iom-cliwp-eng

6

www.comfort-ex.com

EFFICIENCY

CLIWP units are designed to meet the needs of any project

for telecommunications networks, data centers, laboratories,

schools, hospitals and industrial use.

CLIWP units have diverse applications and can be installed

individually or in any combination to achieve the exact capacity of

the project. Their high efficiency and easy operation achieves the

desired temperatures accurately, quickly and with efficient energy

consumption.

The CLIWP units can work 1 + 1 (by means of a separately

purchased sequencer), i.e., one in operation and one in backup.

The units have different connectivity and remote monitoring

options using the most common protocols such as ModBus,

BACnet and TCP/IP.

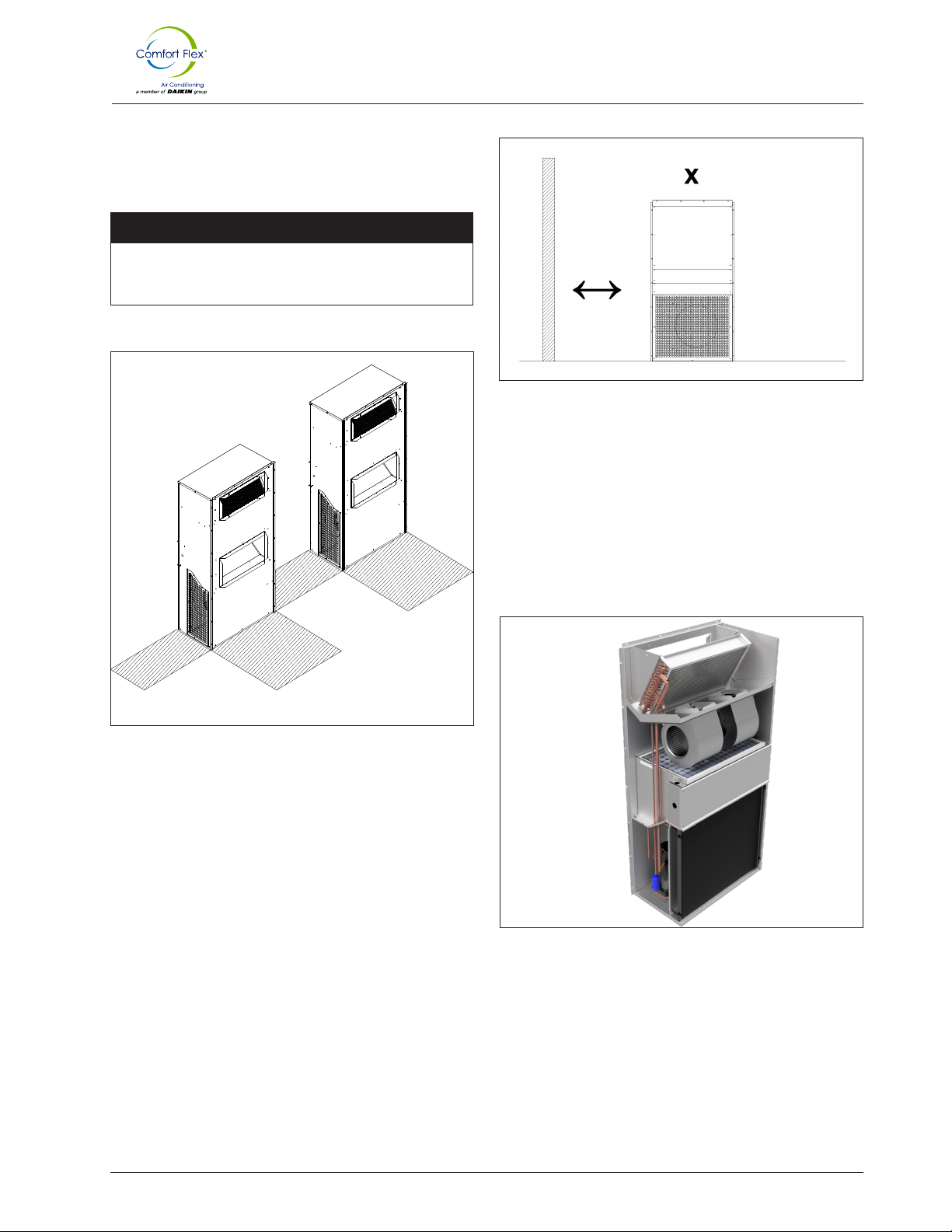

SELF CONTAINED AND SELF SPACE

SAVING

The CLIWP unit is completely self-contained. All its components

are inside the cabinet. It uses no usable space in the room to

be conditioned, it is installed on an exterior wall with a minimum

volume, without requiring roof areas or exterior floors.

EASY TO INSTALL

The equipment is assembled, wired, charged with refrigerant, oil

and is systematically factory tested to ensure that you will have a

quick and trouble-free installation.

DESIGN

The work carried out by our engineering and development

department has resulted in equipment with high efficiency in

design and optimum performance during operation.

The selection of high quality main components, our quality

processes and the control system during manufacturing,

guarantee a high performance and safety equipment.

All major components are rigorously tested and validated before

installation. Each engineered unit has undergone long hours of

rigorous testing to ensure the efficiency, safety, durability and

quality of the entire system.

All external paint is baked-on and meets the most stringent quality

standards (ASTM-B117 1500 hour salt spray test).

The selection of high-end compressors and heat exchangers

ensures the capacity and high efficiency of the equipment.

All our equipment has a reduced footprint, which facilitates

installation and maintenance maneuvers, being able to make use

of stairs, doors and service elevators to move the equipment.

COMMUNICATION

Our equipment can be connected / integrated through different

communication protocols; such as TCP/IP, ModBUS and BacNet**,

the most common protocols used in the Air Conditioning industry.

Our equipment keeps track of all programmable variables in

real time, such as system load monitoring, specific alarms of the

refrigeration cycle, and the electrical system.

MAINTENANCE

The simplicity in the design of the equipment allows for maximum

ease of preventive/corrective maintenance. All major components

are available to maintenance personnel by simply opening the

service panels.

If an emergency shutdown occurs, the digital control of the

equipment will indicate in detail the cause of the alarm, helping to

facilitate and accelerate the solution of the alarm.

TESTS

NOTE:

The control system ensures the correct operation of the equipment

by monitoring in real time the condition of the major components

(high or low refrigerant pressure, compressor conditions and

electrical power monitoring).

In case of failure, the event will be recorded for later analysis,

facilitating the location of a possible failure and its solution.

* Depends on the type of control.

** The available communication protocols depend on the type of

control.

This equipment is charged with the refrigerant necessary for

proper

The units are tested at full load operation, thermal load and line

voltage at actual operating conditions.