7

6X-1047b

7140

INSTALLATION AND OPERATION

transformer in the model 71x5.When this transformer

is installed at pins A and M on the rear panel Bendix

connector must be jumpered together.This can be

done either within the cable plug mating with the

Bendix connector or at the other end of the cable

in the control box assembly, junction box, or other

device that may be used.

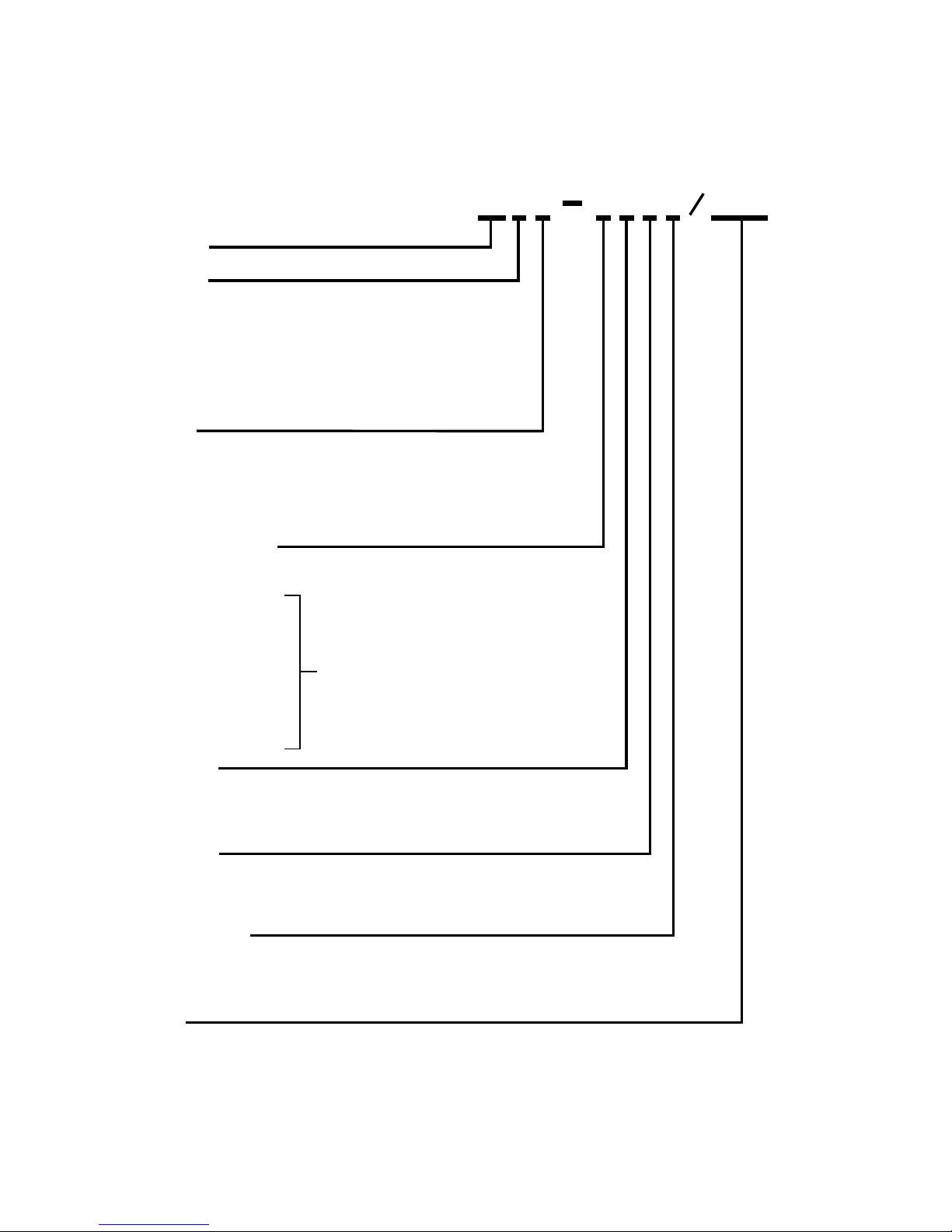

Figure 10 shows a cable wiring diagram where

all connector pins associated with power inputs are

carried through the cable to a control panel, junction

box, or similar housing or device.This cable can be

wired at that end for use with either the 24 V ac/dc or

115 V ac versions of the housing.

WARNING

If 24 V ac is applied to a Cable wired for 115 V

ac operation (having the jumper across pins A

and M) 115 V ac will be back-fed out of pins W

and V. This jumper must be removed if a 115 V

ac Camera is to be operated from 24 V ac.

