COMFORTPOOL ECO+3 Service manual

SWIMMING POOL HEAT PUMP UNIT

Installation & Instruction Manual

ZWEMBAD WARMTEPOMP

Installatie & Gebruikershandleiding

POOL-WÄRMEPUMPE

Installations- & Benutzerhandbuch

Applicable Model / Van toepassing op / Für folgende Modelle:

ECO+3

ECO+5

ECO+8

ECO+10

ECO+12

2

Contents

CONTENTS ___________________________________________________________________________ 2

1. PREFACE _________________________________________________________________________ 5

2. SPECIFICATIONS ____________________________________________________________________ 10

2.1 Performance data of ECO Swimming Pool Heat Pump Unit ___________________________________________________ 10

2.2 Dimensions of swimming pool heat pump unit _____________________________________________________________ 11

3. INSTALLATION OF THE HEAT PUMP UNIT_________________________________________________ 12

3.1 Heat pump location ___________________________________________________________________________________ 13

3.2 Distance to the pool ___________________________________________________________________________________ 14

3.3 Connecting the bypass _________________________________________________________________________________ 14

3.4 Electrical wiring_______________________________________________________________________________________ 15

3.5 Initial start-up________________________________________________________________________________________ 15

3.6 Condensation ________________________________________________________________________________________ 16

4. GUIDELINES _______________________________________________________________________ 16

4.1 Water chemistry ______________________________________________________________________________________ 16

4.2 Winterizing __________________________________________________________________________________________ 16

4.3 Spring start-up________________________________________________________________________________________ 17

4.4 Owner inspection _____________________________________________________________________________________ 17

5. CHECKUP AND MAINTENANCE_________________________________________________________ 18

5.1 Maintenance _________________________________________________________________________________________ 18

5.2 Trouble shooting guide ________________________________________________________________________________ 18

5.3 Microcontroller ______________________________________________________________________________________ 19

6. DETAILED SPECIFICATIONS ____________________________________________________________ 20

6.1 Electrical wiring diagram of the heat pump ________________________________________________________________ 20

7. WARRANTY ______________________________________________________________________ 21

3

Inhoud

1. INLEIDING_________________________________________________________________________ 22

2. SPECIFICATIES______________________________________________________________________ 27

2.1 Technische gegevens van de zwembad warmtepomp________________________________________________________ 27

2.2 Afmetingen van de zwembad warmtepomp _______________________________________________________________ 28

3. INSTALLATIE VAN DE WARMTEPOMP __________________________________________________ 29

3.1 Locatie van de warmtepomp ____________________________________________________________________________ 30

3.2 Afstand tot het zwembad_______________________________________________________________________________ 31

3.3 Aansluiting van de bypass ______________________________________________________________________________ 31

3.4 Elektrische bedrading __________________________________________________________________________________ 32

3.5 Eerste gebruik________________________________________________________________________________________ 32

3.6 Condensatie _________________________________________________________________________________________ 33

4. RICHTLIJNEN_______________________________________________________________________ 33

4.1 Waterchemie_________________________________________________________________________________________ 33

4.2 Winterklaar maken ____________________________________________________________________________________ 33

4.3 Voorjaarsopstart ______________________________________________________________________________________ 34

4.4 Inspectie ____________________________________________________________________________________________ 34

5. CONTROLE EN ONDERHOUD_________________________________________________________ 35

5.1 Onderhoud __________________________________________________________________________________________ 35

5.2 Probleemoplossing ____________________________________________________________________________________ 35

5.3 Microcontroller ______________________________________________________________________________________ 36

6. GEDETAILLEERDE SPECIFICATIES _______________________________________________________ 37

6.1 Elektrisch bedradingsdiagram van de warmtepomp _________________________________________________________ 37

7. GARANTIE_________________________________________________________________________ 38

