Page 7of 16

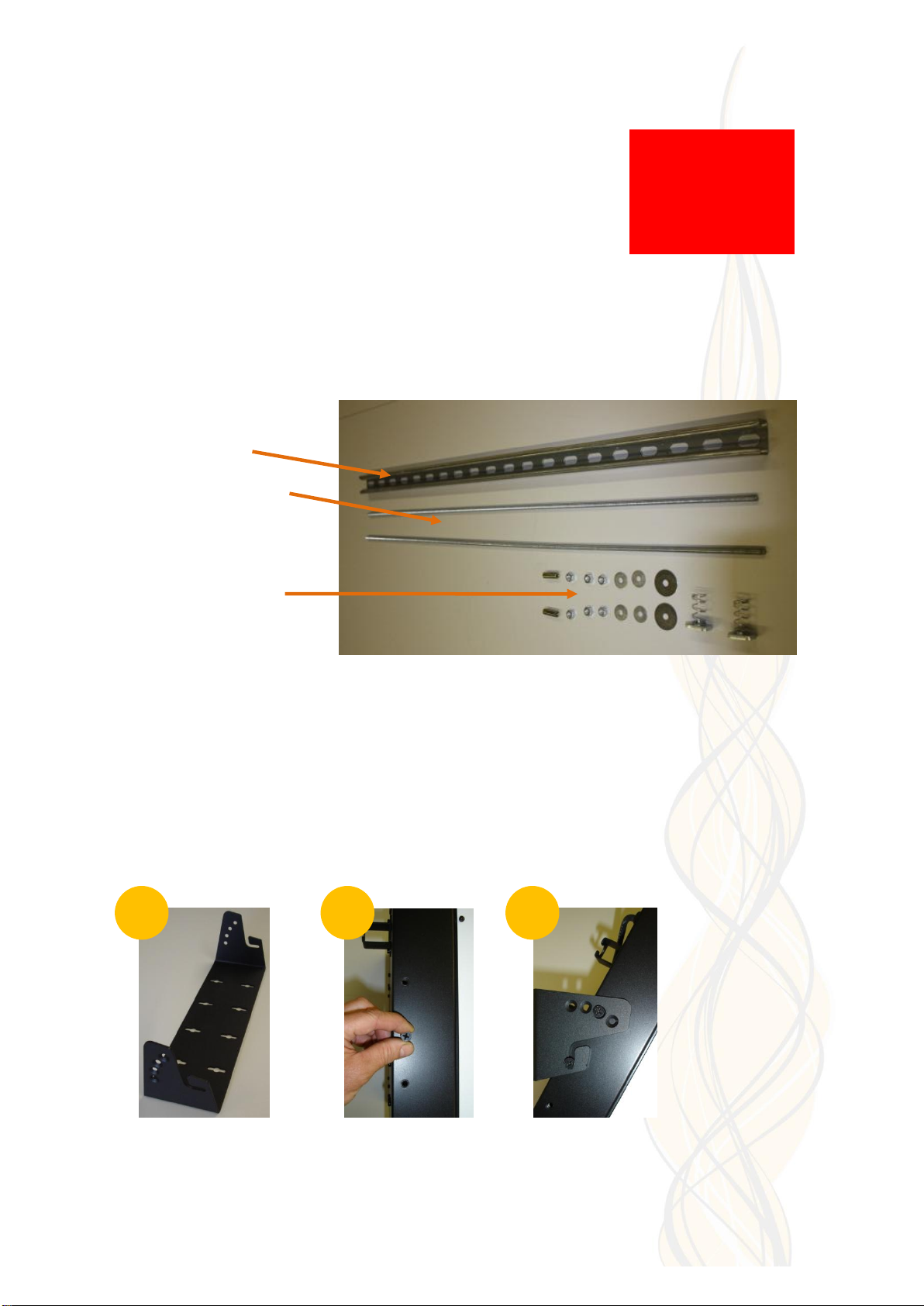

Suspension mounting

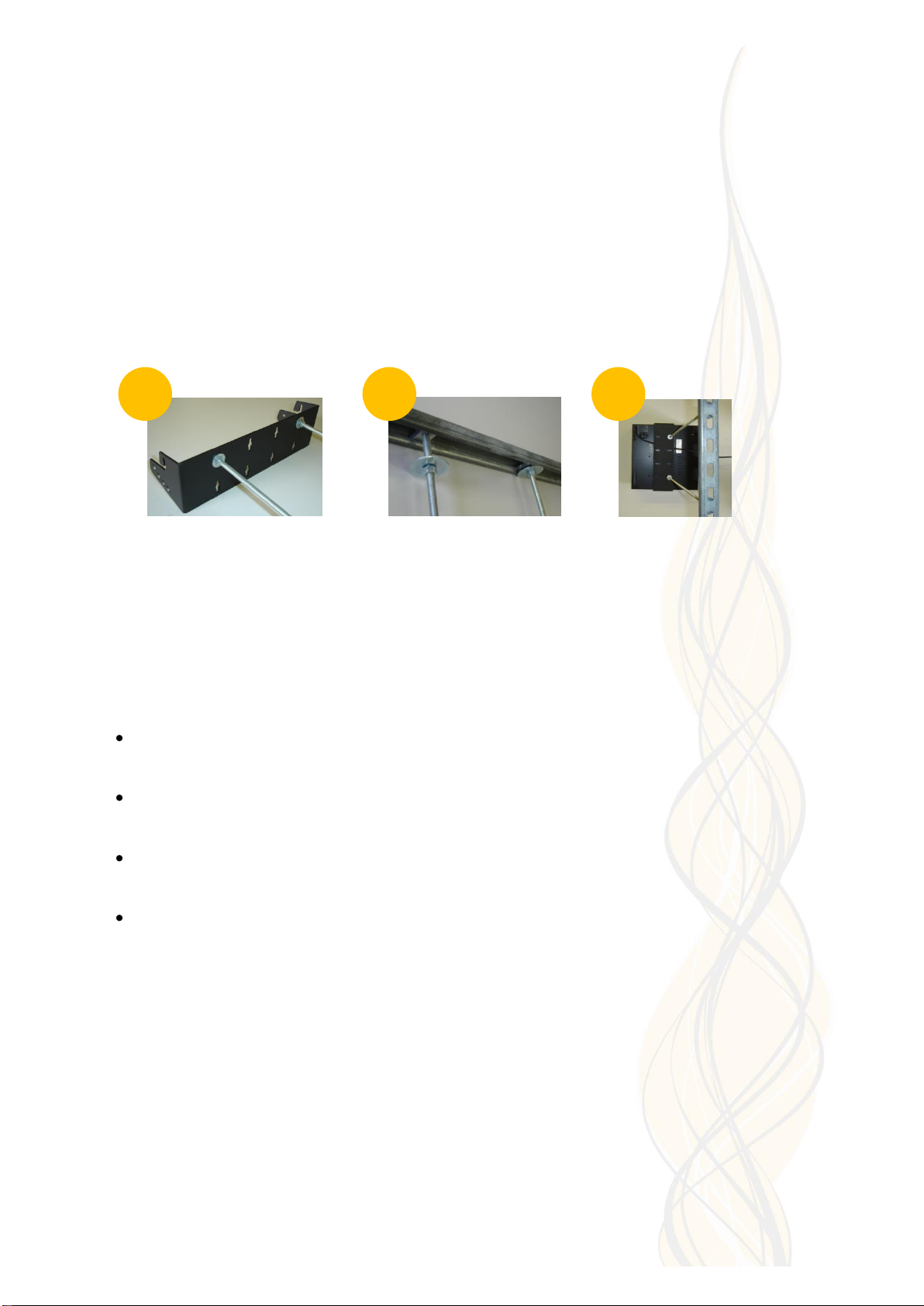

Suspending the Smoke Screen range is achieved using the ‘Suspension Kit’ comprising a length of

Uni-strut, two sections of threaded bar and fixings. Fix the required length of M8 threaded bar to

the wall bracket (use the holes in line with the bracket hooks) using 4 x nuts and 4 x 25mm

washers (4). Fix the uni-strut into place. There are a range of fixings to accommodate concrete

ceiling, girders etc; if in doubt contact the fixing supplier. Attach the threaded bar to the uni-strut

using the channel nuts, 38mm washers and M8 nuts (5). Insert a set screw a few threads into the

lower hole of the top pair of threaded holes on each side of the Smoke Screen (2). As described

under “Wall Mounting”, lift the Smoke Screen into position and insert another set screw on each

side to lock the unit in the ‘non-angled’position. Tighten all four set screws. Any final adjustments

to height can be made at this stage as the nuts and the threaded bar will take the weight of the

Smoke Screen. The final assembly, viewed ‘through the ceiling’ is in photo (6).

CONTROLLING THE SMOKE

Inputs. There are 3 setsof input connections on the Smoke Screen (Alarm Set, Trigger and Hold Off)

