Continental Hydraulics Installation Manual

Page 7 of 8 CEM-AC-A CHI 1013472 April 2012

Scaling of analog input:

The CEM-AC-E0 module has a native analog voltage input range of 0 to +10v. This input can be

scaled and offset with software to allow a wide variety of input voltages. A few examples are:

0 to +10v, 0 to +5v, 1 to 5v, 0.5 to 4.5v

The CEM-AC-E1 module has a native analog current input range of 0 to 20mA. This input can be

scaled and offset with software to allow a wide variety of input currents. A few examples are:

0 to 20mA, 4 to 20mA, 0 to 10 mA

The AIN:W is the Parameter used to adjust the analog input.

Analog voltages or currents are scaled with the following linear equation:

Output = A/B * (Input – C)

“Output” of this scaling equation must always be equal to the module native input range, 0 to +/-

10v. “Input” can be any voltage within this 20v range.

A/B allows for a decimal scaling factor. These two numbers are chosen to provide a “gain” to the

input signal. A and B are positive or negative whole numbers up to 10000. (Default; A = 1000, B

= 1000)

C is an offset, measured as a percentage of range. C has the units of 0.01%, and has the

allowable range of –10000 to 10000. (Default; C = 0)

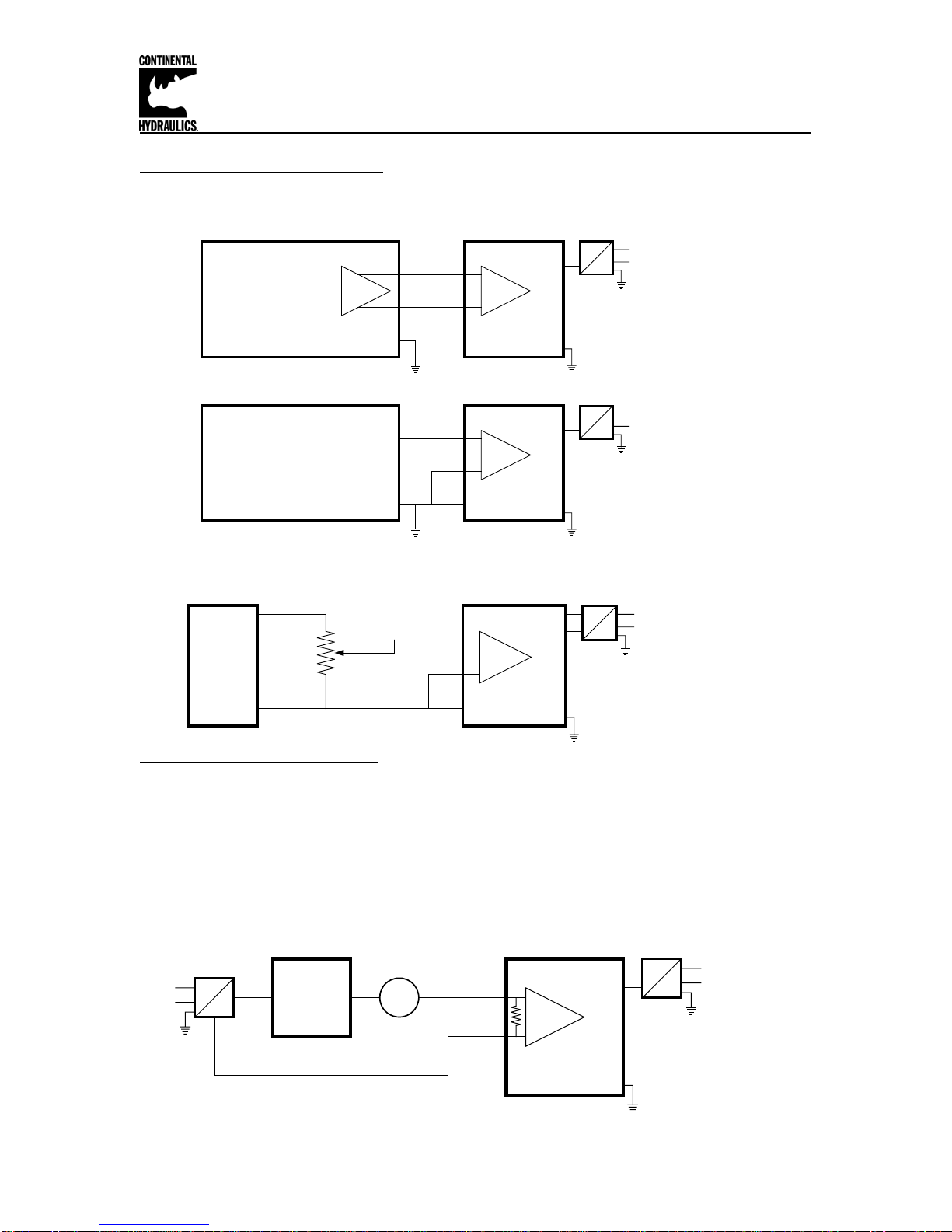

Scaling voltage inputs:

Example: Typical AIN:W parameter settings for popular command voltages:

Command A B C description valve centered

0 to +10v 1000 1000 0 100% scale, 0% offset 0v

0 to +10v 1 1 0 100% scale, 0% offset 0v

0 to +5v 10 5 0 200% scale, 0% offset 0v

+1 to +9v 10 8 1000 125% scale, 10% offset 1.0v

+0.5 to +4.5v 10 4 500 250% scale, 5% offset 0.5v

0 to 8v 10 8 0 125% scale, 0% offset 0v

Scaling current inputs:

Example: Typical AIN:W parameter settings for popular command currents:

Command A B C description valve centered

4 to 20mA 20 16 2000 125% scale, 20% offset 4mA

4 to 20mA 1250 1000 2000 125% scale, 20% offset 4mA

0 to 20mA 20 20 0 100% scale, 0% offset 0mA

0 to 10mA 20 10 0 200% scale, 0% offset 0mA