– 2 –

General Safety Information

DISCONNECT POWER AND RELEASE ALL SYSTEM

PRESSURE BEFORE SERVICING THIS EQUIPMENT.

1. Follow all local electrical and safety codes, as well as the

National Electrical Code (NEC) and the Occupational

Safety and Health Act (OSHA).

2. Never exceed the maximum operating speed or pres-

sure.

3. When using AC motors, ground the motor properly by

wiring with a grounded, metal-clad raceway system,

using a separate ground wire connected to bare metal

of the motor frame, or other suitable means.

4. Guard all moving parts.

5. Drain all liquids from the system before servicing.

6. Check hoses and connections for security before each

use.

7. Periodically check the pump/fluid motor and system

components.

8. Provide a means of pressure relief for pumps whose

discharge line can be shut off or obstructed.

9. Wear safety glasses at all times when working with

pumps/fluid motors.

10. Keep work area clean, uncluttered and properly light-

ed; replace all unused tools and equipment.

11. Keep visitors at a safe distance from the work area.

12. Make the workshop child-proof with padlocks, master

switches, and by removing start keys.

13. Do not operate an engine in an enclosed area.

14. Do not spill gasoline on hot engine surfaces.

15. Store gasoline only in an approved container.

16. Keep dirty and oily cleaning rags in a tightly closed

metal container.

17. Check engine oil level before operating the engine.

18. Familiarize yourself with the controls and emergency

shutdown procedures.

19. Never operate the equipment when you are fatigued.

20. All system components pressure ratings should be

greater than maximum system pressure.

21. Guard all moving parts.

22. Replace all guards when servicing is complete.

Assembly

Models 4F649 through 4F659 are packaged fully assem-

bled and require no further assembly.

Installation

MOUNTING PUMP/FLUID MOTOR ASSEMBLY

TO FLEXIBLE COUPLING DRIVE SYSTEMS

1. Assemble the flexible coupling half to the pump/fluid

motor shaft.

Do not force coupling half onto drive shaft; it must

be a slip fit for adjustment and to avoid internal dam-

age.

2. Tighten the setscrew and insert rubber spider in cou-

pling half.

3. Assemble the other coupling half loosely to the

engine/motor shaft.

4. Bolt the pump/fluid motor loosely to the SAE type

four bolt mounting pump adapter as furnished by the

equipment manufacturer.

5. Align the shafts to make sure they are on center with

each other.

6. Tighten the mounting bolts.

7. Mate the coupling halves together, allowing 1/16”

gap between halves.

8. Check the alignment again.

IMPORTANT: THE GAP IN THE COUPLING HALVES

IS TO PREVENT END LOADING OF THE PUMP/

FLUID MOTOR DRIVE.

9. Tighten the setscrew in the mating coupling half.

10. Remove plastic shipping plugs from the inlet and

outlet ports.

11. Squirt clean oil into pump for pre-lubrication and

start-up.

12. Turn shaft coupling slowly to ensure proper shaft

alignment and coupling installation.

13. Connect inlet and outlet lines with an SAE straight

thread fitting and tighten.

Flush all lines and fittings of contamination.

THREADS ARE SAE, NOT NPTF. USING INCORRECT

FITTINGS COULD DAMAGE THE HYDRAULIC

COMPONENT OR CAUSE PERSONAL INJURY.

NOTE: Do not use teflon tape; the O-ring provides the

seal and teflon tape is not required.

14. When using the assembly as a pump keep inlet hose

short and of adequate size to avoid pump cavitation.

NOTE: Cavitation is recognized by excessive noise and

foaming of hydraulic fluid.

Never run assembly without hydraulic oil.

15. At initial start-up, turn the drive shaft several times by

hand to prime.

16. Bleed all air from the system to prevent erratic opera-

tion.

17. After several cycles, check the reservoir oil level and

refill as necessary.

