COMFORTPOOL PRO+5 Service manual

SWIMMING POOL HEAT PUMP UNIT

Installation & Instruction Manual

ZWEMBAD WARMTEPOMP

Installatie & Gebruikershandleiding

Applicable Model / Van toepassing op:

PRO+5

PRO+7

PRO+10

PRO+13

PRO+18

2

Contents

1. PREFACE ____________________________________________________________________________4

2. SPECIFICATIONS_______________________________________________________________________6

2.1 Parameters of Swimming Pool Heat Pump Unit_______________________________________________________________ 6

2.2 Dimensions of swimming pool heat pump unit _______________________________________________________________ 7

3. INSTALLATION ________________________________________________________________________8

3.1 Heat pump location _____________________________________________________________________________________ 8

3.2 Distance to the pool ____________________________________________________________________________________ 9

3.3 Connecting the by-pass __________________________________________________________________________________ 9

3.4 Electrical wiring _______________________________________________________________________________________ 10

3.5 Initial start-up ________________________________________________________________________________________ 10

3.6 Condensation ________________________________________________________________________________________ 11

4. GUIDELINES _________________________________________________________________________11

4.1 Water chemistry ______________________________________________________________________________________ 11

4.2 Winterizing___________________________________________________________________________________________ 11

4.3 Spring start-up ________________________________________________________________________________________ 12

4.4 Owner inspection______________________________________________________________________________________ 12

5. LCD CONTROLLER DISPLAY _____________________________________________________________13

5.1 Setting step __________________________________________________________________________________________ 13

5.2 The functions of controller display ________________________________________________________________________ 14

5.3 Operation data setting table:____________________________________________________________________________ 17

6. MAINTENANCE AND INSPECTION________________________________________________________18

6.1 Maintenance _________________________________________________________________________________________ 18

6.2 Trouble shooting guide_________________________________________________________________________________ 18

7. WIRING DIAGRAM ____________________________________________________________________20

8. WARRANTY _________________________________________________________________________22

3

Inhoud

1. INLEIDING __________________________________________________________________________23

2. SPECIFICATIES _______________________________________________________________________25

2.1 Technische gegevens van de zwembad warmtepomp_________________________________________________________ 25

2.2 Afmetingen van de zwembad warmtepomp ________________________________________________________________ 26

3. INSTALLATIE _______________________________________________________________________27

3.1 Locatie van de warmtepomp_____________________________________________________________________________ 27

3.2 Afstand tot het zwembad _______________________________________________________________________________ 28

3.3 Aansluiting van de bypass _______________________________________________________________________________ 28

3.5 Elektrische bedrading __________________________________________________________________________________ 29

3.6 Eerste gebruik ________________________________________________________________________________________ 29

3.7 Condensatie _________________________________________________________________________________________ 30

4. RICHTLIJNEN ________________________________________________________________________30

4.1 Waterchemie _________________________________________________________________________________________ 30

4.2 Winterklaar maken ____________________________________________________________________________________ 30

4.3 Voorjaarsopstart ______________________________________________________________________________________ 31

4.4 Inspectie_____________________________________________________________________________________________ 31

5. LCD CONTROLLER DISPLAY _____________________________________________________________32

5.1 Instellen _____________________________________________________________________________________________ 32

5.2 De functies van het bedieningsdisplay _____________________________________________________________________ 34

5.3 Tabel gebruiksinstellingen:______________________________________________________________________________ 37

6. ONDERHOUD AND INSPECTIE___________________________________________________________38

6.1 Onderhoud___________________________________________________________________________________________ 38

6.2 Overzicht probleemoplossing____________________________________________________________________________ 38

7. BEDRADINGSDIAGRAM ________________________________________________________________40

8. GARANTIE __________________________________________________________________________42

4

SWIMMING POOL HEAT PUMP UNIT

Installation & Instruction Manual

1.Preface

* In order to provide our customers with quality, reliability and versatility, this product has been made

to strict producing standards. This manual includes all necessary information about installation,

debugging, discharging and maintenance. Please read this manual carefully before you open or

maintain the unit. The manufacturer of this product will not be held responsible if someone is injured

or if the unit is damaged, as a result of improper installation or use, debugging or unnecessary

maintenance. It is vital that the instructions within this manual are adhered to at all times. Only

qualified persons should install the unit.