that should be connected to clean contacts. For theSmoke Screen to produce ‘smoke’ all 3 sets of

connections must be ‘open circuit’ (this can be changed to ‘closed’ as described under ‘Trigger Mode’ in

the ‘Programming’ section).If one set of connections is ‘closed circuit’ then the Smoke Screen is

prevented from producing smoke. Hence the production of smoke is controlled using one or a

combination of the following:

Alarm Set –a normally closed relay connected across the Alarm Panel ‘Set’ connections, which

open when the Alarm Panel is ‘Set’ and closing when the panel is ‘Unset’.

Trigger –a normally closed relay connected across the Alarm Panel ‘Trigger’ or ‘Intruder’

connections, which open when the Alarm Panel is in ‘alarm’.

Hold-off –usually a PIR or movement sensor connected to the ‘Hold-off PIR’ connections (N/C),

which opens when the sensor sees movement.

Additional Hold-off –any form of N/C relay or micro switch can beconnected to the ‘Hold-off’

connections. Where fitted in addition to the Hold-off PIR both sets of relays must be ‘open’ to

produce ‘smoke’.

Outputs. Outputs are provided for connection to the Alarm Panel for ‘Ready’, ‘Low Fluid’, ‘UPS

Status’ and ‘Verification Output’. See the notes on the “Generic Connection Diagram” for the

function of these outputs.