4

Inhalt

1. VORWORT ________________________________________________________________________ 39

2. SPEZIFIKATIONEN ___________________________________________________________________ 44

2.1 Technische Daten der Pool-Wärmepumpe _________________________________________________________________ 44

2.2 Maße der Pool-Wärmepumpe ___________________________________________________________________________ 45

3. INSTALLATION DER WÄRMEPUMPE ___________________________________________________ 46

3.1 Standort der Wärmepumpe _____________________________________________________________________________ 47

3.2 Entfernung / Abstand zum Pool__________________________________________________________________________ 48

3.3 Anschluss des Bypasses ________________________________________________________________________________ 48

3.4 Elektrische Verdrahtung________________________________________________________________________________ 48

3.5 Die Inbetriebnahme ___________________________________________________________________________________ 49

3.6 Kondenswasserbildung ________________________________________________________________________________ 49

4. RICHTLINIEN_______________________________________________________________________ 50

4.1 Wasserchemie________________________________________________________________________________________ 50

4.2 Winterfest machen ____________________________________________________________________________________ 50

4.3 Frühlingsstart ________________________________________________________________________________________ 50

4.4 Überprüfung _________________________________________________________________________________________ 51

5. KONTROLLE UND WARTUNGSAUFGABEN _______________________________________________ 52

5.1 Wartung_____________________________________________________________________________________________ 52

5.2 Fehlerbehebung ______________________________________________________________________________________ 52

5.3 Mikrocontroller_______________________________________________________________________________________ 53

6. DETAILLIERTE SPEZIFIKATIONEN________________________________________________________ 54

6.1 Elektrisches Anschlussschema der Wärmepumpe ___________________________________________________________ 54

7. GARANTIE_________________________________________________________________________ 55

5

SWIMMING POOL HEAT PUMP UNIT

Installation & Instruction Manual

1.Preface

* In order to provide our customers with quality, reliability and versatility, this product has been made

to strict producing standards. This manual includes all necessary information about installation,

debugging, discharging and maintenance. Please read this manual carefully before you open or

maintain the unit. The manufacturer of this product will not be held responsible if someone is injured

or if the unit is damaged, as a result of improper installation or use, debugging or unnecessary

maintenance. It is vital that the instructions within this manual are adhered to at all times. Only

qualified persons should install the unit.

* Only a qualified installer, center, personnel or an authorized dealer are allowed to repair the unit.

* Maintenance and operation must be carried out at the recommended time and frequency, as stated

in this manual.

* Use genuine standard spare parts only.

* Failure to comply with these recommendations will void the warranty.

* The swimming pool heat pump unit heats the swimming pool water and keeps the temperature

constant.

Our heat pump has following characteristics:

Durable

The heating exchanger is made of PVC and titanium tubes, which can withstand prolonged exposure to

(salt) swimming pool water.

Easy operation

The unit is very easy to operate: switch it on and set the desired pool water temperature.

Quiet operation

The unit comprises an efficient rotary compressor and a low-noise fan motor, which guarantees its quiet

operation. The unit can heat your swimming pool water when the air temperature is 10°C or higher.

Low cost

The operational costs are very low due to its high performance.

6

Safety warnings & instructions

Read and follow all instructions in this manual and on the equipment. Failure to do so could result in severe

or fatal injuries, or damage the heat pump.

Meaning of symbols displayed on heat pump unit

WARNING

This unit uses a flammable refrigerant (R32).

If refrigerant leaks and comes in contact with fire or heating part, it will

create harmful gas and there is risk of fire.

Read the OPERATING INSTRUCTIONS carefully before operation.

Service personnel are reguired to carefully read the OPERATING INSTRUCTIONS and

INSTALLATION MANUAL before operation.

Further information is available in the OPERATING INSTRUCTIONS, INSTALLATION MANUAL,

and the like.

* Since rotating parts and parts which could cause an electric shock are used in this product, be sure

to read these “Safety Precautions” before use.

* Since the cautionary items shown here are important for safety, be sure to observe them.

* After reading this manual, keep it together with the installation manual in a handy place for easy

reference.

