum forward to

remove it from the frame.

To Connect the Drum to the

Frame

1. Place center of drum hub on drum

drive. Pull the release hook up to

securely push the drum on the frame.

2. Slide the belt under and over the

drum and onto the pulley wheel.

3. Push the motor housing downward to locate the belt

onto the pulley wheel.

4. Reinstall belt guard and wing nuts.

Belt Installation

1. Remove wing nuts on the belt guard (pulley wheel

cover) and remove the belt guard.

2. Slide the belt under and over the drum and onto the

pulley wheel.

3. Push the motor housing downward to locate the belt

onto the pulley wheel.

4. Reinstall belt guard and wing nuts.

www.cobratools.com

General maintenance and other tasks detailed in this

manual, such as the replacement of the cable or a

damaged belt guard can be done by a qualied owner.

Other servicing repairs, such as the replacement of a

defective motor switch, must only be done by Cobra

Products. Please contact Cobra Products Customer

Service at 856-241-7700.

When servicing, use only genuine Cobra parts or

contact customer service. Not using proper parts may

result in electric shock/serious injury or death.

Installing Replacement Cable

1.

Ensure the motor switch is OFF and machine unplugged.

2. Loosen the thumbscrew and remove existing cable

from the machine.

3. Disconnect secured cable end from inside drum unit

4. Carefully remove the new cable from the packaging.

The tension is likely built up and has potential to strike

the user.

5. Uncoil the new cable completely.

6. Carefully insert the cable into the drum and

reconnect the cable to the inside drum unit for a

counterclockwise insertion.

7. Once cable is secured in drum, continue to insert the

remaining cable counterclockwise until you reach the

slotted end. This part should remain on the outside of

the drum.

8. Finally, tighten the thumbscrew.

REPAIRING YOUR DRUM

MACHINE

96204: Spear-Head

For exploring and

breaking up stoppages.

99205: 1/2" x 1" Grease Cutter

For lines which have become

badly greased with detergents and

have to be re-opened.

99206: 1/2" x 2" Side Cutter

For exploring and breaking up

blockages or returning samples to

the surface to determine the correct

tool to use.

99202: Straight Boring Head

For cleaning pipes of various

material clinging to pipe walls.

350-142004

Large Button

Head Screw (4)

350-252558

Large Flat Head

Cap Screw (6))

850-990000

3/4" Nose

Cone

Assembly

350-142047

Large Socket

Head Cap Screw (2)

750-002000

Drum Pin

Assembly

401-725550

Drill Attach Collar

350-142024

Large Shoulder

Screw

350-313125

Flat Washer

401-725491

Drill

401-990274

Motor Drive

450-043870

End Cap (3)

850-990210

Frame Assembly

350-142040

Lock Nut (6)

401-998001

Air Actuated

Press Box

401-990446

Air Actuated

Foot Switch

400-990200

Drum

PARTS

401-840000

Bronze Bushing

www.cobratools.com

Manufacturer assumes no responsibility for failure due to improper use.

©2017 Brasscraft Manufacturing Co., Novi, MI 48375-5331 U.S.A. All Rights Reserved.

www.cobratools.com Cobra®brand is a trademark of Brasscraft Mfg. Co.

El fabricante no asume ninguna responsabilidad si la uso no se hace de acuerdo al instructivo.

Todos los Derechos Reservados. Cobra®brand es una marca registrada de Brasscraft Mfg. Co.

651-CP2040

www.cobratools.com

Table of contents

Other Cobra Pro Drum manuals