* Only a qualified installer, center, personnel or an authorized dealer are allowed to repair the unit.

* Maintenance and operation must be carried out at the recommended time and frequency, as stated

in this manual.

* Use genuine standard spare parts only.

* Failure to comply with these recommendations will void the warranty.

* The swimming pool heat pump unit heats the swimming pool water and keeps the temperature

constant.

Our heat pump has following characteristics:

Durable

The heating exchanger is made of PVC and titanium tubes, which can withstand prolonged exposure to

(salt) swimming pool water.

Easy operation

The unit is very easy to operate: switch it on and set the desired pool water temperature.

Quiet operation

The unit comprises an efficient rotary compressor and a low-noise fan motor, which guarantees its quiet

operation. The unit can heat your swimming pool water when the air temperature is -5°C or higher.

Low cost

The operational costs are very low due to its high performance.

5

Safety warnings & instructions

Read and follow all instructions in this manual and on the equipment. Failure to do so could result in severe

or fatal injuries, or damage the heat pump.

* The heat pump should be installed in accordance with local regulations, and the requirements in this manual.

* This is not a TOY. Do not leave children alone and unsupervised around the heat pump.

* Children are not allowed to operate the heat pump.

* This heat pump is not intended for use by someone with reduced physical, sensory or mental capabilities, or a

lack of experience and knowledge, unless they have been given instructions concerning the appliance and are

under supervision of the person responsible for their safety.

* Failure to follow the safety instructions may result in electric shock, water leaks, fire, damage to the heat

pump or other products, serious injuries or death.

* Before the installation, and again before using the heat pump for the first time, the entire product must be

inspected before start-up.

* Only qualified personnel should install the heat pump.

* The heat pump must be equipped with proper electrical connections and grounding, and secured with a

proper fuse. If in doubt, consult a qualified electrician.

* DO NOT use the heat pump if any damage is detected. If you notice that the pump does not operate normally,

or emits a strange odor, immediately shut off the power and contact a qualified heat pump technician.

* Only a qualified technician should move the heat pump.

* DO NOT attempt to repair the heat pump, this will void the warranty.

* DO NOT attempt to disassemble the heat pump, this will void the warranty.

* Always turn off the power to the heat pump before cleaning of performing maintenance on the heat pump or

water system.

* DO NOT use flammable cleaning materials to clean the heat pump.

* DO NOT use or place the heat pump near toxic substances, flammable or combustible liquids such as

gasoline, or in the presence of explosive or flammable fumes.

* Never insert body parts, (loose) clothing or other objects into the openings and moving parts of the pool

vacuum.

* Always place the heat pump on a stable surface to prevent it from tilting or falling.

Above warnings and cautions are not intended to incorporate all possible instances for risks and/or severe

injuries. Owners and users of the heat pump should always exercise caution and common sense when

utilizing the product.

Note: This manual can be modified without notice if the unit is altered in any way.

6

2. Specifications

2.1 Parameters of Swimming Pool Heat Pump Unit

MODEL

PRO+5

PRO+7

PRO+10

PRO+13

PRO+18

PRO+24

Heating Capacity in

A27/W27°C

W

4300

6100

8900

11500

13700

15500

Heating Capacity in

A15/W26°C

W

3000

4500

6500

8000

9200

11000

Heating Capacity

W

3800

5300

7800

9500

12500

14000

Heating Input Power

W

791

1083

1625

1938

2400

2880

Heating Running Current

A

3.6

5.0

7.5

9.2

11

13.3

Cooling Capacity

W

2300

3200

4800

5900

7700

8600

Cooling Input Power

W

750

1030

1550

1910

2650

2980

Cooling Running Current

A

3.4

4.7

7.4

9.1

12.5

13.8

Power Supply

V/Ph/Hz

220V/1Ph/50Hz

Quantity of Compressor

1

1

1

1

1

1

Compressor Type

Rotary

Scroll

Noise

dB(A)

48

48

48

48

48

48

Water Connection

mm

50

50

50

50

50

50

Water Flow Volume

m³/h

2-4

2-4

3-5

4-7

5-8

5-8

Water Pressure Drop

kpa

10

12

12

15

15

15

Dimension (L*w*h)

mm

936*360*550

936*360*550

936*360*550

1010*370*615

1100*440*700

1100*440*700

Packing Size (L*w*h)

mm

1090*390*580

1090*390*580

1090*390*580

1170*415*645

1260*500*730

1260*500*730

Weight (Net / Gross)

kg

37 / 40

53 / 56

54 / 57

63 / 67

70/78

80/88

Above parameters are only for reference, exact details please as per nameplate.