* Be sure to receive a guarantee card from your dealer and check that the purchased data and shop

name, etc. are entered correctly.

Symbols and their meaning

WARNING

Incorrect handling could cause serious hazard, such as death, serious

injury, etc. with a high probability.

CAUTION

Incorrect handling could cause serious hazard depending on the

conditions.

Meaning of symbols used in this manual

Be sure not to do this.

Be sure to follow the instructions.

Never insert your finger or a stick, etc.

Never step onto the indoor/outdoor unit and do not put anything on them.

Danger of electric shock. Be careful.

7

Be sure to disconnect the power supply plug from the power outlet.

Be sure to shut off the power.

Risk of fire.

WARNING

Do not connect the power cord to an intermediate point, use an extension cord, or connect

multiple devices to heat pump. This may cause overheating, fire, or electric shock.

Make sure the power plug is free of dirt and insert it securely into the outlet. A dirty plug may

cause fire or electric shock.

Do not bundle, pull, damage, or modify the power cord, and do not apply heat or place

heavy objects on it. This may cause fire or electric shock.

Do not turn the breaker OFF/ON or disconnect/connect the power plug during operation.

This may create sparks, which can cause fire.

Do not expose your body directly to cool air for a prolonged length of time. This could be

detrimental to your health.

The unit should not be installed, relocated, disassembled, altered, or repaired by the user.

An improperly handled heat pump may cause fire, electric shock, injury, or water leakage,

etc. Consult your dealer.

If the power supply cord is damaged, it must be replaced by the manufacturer or its service

agent in order to avoid a hazard.

When installing, relocating, or servicing the unit, make sure that no substance other than the

specified refrigerant (R32) enters the refrigerant circuit.

Any presence of foreign substance such as air can cause abnormal pressure rise and may

result in explosion or injury.

The use of any refrigerant other than that specified for the system will cause mechanical

failure, system malfunction, or unit breakdown. In the worst case, this could lead to a serious

impediment to securing product safety.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety.

Children should be supervised to ensure that they do not play with the appliance.

The appliance shall be stored in a room without continuously operating ignition sources (for

example: open flames, an operating gas appliance or an operating electric heater).

Do not insert your finger, a stick, or other objects into the air inlet or outlet. This may cause

injury, since the fan inside rotates at high speeds during operation.

8

In case of an abnormal condition (such as a burning smell), stop the heat pump and

disconnect the power plug or turn the breaker OFF. • A continued operation in the abnormal

state may cause a malfunction, fire, or electric shock. In this case, consult your dealer.

When the heat pump does not cool or heat, there is a possibility of refrigerant leakage. If any

refrigerant leakage is found, stop operations and ventilate the room well and consult your

dealer immediately. If a repair involves recharging the unit with refrigerant, ask the service

technician for details. The refrigerant used in the heat pump is not harmful. Normally, it does

not leak. However, if refrigerant leaks and comes in contact with fire or heating part of such

a fan heater, kerosene heater, or cooking stove, it will create harmful gas and there is risk of

fire.

The user should never attempt to wash the inside of the indoor unit. Should the inside of the

unit require cleaning, contact your dealer. • Unsuitable detergent may cause damage to

plastic material inside the unit, which may result in water leakage. Should detergent come in

contact with electrical parts or the motor, it will result in a malfunction, smoke, or fire.

The appliance shall be stored in a room without continuously operating ignition sources (for

example: open flames, an operating gas appliance or an operating electric heater). Be

aware that refrigerants may not contain an odour. Do not use means to accelerate the

defrosting process or to clean the appliance, other than those recommended by the

manufacturer. Do not pierce or burn.

This unit should be installed outdoor or in rooms which exceed the floor space specified

below. GL50 : 2.2 m2 or larger

GL60 : 2.3 m2 or larger

GL71/80: 3.1 m2 or larger

CAUTION

Do not touch the air inlet or the aluminum fins of the heat pump unit • This may cause injury.

Do not use insecticides or flammable sprays on the unit. This may cause a fire or deformation

of the unit.

