(CR0687740) 6

INSTALLATION INSTRUCTIONS

CONFORMITY TO REGULATIONS AND LAWS

The appliance is to be installed by an authorised person in

accordance with AS5601 - the installer must ensure the

installation complies with all regulatory and manufacturer

requirements and operationally and functionally test, make

necessary adjustments and commission the appliance as part

of installation.

WARNING

The manufacture declines any responsibility if these

obligations are not respected.

INSTALLATION

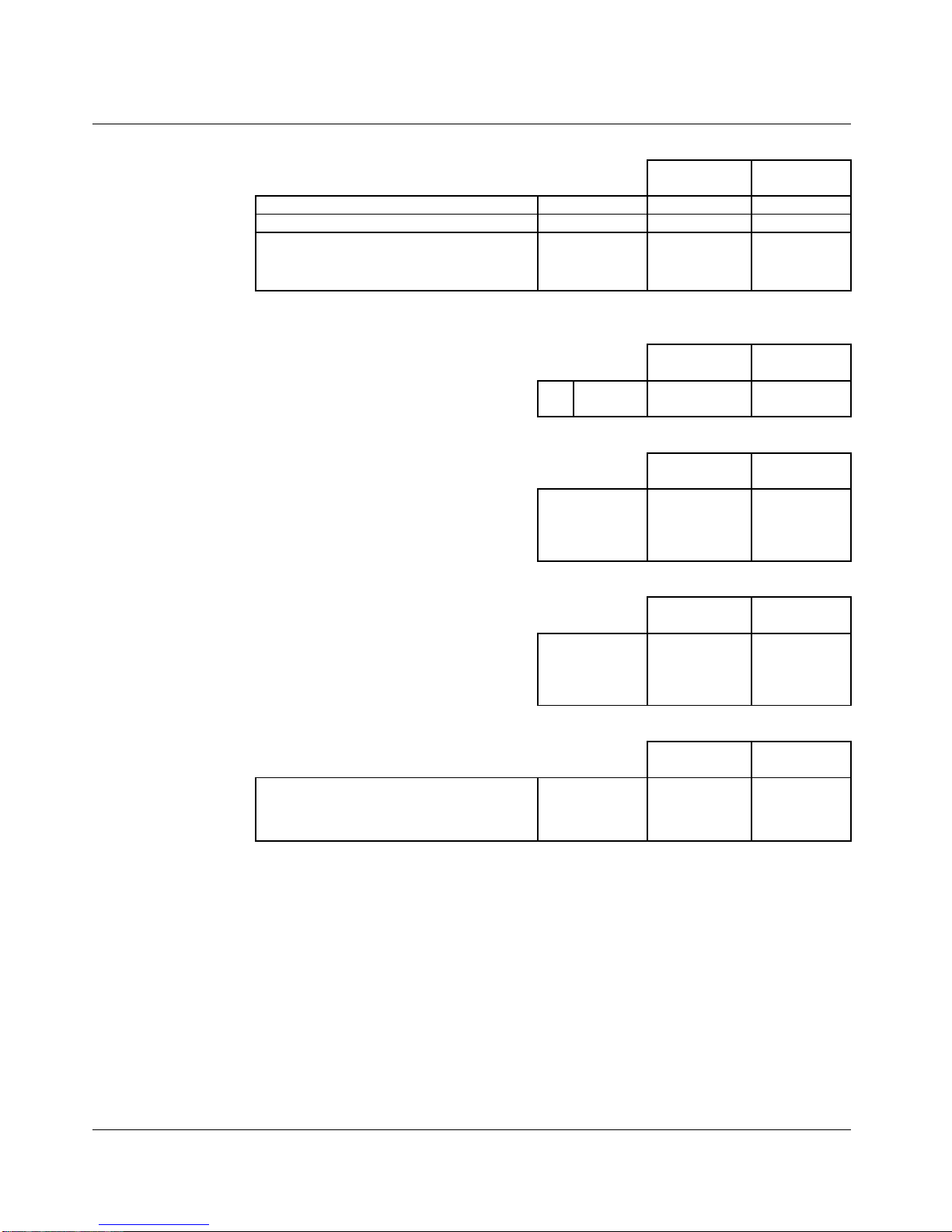

The overall dimensions, position/dimensions of connections

and technical data are given in the installation diagram.