Measurement conditions:

Heating: Dry bulb 24° C, wet bulb 19° C, inlet water temp. 27° C.

Cooling: Dry bulb 35° C, wet bulb 24° C, inlet water temp. 27° C.

32

7

2.2 Dimensions of swimming pool heat pump unit

Model

Size (mm)

PRO+ 5

PRO+ 7

PRO+ 10

PRO+ 13

PRO+ 18

A

330

340

B

680

650

C

300

300

D

360

370

440

E

950

1010

1100

F

200

270

G

110

110

H

600

670

700

8

3. Installation

The factory only provides the heat pump unit. Other items, including an eventual bypass, that are

necessary for the water system, are to be provided by users or installers.

Attention! Please follow these steps when installing the heat pump:

1. All feeding of chemicals to the pool water must be done downstream of the heat pump.

2. Install a bypass when the flow of the pool pump is more than 20% above the rated flow of the heat

exchanger of the heat pump.

3. Install the heat pump on a solid foundation and use the damping rubbers to eliminate vibrations and

noise.

4. Always keep the unit straight up. If the unit has been tilted or put on its side, allow 24h before

starting the unit.

3.1 Heat pump location

The unit may be installed virtually anywhere outdoors. If you wish to place the heat pump inside, make sure

there is enough room and ventilation around the pump.

DO NOT put the unit in an enclosed area with a limited air volume where the unit discharge air will be re-

circulated. DO NOT put the unit next to shrubs, which can block the air inlet. Such locations deny a

continuous source of fresh air, which reduce its efficiency and may prevent adequate heat delivery.

9

The picture below illustrates the minimum required distances from each side of the heat pump.

3.2 Distance to the pool

Install the heat pump as close to the swimming pool as possible to minimize heat loss through the piping.

Normally, the pool heat pump is installed within a 7.5-meter radius of the pool. The greater the distance

from the pool, the greater the heat loss from the piping. If the piping is buried, heat loss will be minimal for

distances of up to 30 meters (15 meters to and from the pump = 30 meters total), unless the soil is wet or

the water level is high. Heat loss per 30 meters can be roughly be estimated at 0.6kw-hour (2000 BTU) for

every 5 ℃temperature difference between the pool water and the soil surrounding the pipe,which

translates to an operation time increase of 3-5%.

3.3 Connecting the by-pass

VALVE1 –Slightly closed

(water pressure increased from 10 to 20 bar)

VALVE2 –Completely open

VALVE3 –Half way open

Setting the valve of the by-pass:

1. Open all 3 valves entirely

2. Slightly close valve 1

3. Close valve 3 about half way to adjust the

refrigerant pressure

10

3.4 Electrical wiring

Note: Verify the local power supply and the operating voltage of the heat pump. It is recommended to use

the included separate circuit breaker for the heat pump, together with the proper wiring characteristics (see

wiring diagram). The current to the heat pump should only be applied when the filter pump is running.

Further connect the electrical supply to the junction box inside the unit. All PRO heat pumps require single-

phase connection.

Grounding: The circuit breaker protects you against electrical shock caused by an eventual short circuit

inside the unit. The heat pump in itself is unable to provide a water flow. Therefore, the heat pump must be

wired electrically together with the filter pump to ensure a water flow while the heat pump is running.

3.5Initial start-up

Startup procedure

After the installation is completed, you should follow these steps:

1. Turn on the filter pump, check for leaks and verify the flow to and from the pool.

2. Turn on the electrical power supply to the unit, then press the ON/ OFF key on the electronic control

panel. The unit should start after the time delay period has lapsed.

3. When the unit has been running for a couple of minutes, check if the air leaving the unit is cooler.

4. Check the performance of the flow switch as follows: with the unit running, turn the filter pump off.

The unit should also switch off automatically. If not, the flow switch needs readjusting. In that case,

please contact the supplier.