Do not expose pets or houseplants to direct airflow. This may cause injury to the pets or

plants.

Do not place other electric appliances or furniture under the heat pump unit. Water may drip

down from the unit, which may cause damage or malfunction.

Do not leave the unit on a damaged installation stand. The unit may fall and cause injury.

Do not step on an unstable bench to operate or clean the unit. This may cause injury if you fall

down.

Do not pull the power cord. This may cause a portion of the core wire to break, which may

cause overheating or fire.

Do not charge or disassemble the batteries, and do not throw them into a fire. This may cause

the batteries to leak, or cause a fire or explosion.

9

Do not use the unit for special purposes, such as storing food, raising animals, growing plants,

or preserving precision devices or art objects. This may cause deterioration of quality, or harm

to animals and plants.

Do not expose combustion appliances to direct airflow. This may cause incomplete

combustion.

Before cleaning the unit, switch it OFF and disconnect the power plug or turn the breaker

OFF. This may cause injury, since the fan inside rotates at high speeds during operation.

When the unit will be unused for a long time, disconnect the power plug or turn the breaker

OFF. The unit may accumulate dirt, which may cause overheating or fire.

Ensure that the area is well-ventilated when the unit is operated together with a combustion

appliance. Inadequate ventilation may cause oxygen starvation.

After the heat pump is used for several seasons, perform inspection and maintenance in

addition to normal cleaning. Dirt or dust in the unit may create an unpleasant odor, contribute

to growth of fungi, such as mold, or clog the drain passage, and cause water to leak from the

indoor unit. Consult your dealer for inspection and maintenance, which require specialized

knowledge and skills.

Do not operate switches with wet hands. This may cause electric shock.

Do not clean the heat pump with water or place an object that contains water, such as a flower

vase, on it. This may cause fire or electric shock.

Do not step on or place any object on the unit. This may cause injury if you or the object falls

down.

IMPORTANT

Dirty pool filters cause condensation in the heat pump which will contribute to the growth of fungi such as

mold. It is therefore recommended to clean or change the filters every 2 weeks.

Above warnings and cautions are not intended to incorporate all possible instances for risks and/or severe

injuries. Owners and users of the heat pump should always exercise caution and common sense when

utilizing the product.

Note: This manual can be modified without notice if the unit is altered in any way.

10

2. Specifications

2.1 Performance data of ECO Swimming Pool Heat Pump Unit

MODEL

ECO+3

ECO+5

ECO+8

ECO+10

ECO+12

Heating Capacity in

A27/W27°C

W

3700

5500

6200

8900

11500

Heating Capacity in

A15/W26°C

W

3000

4000

4500

6100

8200

Heating Capacity

W

3000

4500

5300

7800

9500

Heating Input Power

W

729

1050

1250

1650

2230

Heating Running Current

A

3.3

5

5.7

7.5

10.6

Power Supply

220V/1Ph/50Hz

Controller

Mechancial Controller

Condenser

PVC With Titanium

Quantity of Compressor

1

1

1

1

1

Compressor Type

Rotary

Noise

dB(A)

51

54

55

55

57

Water Connection

mm

50

50

50

50

50

Water Flow Volume

m³/h

3-5

4-6

4-6

4-7

4-7

Water Pressure Drop

kpa

10

10

12

12

15

Dimension (L)

mm

770

936

936

936

1010

(W)

mm

300

360

360

360

370

(H)

mm

490

550

550

550

615

Packing Size(L)

mm

820

1090

1090

1090

1170

(W)

mm

315

390

390

390

415

(H)

mm

525

580

580

580

645

Net Weight / Gross Weight

kg

29/32

36/39

39/42

54/57

63/67

Measurement conditions:

Dry bulb 24° C, wet bulb 19° C, water inlet temp. 27° C.