If the appliance cannot be adjusted to perform correctly call

the tecnichal assistant service.

Positioning

• Install the appliance in a suitably ventilated environment.

• Position the appliance at least 15 cm from surrounding

walls. This distance may be reduced if the walls are

flameproof or protected by insulating material.

• This appliance is not designed for built-in installation.

• Remove the protective film from the external panels.

Use a suitable solvent to remove any glue residue.

• In stand-alone installations, appliances 40 or 60 cm wide

must be fixed to the floor using the flanged feet.

• Level the appliance by means of the adjustable feet.

• In case of installation on a level bench top, it must be used

the approriate feets equipped with the applince (height = 30

mm).

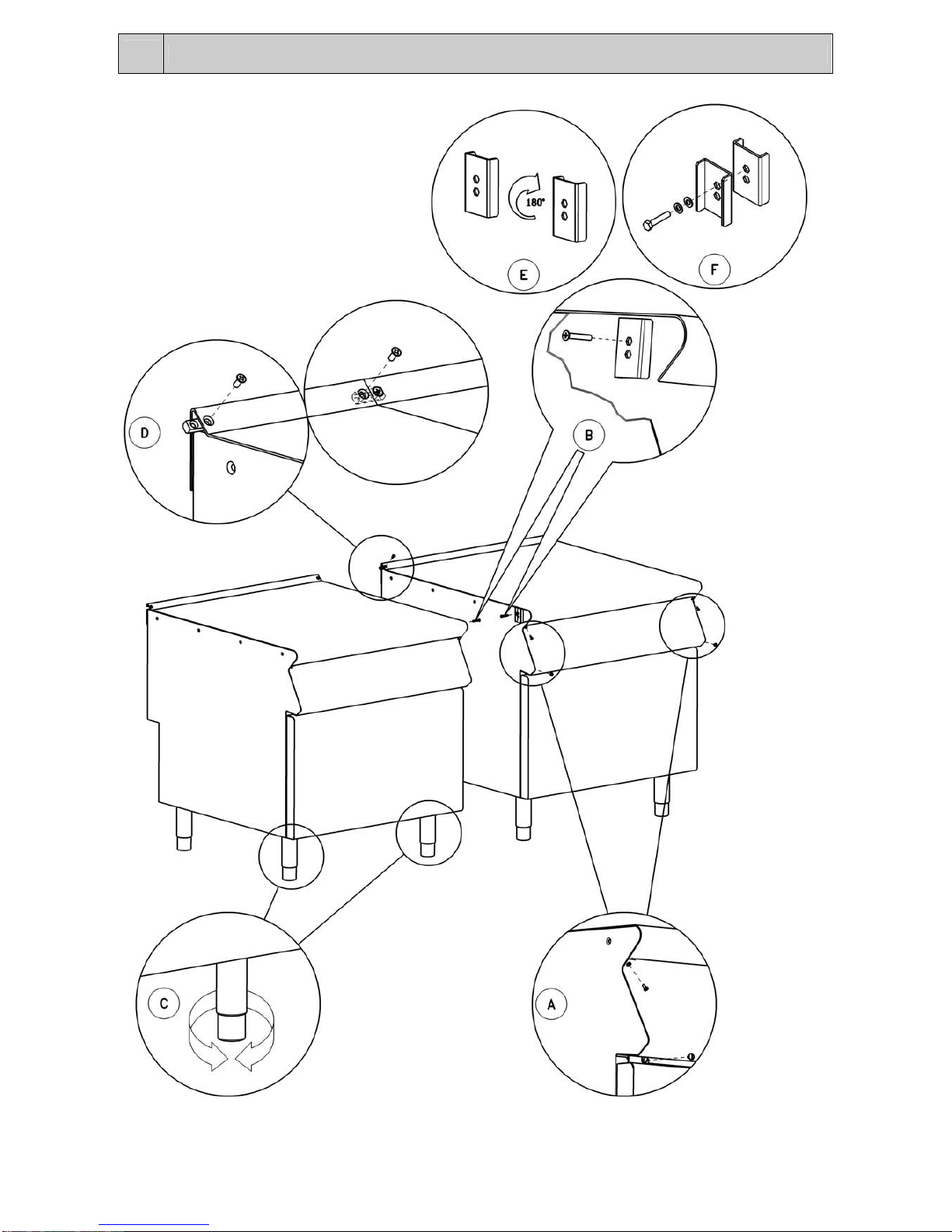

Joining appliances together in line ( Fig. 1 )

• Remove the control panels ( Fig. 1A ).

• Remove the fixing screw nearest the control panels, from

each side to be joined ( Fig. 1B ).

• Place the appliances next to each other and level them until

the tops match ( Fig. 1C ).

• Insert the coupling plate ( supplied ) into the side housings

on the backs. Join together the appliances screwing M5

flathead screws ( supplied ) in to coupling plate ( Fig. 1D ).

• Turn 180º one of the two plates inside the appliances to be

joined together ( Fig. 1E ).

• Join together the appliances , at the front side, screwing the

M5x40 screw ( supplied ) on the opposite insert (Fig. 1F ).

Connecting to the gas supply

• Install a shut-off valve upstream of the appliance, in a

place easily accessible.

• Check if the appliance is adjusted for the type of gas with

which it will be supplied. If not, convert it according to the

instructions in the paragraph "Conversion to different type of

gas".

• Do not use supply pipe having a diameter smaller than the

appliance’s gas connection.

• Check that there are no leaks at the connection points.

CONVERSION TO A DIFFERENT TYPE OF GAS

To convert the appliance to a different gas supply, follow the

instructions below.

Use the injectors contained in the bag supplied with the

appliance.