5. Allow the unit and filter pump to run 24 hours a day until the desired pool water temperature is

reached. When the set temperature is reached, the unit switches itself off. The unit will now

automatically restart (if the filter pump is running) when the temperature of the pool water drops

more than 1°C below set temperature.

Depending on the starting temperature of the pool water and the air temperature, it can take several days

for the water to reach the desired temperature. Covering the pool of the use of ground insulation can

drastically reduce this period.

Water flow switch

The unit is equipped with a flow switch that is switched on when enough water flows through the unit and

that is switched off when the water flow becomes too low. (E.g. when the filter pump is switched off).

Time delay

The unit is equipped with a built in 3-minute start delay to protect the electrical components and contacts.

After this time delay, the unit will automatically be restarted. Even a brief interruption of the power supply

will activate the start delay and prevent the unit from starting immediately. Additional interruptions of the

power supply during the delay period will have no effect on the 3-minute countdown.

11

3.6Condensation

When the swimming pool water is being heated by the heat pump, the incoming air is cooled down quite a

bit, which can cause condensation on the fins of the evaporator. Condensed volumes can attain several

liters per hour under high atmospheric humidity. Sometimes, this is wrongfully interpreted as a water leak.

37

4. Guidelines

4.1 Water chemistry

Special attention should be paid to the chemical balance of the pool water. The pool water values should

always stay within the following limits:

MIN

MAX

pH

7.0

7.4

Free chlorine (mg/1)

0.5

1.2

TAC (mg/1)

80

120

Salt (g/1)

3

Important: failure to comply with these limits will void the warranty.

Note: Exceeding one or several limits can damage the heat pump beyond repair. Always install water

treatment equipment past the heat pump’s water outlet, especially if the chemicals are automatically added

to the water.

Check: A valve should also be installed between the outlet of the heat pump and this equipment, in order to

prevent products from flowing back into the heat pump if the filter pump stops.

4.2 Winterizing

Important: failure to winterize could damage the heat pump and will void the warranty

The heat pump, filter pump, filter and pipes must be protected in areas where the temperature can drop

below the freezing point. Evacuate all water from the heat pump as follows:

1. Turn off the electrical power supply to the heat pump.

2. Close the water supply to the heat pump: completely close valves 2 and 3 of the by-pass.

3. Disconnect the water inlet and outlet coupler fittings of the heat pump and let the water drain out of

the unit.

12

4.3 Spring start-up

If your heat pump has been winterized, perform the following steps when starting the system in the spring:

1. Inspect the system for any debris or structural problems.

2. Connect the water inlet and outlet couplers firmly.

3. Turn on the filter pump to supply water to the heat pump. Adjust the by-pass to allow water flow

through the heat pump.

4. Turn on the electrical power to the heat pump at the main breaker panel.

4.4 Owner inspection

The heat pumps are designed and constructed to provide long performance life when installed and

operated properly under normal conditions. Periodic inspection is important to keep your heat pump

running safe and efficiently.

The following basic guidelines are suggested for your inspection:

1. Make sure the front of the unit is accessible for future service.

2. Keep the surrounding areas of the heat pump clear of all debris.

3. Keep all plants and shrubs trimmed and away from the heat pump.

4. Keep lawn sprinkler heads from spraying on the heat pump to prevent corrosion and damage.

5. If the unit is installed under a very sharp roof pitch or under a roof without a gutter, a gutter or

diverter should be fitted to prevent excessive water from pouring down onto the unit.

6. Do not use the heat pump if any part has been under water. Immediately call a qualified professional

technician to inspect the heat pump and replace any part of the control system that has been

submerged.

The heat pump will produce condensation(water) while in operation. The heat pump base is designed to

allow the condensation to exit through the bottom drain port. The condensation will increase as the outdoor

air humidity level increases. Check the following at regular intervals to ensure proper condensate drainage:

1. Visually inspect and clear the bottom drain port of any debris that could clog the port.

2. Keep the air intake area and discharge area clear of debris so the airflow through the heat pump is

not restricted. The cooler discharge air should not accumulate and be drawn into the side air intake

coils.

During normal operation, the heat pump produces ten to twenty liters of condensate per hour. If condensate

drainage is above this range during operation, or if water continues to drain from the base when the heat

pump is not in operation for more than an hour, a leak in the internal plumbing may have occurred. Call a

qualified heat pump technician to investigate the problem.