11

2.2 Dimensions of swimming pool heat pump unit

A

B

C

D

E

F

G

H

ECO+3

213

295

720

760

80

200

455

490

ECO+5

280

365

906

940

80

200

521

550

ECO+10

280

365

906

940

80

200

521

550

ECO+12

301

375

975

1015

83

270

585

615

12

3. Installation of the heat pump unit

WARNING

Consult your dealer for installing the heat pump. It should not be installed by the user since

installation requires specialized knowledge and skills. An improperly installed heat pump may

cause water leakage, fire, or electric shock.

Provide a dedicated power supply for the heat pump. A non-dedicated power supply may cause

overheating or fire.

Do not install the unit where flammable gas could leak. If gas leaks and accumulates around the

unit, it may cause an explosion.

Ground the unit correctly. Do not connect the ground wire to a gas pipe, water pipe, lightning

rod, or a telephone ground wire. Improper earthing may cause electric shock.

CAUTION

Install a RCD depending on the installation location of the heat pump (such as highly humid

areas).If a RCD is not installed, it may cause electric shock.

Ensure that the drain water is properly drained. If the drain passage is improper, water may drip

down from the unit, wetting and damaging the furniture.

Please prepare the professional tools for R32 refrigerant heat pump before you do maintenance.

R32

leak

detector

Explosion-

proof

vacuum

pump

Antistatic

gloves

The factory only provides the heat pump unit. Other items, including an eventual bypass, that are

necessary for the water system, are to be provided by users or installers.

Attention! Please follow these steps when installing the heat pump:

1. All feeding of chemicals to the pool water must be done downstream of the heat pump.

2. Install a bypass when the flow of the pool pump is more than 20% above the rated flow of the heat

exchanger of the heat pump.

3. Install the heat pump on a solid foundation and use the damping rubbers to eliminate vibrations and

noise.

4. Always keep the unit straight up. If the unit has been tilted or put on its side, allow 24h before

starting the unit.

13

3.1 Heat pump location

The unit may be installed virtually anywhere outdoors. If you wish to place the heat pump inside, make sure

there is enough room and ventilation around the pump.

DO NOT put the unit in an enclosed area with a limited air volume where the discharge air will be re-

circulated. DO NOT put the unit next to shrubs, which can block the air inlet. Such locations deny a

continuous source of fresh air, which reduce its efficiency and may prevent adequate heat delivery. Install

the heat pump where you have the best access to warm air during the swimming season.

14

The picture below illustrates the minimum required distances from each side of the heat pump.

3.2 Distance to the pool

Install the heat pump as close to the swimming pool as possible to minimize heat loss through the piping.

3.3 Connecting the bypass

With the bypass set correctly, your heat pump will deliver its best performance. The bypass has to be built

as shown below:

VALVE1 –Slightly closed

(water pressure increased from 10 to 20 bar)

VALVE2 –Completely open

VALVE3 –Half way open

Setting the valve of the bypass:

1. Open all 3 valves entirely

2. Slightly close valve 1

3. Close valve 3 about half way to adjust the

refrigerant pressure

15

3.4 Electrical wiring

Note: Verify the local power supply and the operating voltage of the heat pump. It is recommended to use

the included separate circuit breaker for the heat pump, together with the proper wiring characteristics (see

wiring diagram). The current to the heat pump should only be applied when the filter pump is running.

Further connect the electrical supply to the junction box inside the unit. All ECO heat pumps require single-

phase connection.

Grounding: The circuit breaker protects you against electrical shock caused by a possible short circuit

inside the unit. The heat pump in itself is unable to provide a water flow. Therefore, the heat pump must be

wired electrically together with the filter pump to ensure a water flow while the heat pump is running.

MODEL

POWER SUPPLY (VOLT)

CIRCUIT BREAKER (A)

RUNNING CURRENT (A)

CABLE DIAMETER (mm2)

cable length max. 15m

ECO+3

220-240

16

3,3

1,5

ECO+5

220-240

16

4,8

1,5

ECO+10

220-240

20

7,5

2,5

ECO+12

220-240

20

10

2,5

* Values in this table are only guidelines. Please check your local regulations.