Note that while a 115 V ac housing can be oper-

ated from 24 V ac/dc this results in a condition where

115 V ac is back fed out of the housing onto pins W

and V. To prevent this, the jumper across pins A and M

must first be removed so that this condition does not

exist.

Figure 11 shows a cable wiring diagram for a 115

V ac version of the cable in which pins A and M are

jumpered together within the cable plug attached to

the rear panel Bendix connector..This wiring arrange-

ment should be used when the housing is optioned

with the 115 Vac transformer.This cable cannot be

used to power the housing from 24 V ac/dc because

one required 24 volt wire is not carried through the

cable.

Refer to figure 12 for a

schematic diagram of the hous-

ing.This diagram shows the

internal power wiring of the

housing and also the inter-

connections with the camera

module.

In sum, then:

1. 115 V ac line (high/hot) applied

to pin W and the neutral applied

to pin V. Pin X is the ac power

ground. When this version of the

camera is to be operated from 115

V ac power, pins A and M must be

externally jumpered together.

2. 24 V ac or 24 V dc applied to pins A and d.When 24

volts is to power the camera ensure that pins A and M

are not jumpered together — especially when the op-

tional 115 V ac power transformer has been installed in

the housing.

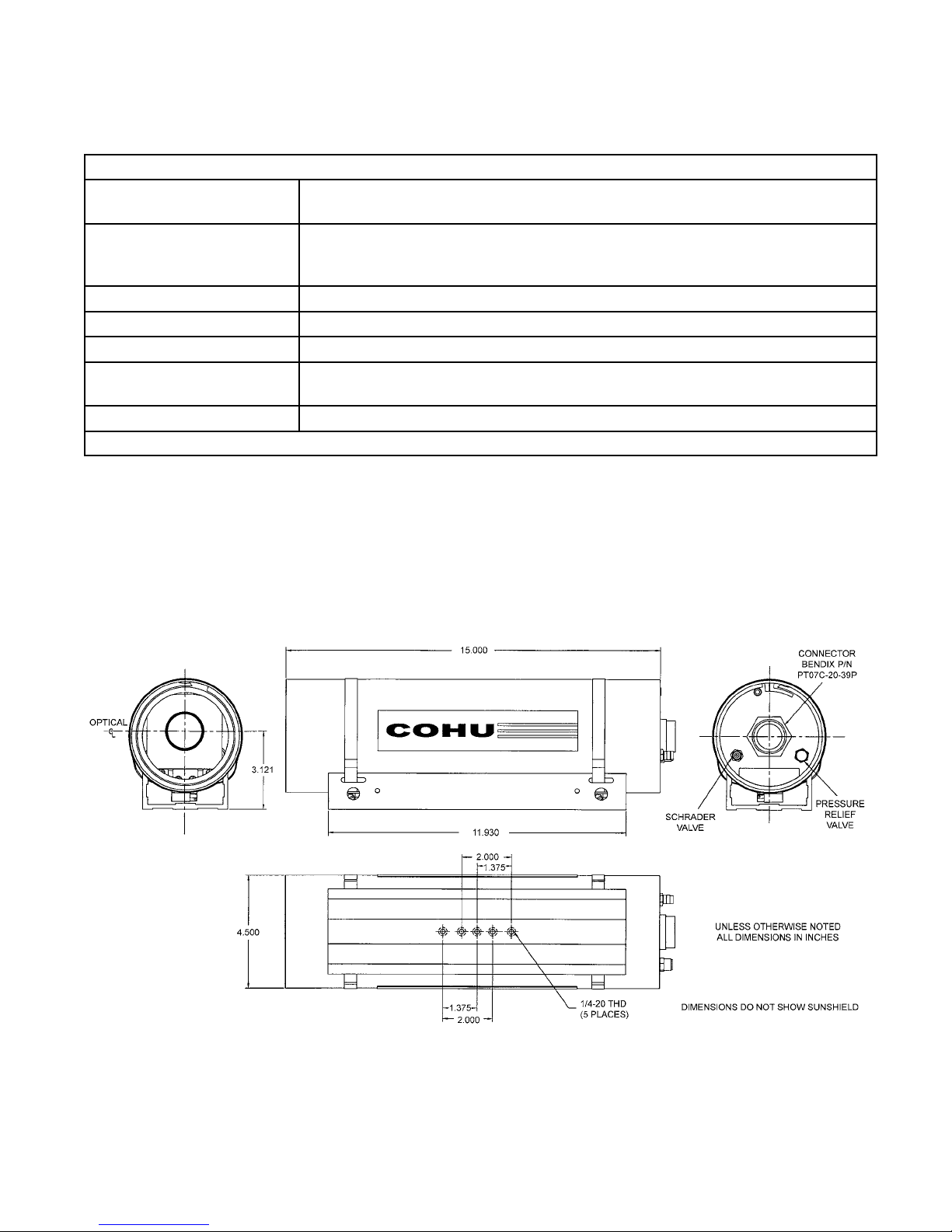

2.5 Mounting Requirements

Five 1/4-20 threaded holes are available on the

base for mounting a Camera. See figure 2. At least two

of these holes should be used. If the camera is to be

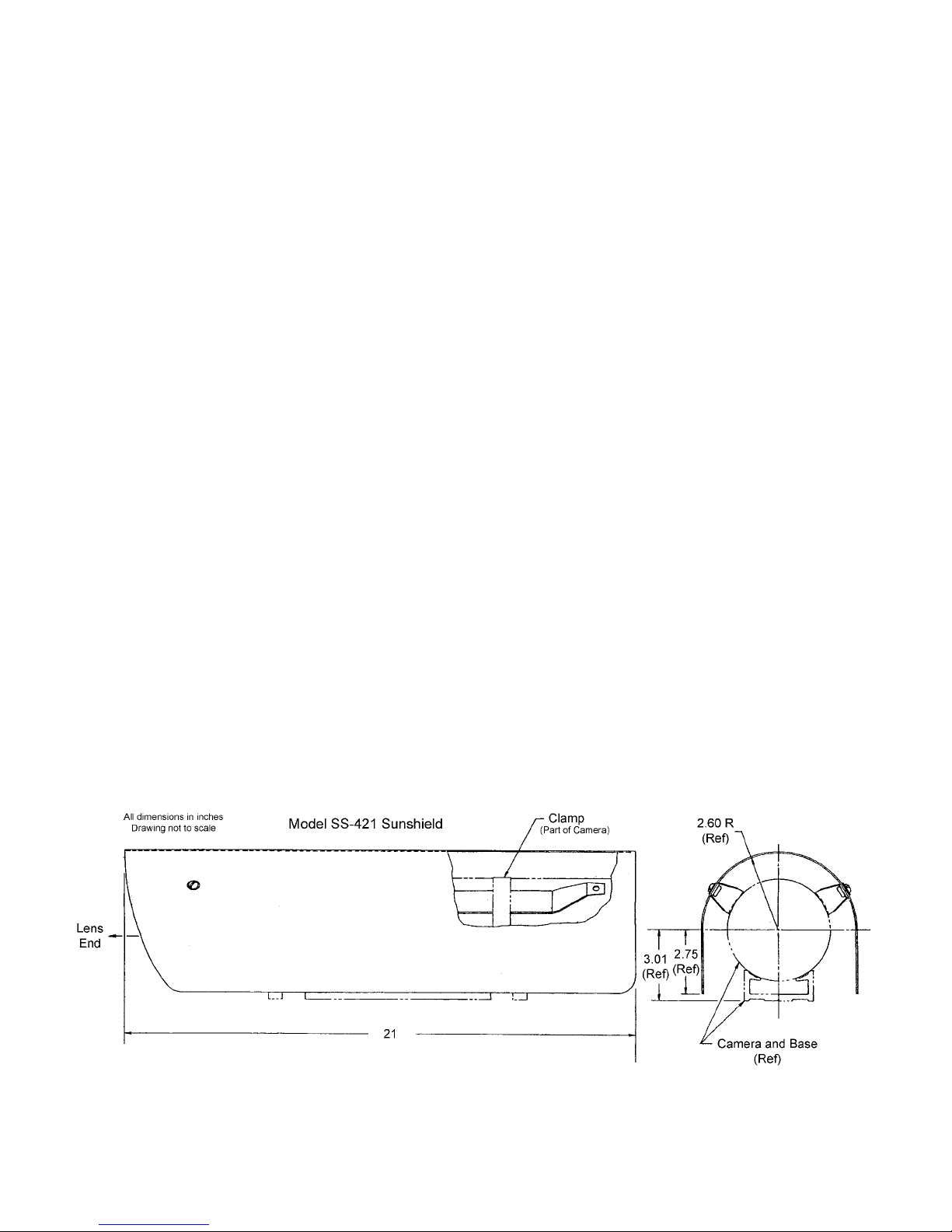

mounted outdoors it is likely the sun shield (figure 3)

will be required.This must be attached to the cam-

era before it is mounted to a pole, wall, or other type

device.

