Continental Hydraulics Installation Manual

Page 2 of 33 CEM-AA-B CHI 1020611 01/2016

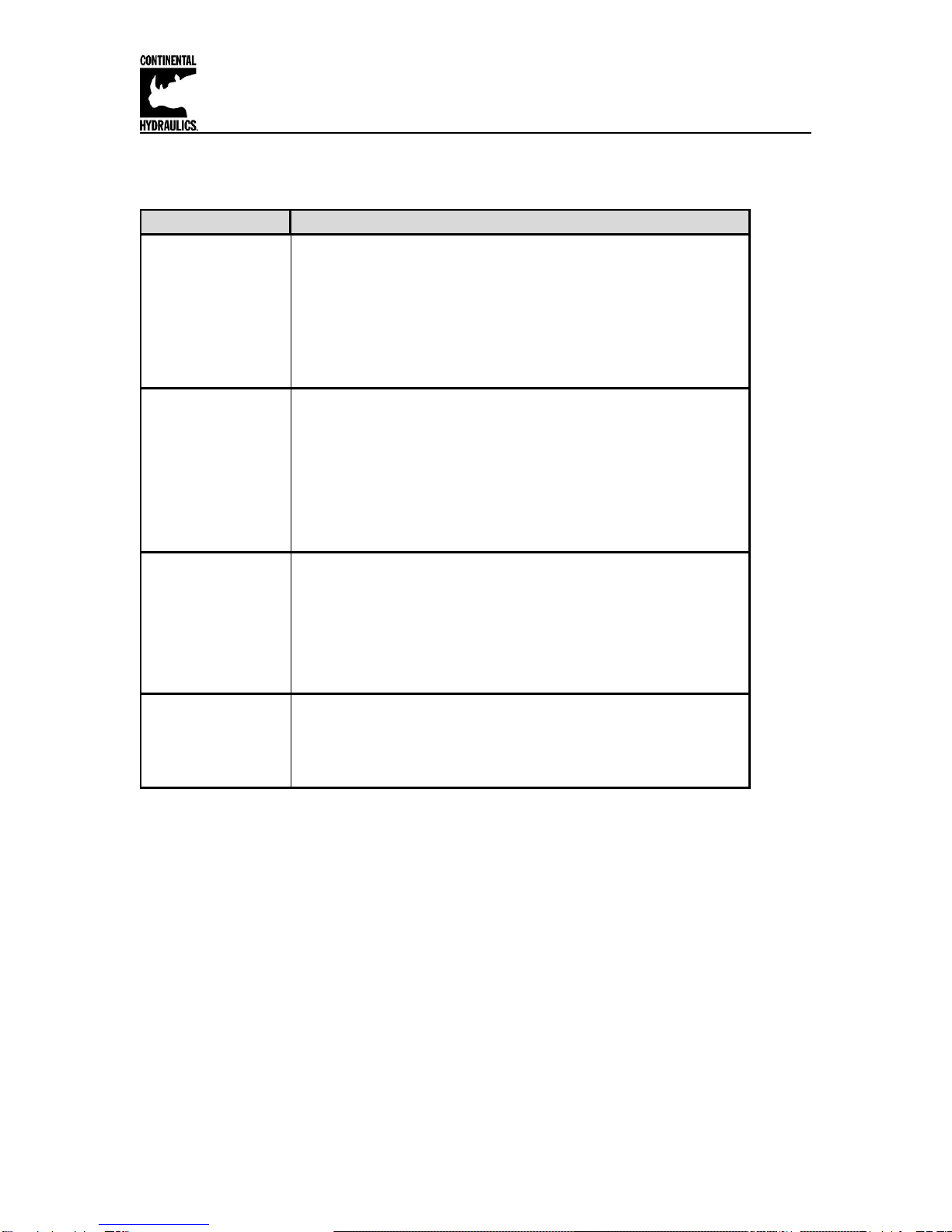

Table of Contents

Information Description Page #

Technical Data - All Function Modes for CEM-AA-B …………………….………..…………… 3

LED Indications - All Function Modes …………………………………………………………… 4

Steps to install and configure a new application ……………………….………………………. 5

Module Mounting Location ………………………………………….……………………………..6

Power Supply ………………………………………………………………………………….…… 6

Wiring to Valve …………………………………………………………………………………….. 6

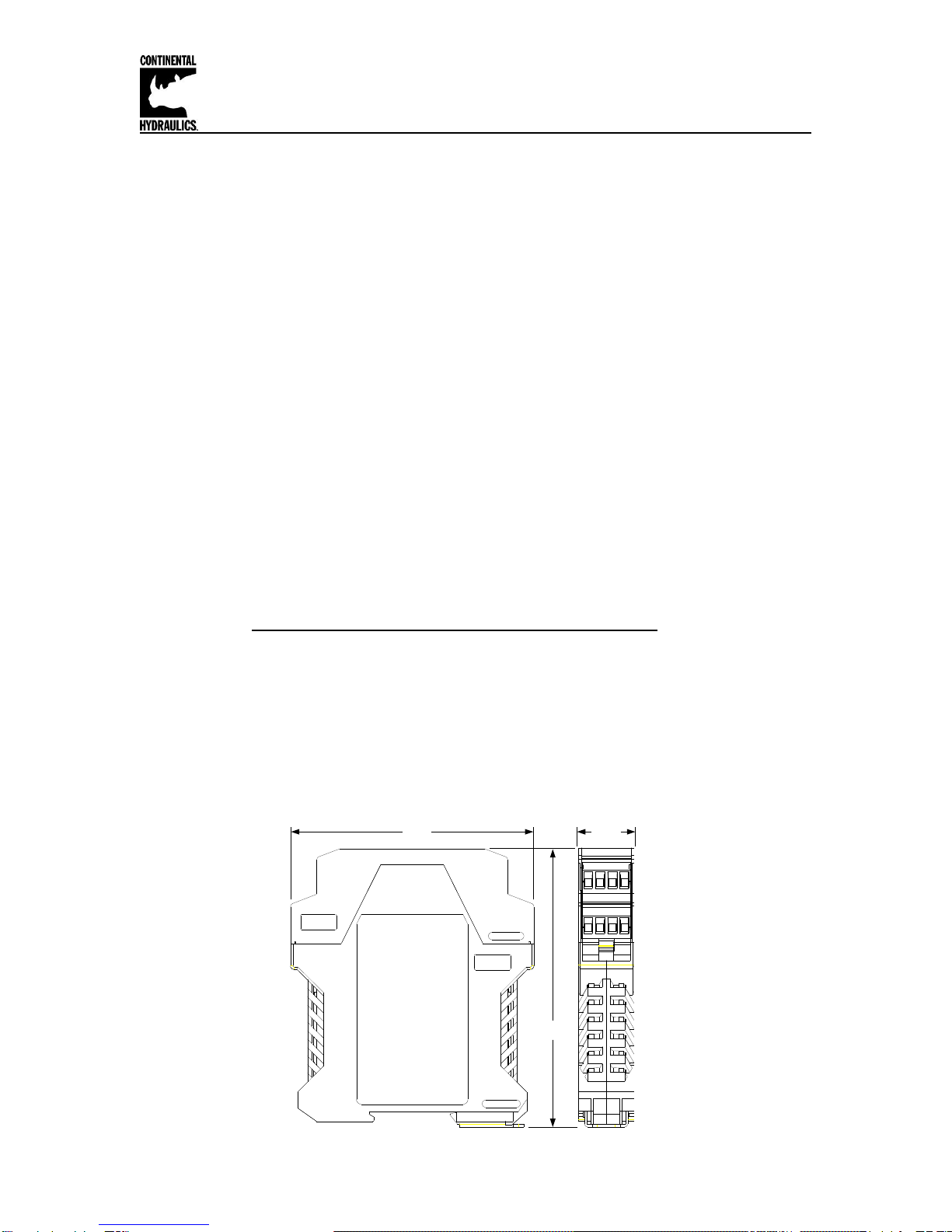

Dimensions …………………………………………….…………………………………………… 6

Circuit Diagram Function AA …………………………………………………………………... 7

Terminal Identification AA Function …………………………………………………………….. 8

Parameter List Function AA …………………………………………….………………….… 9

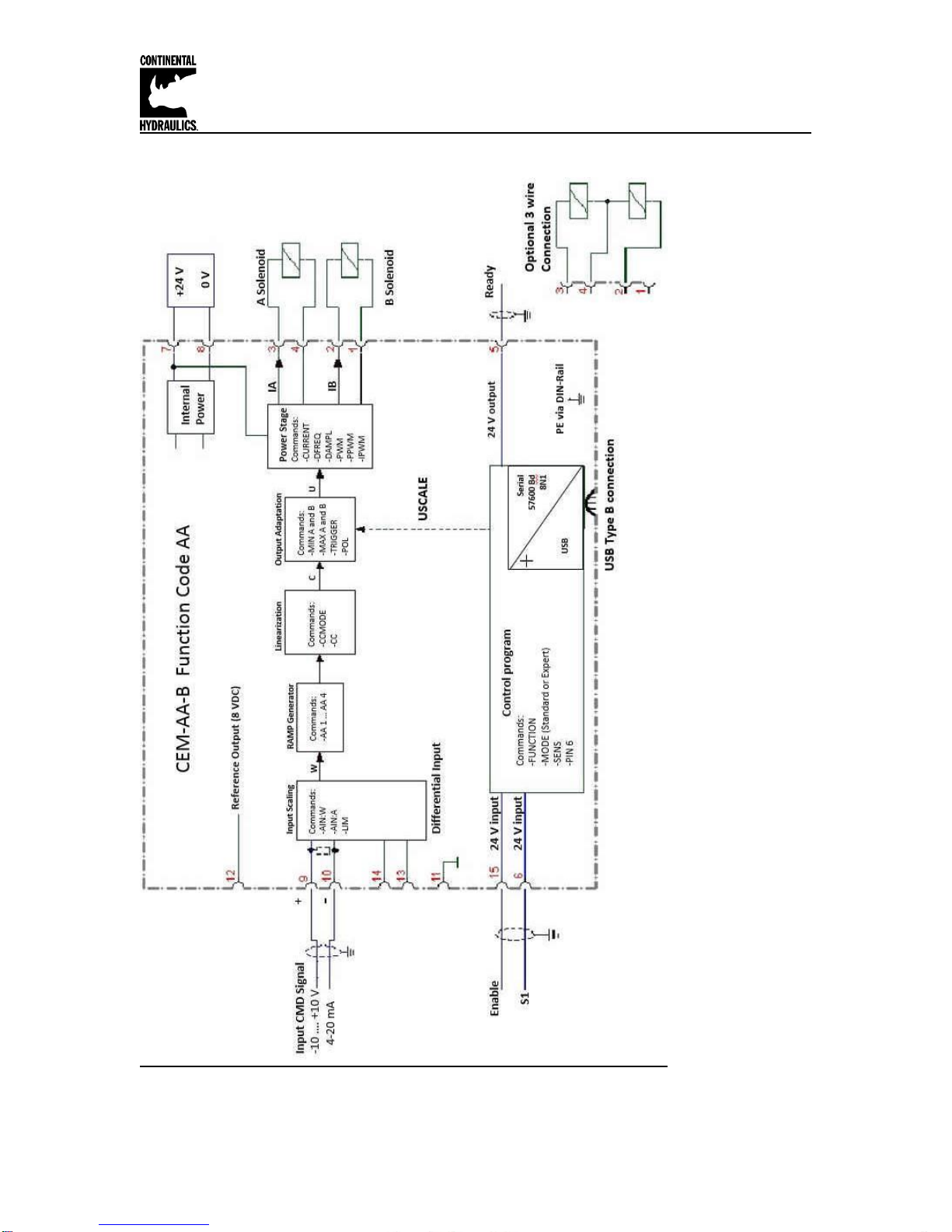

Circuit Diagram Function A-B …………………………………………………………………… 10