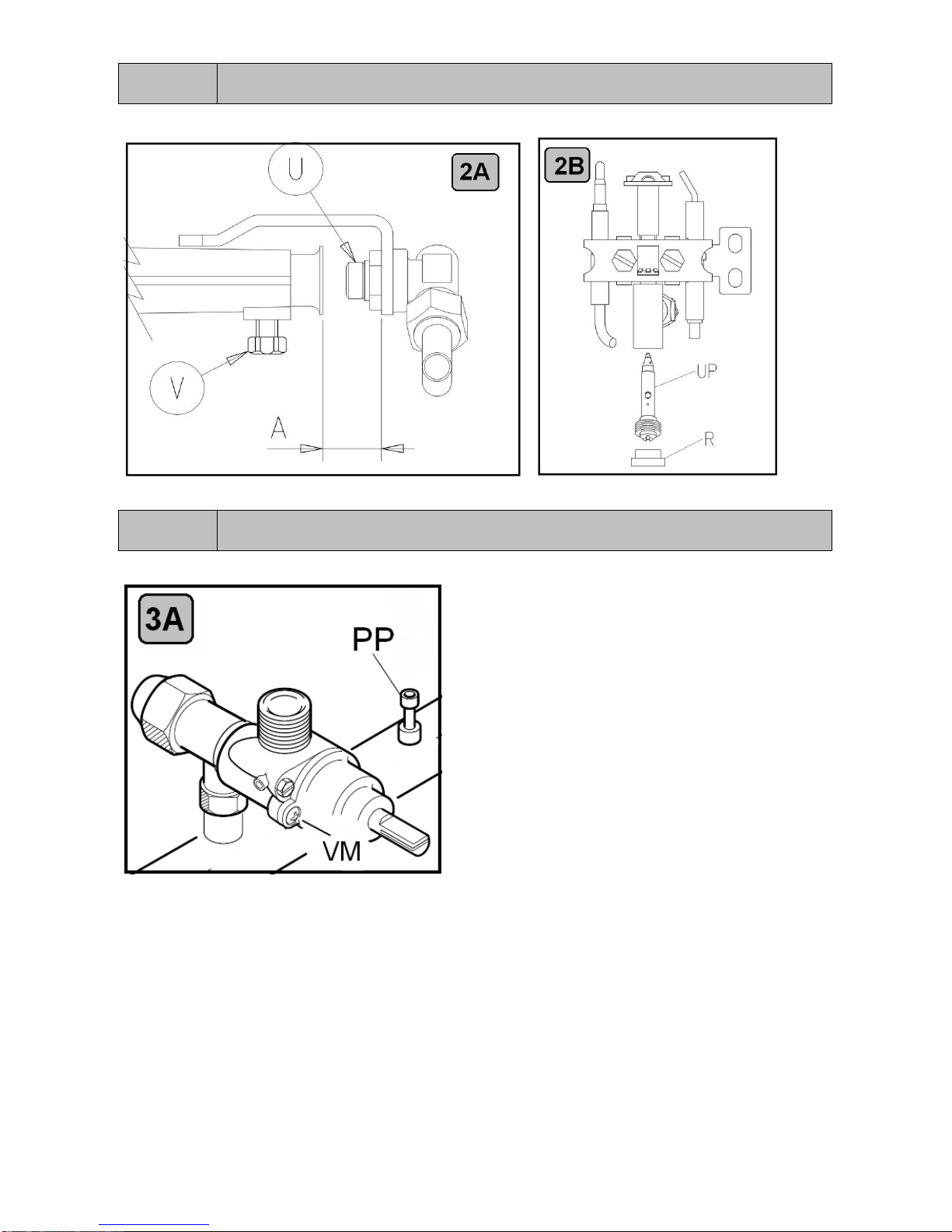

Replacement of burner injector and adjustment of

burner air flow (Fig. 2)