3.5Initial start-up

Startup procedure

After the installation is completed, you should follow these steps:

1. Open bypass valve 1 entirely. Turn on your filter pump, check for water leaks and verify the flow to

and from the pool.

2. Turn on the electrical power supply to the unit, then turn the unit ON with the switch. Slightly close

valve 1 until the heat pump starts.

3. After a few minutes, check if the air leaving the unit is cooler.

4. Allow the unit and filter pump to run 24 hours a day until the desired pool water temperature is

reached. When the set temperature is reached, the unit shuts off. The unit will now automatically

restart (as long as your pool pump is running) when the temperature of the pool water drops more

than 1°C below set temperature.

Several days are needed to bring the temperature of your swimming pool water to its required value.

Covering the pool or the use of ground insulation can drastically reduce this period.

Time delay

The unit is equipped with a built in 3-minute start delay to protect the control circuit components and to

eliminate restart cycling an contactor chatter. This time delay will automatically restart the unit aproximately

3 minutes after each circuit interruption. Even a brief power interruption of the power supply will activate

this delay and prevent the unit from starting until the 3-minute countdown is completed.

16

3.6Condensation

Since the heat pump cools down the air about 8°C –12 °C, water may condense on the fins of the

evaporator. If the relative humidity is very high, this could be as much as several liters an hour. Sometimes

this condensation water is wrongly considered as swimming pool water.

4. Guidelines

4.1 Water chemistry

Special care should be taken to keep the chemical balance of your swimming pool within limits:

pH

7,0 –7,4

Free chlorine (mg/l)

0,5 –1,2

TAC (mg/l)

80 –120

Salt (g/l)

max. 3

Important: failure to keep the swimming pool water between above limits will void the warranty.

Note: when the concentration of one or more products mentioned above becomes too high, irrevocable

damage to your heat pump may occur. Make sure that you always install water treatment equipment after

the heat pump. When an automatic chemical feeder is installed in the plumbing, it must be installed

downstream of the heat pump. A check valve must be installed between the heat pump and the chemical

feeder to prevent back-siphoning of chemically saturated water into the heat pump where it will damage the

components.

4.2 Winterizing

Important: failure to winterize could damage the heat pump and will void the warranty

In areas where freezing temperatures occur, you should protect your pump, filter, and heat pump from the

elements. Perform the following steps to completely drain the heat pump:

1. Turn off the electrical power to the heat pump at the main breaker panel.

2. Shut off the water supply to the heat pump: completely close valve 2 and 3 on the bypass.

3. Disconnect the water inlet and outlet and let the water drain from the heat pump.

4. Re-connect the water inlet and outlet loosely to prevent debris entering the connections.

17

4.3 Spring start-up

If your heat pump has been winterized, perform the following steps when starting the system in the spring:

1. Inspect the system for any debris or structural problems.

2. Connect the water inlet and outlet couplers firmly.

3. Turn on the filter pump to supply water to the heat pump. Adjust the bypass to allow water flow

through the heat pump.

4. Turn on the electrical power to the heat pump at the main breaker panel.

4.4 Owner inspection

The ECO heat pumps are designed and constructed to provide long performance life when installed and

operated properly and under normal conditions. Periodic inspection is important to keep your heat pump

running safe and efficiently. The following basic guidelines are suggested for your inspection:

1. Make sure the front of the unit is accessible for future service.

2. Keep the surrounding areas of the heat pump clear of all debris.

3. Keep all plants and shrubs trimmed and away from the heat pump.

4. Keep lawn sprinkler heads from spraying on the heat pump to prevent corrosion and damage.

5. If the unit is installed under a very sharp roof pitch or under a roof without a gutter, a gutter or

diverter should be fitted to prevent excessive water from pouring down onto the unit.

6. Do not use the heat pump if any part has been under water. Immediately call a qualified professional

technician to inspect the heat pump and replace any part of the control system that has been

submerged.