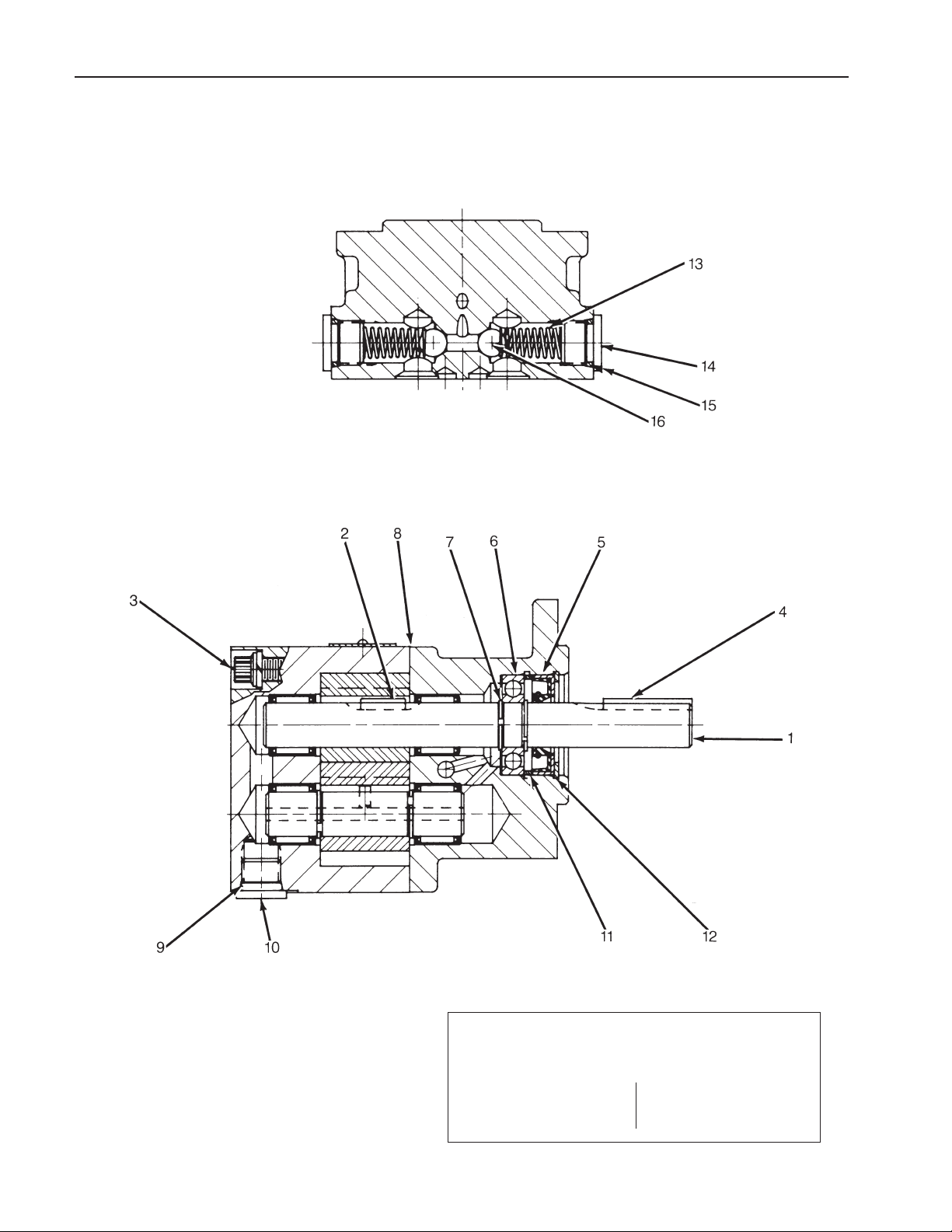

2690098 MODEL 4F649 THRU 4F659

WARNING!

WARNING!

CAUTION

CAUTION

CAUTION