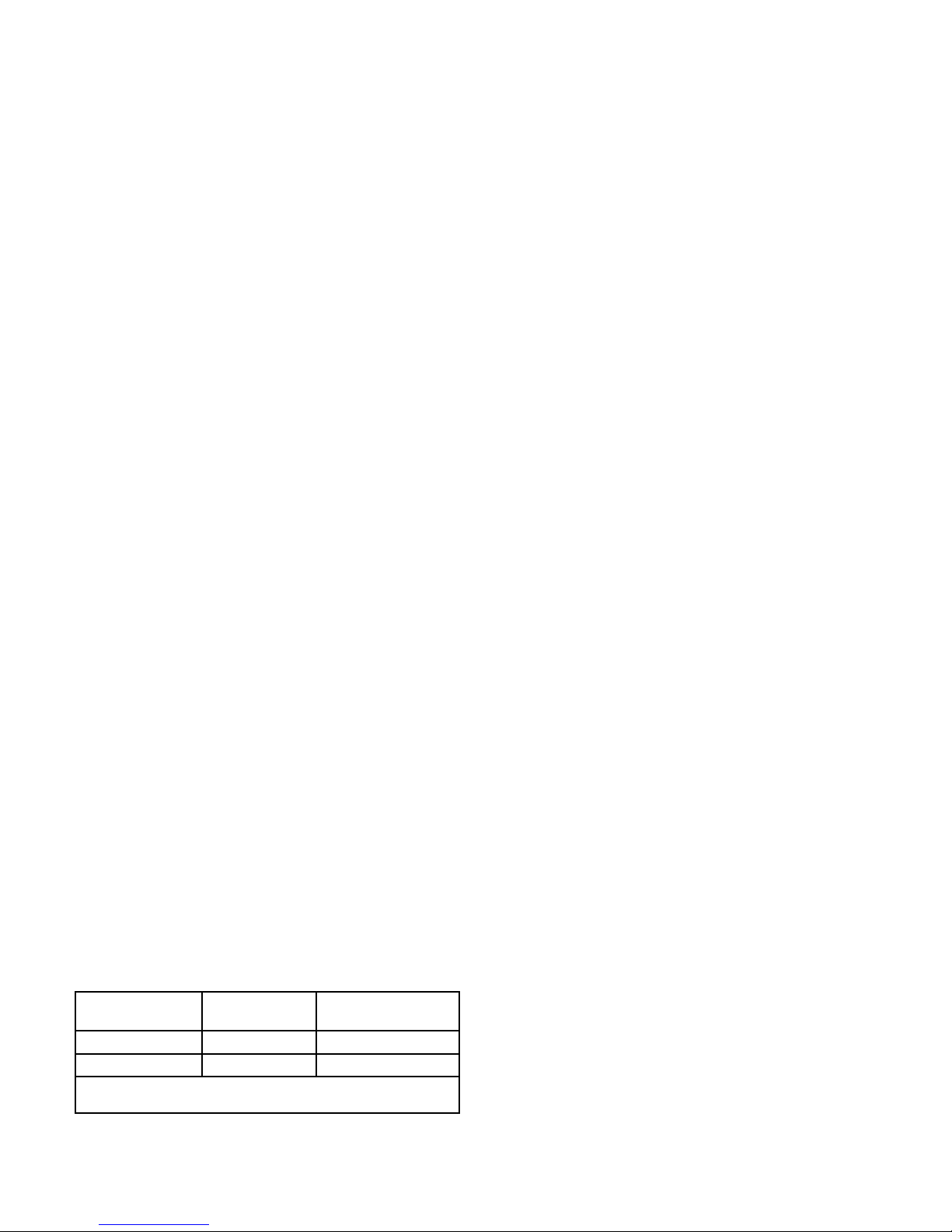

2.6 Camera Module Characteristics

Any one of seven different versions of an inter-

nal camera modules may be installed in the housing

(table 3).These modules have different operating

characteristics as listed in the table.

2.7 Low Pressure Indicator (Option)

The housing is initially pressurized to about

5 psig (pounds square inch gage) (34.5 kPa) of dry

nitrogen. It is possible that this pressure may dissipate

over time, but so long as even a minimal amount of

the dry nitrogen pressure remains in the housing the

camera can be considered operational.When pres-

sure drops to about 1 psig, though, it may be best to

reapply dry nitrogen to bring pressure up to about 5

psig again.