The heat pump will produce condensation(water) while in operation. The heat pump base is designed to

allow the condensation to exit through the bottom drain port. The condensation will increase as the outdoor

air humidity level increases. Check the following at regular intervals to ensure proper condensate drainage:

1. Visually inspect and clear the bottom drain port of any debris that could clog the port.

2. Keep the air intake area and discharge area clear of debris so the airflow through the heat pump is

not restricted. The cooler discharge air should not accumulate and be drawn into the side air intake

coils.

During normal operation, the heat pump produces ten to twenty liters of condensate per hour. If condensate

drainage is above this range during operation, or if water continues to drain from the base when the heat

pump is not in operation for more than an hour, a leak in the internal plumbing may have occurred. Call a

qualified heat pump technician to investigate the problem.

Note: A quick way to verify if the water running through the drain is condensation water is to shut off the

unit and keep the pool pump running. If the water stops running out of the base pan, it is condensation

water. An even quicker way is to test the drain water for chlorine. If there is no chlorine present, then it’s

condensation.

18

5. Checkup and maintenance

5.1 Maintenance

•Check the water supply to the unit often. Low water flow or air entering the system should be

avoided, as this will diminish the unit’s performance and reliability. You should clean the pool/spa

filter regularly to avoid damage to the heat pump as a result of dirty or clogged filter.

•The area around the unit should be dry, clean and well ventilated. Clean the side heating exchanger

regularly to maintain good heat exchange and to save energy.

•Only a certified technician should service the operation pressure of the refrigerant system.

•Check the power supply and cable connection often. Should the unit begin to operate abnormally,

switch it off and contact a qualified technician.

•In winter, discharge all water from the heat pump and other systems to prevent damage from

freezing.

•You should discharge the water at the bottom of the heat pump if the unit will not work for an

extended period of time. You should check the unit thoroughly and fill the system with water fully

before using it for the first time after a prolonged period of no usage.

5.2 Trouble shooting guide

Improper installation will create an electrical hazard, which could result in death or serious injury to pool

users, installers, or others due to electrical shock, and my also cause damage to property. DO NOT attempt

any internal adjustments inside the heat pump.

WARNING:

1. Keep your hands and hair clear of the fan blades to avoid injury.

2. If you are not familiar with your pool filtering system and heat pump:

a. DO NOT attempt to adjust or service without consulting your dealer or professional pool

technician.

b. Read the entire installation and users guide before attempting to use, service of adjust

the heater of pool filtering system.

NOTE: Turn off the power to the unit prior to attempt service or repair.

19

PROBLEM

CAUSE

SOLUTION

Heat pump not running

1. No electricity

1. Switch on the electrical power

2. Heat pump not turned on

2. Switch on the heat pump

3. Water pump not running

3. Switch on the water pump

4. Wrong temperature setting

4. Adjust the temperature setting

5. Bypass wrongly adjusted

5. Adjust bypass as shown in manual

6. No gass pressure

6. Call a qualified technician

7. Time delayed operation

7. Wait 3 min for heat pump to start

8. Air temperature below 10°C

8. Wait until temperature has risen

No sufficient heating

1. Obstacles blocking air flow

1. Increase access of fresh air

2. Ice on the evaporator

2. Turn heat pump off (air too cold)

3. Bypass wrongly adjusted

3. Re-adjust the bypass

4. Too much water flow

4. Adjust the bypass

5.3 Microcontroller

The ECO+ heat pumps are equipped with a microcontroller on which it is possible to read error codes.

These error codes are formulated by LED lights on the circuit board. To access the circuit board, remove

the 4 screws of the service cover (with “ECO+” on it). At the top of heat pump you will find the PCB

containing the LED lights.

