Thanks for choosing small parts racking from Constructor.

It is of greatest importance that you follow the instructions in this guide in order for your rack to meet your require-

ments and to comply with the current standard.

The purpose of this guide is to inform the company’s warehouse staff and management about important facts

regarding the small parts rack, as well as precautions against potential danger risks.

If you have any questions, please contact us for further information.

The condition of the small parts rack in terms of security is best maintained through regular inspections and main-

tenance.

As for shelf and sections loads we refer to the load sign for each individual installation.

Each installation must be provided with a load sign.

page

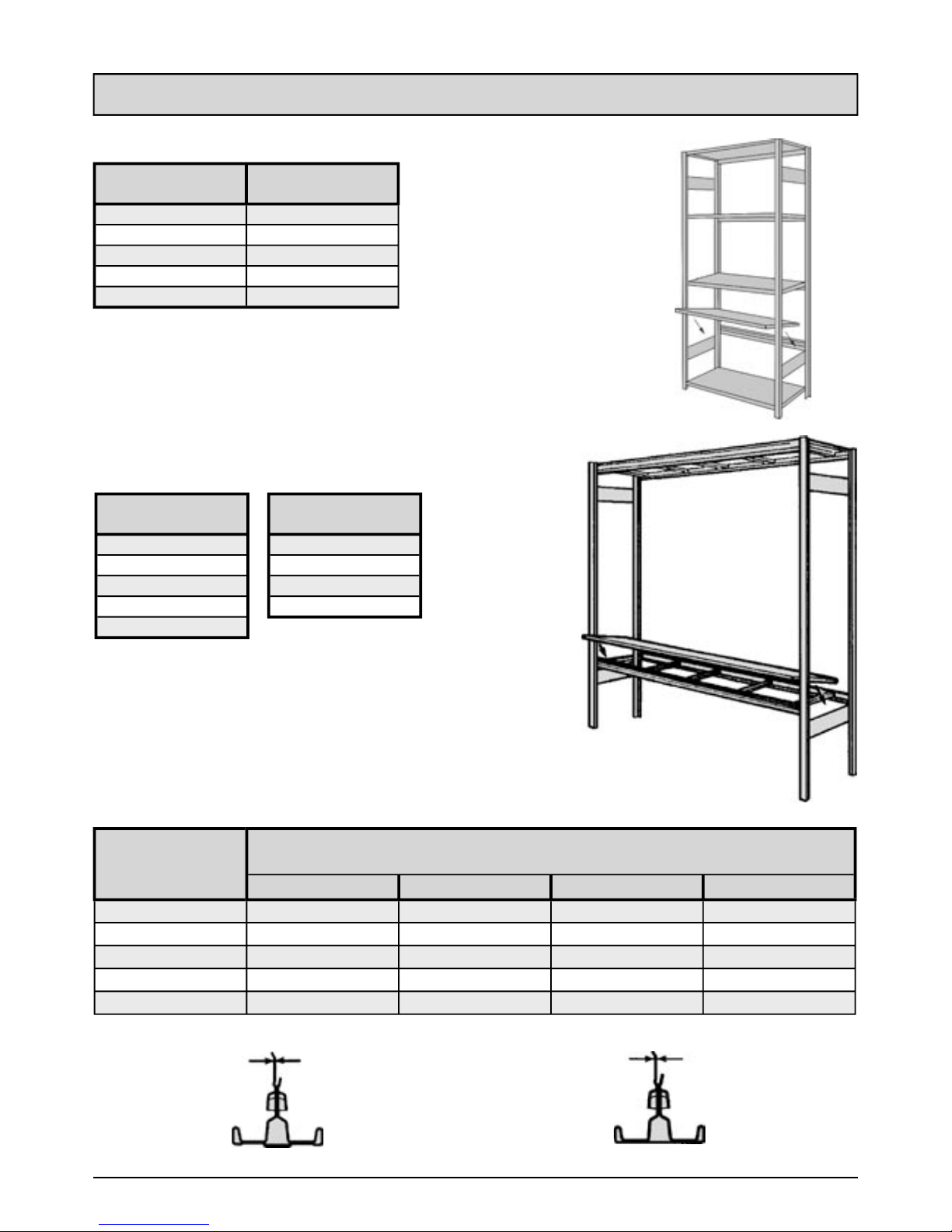

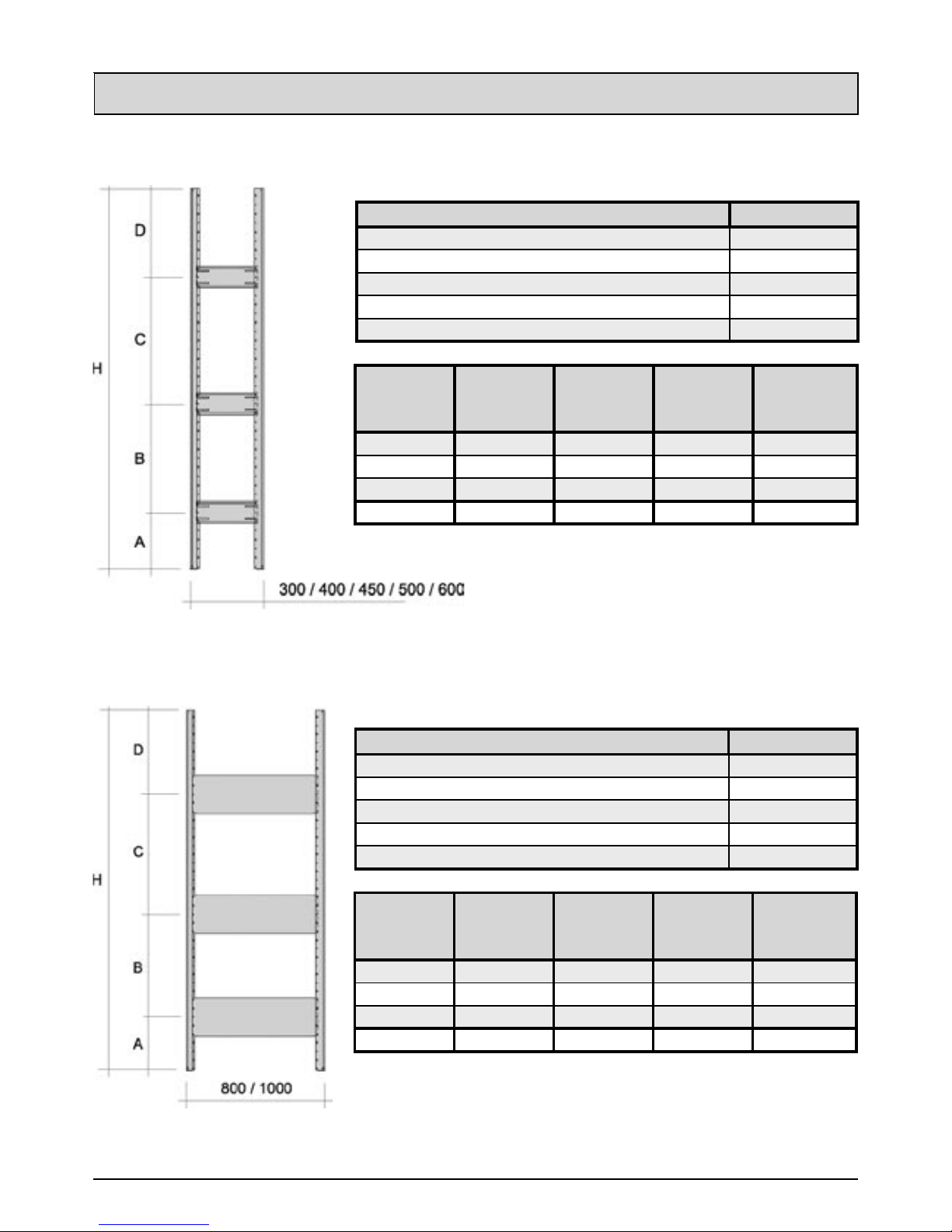

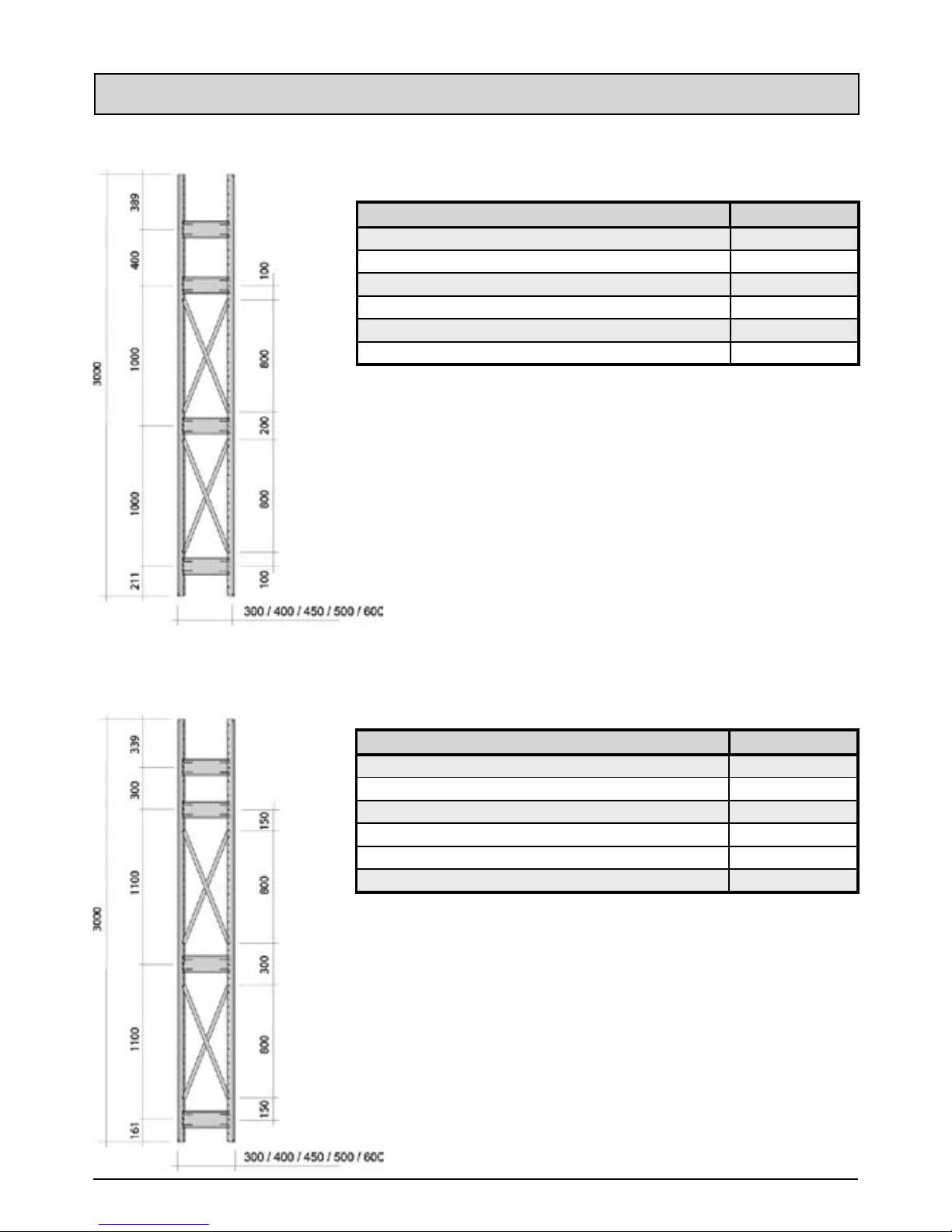

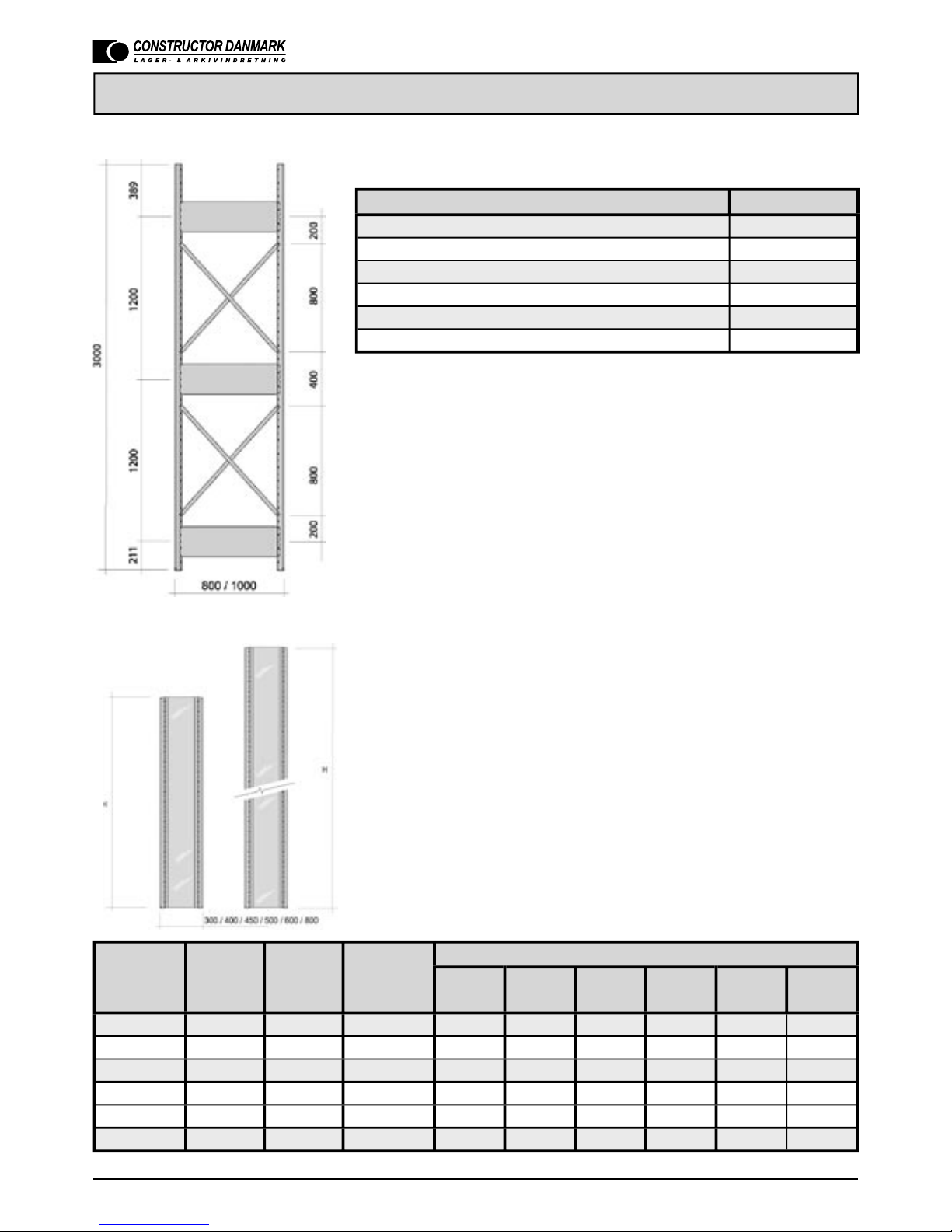

- Technical data

Shelves, medium span, recommended cross beams, upright types 3

Stay plates 4-8

- Assembly guide

Frame stay / stay plates 9

Frame plate 10

Frame mesh 11

Base 12

Shelf and support beams 13

Shelves / support shelves 14

Back cross / back mesh / double rack 15

Door 16

Suspension trays and shelves 17

Reinforced shelves 18

Accessories 19

Working bench / tools panel / ttings 20

- Important control points 21

- Security issues 22

- Protocol for periodical control of the small parts rack 23

Contents

2