To provide an indication of low pressure, the

housing can be optioned with a low pressure sensor

that provides two indications when pressure drops

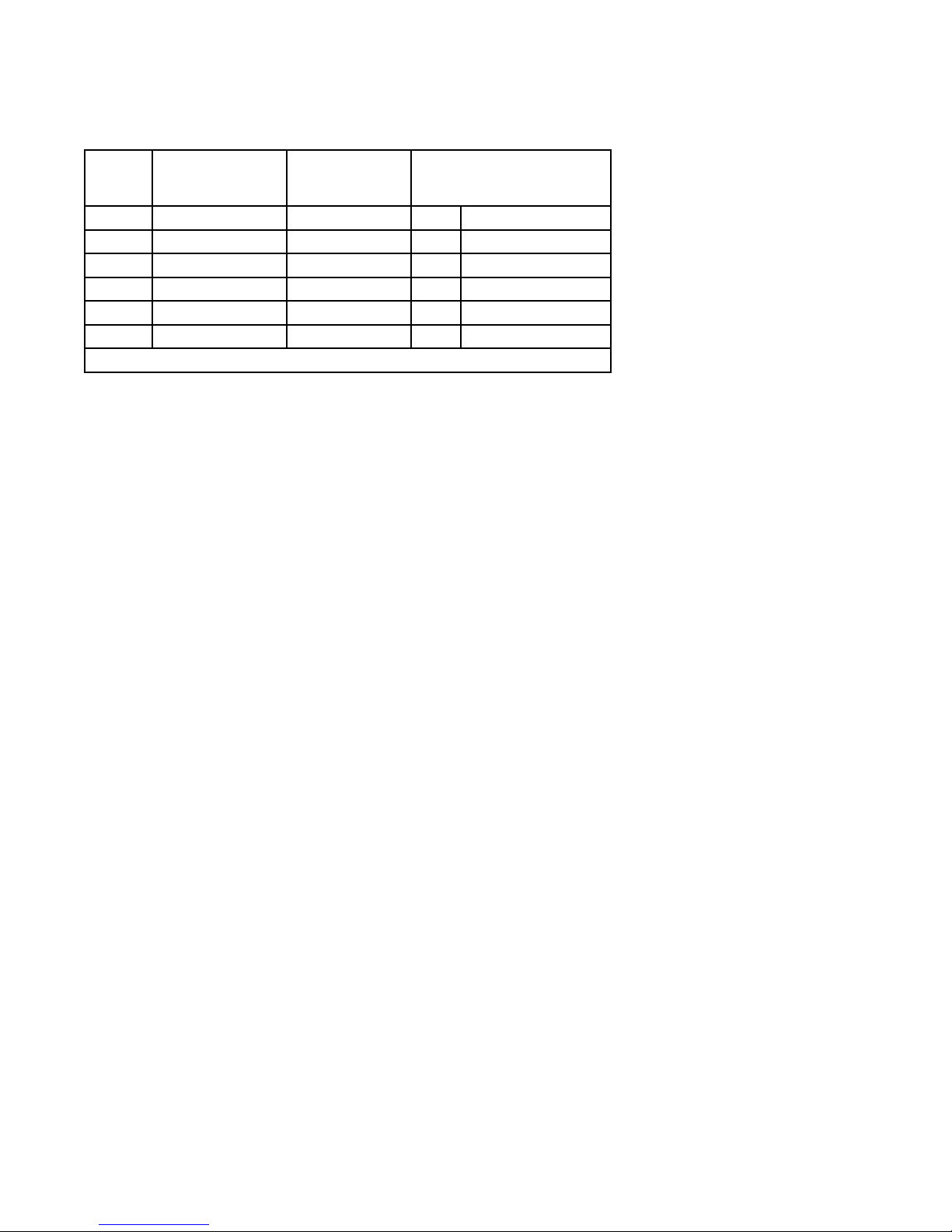

Table 3. Camera Module Characteristics

Imager

Model

Resolution

Max Image Size

H & V

Frame Rate at

704 x 480 V

Resolution

Frame Rate

at Max Resolution

(H & V)

301 1280 x 1024 6 ips 1.5 1280 x 1024

302 1600 x 1200 6 1.0 1600 x 1200

303 2048 x 1536 6 0.5 2048 x 1536

601 1280 x 1024 100 + ips 30 1280 x 1024

602 1600 x 1200 100 + ips 20 1600 x 1200

603 2048 x 1536 100 + ips 12 2048 x 1536