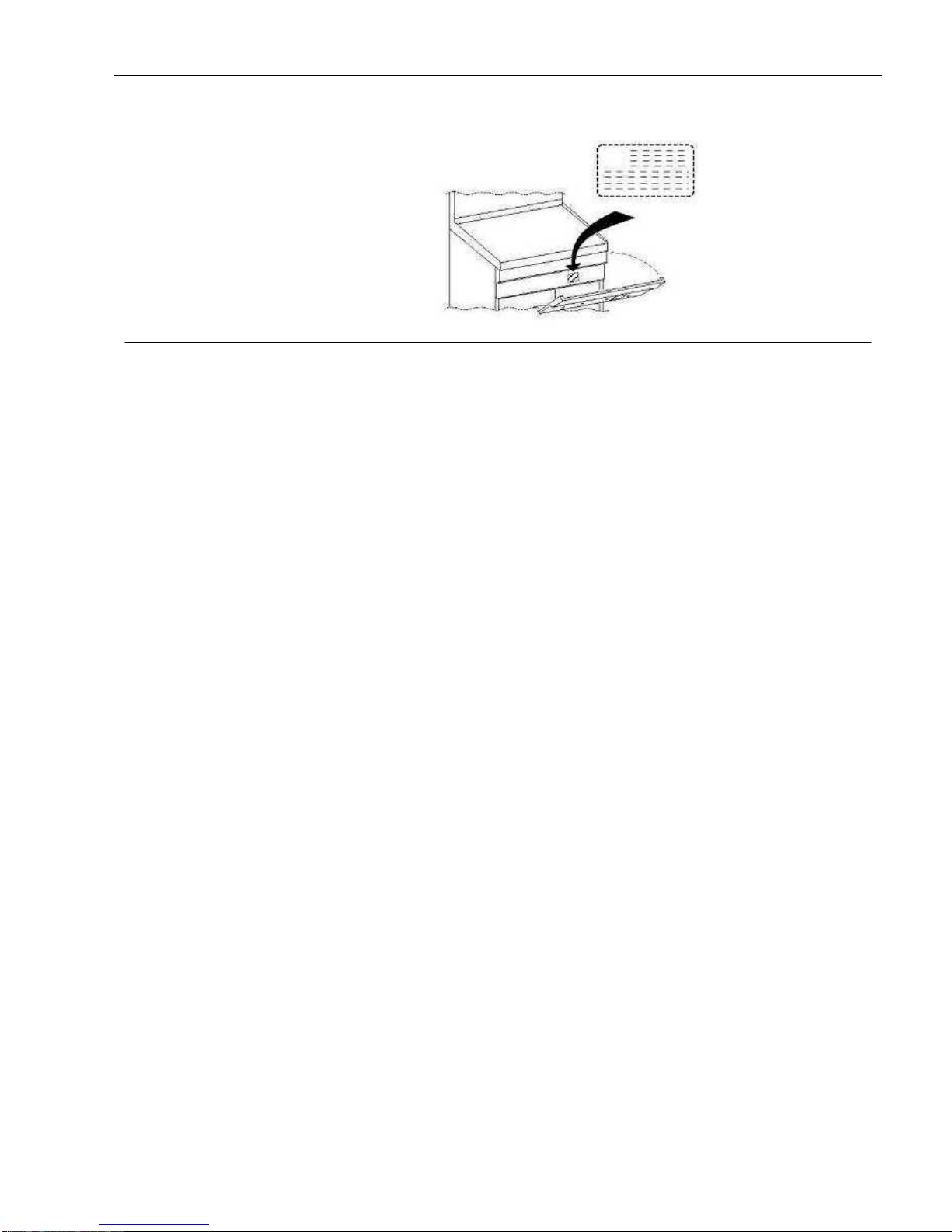

• Remove the upper front panel and drawer.

• Unscrew the existing injector "U" and replace it with the

one indicated in Table T1 in Technical Data section.

• Position the air regulator at the distance “A” indicated in

Table T2 in Technical Data section.

• Retighten screw V and seal it with red paint.

Adjustment of minimum flow to the burner (Fig. 3)

• Remove the upper front panel.

• Unscrew the existing screw "VM" and replace it with the

one indicated in Table T1 in Technical Data section.

Replacement of pilot burner injector (Fig. 2)

• Remove the upper front panel.

• Unscrew fitting R and replace injector UP with the one

indicated in Table T1 in Technical Data section.

• Retighten fitting R.

COMMISSIONING PROCEDURE

Testing the gas system

• Switch on the appliance following the instructions for use.

Test burners ignition and flame uniformity. Also check the

appliance for gas leaks and make sure the gas exhaust system

functions correctly.

• If necessary, consult the “Troubleshooting guide” below.

Testing the gas nominal thermal power

• After installation, conversion to a different type of gas or

servicing, check the nominal thermal power of the appliance.

• The appliance functions at the nominal thermal power when

is fitted with the appropriate injectors for the gas used and

the gas pressure measured at the manifold pressure test point

is commissioned to the appropriate nominal value as

specified in Table T5 in Technical Data section.

Setting the manifold gas pressure (Fig. 3)

• Remove the lower front panel.

• Remove sealed bolt PP from the test point pressure and

connect the pressure gauge pipe.

• Switch on the appliance following the instructions for use

and commission the test point pressure value to the

appropriate nominal values as specified in Table T5 in

Technical Data section.

TROUBLESHOOTING GUIDE

The pilot burner is difficult or impossible to ignite

• Gas supply pressure low.

• Gas pipe or injector clogged.

• Gas tap faulty.

• Piezo igniter faulty.

• Ignition electrode (ignition spark gas should be 3 + 1/0 mm)

or cable faulty.

The pilot burner goes out during use

• Thermocouple faulty, insufficiently heated or incorrectly

connected to gas valve.

• Gas tap faulty.

The main burner is difficult or impossible to ignite

•Gas supply pressure low.

• Injectors clogged.

• Gas tap faulty.

REPLACEMENT OF SPARE PARTS

Before every intervention close the gas and water shut-off

valves upstream the appliance and disconnect the

electrical supply.

Never tamper with any of the sealed components.

After every intervention, check for gas leaks, if necessary.