Compare which LEDs are lit to the following error code table

ERROR CODE

LED 1

LED 2

LED 3

LED 4

TROUBLE SHOOTING

000 Standby mode

⚫

⚫

⚫

☆

Standard mode

001 Running mode

⚫

⚫

☆

⚫

Standard mode

002 Air ambient

temp. sensor error

⚫

☆

⚫

⚫

Check the cable connection of the ambient temp. sensor

/ replace the sensor

003 High pressure

protection

☆

⚫

⚫

⚫

Refrigerant system pressure is high, check pressure

gauge, increase the water volume

004 Low pressure

protection

⚫

⚫

☆

☆

Refrigerant system pressure is low, check pressure

gauge, refeed refrigerant

005 Water flow

protection

⚫

☆

⚫

☆

Check if the water inlet/outlet connection is correct of not,

increase the water volume

006 Stop running in

limited air temp.

(8°C)

☆

⚫

⚫

☆

Air temp. is lower than 8°C, stop the heat pump until

temp. over 8°C

20

6. Detailed specifications

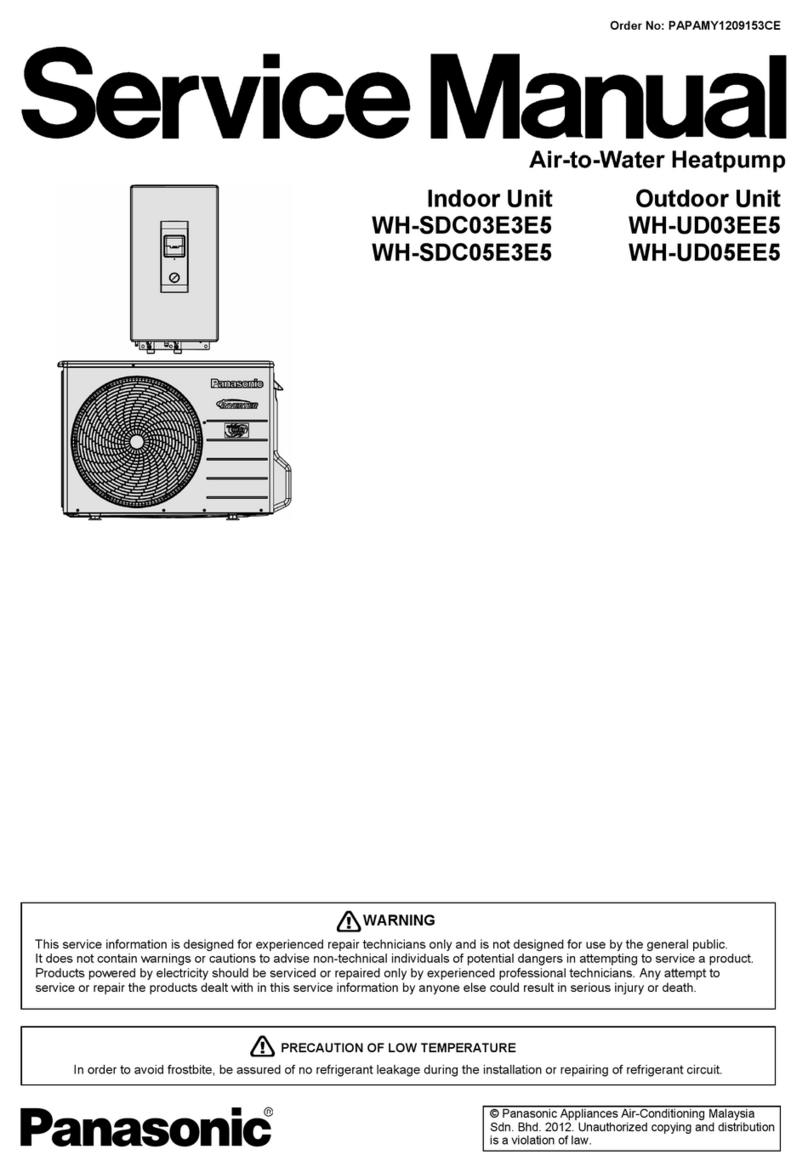

6.1 Electrical wiring diagram of the heat pump

This manual suits for next models

4

Table of contents

Languages:

Other COMFORTPOOL Heat Pump manuals