Note: A quick way to verify if the water running through the drain is condensation water is to shut off the

unit and keep the pool pump running. If the water stops running out of the base pan, it is condensation

water. An even quicker way is to test the drain water for chlorine. If there is no chlorine present, then it’s

condensation.

13

5. LCD Controller Display

5.1 Setting step

1. Under running status, press to adjust the temperature.

2. Press “Mode” to choose the mode:

3. Press “Mode” again cooling

4. Press “Mode” again heating

5. Standby status:

Warning! These default settings are correctly preset. Only allow a qualified heat pump technician to change them.

- Press “Mode” 5 seconds, get a sound “B”, LCD display will show “0” “27”. Press “SET” to enter Cooling temp. setting.

Press to alter cooling temp. Press “SET” again to confirm.

- Press “Mode” again “1” “27”. Press “SET” to enter Heating temp. setting. Press to alter heating temp. Press

“SET” again to confirm.

- Press “Mode” again “2” “40”. Press “SET” to enter Defrosting time setting. Press to alter defrosting time. Press

“SET” again to confirm.

- Press “Mode” again “3” “-7”. Press “SET” to enter Defrosting temp. setting. Press to alter defrosting temp. Press

“SET” again to confirm.

- Press “Mode” again “4” “13”. Press “SET” to enter Exit defrosting temp. setting. Press to alter exit defrosting

temp. Press “SET” again to confirm.

- Press “Mode” again “5” “8”. Press “SET” to enter Exit defrosting time setting. Press to alter exit defrosting time.

Press “SET” again to confirm.

Press “Mode” again “6” “1”. Press “SET” to enter System quantity setting. Press to alter system quantity. Press

“SET” again to confirm.

- Press “Mode” again “7” “1”. Press “SET” to enter Automatic setting. Press to alter. Press “SET” again to

confirm.

- Press “Mode” again “8” “1”. Press “SET” to enter Mode setting. Press to alter. Press “SET” again to confirm.

- Press “Mode” again “9” “0”. Press “SET” to enter Water pump setting. Press to alter. Press “SET” again to

confirm.

- Press “Mode” again “A” “40”. Press “SET” to enter Return water temp. setting. Press to alter. Press “SET” again

to confirm.

- Press “Mode” again “B” “5”. Press “SET” to enter Overheat protection (heating mode) setting. Press to alter.

Press “SET” again to confirm.

- Press “Mode” again “C” “35”. Press “SET” to enter Electronic expansion valve setting. Press to alter. Press

“SET” again to confirm.

- Press “Mode” again “D” “5”. Press “SET” to enter Overheat protection (cooling mode) setting. Press to alter.

Press “SET” again to confirm.

14

- Press “Mode” again “E”“40”. Press “SET” to enter Max. temp. setting. Press to alter. Press “SET” again to

confirm.

- Press “Mode” again “F” “2”. Press “SET” to enter Split temp. setting. Press to alter. Press “SET” again to

confirm.

- Press “Mode” again “G” “-10”. Press “SET” to enter Ambient temp. protection setting. Press to alter. Press

“SET” again to confirm.

Further explanation of PCB connections.

4. Clock setting

Under running or standby status, press “SET” for 5 seconds, get a sound “B”. Press to alter hour. Press “SET”

again to alter minute. Press “SET” again to confirm.

5.Timer setting

Under running or standby status, press for 5 seconds, get a sound “B”. Press to alter hour of timer ON. Press

again to alter minute of timer ON. Press again to alter timer OFF. 103

5.2 The functions of controller display

Setting operation parameter

Under standby status, press “Mode” button 5 sec. to enter Operation Parameter setting interface;

Press “Mode” again to start setting (parameter from 00-D, see the Operation Parameter Table);

Under parameter setting. Press or to set data;

Note: If no motion is detected on the display for 10 sec, the LCD will display water-in/water-out temp.

(under running) or ambient temp. (under standby status).

Under running status, you can press “Mode” 5 sec to check current parameter, but you cannot change data

of parameter!

Remarks: Standby status means the unit is connected to electricity, but is not running.

15

16

To choose Mode

How to check the current status

Under running status, press “Mode” for 5 seconds to check the current status of the unit! You can check

water-in/water-out temp, condenser temp and ambient temp. Note: If no motion is detected on the display

for 10s, the LCD will display water-in/water-out temp (under running) or ambient temp. (unit stops)

C

Ambient temp.

