www.componentengineering.com

4

Chapter 2. Designing a System

What do you want to happen when?

Write out the most complicated program you are likely to have to run, but do it in two columns. One

column will show those things which will always happen at the same point in the program, and the

other column will show those things which are governed by the film. Now, while checking the list of

"Events", give each of the "always the same" entries an "E" number.

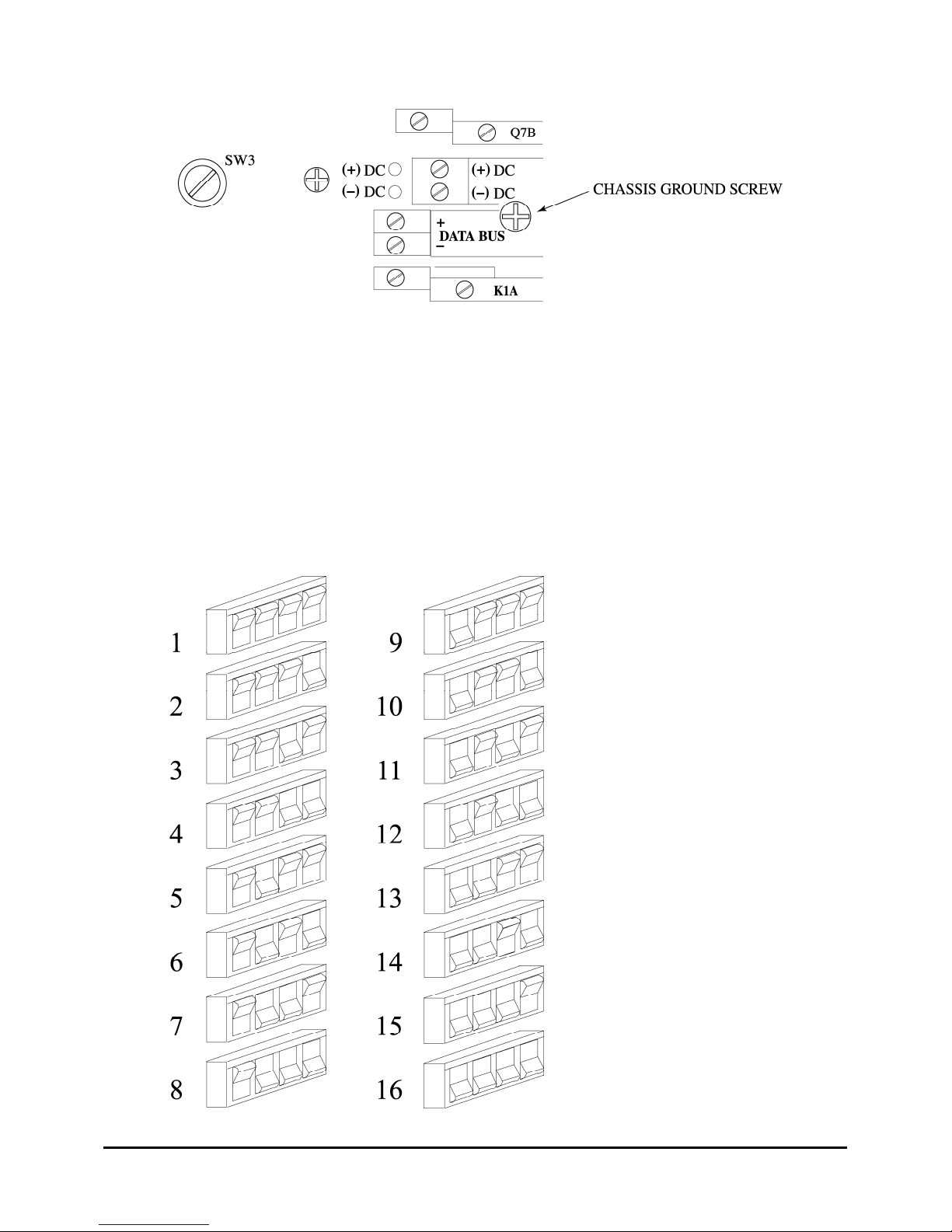

Next, referring to the sample on the page that follows, you will assign "Q" numbers to the list of cues

that are governed by the film. There are however a few things to consider. It is a good idea to try to

make the most frequently used cues the ones that are easiest to apply. Try to save the edge-only cues

for those functions, which might have to be triggered while the picture is on the screen. Don't get too

fancy. You have only 7 cues and one has to be reserved for "Intermission".

At this point you need to know more about the "Intermission" cue. This cue is used for several

purposes besides beginning the Intermission Sequence. It all depends upon where you are in the

program. After the douser is open and the show is running, triggering "Intermission" will begin the

Intermission Sequence as you would expect. After the douser has closed, but the film has not run out,

another "Intermission" cue will re-start the show by initiating the normal 7 second Start Sequence.

Those who like to put a “Curtain Call” in their program can use this feature. It also can be used when

making a lens change. See "Operating Instructions” for more on this Cue.

After you have made your choices, you can go back to your list and fill in the "Q" numbers. Please

see the next page for a sample list with all the assignments made. Note that the dedicated functions

are not listed.....only the user defined ones.

You can see how it works. The standard parts of the show are controlled by the events, but the mid-

show changes are controlled by the discrete cues. For this example, it has been decided that the house

standard is to Mute the Non-Sync at show start, so this function is tied to an Event (E1) rather than a

Cue. It is also tied to another Event (E4) at the end of the show.

As most trailers now are in a Stereo format, we save cueing by using E2 to bring in Stereo Sound.

(Mono Sound can be called for by Q2.) If there is a mono trailer or Logo, a Cue will have to be

added.

As both the event relays and the “Q” relays are double pole relays, functions that are always

preformed together can be wired to the separate poles of the same relay. The following example

assumes a dimmer system that allows for half-light, which is triggered by E1. Q3 takes them down

the rest of the way, while Q4 will bring them back to Half during the closing credits.

Note: There are bound to be needs not provided for in this system, and others, which may well be

possible but not outlined in these instructions. If you have questions or are not sure how to attain

your design goals, please call us at (206) 284-9171 and let us try to help.