Terminal Identification A-B Function …………………………………………………………….. 11

Parameter List Function A-B ………………………………………………….……………… 12

Circuit Diagram Function RA …………………………………………………………………… 13

Terminal Identification RA Function …………………………………………………………….. 14

Parameter List Function RA ……………………………………………………….…………… 15

Command Parameter Descriptions

FUNCTION……………………………………………………………………………..… 16

LG (Language)…………………………………………………………………………… 16

MODE……………………………………………………………………………………... 16

SENS ……………………..……………………………………………………. ………... 17

CCMODE………………………………………………………………………………… 17

SOLENOIDS……………………………………………………………………………... 17

PIN:6………………………………………………………………………………………. 18

USCALE………………………………………………………………………………….. 18

ENABLE_B……………………………………………………………………………….. 18

LIM………………………………………………………………………………………… 19

POL……………………………………………………………………………………….. 20

AINA / AINB………………………………………………………………………………. 20

AIN………………………………………………………………………………………….21

AA:I / AB:I (RAMP Time)…………………………………………..………………….... 22

RMODE…………………………………………………………………………………… 23

S:0 –S:7………………………………………………………………………………….. 23

RA:0 –RA:7………………………………………………………………………………. 24

CCA / CCB……………………………………………………………………………..… 25

CC (Characteristics Linearization)…………………………………………………….. 26

MIN………………………………………………………………………………………... 27

MAX……………………………………………………………………………………... 27

TRIGGER………………………………………………………………………………... 27

CURRENT……………………………………………………………………………….. 29

DFREQ…………………………………………………………………………………… 29

DAMPL…………………………………………………………………………………… 29

PWM……………………………………………………………………………………… 30

ACC………………………………………………………………………………………. 30

PPWM / IPWM…………………………………………………………………………… 31

PROCESS DATA (Monitoring)…………………………………………………………………… 32

Failure Monitoring………………………………………………………………………………….. 33

Troubleshooting…………………………………………………………………………………….. 33