17

5.3 Operation data setting table:

DIGIT

MEANING

RANGE

DEFAULT

ADJUST (YES/NO)

00

Return water temp. setting (cooling

mode)

8°C –28°C

27°C

yes

01

Return water temp. setting (heating

mode)

15°C –40°C

27°C

yes

02

Total working time of compressor after

frosting

30 –90 min

40 min

To be adjusted by

technicians

03

Setting initialization temp. for

defrosting

-30°C –0°C

-7°C

To be adjusted by

technicians

04

Temp. of exit defrost under heating

model

2°C –30°C

13°C

To be adjusted by

technicians

05

Max. time of defrost under heating

mode

1 –12 min

8 min

To be adjusted by

technicians

06

Electronic expansion valve mode

0 (manual) /

1 (auto)

1

To be adjusted by

technicians

07

Automatic restarting after power off

0 –1

1 (record)

To be adjusted by

technicians

08

Mode (cooling only/heat

pump/auxiliary electrical heating/hot

water)

0 –3

1 (warmtepomp)

To be adjusted by

technicians

09

Heat pump keeps running or stops

after compressor stop for 30s

0 (keeps running) /

1 (stops)

0

To be adjusted by

technicians

A

Auto mode (return water temp.)

8°C –60°C

40°C

To be adjusted by

technicians

B

Setting of EEV. (heating mode)

-F(-15°C) ~F (-

15°C)

5°C

To be adjusted by

technicians

C

Electronic expansion valve manual

steps

10 ~ 50

35

To be adjusted by

technicians

D

Setting of EEV. (cooling mode)

-F(-15°C) ~F (-

15°C)

5°C

To be adjusted by

technicians

E

Maximum temperature setting

30°C –70°C

40°C

To be adjusted by

technicians

F

DeltaT setting

1°C –20°C

2°C

To be adjusted by

technicians

G

Ambient temp. protection(Min.)

-15°C –15°C

-10°C

To be adjusted by

technicians

18

6. Maintenance and Inspection

6.1 Maintenance

•Check the water supply device and the releaser often. There should always be water entering the

system. The condition air entering the system should be avoided, or it will influence unit's

performance and reliability. You should clear the water filter regularly to avoid damage to the unit

because of a jammed filter.

•The area around the unit should be dry, sanitary and ventilated. Clean the side of the heating

exchanger regularly to allow proper heating exchange and save energy.

•Check the operation of every process in the unit, and the pressure of the refrigerant system. You

should maintain it and change it in time.

•Check the power supply and cable connections often, if there is any abnormal action or a bad smell

coming of the electrical component, please maintain it or change it in time.

•Please discharge all water in the heat pump and water system to avoid freezing of the heat pump or

water system. You should discharge the water at the bottom of the heat pump if the unit will not be

used for a long time. Check the units thoroughly and fill the entire system with water before

powering the units on again.

6.2 Trouble shooting guide

MALFUNCTION

CONTROLLER

DISPLAY

REASON

RESOLUTION

Water in temp. Sensor

failure

PP 01

The sensor is open or short

circuit

Check or replace a new sensor

Water out temp. Sensor

failure

PP 02

The sensor is open or short

circuit

Check or replace a new sensor

Coil sensor failure

(Heating mode)

PP 03

The sensor is open or short

circuit

Check or replace a new sensor

Gas return sensor

failure

PP 04

The sensor is open or short

circuit

Check or replace the sensor

Ambient sensor failure

PP 05

The sensor is open or short

circuit

Check or replace the sensor

Temp. is too much

different between water-

in and water-out

PP 06

Water volume isn’t enough

Increase water volume

Anti-freezing under

cooling mode

PP 07

Ambient temp. too low

19

The first time freezing

protection in winter

PP 07

Ambient temp. too low

The second time

freezing protection in

winter

PP 07

Ambient temp. too low

Coil sensor failure

(Cooling mode)

PP 08

The sensor is open or short

circuit

Check or change the sensor

High pressure protection

EE 01

Refrigerant system pressure

is high

Check pressure gauge, increase

the water volume

Low pressure protection

E E02

Refrigerant system pressure

is low

Check pressure gauge, refeed

refrigerant

Flow switch failure

EE 03

No water/little water in water

system.

- Check the water flow volume

- Clean filter

- Execute backwash of filter

pump

Power supply

connections wrong (for

3phase unit)

EE 04

Wrong phase or

lack of phase power

connection

Check connections of power

cable

3times display PP06

(Temp. is too much

different between water-

in&out) in 30minutes

EE 05

Water flow volume not

enough, water pressure

difference is too low

Check the water flow volume, or

water system is jammed or not

Defrosting

Defrost code

display

Communication failure

EE 08

Wire controller and The PCB

connection failure

Check the wire connection

20

7. Wiring diagram

Model: PRO+5 PRO+7 PRO+10 PRO+13

This manual suits for next models

5

Table of contents

Languages:

Other COMFORTPOOL Heat Pump manuals

Popular Heat Pump manuals by other brands

Bard

Bard Q24H1D installation instructions

Enertech

Enertech BS018 Installation & operation manual

Trane Technologies

Trane Technologies 4TWA4036A3000A Installer's guide

GE

GE NS18HMA installation instructions

Kingspan

Kingspan Aeromax Plus Homeowner's guide

Cornelius

Cornelius UC-40 Installation and service manual

Toshiba

Toshiba HWS-804H-E installation manual

ECOFOREST

ECOFOREST ecogeo hp Installation and operating manual

Galmet

Galmet Small Installation and operation manual

Lennox

Lennox HP25 Series installation instructions

Amana

Amana Asure ASH13 Product specifications

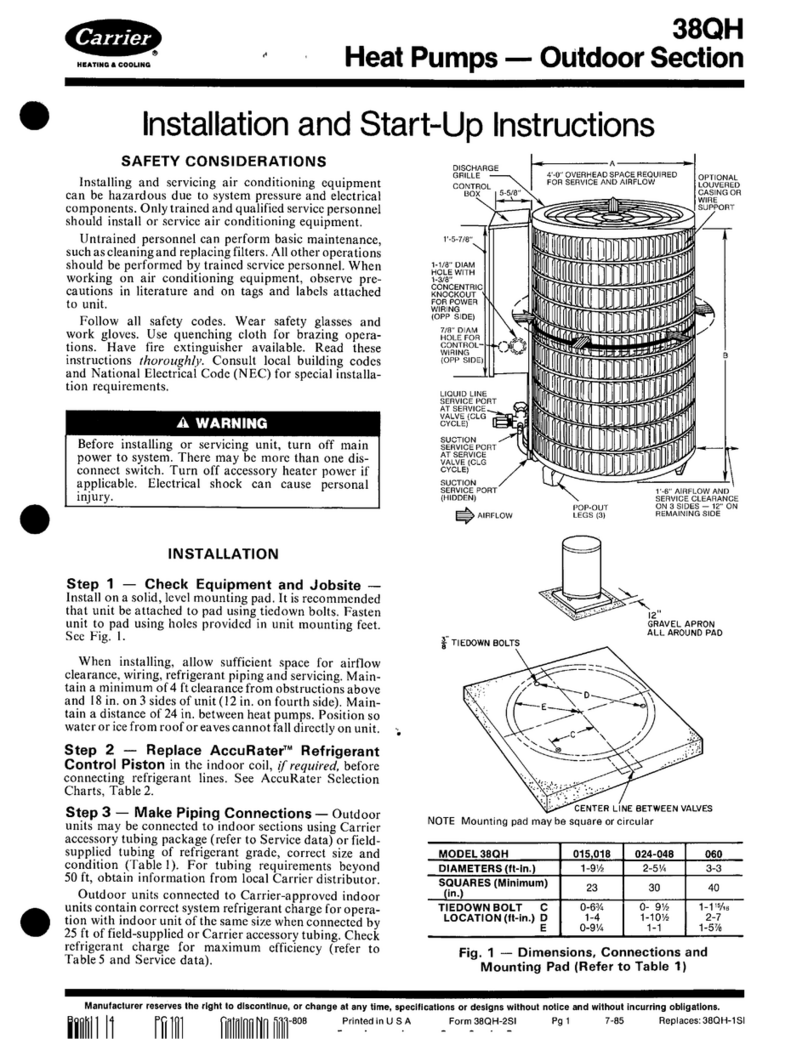

Carrier

Carrier 38QH Installation and start-up instructions